Professional Documents

Culture Documents

IECEx certified cable glands

Uploaded by

Umar FarooqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IECEx certified cable glands

Uploaded by

Umar FarooqCopyright:

Available Formats

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 1 of 8

Equipment:

The E** series Type ranges of cable glands consist of a male-threaded front entry component

containing an elastomeric sealing ring and a Nylon 6 skid washer which effect flameproof sealing

onto the cable inner sheath and is intended to screw into an entry point of its associated enclosure

in accordance with relevant codes of practice. The flameproof seal is actuated by an adjoining

coupling component. The coupling component is attached to a main body. Their mating thread may

be fitted with an optional 'O' ring seal to provide increased ingress protection. Clamping of the

armoured or braided cable is effected by a combination of the coupling component, main body and

the different optional armour cone and armour sleeve combinations being fastened together. An

outer seal nut, containing an elastomeric sealing ring and a Nylon 6 ferrule, threads onto the main

body and effects environmental sealing onto the cable outer sheath.

T3CDS - a range of displacement type cable glands, each comprises of a hollow threaded entry

component containing an elastomeric compensating displacement seal (CDS) system with

associated ferrule, a skid washer, flameproof sealing ring with compensator, a clamping sleeve and

armour cone are provided for termination of various armour types. The flameproof sealing

assembly is actuated by an inner seal nut. The entry component is fitted with an 'O' ring seal to

provide increased ingress and deluge protection. Clamping of the armoured or braided cable is

effected by a combination of the entry component, main body

and the different optional armour cone and armour sleeve combinations being fastened together.

An outer seal nut, containing an elastomeric sealing ring and a Nylon 6 ferrule, threads onto the

main body and effects environmental sealing onto the cable outer sheath. The glands are intended

for use with appropriately sized SWA, P.W.A., strip armoured, tape armoured or braided cables. The

design is such that a constant pressure is maintained on the displacement seal by the use of the

compensation ferrule.

T3CDS/PB Identical to the T3CDS Type but incorporates a continuity washer and are suitable for

use with lead sheathed cables.

TE1F* Type - Identical inner seal/armour clamp front/outer seal to the T3CDS Type but overall

length is shortened. The glands are intended for use with appropriately sized SWA, P.W.A., strip

armoured, tape armoured or braided cables.

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 2 of 8

Design options - Cable Gland Types E**

• The front entry component may be manufactured with a profiled groove to captivate an 'O' ring

seal which locates on the mating face with the associated enclosure. This option having the

gland type designation prefixed with the letter R, e.g. 25RE1FW.

• Materials of manufacture:

Brass to EN12168:1998 Grade CuZn39Pb (CW614N)

Mild steel to BS EN 10088-3:2005 Grade 220M07Pb

Stainless steel to BS EN 10088-3:2005 Grade 316S11, 316S13, 316S31 or 316S33

Aluminium alloy not inferior to grade 6082 to EN755,1-3:1996 or LM25 to BS EN 1676:2010 (Not

Group I)

• Alternative entry component thread forms:

Metric ISO 965-1, IS0965-3 medium fit (6g) for external threads

ET(Conduit) BS 31:1940 (1979), Table A

PG DIN 40430:1971

BSPP BS 2779:1973 class A full form for external threads

BSPT BS 21:1985 standard threads only as clause 5.4, gauging to clause 5.2 system A

ISO ISO 7/1:1982, gauging to ISO 7/2 clause 6.3 for external threads

NPT ANSI/ASME B1.20.1-1983 gauging to clause 8.1 for external threads

NPSM ANSI/ASME B1.20.1-1983 gauging to clause 9 for external threads

• The option to manufacture glands with entry threads that are one size up from the nominal

quoted gland size.

• The use of alternative armour clamping components specified by the cable gland type

designation. The various arrangements vary the cable gland suitability for differing armour or

braided type cables.

• The use of a component having an alternative profile allowing an integral earthing facility. The

type designation identifying the cable gland being fitted with this option.

• The use of metallic continuity diaphragm component specified by the cable gland type

designation for use when terminating lead sheathed cables.

• The use of an earthing device component specified by the cable gland type designation for

use with variable speed drive (VSD) / variable frequency drive (VFD) cables.

