Professional Documents

Culture Documents

Numerical Modelling o Non-Uniform Flow in Settling Basins

Uploaded by

Pravash MoolOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Numerical Modelling o Non-Uniform Flow in Settling Basins

Uploaded by

Pravash MoolCopyright:

Available Formats

Numerical Modeling of Non-

uniform Flow in Settling Basins

Hanne Nøvik, Abha Dudhraj, Professor Nils

ReidarBøe Olsen, Dr. Meg B Bishwakarma

and Professor Leif Lia Hanne Nøvik Abha Dudhraj Nils ReidarBøe Olsen Meg B Bishwakarma Leif Lia

Abstract : The settling basins for hydropower plants are designed to remove suspended sediments from the wa-

ter flow. The inlet geometry of the settling basin may cause formation of recirculation zones and high turbulence,

which may lead to diminished trap efficiency, and as a consequence, turbine erosion. Most analytic approaches for

calculating the trap efficiency of settling basins are based on the assumption of a uniform flow; hence, simplified

one-dimensional equations are used to determine the velocity distribution and the turbulence characteristics of the

flow. However, the velocity field in settling basins is often unevenly distributed, and the simplified equations are not

always applicable. This study describes a new method for improving the assessment of settling basin performance.

The idea is to extract values for the velocity distribution and the turbulence characteristics along the settling basins

from computational fluid dynamic (CFD) models. The extracted CFD values are then used as input parameters to the

standard analytical approaches for calculation of settling basin trap efficiency. This promising method is tested on a

case study of a physical model of the settling basin for the Lower Manang Marsyangdi Hydropower Project in Nepal.

The CFD calculations turn out to provide additional information to the sedimentation calculations in settling basins,

and are useful for the assessment of different design alternatives at an early stage.

Key words: Settling basin, trap efficiency, CFD, hydropower, Nepal

Introduction strong influence on the water velocity distribution and

S ettling basins for hydropower plants in sediment the turbulence levels in the settling basins. The influence

loaded rivers are designed to remove suspended of the geometry can be difficult to implement as one-

sediment particles, which may cause erosion and dimensional parameters in the analytical approaches.

damage to the turbines, and which cost for the repair The technology of computation fluid dynamic (CFD)

and replacement of turbine components. In the settling calculations is well-known, and has also been used

basin, the suspended particles larger than a certain size for engineering purposes in the hydro power industry

are supposed to settle and deposit on the bottom. The for more than a decade (Groeneveld 1999). Today, the

deposited sediments are then removed from the settling computational tools provide for reasonable calculation

basin by various methods.

time and the opportunity to benefit from these powerful

The settling basin must be designed for reducing computational tools for the design of settling basins.

the turbulence level in the water flow in order to allow The motivation for the current study is to assess the

for the sediment particles to settle. The trap efficiency performance of settling basins based on CFD calculations

of a settling basin, η , is the reduction in the sediment of the flow patterns and the corresponding turbulence

concentration, c, from the inflow to the outflow, which characteristics, without including the complex sediment

is defined as: transport in the CFD models. The results from the CFD

Most analytic approaches used today for calculating calculations are used to adjust and improve the input

cin − cout parameters used in the commonly used trap efficiency

η= calculation methods. This new approach is tested on the

cin hydraulic physical model of the settling basins of the

the sediment concentrations, and trap efficiency of Lower Manang Marsyangdi Hydropower Project built at

settling basins are based on the assumption that the the Hydro Lab Pvt. Ltd. in Kathmandu, Nepal.

area intended for the settling of sediments named In this paper, the governing characteristics affecting

the effective surface area of the settling basin, As the trap efficiency of sediments in a settling basin are

has a close to uniform flow. Hence, simplified one- described, followed by a chapter on design principles

dimensional equations are applied to determine the and existing trap efficiency calculation methods, before

velocity distribution and turbulence characteristics of the new approach for assessing the settling basin

the flow. These conventional approaches predict the trap performance is presented and tested on a case study.

efficiency well, as long as there is an evenly distributed

flow throughout the effective settling area of the basins. Flow Characteristics Affecting the Trap Efficiency

However, observations from field and laboratory studies Suspended particles are primarily carried with the water

indicate that settling basins with recirculation zones and flow, and transported with a velocity more or less equal

secondary currents within the defined effective surface to the ambient water velocity (Hazen 1904). The gravity

area of the settling chambers are less efficient than force draws the particles downwards, with a resulting

predicted. The geometry and inflow conditions have a fall velocity, w, whereas the turbulence motion of the

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

27

water flow tends to lift the sediment particles. The trap Q is the water discharge, A is the cross section area

efficiency of a settling basin depends on the velocity field and n is the Manning’s friction factor which needs to

distribution and the turbulence level. be estimated. This simplified method for finding U *

A turbulence characteristic that can be measured is commonly used for settling basin trap efficiency

directly is the turbulent kinetic energy, k, of the calculations, but is not accurate for more complex flow

fluctuating motion in three directions, i, j and k at a given situations. The recirculation zones in a settling basin

point in the flow (Rodi 1980): contribute to maintaining suspended sediment particles

1 in motion, since the suspended particles has more or

k

=

2

( u 'i2 + u '2j + u 'k2 ) less the same velocity as the ambient water flow. The

governing parameter defining the turbulence level in

Where u ' is the velocity fluctuation. The turbulent conventional settling basin trap efficiency calculations is

kinetic energy, k, describes the energy in the turbulent the shear velocity, U* (Camp 1946;Vanoni 1975; Garde et

eddies. al. 1990).

The turbulent fluctuations in the water may be

described by the stress tensor component, the Reynolds Design Principles and Trap Efficiency Calculation

stresses, ui ' u j ' , where u 'is the velocity fluctuation in Methods for Settling Basins

a given direction i and j (Nezu and Nakagawa 1993). The settling basin must be designed to reduce the

Boussinesq (1877) introduced the eddy-viscosity,ν T , (in turbulence level in the water flow so that the sediment

an analogy to the viscous stresses in the laminar flow) for particles will settle. Favorable flow conditions are

modeling the turbulence. The eddy-viscosity concept is slow transit velocity, ut, through the basin, an evenly

based on the turbulent stresses (the Reynolds stresses) distributed flow without any recirculation zones or

being proportional to the mean-velocity gradients (Nezu secondary currents and low turbulence effects. The net

and Nakagawa 1993). effective surface area, As, of the settling basins shall only

include the area of the basin where the flow is evenly

∂u ∂u 2 distributed over the width and depth in the water body.

−ui ' u j =' ν T i + j − kδ ij

∂x The performance of a settling basin is mainly governed

j ∂xi 3

by the geometry of the basin, namely the size and the

where δ ij is the Kronecker delta and k the turbulent shape (Lysne et al. 2003).

kinetic energy (Eq.1.2). The eddy-viscosity, T , charac- ν There are three main analytical approaches for the

terizes the transport and dissipation of energy in the hydraulic design of settling basins, all based on one-

smaller scale flow, and is assumed to be essential for sus- dimensional equations and evenly distributed flow.

pended particle transport. The eddy-viscosity, T , de- ν Suspended particles in rivers have a fall velocity, w,

pends on the velocity field and turbulence, and it varies

in stagnant water that is primarily dependent on the

significantly from point to point in a flow. According to

submerged weight and the size and form of the particle,

Rodi (1980), the eddy-viscosity concept is still the basis

for most turbulence models, and has successfully been but also on the temperature and viscosity of the water

used in many practical calculations. The eddy-viscosity (Vanoni 1975). The ideal particle approach of Hazen

cannot be measured directly. Nevertheless, according to (1904), for no turbulence, requires the ratio between the

Keefer (1971), the depth average eddy-viscosity for natu- fall velocity, w, and the average horizontal velocity in the

ral, uniform rivers can be approximated by: basin, ut, to be equal or larger than the ratio between the

ν T = 0.11 ⋅ U * ⋅ H depth of the basin, H, and the length of the basin, L,:

t

Hu Q

Where U * is the shear velocity and H is the water w

= =

L As

depth. The shear velocity scales the turbulence in uni-

form open-channel flows (Nezu and Nakagawa 1993), Note that the effective surface area, As, is the

and is regarded as the most fundamental scaling param- governing parameter in the expression of the velocity

eter for uniform open-channel flows. The shear velocity ratio, and As is therefore important in trap efficiency

is also difficult to measure directly, but there exist sev- calculations. Camp (1946) and Dobbin’s (1944) method

eral methods for estimating U * in hydraulic research also includes the influence of turbulence in the water

(Rowiński, Aberle et al. 2005). For uniform rivers, a sim- flow, described by a variant of the Rouse number (Rouse

plified method for the estimation of the shear velocity is 1937); w U * . A reduced turbulence level, and hence an

done by use of the energy slope, Se, in the canal and the

increased Rouse number, increases the trap efficiency, η

hydraulic radius, Rh :

. Moreover, the Camp-Dobbin diagram is widely used for

U * = gRh Se design purposes today.

The second design approach is the concentration

The energy slope for uniform rivers can be estimat- approach which assumes fully mixed conditions. Vetter’s

ed from the Manning’s formula where:- method is presented in Vanoni (1975) and the trap

Qn

2

efficiency is defined as:

Se = 23

ARh

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

28

−

wAs

Q

η = 1− e for more refined settling basin design assessment, among

Garde et al. (1990) compared their own experimental others: Stamou et al. (1989), Adams and Rodi (1990),

data of trap efficiency and experiments from Singh Atkinson (1992), Olsen and Skoglund (1994), Olsen

(1987), with the existing Camp-Dobbins’ relation and Kjellesvig (1999), Dufresne, Dewals et al. (2011)

(Dobbins 1944; Camp 1946), the U.S.B.R relationship

and Shrestha (2012). The overall conclusion is that CFD

(Vanoni 1975) and the Sumer relationship (1977). All the

models can be used to assess a settling basin design, but

computed efficiencies,η , were much larger than actually

measured efficiencies for finer particles. In an attempt that the sediment transport is very complex.

to improve the efficiency calculation, Garde et al. (1990)

developed a new, exponential relationship: A New Approach for Assessing Settling Basin

Performance

η η0 (1 − e −α L H )

= A new approach for assessing settling basin performance

is tested on a case study of the physical model of the

η

where 0 is the limiting trap efficiency and a α settling basins of the Lower Manang Marsyangdi HPP.

coefficient, both obtained from diagrams for a given The commercial CFD code STAR CCM+ is used to assess

w U* ratio. Methods for including geometry parameters recirculation zones and the effective surface area of the

are suggested by Raju et al. (1999) and Ortmanns ν

settling basin, As, in addition to the eddy-viscosity, T ,

(2006), and both methods improved the trap efficiency and the shear velocities, U * . The numerical values

calculations for some cases.

for As, U * and ν T , are used as input parameters to

A third method for sediment concentration the Camp-Dobbins diagram for trap efficiency, the

calculations through settling basins is to divide the Vetter’s method, and in the discretization schemes for

settling basin into cells and use a two-dimensional solving the diffusion-convection equation for sediment

discretization scheme to solve the diffusion-convection concentration. The goal is by use of parameters from the

equation, Eq. 1.9 (Patankar 1980): CFD models to obtain more accurate predictions of the

trap efficiency for settling basins with the conventional

∂c ∂c ∂ ∂c design tools for settling basins.

ui +w = ν T

∂xi ∂z ∂x ∂xi Physical Model Set-up

A 1:40 physical scale model of the settling basins of

The sediment concentration, c, in all the cells

the planned 144 MW Lower Manang Marsyangdi

throughout the basin are calculated as a weighted average

Hydropower Project (LMM HPP) has been constructed

of the sediment concentration in the neighboring cells

(Olsen 2012). The convective sediment concentration at the Hydro Lab Pvt. Ltd, Kathmandu, Nepal (Figure

fluxes, caused by the mean water velocity and the fall 1). There are eight submerged inlets divided on two

velocity of the sediment particles, are given on the left side separated settling basins that are designed for a total

of Eq. 1.9. The diffusive fluxes, caused by the turbulence discharge of Q = 57m3/s. The Froude scaling law gives a

and the velocity gradients are given on the right side of the corresponding discharge in the physical model equal to

equation. The water velocity distribution and turbulence 0.0056 m3/s.

field in the vertical direction, the horizontal velocity, ui, The sediment loaded water enters through submerged

ν

and the eddy-viscosity, T , are considered to be constant inlet gates, flows through the gravel traps, and then

in the entire basin. Therefore, the same weighted average through a pressurized approach section before entering

factors can be used for all the cells in a discretization into the settling basins. The length of the settling basins

scheme. The use of constant weighted average factors is

with its full width is L=160 m in the prototype and

common practice in sediment concentration calculations

of settling basins today, but is not accurate as the T ν L=4.0 m in the model scale. The width, B, of the model

may differ significantly throughout the flow field (Olsen is B = 0.875 m. The water depth, H, in the settling basin

2012). during the measurements was maintained at H=0.345

m, corresponding to H=13.51 m in the prototype. The

A number of numerical models have been proposed water discharge through the settling basin was measured

Figure 1. Proposed settling basins on the physical model of LMM HPP.

