0% found this document useful (0 votes)

227 views40 pagesCNC Machining: G-Code and M-Code Guide

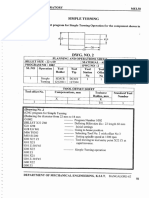

The document provides information about CNC machining processes and operations that can be performed on lathes. It discusses the components and functions of lathes, as well as common turning operations like turning, facing, grooving and threading. It also covers CNC lathes and describes the G-code and M-code programming languages used to control CNC machine tools like lathes. Key points include that G-code controls tool movements and paths, while M-code controls machine functions like spindle rotation and tool changes.

Uploaded by

CrocodileCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

227 views40 pagesCNC Machining: G-Code and M-Code Guide

The document provides information about CNC machining processes and operations that can be performed on lathes. It discusses the components and functions of lathes, as well as common turning operations like turning, facing, grooving and threading. It also covers CNC lathes and describes the G-code and M-code programming languages used to control CNC machine tools like lathes. Key points include that G-code controls tool movements and paths, while M-code controls machine functions like spindle rotation and tool changes.

Uploaded by

CrocodileCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd