Professional Documents

Culture Documents

Ishikawa MUSTER Non Detection

Ishikawa MUSTER Non Detection

Uploaded by

Gašper Bobnar0 ratings0% found this document useful (0 votes)

2 views1 pageThe document discusses quality control procedures for welding including visual weld inspections, destruction tests to check weld strength at set frequencies, monitoring temperatures, pressures, and outputs during welding, using comparison parts and ultrasounds for additional inspections, and training people on the inspection processes and control plans. Bad spot welds may be missed due to non-detection by the quality control methods.

Original Description:

Original Title

ishikawa MUSTER non detection.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses quality control procedures for welding including visual weld inspections, destruction tests to check weld strength at set frequencies, monitoring temperatures, pressures, and outputs during welding, using comparison parts and ultrasounds for additional inspections, and training people on the inspection processes and control plans. Bad spot welds may be missed due to non-detection by the quality control methods.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageIshikawa MUSTER Non Detection

Ishikawa MUSTER Non Detection

Uploaded by

Gašper BobnarThe document discusses quality control procedures for welding including visual weld inspections, destruction tests to check weld strength at set frequencies, monitoring temperatures, pressures, and outputs during welding, using comparison parts and ultrasounds for additional inspections, and training people on the inspection processes and control plans. Bad spot welds may be missed due to non-detection by the quality control methods.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

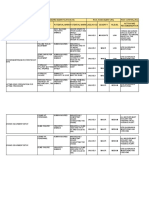

NON DETECTION

1.

MACHINE . METHOD

FREQUENCY OF CONTROL PLAN FOR DESTRUCTION

WORK INSTRUCTIONS FOR VISUAL WELD CHECK

CONTROL FOR TEMPERATURE

CHANGE FOR COOLING WATER

OUTPUT WORK INSTRUCTION FOR DESTRUCTION TEST

COMPARISON PART FOR WELD CHECK

CONTROL FOR PRESSURE ON WELDING

CLAMPS

BAD SPOT WELDS

NOT DETECTED

TRAINING FOR DESTRUCTION TEST

FOLOWING CONTROL PLAN FREQUENCY

FOR DESTRUCTKION TEST UNDERSTANDING WORK INSTRUCTIONS

FOLLOWING CONTROL PLAN TRAINED FOR ULTRASOUND CONTROL

FREQUENCY FOR ULTRASOUND

TRAINED FOR VISUAL CONTROL FOR WELDS

PROBABLE CAUSE

NOT POSSIBLE

MEASURMENT PEOPLE

You might also like

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- RISK ASESSMENT For Broken Glass ReplacementDocument10 pagesRISK ASESSMENT For Broken Glass Replacementadeoye Adeyemi100% (2)

- Process FMEADocument14 pagesProcess FMEAPranjal JangidNo ratings yet

- Presentation - CrowdStrike Falcon InsightDocument24 pagesPresentation - CrowdStrike Falcon InsightAlbert gonzalez fuentesNo ratings yet

- Jsa Fueling Equipment On DeckDocument2 pagesJsa Fueling Equipment On DeckIlya BordonosovNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentSerene TayNo ratings yet

- Risk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Document4 pagesRisk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Muhammad Naim Abd Wahab100% (1)

- What Is Disruption ClaimDocument8 pagesWhat Is Disruption ClaimAbd Elrahman RostomNo ratings yet

- FMEA Form and ExampleDocument8 pagesFMEA Form and Examplebenaoumeur benounaNo ratings yet

- HIRARCDocument2 pagesHIRARCreezmanNo ratings yet

- Part Name.:-Distribution Assy 3P386983-1Document50 pagesPart Name.:-Distribution Assy 3P386983-1Sameer SaxenaNo ratings yet

- Human Error - KiranKotaDocument3 pagesHuman Error - KiranKotaBiopharma GuruNo ratings yet

- PFMEA Format UpdatedDocument2 pagesPFMEA Format Updatedsriharishkumar.puNo ratings yet