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

29

at the downstream outlet with a V-notch gauge. The smooth surfaces. The impact of the selected wall law

average velocity, ut , in the settling basin chambers equations was tested with a smooth wall compared to

during the measurements was u=0.022m/s, and the a low roughness r = 0.0001m. The effect of an absolute

average Reynolds number in the physical model is roughness r = 0.001m, which is rougher than ‘rough

UR

=Re h

≈ 2900 , (larger than 750, hence fully concrete’ according Colebrook (1939), was also tested.

ν

turbulent as in the prototype where Re=7*105). The model runs with different wall roughness values

Velocity and turbulence measurements in the settling were performed on set-ups with the k-ε turbulence

basins were taken with a Sontek 16-MHz side-looking model. The impact of the three turbulence models, was

3D MicroADV (SonTek 2013) at six cross sections, tested on model set-ups with wall roughness r = 0.001m.

with 18 point measurements at each cross section. The The velocities and the turbulent kinetic energy, k,

measurements were taken for 60s with a sampling in the points corresponding to the location of the ADV

rate of 50 Hz. The velocity distribution over the eight measurements were extracted for a converged solution.

inlets was measured with a Mini Air 20 Micro propeller Velocities were extracted at the same rate as the ADV

(Omni 2013) at the left, center and right side of each measurement: 50 data sets every second in the solution

of the eight inlets since ADV measurements were not time, over a period of 60 seconds.

possible because of the shallow flow. The model is

built of Plexiglas and painted plywood. The Manning’s Results

number is assumed to be n=1/110=0.009, and the value The results from the CFD models are compared with

corresponds to n = 1/60 = 0.017 in the prototype. The the measurements at the physical model. The extracted

Manning’s value normally used for acrylic materials is turbulence characteristics from the CFD models are

in the range (0.009-0.01), and the value n = 0.009 is compared to values obtained from one-dimensional

the lowest recommended value for smooth, non-metal equations. The calculated trap efficiencies of the settling

surfaces in the Manning’s value table in Chow (1959). basins with the standard methods were then compared

The value n = 0.017 is representing the roughness of for calculations with and without adjusted input

concrete canals with gravel on the bed. Note that the low parameters from the CFD calculations.

Manning’s number for the physical model is exceeding

the valid range for the Manning’s formula, whereas Compared Velocity Field

for the prototype the chosen value may be too coarse. The velocity field in the physical model, measured with

The Manning’s values for the settling basin in physical ADV, was compared to numerically calculated velocities

models are difficult to verify because the decrease in the in STAR CCM+. The velocity field at a height z/H=0.53

energy line is very small. In this study, the decrease was for a simulation with k-ε model and r=0.001m is shown

within the measuring limitations, and n is therefore only in Figure 2. At the upstream end of the settling basins, the

assumed. velocity field was unevenly distributed. The calculated

velocities are comparable with the measured velocities in

Numerical Model Set-up the downstream end of the settling basins, whereas at the

The commercial program STAR CCM+ was used to solve upstream part of the settling basins more discrepancy

the Reynolds Average Navier-Stokes equation for the was observed between the measured- and the calculated

water body of the physical model of the settling basins. A velocities.

3D implicit unsteady solution, in which the water surface

is calculated with the Volume of Fluid (VOF) method, ADV measurements compared with CFD results

was chosen. Based on a grid sensitive test, a grid with 2.0 The discrepancy at the upstream end might be due to

million rectangular cells was used. A refinement of the recirculation zones where velocities vary strongly over

grid was done at the inlet, the outlet, at the water surface the cross section. Hence, any inaccuracy in the location

and at the entrance to the approach canals. of the ADV measurements may cause change in the

Three different turbulence models were tested in velocity. The velocities were averaged over 60 seconds,

order to assess the sensitivity, namely the standard k-[ε and a longer time series would also possibly have an

model, a standard k-ω method and the complex and impact on the results, as the prototype as well as the

computational time costly Reynolds stress transport CFD calculations are unsteady and change over time. In

model (CD-adapco 2013). The inlet boundary conditions order to assess the recirculation zones, the cross stream

were set to ‘velocity inlet’ with velocities obtained from velocities were studied at given location in the length of

the propeller measurements at the physical model. the flow direction, x/H (see Figure 3).

The outlet boundary was set to ‘pressure outlet’ with The ADV measurements (black lines) show a clock-

a pressure level according to the measured water level wise cross stream current in both chambers. The CFD

at the outlet. The top of the model was set to pressure model suggests the same flow pattern, although the

outlet with pressure equal to atmospheric pressure. For velocity vectors in the points are not identical. The

the boundary condition for the bottom and the walls, recirculation zones in the upstream part of the settling

a sensitivity analysis of the boundary roughness was basins are also visualized at the plan view velocity plot at

conducted. Plexiglas and painted plywood has relatively z/H = 0.53 in Figure 4, where the velocities are unevenly

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

30

Length in the flow direction x/L

Figure 2. Velocity field, plan view at z/H = 0.53,

distributed. The effective surface area, As, is defined to related to a specified level of the turbulent kinetic energy.

be the area where the velocity distribution is close to The definition of the criteria for As should be verified in

being evenly distributed, though the definition “close to further research. Nonetheless, the CFD tool is useful for

evenly distributed” is vague. As should not include any comparing different designs, as well as adjusting the

effective area, As, used for trap efficiency calculations.

Compared Turbulent Kinetic Energy

The turbulent kinetic energy, k, decreases as the flow

propagate through the settling basin. The calculated

values for k are compared to the measured k in both the

right- (o makers) and left (diamond markers) settling

basins in the physical model. The sensitivity to the

chosen wall roughness, r, and different turbulence model

is shown in Figure 5 (a) and (b), respectively.

Both the ADV measurements and the CFD

Figure 3. Cross sectional velocity field at the length in the flow

direction x/H = 3.1. ADV measurements compared with the results calculations show that the turbulent kinetic energy

from CFD model. decreases as the flow propagates through the basins. The

variation between the calculated k-values obtained from

recirculation zones, nor any cross flow currents. The the different turbulence model is caused by the different

theoretical effective surface area is A = L × B .In Figure 4, equations used for estimation of the Reynolds stress

s

a suggested effective surface area As on a velocity plot at term in the Navier-Stokes equation. Differences in the

z /H=0.53 is marked. Reynolds stress term will give slight differences in the

Based on a rough graphical assessment of the velocities, the velocity gradients and hence also in the

effective surface area where no velocities are higher than turbulent kinetic energy. However, the calculated values

2 x ut , the actual As seems to be approximately 67% and for turbulent kinetic energy correspond well with the

62% of the theoretical As of the left- and right settling measured values. Corresponding to the measurements

basins, respectively. Two times the ut was a first attempt and the calculations, the k is higher in the right than in

to define a criteria for As, but the criteria could also be the left settling basin, especially in the first half of the

settling basins. There are higher velocities at

the entrance to the right basin, than in the left

basin, which is caused by slightly higher water

discharge. Higher pressure in the outer bend

may cause a higher energy gradient in the right

approach canal with the largest bend, and

hence higher discharge, velocities and k-values.