• Alternative material of manufacture of the ferrule to be the same as the gland material.

• The use of seals suitable for flat form cables

• The use of an 0 ring seal between the body and the entry item to provide a deluge seal.

• Alternative outer seal arrangement to allow the glands to be fitted to flexible conduit.

• The option to fit a blanking disc between the outer seal and the main body to maintain a

minimum IP66 rating. The disc is to be marked 'Ex e only' to indicate that the gland is not

suitable for Ex d applications when the disc is fitted.

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 3 of 8

Type designation code

E F /

D = Fitted with Deluge seal

C = Fitted with the alternative cast integral earth lug

entry component.

VAR = Fitted with an additional metallic continuity device

for use with variable speed drive (VSD) / variable

frequency drive (VFD) cables.

FF = Fitted with seals suitable for flat form cables

W = Fitted with single plain armour cone & reversible

armour sleeve to suit SWA cables.

X = Fitted with single grooved armour cone &

reversible armour sleeve to suit SWA, STA, strip

armoured, pliable wire armoured and braided

cables.

U = Fitted with reversible armour cone & reversible

armour sleeve to suit SWA, STA, strip armoured,

pliable wire armoured and braided cables.

VAR = Optional construction where the cone and sleeve

assembly is replaced by a metallic continuity

device for use with variable speed drive (VSD) /

variable frequency drive (VFD) cables.

1 = Standard circular armoured and braided cables.

2 = Fitted with additional metallic continuity diaphragm

for the use with inner lead sheathed SWA, strip

armoured and braided cables.

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 4 of 8

The gland and seal sizes are determined by the entry thread and cable range take sizes:

Gland Size Entry Cable Inner SWA SWA, STA, Cable Outer

Thread Seal Sheath Ø (mm) strip armour, Seal Sheath Ø

(mm) pliable wire (mm)

armour* and

wire braid (mm)

Min. Max. Min. Max. Min. Max. Min. Max.

16 M16 x 1.5 3.1 8.6 0.8 1.25 0 0.8 6.1 13.2

20s/16 M20 x 1.5 3.1 8.6 0.8 1.25 0 0.8 6.1 13.2

20s16/20s M20 x 1.5 3.1 8.6 0.8 1.25 0 0.8 9.5 15.9

20s M20 x 1.5 6.1 11.6 0.8 1.25 0 0.8 9.5 15.9

20s/20 M20 x 1.5 6.1 11.6 0.8 1.25 0 0.8 12.5 20.9

20 M20 x 1.5 6.5 13.9 0.8 1.25 0 0.8 12.5 20.9

20/25s M20 x 1.5 6.5 13.9 1.25 1.6 0 1.1 14.0 22.0

20/25 M20 x 1.5 6.5 13.9 1.25 1.6 0 1.1 18.2 26.2

25s M25 x 1.5 11.1 19.9 1.25 1.6 0 1.1 14.0 22.0

25 M25 x 1.5 11.1 19.9 1.25 1.6 0 1.1 18.2 26.2

25/32 M25 x 1.5 11.1 19.9 1.6 2.0 0 1.2 23.7 33.9

32 M32 x 1.5 17.0 26.2 1.6 2.0 0 1.2 23.7 33.9

32/40 M32 x 1.5 17.0 26.2 1.6 2.0 0 1.2 27.9 40.4

40 M40 x 1.5 22.0 32.1 1.6 2.0 0 1.2 27.9 40.4

40/50s M40 x 1.5 22.0 32.1 2.0 2.5 0 1.5 35.2 46.7

50s M50 x 1.5 29.5 38.1 2.0 2.5 0 1.5 35.2 46.7

50s/50 M50 x 1.5 29.5 38.1 2.0 2.5 0 1.5 40.4 53.1

50 M50 x 1.5 35.6 44.0 2.0 2.5 0 1.5 40.4 53.1

50/63s M50 x 1.5 35.6 44.0 2.0 2.5 0 1.5 45.6 59.4

63s M63 x 1.5 40.1 49.9 2.0 2.5 0 1.5 45.6 59.4

63s/63 M63 x 1.5 40.1 49.9 2.0 2.5 0 1.5 54.6 65.9

63 M63 x 1.5 47.2 55.9 2.0 2.5 0 1.5 54.6 65.9

63/75s M63 x 1.5 47.2 55.9 2.0 2.5 0 1.5 59.0 72.1

75s M75 x 1.5 52.8 61.9 2.0 2.5 0 1.5 59.0 72.1

75s/75 M75 x 1.5 52.8 61.9 2.5 3.0 0 1.5 66.7 78.5

75 M75 x 1.5 59.1 67.9 2.5 3.0 0 1.5 66.7 78.5

75/90 M75 x 1.5 59.1 67.9 3.0 3.5 0 1.6 76.2 90.4

90 M90 x 2.0 66.6 79.9 3.0 3.5 0 1.6 76.2 90.4

90/100 M90 x 2.0 66.6 79.9 3.15 4.0 0 1.6 86.1 101.5

100 M100 x 2.0 76.0 90.9 3.15 4.0 0 1.6 86.1 101.5

100/115 M100 x 2.0 76.0 90.9 3.15 4.0 0 1.6 101.5 110.3

115 M115 x 2.0 86.0 97.9 3.15 4.0 0 1.6 101.5 110.3

115/130 M115 x 2.0 86.0 97.9 3.15 4.0 0 1.6 110.2 123.3

130 M130 x 2.0 97.0 114.9 3.15 4.0 0 1.6 110.2 123.3

E*-FF in these sizes only:

Gland Size Entry Cable Inner Seal Sheath Cable Outer Seal Sheath

Thread (mm) (mm)

Min. Max. Min. Max.

20s M20 x 1.5 4.0 x 6.2 6.8 x 11.7 4.4 x 7.8 6.8 x 11.7

20 M20 x 1.5 5.7 x 8.0 8.7 x 13.5 4.4 x 10.9 8.7 x 16.0

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 5 of 8

Design options - Cable Gland Types Triton T3** and TE**

• The front entry component may be manufactured with a profiled groove to captivate an 'O' ring

seal which locates on the mating face with the associated enclosure. This option having the

gland type designation prefixed with the letter R, e.g. 25RT3CDS.

• Materials of manufacture:

Brass to EN12168:1998 Grade CuZn39Pb (CW614N)

Mild steel to BS EN 10088-3:2005 Grade 220M07Pb

Stainless steel to BS EN 10088-3:2005 Grade 316S11, 316S13, 316S31 or 316S33

Aluminium alloy not inferior to grade 6082 to EN755,1-3:1996 or LM25 to BS EN 1676:2010 (Not

Group I)

• Alternative entry component thread forms:

Metric ISO 965-1, IS0965-3 medium fit (6g) for external threads

ET(Conduit) BS 31:1940 (1979), Table A

PG DIN 40430:1971

BSPP BS 2779:1973 class A full form for external threads

BSPT BS 21:1985 standard threads only as clause 5.4, gauging to clause 5.2 system A

ISO ISO 7/1:1982, gauging to ISO 7/2 clause 6.3 for external threads

NPT ANSI/ASME B1.20.1-1983 gauging to clause 8.1 for external threads

NPSM ANSI/ASME B1.20.1-1983 gauging to clause 9 for external threads

• The option to manufacture glands with entry threads that are one size up from the nominal

quoted gland size.

• The option to have an alternative entry component profile that incorporates an earth lug.

• Single or double sided and with an identically dimensioned plain taper each side for SWA type

cables, the gland type designation becoming T3CDSW, T3CDSW/PB, TE1FW and TE1FW/PB.

• Single or double sided with an identically dimensioned grooved taper each side for SWA,

P.W.A., strip armoured, tape armoured or braided type cables; the gland type designation

becoming T3CDSX, T3CDSX/PB, TE1FX and TE1FX/PB.

• The use of alternative armour clamping components specified by the cable glands type

designation. The various arrangements vary the cable gland suitability for differing armour or

braided type cables.

• The use of seals suitable for flat form cables

• Alternative outer seal arrangement to allow the glands to be fitted to flexible conduit.