- Inst Note - Inspection Flow Chart 17.3.10Document7 pagesInst Note - Inspection Flow Chart 17.3.10Harry HavocNo ratings yet

- 00 Safe Working Procedure TemplateDocument1 page00 Safe Working Procedure TemplateSisekosihle Masekoo-Masterkoo Matolweni-MqitsanaNo ratings yet

- Triaging Pregnant WomenDocument1 pageTriaging Pregnant Womenindugamilli sainadhNo ratings yet

- I M 5Document24 pagesI M 5Abraham GuemezNo ratings yet

- SELF LOCKING ANT Drop ChecklistDocument1 pageSELF LOCKING ANT Drop ChecklistlawrencemumharuNo ratings yet

- Parallel Sessions GBES UTM 2019Document17 pagesParallel Sessions GBES UTM 2019jeneralrhrNo ratings yet

- MRM Tools Relation - Woradech SDocument1 pageMRM Tools Relation - Woradech Sธัชเวชช์ สาขะมุติNo ratings yet

- Shamatha-Vipashyana Charts Pete BragDocument2 pagesShamatha-Vipashyana Charts Pete BragCarlosAndrésLópezNo ratings yet

- Process Flow Charts Anjar UnitDocument10 pagesProcess Flow Charts Anjar UnitKuna MarndiNo ratings yet

- 05.1 - Lecture Notes - M5 - Audit-Sampling (March 2)Document68 pages05.1 - Lecture Notes - M5 - Audit-Sampling (March 2)Bea GarciaNo ratings yet

- Menvier Fire System MF200/400 MF200-72/400-72: Please Pass This Booklet To The User, After Installation Keep With PanelDocument12 pagesMenvier Fire System MF200/400 MF200-72/400-72: Please Pass This Booklet To The User, After Installation Keep With PanelShadi AbdelsalamNo ratings yet

- Team Name: Function Potential Failure Mode Potential Effects of Failure Potential Causes of FailureDocument6 pagesTeam Name: Function Potential Failure Mode Potential Effects of Failure Potential Causes of FailureamanNo ratings yet

- Decision OP: Damage & Needs AssessmentDocument4 pagesDecision OP: Damage & Needs AssessmentJulius de la CruzNo ratings yet

- Continuous Iperc FormatDocument3 pagesContinuous Iperc FormatScribdTranslationsNo ratings yet

- Stampedes and Disaster ManagementDocument35 pagesStampedes and Disaster ManagementlomongoybrevrhainNo ratings yet

- Preventive Maintenance Inspection FormDocument1 pagePreventive Maintenance Inspection FormAdam CabarrubiasNo ratings yet

- Red Team Blue Team ExerciseDocument1 pageRed Team Blue Team Exercisekian.salem90No ratings yet

- Painting HandoutDocument61 pagesPainting Handoutislamfarag2No ratings yet

- HFACSDocument37 pagesHFACSPrince KumarNo ratings yet

- Mind MapDocument26 pagesMind MapMohammad MACUDNo ratings yet

- Management FailureDocument1 pageManagement Failurerondenacristina23No ratings yet

- JHA RA FormatDocument5 pagesJHA RA Formatmadellekylenetabinas01No ratings yet

- Triangle Fraud and PreventionDocument1 pageTriangle Fraud and PreventionLinna GuinarsoNo ratings yet

- HEMP-005 Excavation Manual & Mechanical Rev.2Document9 pagesHEMP-005 Excavation Manual & Mechanical Rev.2saravana.bNo ratings yet

- Hirarc Form Admin HcmdocDocument3 pagesHirarc Form Admin Hcmdocmuzica muzNo ratings yet

- AlienRPG CharacterSheetDocument1 pageAlienRPG CharacterSheetT VNo ratings yet

- Organigrama MPFDocument1 pageOrganigrama MPFRadhames Gonzalez CabreraNo ratings yet

- Web PentestDocument14 pagesWeb PentestSurya Santosa I WayanNo ratings yet