As expected, the choice of turbulence models

seems to be more important than the choice

of wall roughness value. The simulations with

Figure 4. Plan view velocity plot of the settling basins, z/H=0.53. A suggested effective different turbulence models give slightly larger

surface area, As, based on the CFD calculations of the velocity field is sketched.

variations in the calculated k-values than the

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

31

Figure 5. Development of the turbulent kinetic energy, k, in the right- (o) and left (diamonds) settling basins; (a) Sensitivity to the roughness

value,(b) Sensitivity to the turbulence model.

simulations with different roughness values. However, in the calculated U values between the different

*

the comparison between the computed and measured turbulence models, which is due to the differences in the

turbulent kinetic energy shows that the CFD model Reynolds stress term, which result in slight difference in

can predict the turbulence level with a reasonably high the velocities and hence also in the shear velocities. The

degree of accuracy. trend is that the calculated values are in the range of 4.1 -

5.1 and 1.6 - 2.1 times the U obtained from Eq. 1.5, at the

*

Extracted Turbulence Characteristics from the entrance and the downstream end of the settling basins,

CFD Models respectively. The significantly higher values for U from

*

The common parameter for scaling turbulence, the shear the CFD model compared to Eq. 1.5 are later used as

velocity U, is complicated to measure, and no near-bed input values to the trap efficiency calculations.

velocity measurements were taken at the physical model The turbulence parameter used to solve the convection-

of the LMM HPP. However, an average of the U was diffusion equation (Eq.1.9) in the numerical schemes

*

extracted from the CFD model between six cross sections for sediment concentration calculations is the eddy-

throughout the settling basin (both basins included) as ν

viscosity, T .Equations 1.4 and 1.5 yield the simplified

shown in Figure 6. ν

one-dimensional value for T in the settling basin in the

In contrast to the simplified one-dimensional LMM physical model equal= ν 3.15 ×10−5 m2 s . Based

T

value for the shear velocity, U (Equation 1.5), the

*

numerical values for U shows the same decreasing

*

pattern throughout the settling basin as the measured

turbulent kinetic energy. There are some variations

Figure 7. Development of the eddy-viscosity in the right (o) and left

Figure 6.The shear velocity,U , through the settling basin for differ-

* shear velocity from eq. 1.5.

ent CFD models, compared to the

(diamonds) settling basins. The calculated values are compared to the

eddy-viscosity from eq. 1.4.

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

32

on the CFD calculation, the eddy-viscosity also decreases

downstream through the settling basin (Figure 7), with a are higher at the downstream end of the settling basins

higher value in the right than in the left basin, as for the ν

for the calculations with T values and As extracted

k, caused by the different design of the approach canals. from the CFD-model than for the standard method

ν

The calculated T values are higher than the ν

with a constant T . The reduced effective surface area,

ν

simplified one-dimensional value for T ranging from As, seems to have more of an effect on the sediment

10.0 to 4.1 times at the entrance to the settling basins, ν

concentration than the eddy-viscosity, T .The results

and ranging from 2.5 to 0.2 times at the downstream from the convection-diffusion could possibly be more

end. Furthermore, the different turbulence models used accurate if also local velocities from the CFD-model were

in the CFD calculations have a significant influence on

included. The actual sediment concentrations have not

the eddy-viscosity result, as for the k-values, because of

been validated with measurements, but this should be

the differences in the Reynolds stress term, the velocity

gradients and hence also the eddy-viscosity. done in further research.

The results for the calculated trap efficiencies with

The Effect on the Trap Efficiency Calculations the use of standard methods, although with adjusted

The impact from the CFD calculated values on the effective surface area, As, eddy-viscosity,

T

, and ν

calculated trap efficiencies is assessed below. The settling turbulence level, w U , extracted from the CFD-model

*

basin at the Lower Manang Marsyangdi HPP is designed are summarized in Table 1.

to trap 90% of sediment particles up to a grain size of CFD adjustment for

0.2mm and at water with temperature 10°C, the fall Uniform flow non-uniform flow

velocity for coarse silt fraction is w=0.02 m/s (Rouse Left Right

1937). The corresponding critical fall velocity in the

Camp-Dobbins Method 100% 100% 99%

physical model is w=0.003 m/s. With U from Equation

*

1.5, the corresponding value for the turbulence level as Vetter’s Method eq. 1.7 86% 73%

described by the Rouse number is w U * = 3.8 . The value Gardeet al. eq. 1.8 93% 91%

is high and indicates low turbulence and high trap

efficiency. The higher values for U from the CFD models, Convection-diffusion Adjusted ν T : 98%

* 99%

Figure 6, decrease the Rouse number to 0.7-0.9 at the eq. 1.9 Adjusted ν T , As : 95 %

entrance and 1.7-2.3 at the downstream end. The

estimates from the CFD results for the effective surface The calculated trap efficiency has been slightly reduced

area, As ,reduce the velocity ratio wAs from 1.98 to 1.32 for all the different conventional calculation methods

and 1.23 for the left-and right settling basins, with adjusted input parameters from the CFD model.

respectively.

Q

Table 1. Trap efficiency calculations for LMM settling basins. Results

Calculations of the sediment concentration with the use of simplified, one-dimensional turbulence parameters

from the convective-diffusive equation (Eq. 1.9) were compared to results with the use of turbulence parameters adjusted

performed for three cases; the standard method with from the CFD results.

ν

constant T from Eq. 1.4, one with adjusted T values ν

for each section of the settling basins, based on the Conclusions and Recommendations

CFD model and with both an adjusted

T νand reduced The new approach for assessment of settling basins design

effective surface area, As. The inlet concentration is presented in this paper is straight forward and promising.

assumed to have an even distribution of 2,000 ppm at The geometry has a strong influence on the settling

the upstream end of the effective surface area, As . The basins performance, and the CFD-models provide for

concentrations results are compared in Figure 8. additional information on the effective surface area

As shown in Figure 8, the sediment concentrations and the turbulence characteristics for a given design.

This study demonstrates that detailed information

on velocity fields and the shear velocity, U *

ν

, and the eddy-viscosity, T , can efficiently be

calculated with available CFD-tools. Although,

no sediment concentration measurements

are available to validate the calculated trap

efficiency, it is clear that an increased accuracy

of the turbulence characteristics will increase the

accuracy of the trap efficiency calculations with

standard methods. For future research, sediment

concentration measurements are recommended

in combination with ADV measurements.