• The option to fit a blanking disc between the outer seal and the main body to maintain a

minimum IP66 rating. The disc is to be marked 'Ex e only' to indicate that the gland is not

suitable for Ex d applications when the disc is fitted.

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 6 of 8

Type designation code

T3CDS

PB = Alternative cone assembly incorporating an

additional metallic continuity diaphragm for the use

with inner lead sheathed SWA and braided cables.

VAR = Optional metallic continuity device for use with

variable speed drive (VSD) / variable frequency

drive (VFD) cables.

FF = Fitted with seals suitable for use with flat form

cables

TE F

VAR = Optional metallic continuity device for use with

variable speed drive (VSD) / variable frequency

drive (VFD) cables.

FF = Fitted with seals suitable for use with flat form

cables

W = Fitted with single plain armour cone & reversible

armour sleeve to suit SWA cables.

X = Fitted with single grooved armour cone &

reversible armour sleeve to suit SWA, STA, strip

armoured, pliable wire armoured and braided

cables.

U = Fitted with reversible armour cone & reversible

armour sleeve to suit SWA, STA, strip armoured,

pliable wire armoured and braided cables.

1 = Standard circular armoured and braided cables.

2 = Fitted with additional metallic continuity diaphragm

for the use with inner lead sheathed SWA, strip

armoured and braided cables.

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 7 of 8

The gland and seal sizes are determined by the entry thread and cable range take sizes:

Gland Entry Cable Inner SWA SWA, STA, strip Cable Outer Seal

Size Thread Seal Sheath Ø (mm) armour, pliable Sheath Ø (mm)

(mm) wire armour*

and wire braid

(mm)

Min. Max. Min. Max. Min. Max. Min. Max.

16 M16 x 1.5 3.1 8.7 0.8 1.25 0 0.8 6.1 13.2

20s/16 M20 x 1.5 3.1 8.7 0.8 1.25 0 0.8 6.1 13.2

20s16/20s M20 x 1.5 3.1 8.7 0.8 1.25 0 0.8 9.5 15.9

20s M20 x 1.5 6.1 11.7 0.8 1.25 0 0.8 9.5 15.9

20 M20 x 1.5 6.5 14.0 0.8 1.25 0 0.8 12.5 20.9

25s M25 x 1.5 11.1 20.0 1.25 1.6 0 1.1 14.0 22.0

25 M25 x 1.5 11.1 20.0 1.25 1.6 0 1.1 18.2 26.2

32 M32 x 1.5 17.0 26.3 1.6 2.0 0 1.2 23.7 33.9

40 M40 x 1.5 22.0 32.2 1.6 2.0 0 1.2 27.9 40.4

50s M50 x 1.5 29.5 38.2 2.0 2.5 0 1.5 35.2 46.7

50 M50 x 1.5 35.6 44.1 2.0 2.5 0 1.5 40.4 53.1

63s M63 x 1.5 40.1 50.0 2.0 2.5 0 1.5 45.6 59.4

63 M63 x 1.5 47.2 56.0 2.0 2.5 0 1.5 54.6 65.9

75s M75 x 1.5 52.8 62.0 2.5 3.0 0 1.5 59.0 72.1

75 M75 x 1.5 59.1 68.0 2.5 3.0 0 1.6 66.7 78.5

90 M90 x 2.0 66.6 80.0 3.15 4.0 0 1.6 76.2 90.4

100 M100 x 2.0 76.0 91.0 3.15 4.0 0 1.6 86.1 101.5

115 M115 x 2.0 86.0 98.0 3.15 4.0 0 1.6 101.5 110.3

130 M130 x 2.0 97.0 115.0 3.15 4.0 0 1.6 110.2 123.3

T3* or TE*-FF in these sizes only:

Gland Entry Cable Inner Seal Sheath Ø Cable Outer Seal

Size Thread (mm) Sheath Ø (mm)

Min. Max. Min. Max.

