Professional Documents

Culture Documents

Handwriting Check PDF

Handwriting Check PDF

Uploaded by

karthik0 ratings0% found this document useful (0 votes)

8 views1 pageOriginal Title

handwriting_check.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageHandwriting Check PDF

Handwriting Check PDF

Uploaded by

karthikCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

introduction?

Redieng the time anc cost hvelved in the prodtuct development s vary mportant te stay

competitive in the market. Design For Manufacturing ard Assembly COeMA) is a cost=

reduction Framework. For designers to evaluate manufacturing aspects of a product,

designs

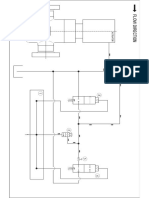

bn this ceport it explained in detad the cedesign concept For the Pneumatic contol piston

astemaly for manufiactiirng cost reckiction Libing OFA methodclagy consumer products

LL DEMA implementation approach,

A brief overview of the general proceciire For DFMA analysis 1S shown in Faire le

The first otep is te klentify the product on which OFMA analyse will be performeck After

selection, the product 6 then disassembled, and mdividual parts are medelled in cAD

softwares

Product Desgn Mraliypiot in this otepy the design team analyses the product design te

lent y opportunties For cost restuction

Design Simplification: In this Step, the design team Simplifies the prodkict design by redticng,

the number of parts, simpliing the assembly process, and improving the product's

man factiscatlitsy

Assembly Anolusis! They identify the best sequence for assembling the prodict and

recommend design changes to make the assembly process more efficients

cost Pralypist They compare the costs of the orignal design with the costs of the

recesigned product te determine the cost savings.

2. Product archtecture

The product architecture refers to the arrangement of parts anc subsystems withn

Pradict. The product architecture plays a critical cale in the marufacturablity and

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dwg-We0067-013-002 Rev.0Document1 pageDwg-We0067-013-002 Rev.0karthikNo ratings yet

- Page 4 PDFDocument1 pagePage 4 PDFkarthikNo ratings yet

- Application FormDocument2 pagesApplication FormkarthikNo ratings yet

- Drawings - WE1609.061 - E1942Document3 pagesDrawings - WE1609.061 - E1942karthikNo ratings yet

- Q4 From BrainlyDocument5 pagesQ4 From BrainlykarthikNo ratings yet

- Hall TicketDocument2 pagesHall TicketkarthikNo ratings yet

- Dwg-We0067-013-001 Rev.0Document1 pageDwg-We0067-013-001 Rev.0karthikNo ratings yet

- WE1917.006 - Eng RequestDocument1 pageWE1917.006 - Eng RequestkarthikNo ratings yet

- WE2118.001 - Eng RequestDocument1 pageWE2118.001 - Eng RequestkarthikNo ratings yet

- AsfaqDocument2 pagesAsfaqkarthikNo ratings yet

- WE1917.010 - Eng Request - REV1Document1 pageWE1917.010 - Eng Request - REV1karthikNo ratings yet

- Factsheet PPL DXB 10415Document2 pagesFactsheet PPL DXB 10415karthikNo ratings yet

- NPT Gewinde NPT Nach ASME B1.20.1Document1 pageNPT Gewinde NPT Nach ASME B1.20.1karthikNo ratings yet

- WE2319 - E2006 - Radial-Seal-CalculationsDocument1 pageWE2319 - E2006 - Radial-Seal-CalculationskarthikNo ratings yet

- Mentor Consent FormDocument1 pageMentor Consent FormkarthikNo ratings yet

- WE1609.061 - Eng RequestDocument1 pageWE1609.061 - Eng RequestkarthikNo ratings yet

- WE2319 - E2007 - Radial-Seal-CalculationsDocument1 pageWE2319 - E2007 - Radial-Seal-CalculationskarthikNo ratings yet

- HLR - 7790BPM Velocity Check Valve PagesDocument3 pagesHLR - 7790BPM Velocity Check Valve PageskarthikNo ratings yet

- Senthilkumar Pay Slip Aug.2022Document1 pageSenthilkumar Pay Slip Aug.2022karthikNo ratings yet

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- Table CDocument12 pagesTable CkarthikNo ratings yet

- Solankikirankumar Fateshisinhmr - 4 - 3Document2 pagesSolankikirankumar Fateshisinhmr - 4 - 3karthikNo ratings yet

- ObjectiveDocument4 pagesObjectivekarthikNo ratings yet

- Ima ssv2Document1 pageIma ssv2karthikNo ratings yet

- Dwg-E1675-11 R1Document1 pageDwg-E1675-11 R1karthikNo ratings yet

- Final Laboratory Report: 32 Years 2239041054Document1 pageFinal Laboratory Report: 32 Years 2239041054karthikNo ratings yet

- Ima ssv3Document1 pageIma ssv3karthikNo ratings yet

- SS-H 4HL2Document2 pagesSS-H 4HL2karthikNo ratings yet

- International SOS App: Caterpillar: Confidential GreenDocument1 pageInternational SOS App: Caterpillar: Confidential GreenkarthikNo ratings yet

- Shalin VK - Mechanical Engineer - Resume PDFDocument3 pagesShalin VK - Mechanical Engineer - Resume PDFkarthik100% (1)