The study shows that the CFD-models can

Figure 8. Sediment concentration through the settling basin (a) con- predict the velocity fields as well as the turbulent

stant eddy-viscosity(b) eddy-viscosity from the CFD-model,(c) Eddy-

kinetic energy in the settling basin provided that

viscosity and effective surface area, As, from the CFD-model.

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

33

a sufficiently fine grid resolution is achieved, and the

time averaged values for the velocity field are preferred. Dr. Ing. Meg B. Bishwakarma is a hydraulic

The model is not very sensitive to the wall roughness, engineer and since last 8 years he is serving Hydro Lab

but is more sensitive to the selected turbulence model. Pvt. Ltd. as the General Manager. Prior to joining Hydro

Nevertheless, all the CFD-models are evaluated to be Lab in 2001, he worked with Butwal Power Company

within a reasonable level of uncertainty. The CFD- Ltd. in Nepal for about 12 years involving in the design,

calculated shear-velocities, eddy-viscosities and effective construction supervision, overall management and

surface areas for the LMM HPP settling basins differ administration of different hydropower projects in

significantly from the simplified one-dimensional values Nepal. He has published more than 16 articles and

assuming a uniform flow. By including a reduced effective papers in national and international journals and

surface area and the turbulence characteristics obtained conference proceedings.

from the CFD-models, the calculated settling basin trap

efficiency is slightly decreased with the use of all of the Leif Lia, PhD, is Professor in Hydro Power Structures

standard calculation methods. The assessment of the at the Department of Hydraulic and Environmental

turbulence, any recirculation zones and the effective Engineering of the NTNU, Trondheim, Norway. His

surface area, As, are all essential for the optimal design main expertise is hydro power engineering and he

of settling basins. CFD calculations can provide for has nearly 20 years of experience from planning,

valuable additional information to the standard methods engineering and research in the topic.

for computing trap efficiency and an assessment of the

performance of settling basins for hydropower plants. References

__ Adams, E. W. and W. Rodi (1990). "Modeling flow and

Acknowledgments mixing in sedimentation tanks." Journal of Hydraulic

The writers wish to thank Hydro Lab Pvt. Ltd. for Engineering 116 (7): 895-913.

construction of the physical model and for all their Atkinson, E. (1992). The desgin of sluiced settling basins.

technical assistance during the measurements. We also - A numerical approach. Rep. OD 124, Overseas

wish to thank the Butwal Power Company (BPC) for Development Unit. HR Wallingford, UK.

providing us with data and for agreeing to publish the Boussinesq (1877). "Turbulence models."

results. Camp, T. R. (1946). "Sedimentation and the Design of

Settling tanks." Trans. ASCE, Vol III: pp. 895-936.

Hanne Nøvik MSc graduated in civil engineering from CD-adapco (2013). "User Guide STAR-CCM+ Version

the Norwegian University of Science and Technology 8.02.008."

(NTNU) in 2007. She worked as a project engineer Chow, V. T. (1959). "Open-channel Hydraulics."

with planning of hydropower and hydraulic design McGraw-Hill Book Company, New York.

for the consulting company, Sweco Norge AS, and for Colebrook, C. F. (1939). "Turbulent Flow in Pipes

the Hydropower Company BKK Produksjon AS before with Particular Reference to the Transition Region

she started her PhD on “Intake Hydraulics and Intake between the Smooth and Rough Pipe Laws." Journal

Design for Small Hydropower Plants” in 2010. From of Institution of Civil Engineering 11: 133-156.

2014 she will work in Multiconsult AS. Dobbins, W. E. (1944). "Effect of turbulence on

Corresponding address: hanne.novik@ntnu.no sedimentation." Trans. ASCE, Vol I 109: pp. 629-653.

Dufresne, M., et al. (2011). "Numerical investigation

Abha Dudhraj recently completed her MSc in Civil of flow patterns in rectangular shallow reservoirs."

Engineering with specialization in hydropower Engineering Applications of Computational Fluid

development from NTNU, and is currently working Mechanics 5(2): 247-258.

as a hydropower engineer in a Norwegian water Garde, R. J., et al. (1990). "Design of settling basins."

management Association company, Glommensog Journal of Hydraulic Research 28(1): 81-91.

Laagens Brukseierforening (GLB). Groeneveld, J. (1999). "Computer Simulation Leads to

Faster, Cheaper Options." Water Engineering and

Nils Reidar B. Olsen PhD, is Professor in Hydro Management 146(6): 14-17.

mechanics at the Department of Hydraulic and Hazen, A. (1904). "On Sedimentation." Trans. ASCE,

Environmental Engineering of the NTNU, Trondheim, Vol. 53, paper 980.

Norway. He completed his Dr. Ing. degree on 3D Keefer, T. N. (1971). The relation of turbulence to

numerical modeling of water and sediment transport diffusion in open-channel flows, Colorado State

in 1991 and has since then continued to work on this Univeristy. PhD thesis.

topic. This has resulted in about 40 peer-reviewed Lysne, D. K., et al. (2003). Hydraulic Design Hydropower

articles in international journals. Prof. Olsen has Development. Trondheim, Norwegian University of

worked on sediment projects in a number of countries, Science and Technology. Vol 8.

including Nepal, Zimbabwe, Pakistan, Costa Rica, USA, Nezu, I. and H. Nakagawa (1993). "Turbulence in open-

Switzerland, Germany and Austria. channel flows." Turbulence in open-channel flows.

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

34

Olsen, N. and M. Skoglund (1994). "Three-dimensional of fluid turbulence." Trans. ASCE, Vol. 102: pp. 463-

numerical modeling of water and sediment flow in 554.

a sand trap." Journal of Hydraulic Research 32 (6): Rowiński, P. M., et al. (2005). "Shear velocity estimation

833-844. in hydraulic research." Acta Geophysica Polonica

Olsen, N. R. B. (2012). "Numerical Modelling and 53(4): 567-583.

Hydraulics." Department of Hydraulic and Shrestha, B. V. (2012). 3D Numerical Investigation on

Environmental Engineering, NTNU, Trondheim. Settling Basin Layout. Department of Hydraulic and

Olsen, N. R. B. and H. M. Kjellesvig (1999). "Three- Environmental Engineering. Trondheim, Norway,

dimensional numerical modelling of bed changes in Norwegian University of Science and Technology.

a sand trap." Journal of Hydraulic Research 37(2): MSc thesis.