20s M20 x 1.5 4.0 x 6.2 6.8 x 11.7 4.4 x 7.8 6.8 x 11.7

20 M20 x 1.5 5.7 x 8.0 8.7 x 13.5 4.4 x 10.9 8.7 x 16.0

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

IECEx Certificate of

Conformity

Certificate No.: IECEx SIM 14.0007X Issue No.: 0

Annex Page 8 of 8

Manufacturer’s documents:

Drawing No Subject Rev. Date

GA355A E TYPE SERIES GENERAL ARRANGEMENT - SIMTARS 00 21/05/2014

GA356A TE1FU GENERAL ARRANGEMENT - SIMTARS 00 21/05/2014

GA357A TRITON CDS GENERAL ARRANGEMENT - SIMTARS 00 21/05/2014

SCH0321 INNER SEAL DETAILS 00 27/09/2012

SCH0322 OUTER SEAL DETAILS 00 27/09/2012

SCH0323 TYPICAL ARMOUR CLAMP DETAILS 00 27/09/2012

SCH0328 CDS ASEMBLY DETAILS 00 27/09/2012

Certificate issued by:

Safety in Mines Testing

and Research Station

(Simtars)

2 Smith Street

REDBANK QLD 4301

Australia

You might also like

- Atex CML T3CDS Te1fuDocument7 pagesAtex CML T3CDS Te1fuSriNo ratings yet

- CABLE GLAND Star Teck ST Series Fittings For Teck and Acwu CableDocument2 pagesCABLE GLAND Star Teck ST Series Fittings For Teck and Acwu CableRobNo ratings yet

- VahleDocument18 pagesVahleSyamsi Straw HatNo ratings yet

- Cable Glands for Hazardous Area ConnectionsDocument81 pagesCable Glands for Hazardous Area ConnectionsLenzy Andre Famela100% (1)

- LV Power Cable Specification - 06.11.2009Document10 pagesLV Power Cable Specification - 06.11.2009ErAkashAryanNo ratings yet

- Ujc-S Underground Junction Chamber: Catalogue 2018Document6 pagesUjc-S Underground Junction Chamber: Catalogue 2018Anonymous tCb9gF0No ratings yet

- TS of HardwareDocument9 pagesTS of HardwareabhishekNo ratings yet

- Glands - Accessories LSF PDFDocument44 pagesGlands - Accessories LSF PDFshaaban2009100% (1)

- CableTraySystems InterflexDocument90 pagesCableTraySystems InterflexSEO BDMNo ratings yet

- OPTICAL FIBRE CABLES GUIDEDocument18 pagesOPTICAL FIBRE CABLES GUIDEProject OfficeNo ratings yet

- httpswww.bakerhughesds.comsitesgfilescozyhq596files2020-093300XL20Transducer20Accessories20Datasheet20-20145668.pDocument15 pageshttpswww.bakerhughesds.comsitesgfilescozyhq596files2020-093300XL20Transducer20Accessories20Datasheet20-20145668.pqdzungNo ratings yet

- Terminals and Splices Selection Guide: For More Information TE Technical Support CenterDocument36 pagesTerminals and Splices Selection Guide: For More Information TE Technical Support CenterFranco RiosNo ratings yet

- Line Bushings: Multi-Core With Threaded SleeveDocument7 pagesLine Bushings: Multi-Core With Threaded SleeveIvanNo ratings yet

- TELECOMMODULE 5Document40 pagesTELECOMMODULE 5MADRIAGA, CYRILLE MAE RUMANo ratings yet

- WBSEDCL LT ABC Accs. SpecDocument8 pagesWBSEDCL LT ABC Accs. SpecahmedNo ratings yet

- Guide to Cable Gland Types and InstallationDocument8 pagesGuide to Cable Gland Types and InstallationHimdad TahirNo ratings yet

- Cable Gland-2 PDFDocument38 pagesCable Gland-2 PDFhkaruvathilNo ratings yet

- (Gsa-Oa) 1zse 2750-111 en Rev 6 NBDocument16 pages(Gsa-Oa) 1zse 2750-111 en Rev 6 NBUmar ChNo ratings yet

- Enphase Datasheet Engage CableDocument2 pagesEnphase Datasheet Engage CableOnur KayaNo ratings yet

- ADSS, HT Lines: Aerial Dielectric Self Supporting CablesDocument1 pageADSS, HT Lines: Aerial Dielectric Self Supporting CablesAdmir KuhinjaNo ratings yet