189-198. Singh, K. K. (1987). Experimental Study of Settling

Omni (2013). "Data sheet MiniAir20 Mico Propellar." Basins. Dept. of Civil Engineering, University of

Retrieved 9/10/2013, from http://www. Roorkee, India. MSc thesis.

omniinstruments.net/flow-meters/air-flow-probes/ SonTek (2013). "Data sheet 16-MHz MicroADV."

miniair-20-portable-vane-anemometer-with- Retrieved 8/20/2013, from http://www.sontek.com/

display. html. pdf/expdes/MicroADV-Expanded-Description.pdf.

Ortmanns, C. (2006). Entsander of Water power Stamou, A. I., et al. (1989). "Numerical modeling of

concern. Entsander von Wasserkraftanlagen. PhD flow and settling in primary rectangular clarifiers."

thesis: v-210. Journal of Hydraulic Research 27(5): 665-682.

Patankar, S. V. (1980). "Numerical heat transfer and Sumer, B. M. (1977). "Settlement of solid particles in

fluid flow." McGraw-Hill Book Company, New York. open-channel flow." ASCE J Hydraul Div 103(11):

Ranga Raju, K. G., et al. (1999). "Sediment removal 1323-1337.

efficiency of settling basins." Journal of Irrigation Vanoni, V. A. (1975). "Sedimentation engineering." ASCE

and Drainage Engineering 125(5): 308-314. (Manual 54).

Rodi, W. (1980). Turbulence models and their application

in hydraulics: A State-of-The-Art Review. T. F. Group,

Institut für Hydromechanik, University of Karlsruhe.

Rouse, H. (1937). "Modern conceptions of the mechanics

Continued from page 48

Lieke Melsen obtained her BSc and MSc at

Wageningen University, the Netherlands, in the field Environment Programme (UNEP), Kathmandu,

of Hydrology. As part of her Masters, she spent four Nepal.

months at the Nepal Engineering College to work on Joshi, N. P., Maharjan, K. L. and Piya, L.,2011, Effect

the project of Water Security in Peri-urban South- of climate variables on yield of major food crops in

Asia. Currently, she is working as a PhD-student on Nepal,Journal of Contemporary India Studies: Space

parameter identification in hydrological models, at and Society (1):19-26.

Wageningen University. Narain, V. and S. Nischal, 2007. The peri-urban interface

in ShahpurKhurd and Karnera, India, Environment

References and Urbanization, 19(1): 261-273.

Baidya, S. K., Shrestha, M. L., and Sheikh, M. M.,2008, Practical Action, 2009, Spatial and Temporal Variability

Trends in daily climatic. of Climate Change Over Nepal (1976-2005),

extremes of temperature and precipitation in Nepal, Kathmandu, Nepal.

Journal of Hydrology and Meteorology, 5:38-51. Pradhan, P. and Perera, R., 2005, Urban growth and

CBS (Central Bureau of Statistics), 2012, National its impact on the livelihoods of Kathmandu valley,

Population and Housing Census 2011(Village Nepal,Urban Resource Network for Asia and Pacific

Development Committee/Municipality), Government (URNAP), Urban Management Programme for Asia

of Nepal, Kathmandu, Nepal. and the Pacific (UMP) Occasional Paper No. 63

Chaulagain, N. P., 2006. Impacts of Climate Change (Thailand).

on Water Resources of Nepal: The Physical and WECS (Water and Energy Commission Secretariat),

Socioeconomic Dimensions. Msc thesis, University of 2011, Water Resources of Nepal in the Context of

Flensburg, Flensburg, Germany. Climate Change, Government of Nepal, Kathmandu.

ICIMOD (International Center for Integrated Nepal.

Mountain Developmpent), 2007, Kathmandu Valley WMO (World Meteorological Organization), 1966,

Environment Outlook. Ministry of Environment, Climate Change. Technical Report, 79.

Science and Technology (MoEST) and United Nations

HYDRO NEPAL ISSUE NO. 14 JANUARY, 2014

35

You might also like

- Jis G 3106 PDFDocument38 pagesJis G 3106 PDFTùng Lê Đinh50% (2)

- Scope and Sequence High School Math PhysicsDocument8 pagesScope and Sequence High School Math PhysicsJim DelfinNo ratings yet

- Speed vs. Power Jumpers in High JumpDocument10 pagesSpeed vs. Power Jumpers in High JumpDominique Delannoy100% (1)

- Discharge Measurements in Open Channels Using Compound Sharp-Crested WeirsDocument8 pagesDischarge Measurements in Open Channels Using Compound Sharp-Crested WeirsNemo SecretNo ratings yet

- Flood Routing - 1Document36 pagesFlood Routing - 1SAURABH GUPTANo ratings yet

- Absid392 Study The Performance of Circular Clarifier in Existing Potable Water Treatment Plant by Using Computational Fluid DynamicsDocument19 pagesAbsid392 Study The Performance of Circular Clarifier in Existing Potable Water Treatment Plant by Using Computational Fluid Dynamicskivumbi AchileoNo ratings yet

- Effective Discharge Calculation: by D. S. Biedenharn and R. R. CopelandDocument10 pagesEffective Discharge Calculation: by D. S. Biedenharn and R. R. CopelandCamila FigueroaNo ratings yet

- Design of Around The End HydraulicDocument12 pagesDesign of Around The End HydraulicKerishaNo ratings yet

- Experimental Determination of Contraction Coefficient and Velocity Coefficient For Radial Gates With Elliptical LipsDocument9 pagesExperimental Determination of Contraction Coefficient and Velocity Coefficient For Radial Gates With Elliptical LipsAmad AhmedNo ratings yet

- International Journal of Heat and Mass Transfer: Tannaz Harirchian, Suresh V. GarimellaDocument9 pagesInternational Journal of Heat and Mass Transfer: Tannaz Harirchian, Suresh V. GarimellaSrinivas Raghavn SrkNo ratings yet

- Computation of Turbulent Jets in Annular Counter FlowDocument8 pagesComputation of Turbulent Jets in Annular Counter FlowKaffelNo ratings yet

- Modelling Cohesive Sediment Transport in Rivers: Canadian Journal of Civil Engineering February 2011Document11 pagesModelling Cohesive Sediment Transport in Rivers: Canadian Journal of Civil Engineering February 2011agussantoso_stNo ratings yet

- Grupo 5-Calculo de Coeficiente de Gasto en Vertederos Rectangulares Con ContraccionesDocument6 pagesGrupo 5-Calculo de Coeficiente de Gasto en Vertederos Rectangulares Con ContraccionesJhoseph Cruzado AraujoNo ratings yet

- 1 s2.0 S0308016120300569 MainDocument7 pages1 s2.0 S0308016120300569 MainliwansNo ratings yet

- Laboratory Studies of Five-Spot Waterflood PerformanceDocument8 pagesLaboratory Studies of Five-Spot Waterflood Performancealamgir hossainNo ratings yet

- Jmse 10 01792 v2Document13 pagesJmse 10 01792 v2ThiyagarajanNo ratings yet

- CFD Modeling of Corrugated Flexible PipeDocument10 pagesCFD Modeling of Corrugated Flexible PipeSaad AhmedNo ratings yet

- Numerical modelling of subcritical open channel flowDocument7 pagesNumerical modelling of subcritical open channel flowchrissbansNo ratings yet

- FDC Australia PDFDocument6 pagesFDC Australia PDFRaul TyvNo ratings yet

- Mass Transfer in Agitated Vessels: Energetic AspectsDocument2 pagesMass Transfer in Agitated Vessels: Energetic AspectsAyleen MayorgaNo ratings yet

- Golan 1996 - Well Performance Cap 2 PDFDocument128 pagesGolan 1996 - Well Performance Cap 2 PDFSantiago AriasNo ratings yet

- SPE 77951 Multirate Test in Horizontal Wells: SurcolombianaDocument12 pagesSPE 77951 Multirate Test in Horizontal Wells: SurcolombianaJorge RochaNo ratings yet

- CFD Modelling of Floating and Se Ttling Phases in Settling TanksDocument7 pagesCFD Modelling of Floating and Se Ttling Phases in Settling Tanksdatam38No ratings yet

- Cold flow analysis of trapped vortex combustorDocument12 pagesCold flow analysis of trapped vortex combustorAnonymous 6SivdzjNo ratings yet

- 1 s2.0 014102969592643M MainDocument7 pages1 s2.0 014102969592643M Mainyusep ramdaniNo ratings yet

- New Equation for Reservoir Area-Capacity CalculationsDocument9 pagesNew Equation for Reservoir Area-Capacity CalculationsIshit DhadaNo ratings yet

- Comparison of LES and RANS Calculations of The Flow Around Bluff BodiesDocument21 pagesComparison of LES and RANS Calculations of The Flow Around Bluff BodiesMahrukh ZAIDINo ratings yet

- 61 72 PDFDocument12 pages61 72 PDFmusebladeNo ratings yet

- 2015 - Calibration of An Air Entrainment Model For CFD Spillway ApplicationsDocument12 pages2015 - Calibration of An Air Entrainment Model For CFD Spillway ApplicationsYen Kun HoNo ratings yet

- Water: Hydraulic Optimization of Double Chamber Surge Tank Using NSGA-IIDocument20 pagesWater: Hydraulic Optimization of Double Chamber Surge Tank Using NSGA-IIBabi BaralNo ratings yet

- Estimation of Reservoir CapacityDocument4 pagesEstimation of Reservoir CapacityNani TirumalasettiNo ratings yet

- CFD WaterjetDocument8 pagesCFD WaterjettafocanNo ratings yet

- 16902-Article Text-55672-1-10-20170305Document15 pages16902-Article Text-55672-1-10-20170305aNo ratings yet

- Fluid FlowDocument15 pagesFluid Flowdekra abdoNo ratings yet

- Fluid FlowDocument15 pagesFluid FlowRahul TaleNo ratings yet

- Water: Numerical Analysis of Drag Force Acting On 2D Cylinder Immersed in Accelerated FlowDocument24 pagesWater: Numerical Analysis of Drag Force Acting On 2D Cylinder Immersed in Accelerated FlowRishbha SapkotaNo ratings yet

- Flow over ogee spillway analysisDocument26 pagesFlow over ogee spillway analysisharsh agarwalNo ratings yet

- E060701020025 PDFDocument6 pagesE060701020025 PDFمنير أحمدNo ratings yet

- Calculating The Parameters of Muskingum Methods For A Rectangular ChannelDocument5 pagesCalculating The Parameters of Muskingum Methods For A Rectangular Channelsherif ashrafNo ratings yet

- The Calculation of Turbulent Boundary Layers On Spinning and Curved SurfacesDocument9 pagesThe Calculation of Turbulent Boundary Layers On Spinning and Curved Surfacesyaser AlahmadiNo ratings yet

- Numerical Study of Cavitation Inception Due To Vortex/Vortex Interaction in A Ducted PropulsorDocument33 pagesNumerical Study of Cavitation Inception Due To Vortex/Vortex Interaction in A Ducted PropulsorncharalaNo ratings yet

- Artigo Cientifico CFDDocument7 pagesArtigo Cientifico CFDJanduir FilhoNo ratings yet

- Flood - RoutingDocument8 pagesFlood - RoutingLuna KimNo ratings yet

- Wave propagation modeling for coastal engineeringDocument12 pagesWave propagation modeling for coastal engineeringsimoNo ratings yet

- Dam Failure Part 2Document83 pagesDam Failure Part 2박래건No ratings yet

- Numerical and Experimental Study of Classical Hydraulic JumpDocument16 pagesNumerical and Experimental Study of Classical Hydraulic JumpM A AbdulrazaqNo ratings yet

- Modelling The Flow: in HydrocycloneDocument8 pagesModelling The Flow: in HydrocycloneCitlalli QuetzalcoatlNo ratings yet

- 7.0 Groundwater and Stabilizer Transport ModelingDocument56 pages7.0 Groundwater and Stabilizer Transport ModelingTATATAHERNo ratings yet

- Vortex ViennaDocument13 pagesVortex Viennamohdsyahirbk20No ratings yet

- Research On The Cavitation Characteristic of Kaplan Turbine Under Sediment Flow ConditionDocument10 pagesResearch On The Cavitation Characteristic of Kaplan Turbine Under Sediment Flow ConditionFabio FolpiniNo ratings yet

- 2010 - Asme - Imece2010-39752 - Horizontal Cylindrical TankDocument8 pages2010 - Asme - Imece2010-39752 - Horizontal Cylindrical TankEswaran MuthaiahNo ratings yet

- Applied Mathematical Modelling: S.M. Seyedpoor, J. Salajegheh, E. SalajeghehDocument15 pagesApplied Mathematical Modelling: S.M. Seyedpoor, J. Salajegheh, E. SalajeghehDaniel WorkuNo ratings yet

- Fluvial Geomorphology PDFDocument84 pagesFluvial Geomorphology PDFNelson Edwin Huaman VillacortaNo ratings yet

- Dispersed Two-Phase Flow in A Gas-Liquid Cylindrical Cyclone SeparatorDocument12 pagesDispersed Two-Phase Flow in A Gas-Liquid Cylindrical Cyclone SeparatorManivannanVenkatesanNo ratings yet

- Comparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaDocument8 pagesComparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaGanesh GPNo ratings yet

- Hydrological Vs Hydraulic RoutingDocument6 pagesHydrological Vs Hydraulic RoutingRahulKaushikNo ratings yet