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000No ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- Udey Pyrocables - Instrumentation Cables Write-UpDocument14 pagesUdey Pyrocables - Instrumentation Cables Write-UpameyraneNo ratings yet

- Npcil TSDocument10 pagesNpcil TSBhavesh KeraliaNo ratings yet

- IC - Pd.600.2a.02 Solenoid CoilDocument23 pagesIC - Pd.600.2a.02 Solenoid CoilAldwinNo ratings yet

- Chapter 13 EX Wiring Methods - IECDocument51 pagesChapter 13 EX Wiring Methods - IECdanishaslNo ratings yet

- Flexible Cord Connectors-Strain ReliefDocument15 pagesFlexible Cord Connectors-Strain ReliefAnonymous AsIbqUNo ratings yet

- 4ductor EnglDocument8 pages4ductor EnglMuadz MuhammadNo ratings yet

- Cable Specifications for All-Dielectric Self-Supporting Fiber Optic Cable (ADSSDocument0 pagesCable Specifications for All-Dielectric Self-Supporting Fiber Optic Cable (ADSSdjordjitoNo ratings yet

- Introduction To Industrial Cable GlandsDocument3 pagesIntroduction To Industrial Cable GlandsretrogradesNo ratings yet

- Test terminal blocks safely calibrate energy metersDocument4 pagesTest terminal blocks safely calibrate energy metersAsim Ali GardeziNo ratings yet

- Bus Duct PPT - 27.07.20Document36 pagesBus Duct PPT - 27.07.20aslam shaikh100% (1)

- UntitledDocument78 pagesUntitledZeri FalmizaNo ratings yet

- 7 Hitachi - Energy - 145kV - Dry - Plug-In - GIS - Transformer - TerminationDocument4 pages7 Hitachi - Energy - 145kV - Dry - Plug-In - GIS - Transformer - TerminationMonisha S.No ratings yet

- Cover MVDocument6 pagesCover MVFani Dwi PutraNo ratings yet

- AVS28 ReelsDocument2 pagesAVS28 ReelsmahmoudglobaltechNo ratings yet

- Cable Glands: Type of GlandDocument7 pagesCable Glands: Type of GlandSanlit JainNo ratings yet

- Evaluating Critical VFD Cable ParametersDocument4 pagesEvaluating Critical VFD Cable ParameterstareqNo ratings yet

- ZNCC USAID/USACE Project Technical SpecificationDocument1 pageZNCC USAID/USACE Project Technical SpecificationAbdul Mosawer ZahidNo ratings yet

- Cable Duct 5302052Document3 pagesCable Duct 5302052Zak zsNo ratings yet

- DEWA Instrumentation Cable SpecsDocument12 pagesDEWA Instrumentation Cable SpecsFlavioNo ratings yet

- CM Dc9000-Eng-Int-DDocument20 pagesCM Dc9000-Eng-Int-DJavier CutipaNo ratings yet

- BQ5477Document10 pagesBQ5477Helar Armejo VasquezNo ratings yet

- TS of Cable AccessoriesDocument20 pagesTS of Cable AccessoriesMayur JainNo ratings yet

- Msedcl Ts LT CablesDocument41 pagesMsedcl Ts LT CablesAshish bhattNo ratings yet

- Cable TrayDocument28 pagesCable Traykirink73No ratings yet

- Koneductor RN4Document8 pagesKoneductor RN4Felipe GhiseliniNo ratings yet

- AccuRibbon LXE 126 WebDocument4 pagesAccuRibbon LXE 126 Webbharatsehgal00No ratings yet

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 pagesWTEC 35KV MV Cable LLDPE Rev S 20160226carloNo ratings yet

- 1009 00 PP Ten 2020 - d1 (Vol III) Technical Part9 E&i SpecificationDocument300 pages1009 00 PP Ten 2020 - d1 (Vol III) Technical Part9 E&i SpecificationRashmi Ranjan MohantyNo ratings yet

- Earthing Protection SpecificationDocument5 pagesEarthing Protection SpecificationNi ReNo ratings yet

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06No ratings yet

- Installation PDFDocument204 pagesInstallation PDFkuscuxNo ratings yet

- Gaon Cable's Guide to Medium Voltage Cable CharacteristicsDocument18 pagesGaon Cable's Guide to Medium Voltage Cable Characteristicsphyo7799100% (2)