- 07 Chapter 1Document70 pages07 Chapter 1Gertjan DuniceriNo ratings yet

- Quick Strip Theory Calculations in Ship Design: WWW - Shipmotions.nlDocument11 pagesQuick Strip Theory Calculations in Ship Design: WWW - Shipmotions.nlYoungkook KimNo ratings yet

- Setting Up Rating Curves Using HEC-RAS: January 2007Document12 pagesSetting Up Rating Curves Using HEC-RAS: January 2007João AugustoNo ratings yet

- Journee PRADS92 - Quick Strip Theory Calculations in Ship DesignDocument11 pagesJournee PRADS92 - Quick Strip Theory Calculations in Ship Designumair abbasNo ratings yet

- Experimental Study of Flow About A Square Cylinder Placed On A WallDocument4 pagesExperimental Study of Flow About A Square Cylinder Placed On A Wallxikun WNo ratings yet

- 110 SDR 40 04Document22 pages110 SDR 40 04Pravash MoolNo ratings yet

- Smart CityDocument8 pagesSmart CityPravash MoolNo ratings yet

- icimodHP 2017Document15 pagesicimodHP 2017Pravash MoolNo ratings yet

- Anamaya VehicleDocument1 pageAnamaya VehiclePravash MoolNo ratings yet

- Letter No. 02 Dated 19 12 2022 - HRT Concrete Lining ProgressDocument1 pageLetter No. 02 Dated 19 12 2022 - HRT Concrete Lining ProgressPravash MoolNo ratings yet

- Head Loss in TunnelsDocument16 pagesHead Loss in TunnelsSai Charan RajuNo ratings yet

- AshimSingh Basnet ResumeDocument3 pagesAshimSingh Basnet ResumePravash MoolNo ratings yet

- Company Profile 2022 HCE - Rev2.m PDFDocument79 pagesCompany Profile 2022 HCE - Rev2.m PDFPravash MoolNo ratings yet

- Operation and Maintenance Manual: Dordi Khola Hydro Electric ProjectDocument73 pagesOperation and Maintenance Manual: Dordi Khola Hydro Electric ProjectPravash MoolNo ratings yet

- Development of The Kvaerner Multiresonant OWCDocument7 pagesDevelopment of The Kvaerner Multiresonant OWCDimSolNo ratings yet

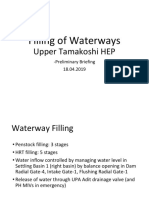

- Filling of Waterways at Upper Tamakoshi HEPDocument15 pagesFilling of Waterways at Upper Tamakoshi HEPPravash MoolNo ratings yet

- Time To Sink A Boat PDFDocument2 pagesTime To Sink A Boat PDFabhayNo ratings yet

- Rethinking The Classical Mechanics, Part #1 of 10Document1 pageRethinking The Classical Mechanics, Part #1 of 10Boris50% (2)

- 09-07-23 JR - Iit Star Co-Sc (Model-A) Jee Adv 2017 (P-II) Wat-11 QP FinalDocument19 pages09-07-23 JR - Iit Star Co-Sc (Model-A) Jee Adv 2017 (P-II) Wat-11 QP FinalRutvika Chowdary NemalapudiNo ratings yet

- Chapter 5 Airy Stress FunctionDocument19 pagesChapter 5 Airy Stress FunctionGilang Farhan Ramadhan MulyadiNo ratings yet

- Turbomachinery Fundamentals: Turbines, Compressors and Fluid MechanicsDocument39 pagesTurbomachinery Fundamentals: Turbines, Compressors and Fluid MechanicsHailu FekaduNo ratings yet

- Module 2 DynamicsDocument6 pagesModule 2 DynamicsFrancis Philippe CariñoNo ratings yet

- ME 8391 Engineering Thermodynamics Workbook - UNIT 1Document154 pagesME 8391 Engineering Thermodynamics Workbook - UNIT 1BIBIN CHIDAMBARANATHANNo ratings yet

- Physics JAM 2023 Section A QuestionsDocument42 pagesPhysics JAM 2023 Section A QuestionsAkshay Simha HNo ratings yet

- UG Question Papers & Answer Keys 17.01.2019Document837 pagesUG Question Papers & Answer Keys 17.01.2019smcyber0% (1)

- Lecture 3 (Mathematical Modeling of Mechanical Systems)Document62 pagesLecture 3 (Mathematical Modeling of Mechanical Systems)muhammad hamzaNo ratings yet

- 1-Static 1-1Document10 pages1-Static 1-1Minh LâmNo ratings yet

- Boundary Layer Video LecturesDocument28 pagesBoundary Layer Video LecturesNidhi JainNo ratings yet

- How to Draw Free-Body Diagrams (FBDDocument16 pagesHow to Draw Free-Body Diagrams (FBDJohn WarrycraftNo ratings yet

- Hindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)Document15 pagesHindusthan College of Engineering and Technology: (An Autonomous Institution, Affiliated To Anna University, Chennai)VEERAMANIKANDANNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Mech Final Year CVV QuestionsDocument13 pagesMech Final Year CVV QuestionsMAHESH PMNo ratings yet

- Pbee Toolbox - Examples of ApplicationDocument54 pagesPbee Toolbox - Examples of ApplicationCem Demir100% (1)

- Laminated Rubber Bridge BearingDocument10 pagesLaminated Rubber Bridge BearingSaeedreza ZahNo ratings yet

- Principles of Projectile MotionDocument8 pagesPrinciples of Projectile MotionOh WellNo ratings yet

- DownloadLecture 10 - Entropy, Clausius InequalityDocument4 pagesDownloadLecture 10 - Entropy, Clausius Inequalityeuglena6No ratings yet

- Drain Time of TankDocument6 pagesDrain Time of TankDhananjay KadamNo ratings yet

- Rotational motion of rigid objectsDocument63 pagesRotational motion of rigid objectsNurulWardhani11No ratings yet

- Common Mistakes in Fatigue AnalysisDocument14 pagesCommon Mistakes in Fatigue AnalysismuhannedNo ratings yet

- Tut 3 - BalancingDocument3 pagesTut 3 - Balancinglittleprince889No ratings yet

- Projectile MotionDocument38 pagesProjectile MotionLope Ballovar Baylon JrNo ratings yet

- Arches MCQDocument9 pagesArches MCQjampanivenkat8No ratings yet

- Unit 4: Non - Flow ProcessDocument17 pagesUnit 4: Non - Flow ProcessMarco KrugerNo ratings yet

- Ruskin Tubular Dissipative Silencer CN-C-403Document2 pagesRuskin Tubular Dissipative Silencer CN-C-403CTLNo ratings yet