- Crane cablesDocument21 pagesCrane cablesDaniel AlbanoNo ratings yet

- 03-000-R1 Alternative DC Power Systems SummaryDocument20 pages03-000-R1 Alternative DC Power Systems Summaryengr khanNo ratings yet

- SBCT Sheet WebDocument2 pagesSBCT Sheet WebpitillinNo ratings yet

- PowerSafe OPzS - GeneralDocument2 pagesPowerSafe OPzS - GeneralWido BazanNo ratings yet

- Neom EmailDocument1 pageNeom EmailJohn Turi100% (3)

- Stahl The Basics of Exlosion Protection BrochureDocument48 pagesStahl The Basics of Exlosion Protection BrochureUmar FarooqNo ratings yet

- Basics of Hazardous AreaDocument93 pagesBasics of Hazardous AreaUmar FarooqNo ratings yet

- Aramco List PDFDocument239 pagesAramco List PDFShah UbaidNo ratings yet

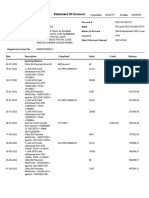

- Statement of AccountDocument7 pagesStatement of AccountUmar FarooqNo ratings yet

- Hazardous AreasDocument84 pagesHazardous AreasUmar FarooqNo ratings yet

- List of MachinesDocument2 pagesList of MachinesUmar FarooqNo ratings yet

- Umar ResumeDocument1 pageUmar ResumeUmar FarooqNo ratings yet

- ERMDocument100 pagesERMSteve WawukNo ratings yet

- Estimation of BudgetDocument1 pageEstimation of BudgetUmar FarooqNo ratings yet

- CML Type Examination Certificate for CMP Cable GlandsDocument7 pagesCML Type Examination Certificate for CMP Cable GlandsUmar FarooqNo ratings yet

- Stahl The Basics of Exlosion Protection BrochureDocument48 pagesStahl The Basics of Exlosion Protection BrochureUmar FarooqNo ratings yet

- Lesson Plan Nº1Document7 pagesLesson Plan Nº1Veronica OrpiNo ratings yet

- A Socio-Cultural Dimension of Local Batik Industry Development in IndoneisaDocument28 pagesA Socio-Cultural Dimension of Local Batik Industry Development in Indoneisaprihadi nugrohoNo ratings yet

- Distributed Oracle EAM - A White PaperDocument38 pagesDistributed Oracle EAM - A White PaperrpgudlaNo ratings yet

- Manual Reductora IVECO TM 265 - TM 265ADocument31 pagesManual Reductora IVECO TM 265 - TM 265ARomà ComaNo ratings yet

- EagleBurgmann BT-ARP ENDocument4 pagesEagleBurgmann BT-ARP ENMarin PintarićNo ratings yet

- 8D Form - LongDocument6 pages8D Form - LongmaofireNo ratings yet

- Speed, Velocity and FrictionDocument10 pagesSpeed, Velocity and FrictionCristie Ann GuiamNo ratings yet

- Civil Engineering Materials CE-115 by Dr. Muhammad Salik JavaidDocument32 pagesCivil Engineering Materials CE-115 by Dr. Muhammad Salik Javaidfaizankhan23No ratings yet

- Skills and Techniques in Counseling Encouraging Paraphrasing and SummarizingDocument35 pagesSkills and Techniques in Counseling Encouraging Paraphrasing and SummarizingjaycnwNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- Clock 38 InstructionsDocument20 pagesClock 38 InstructionsCanNo ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Digital Banking in Vietnam: A Guide To MarketDocument20 pagesDigital Banking in Vietnam: A Guide To MarketTrang PhamNo ratings yet

- Microorganisms Friend or Foe Part-5Document28 pagesMicroorganisms Friend or Foe Part-5rajesh duaNo ratings yet

- C27 and C32 Generator Set Engines - Troubleshooting - RENR9348-01 - Jan 2007 - CATERPILLARDocument180 pagesC27 and C32 Generator Set Engines - Troubleshooting - RENR9348-01 - Jan 2007 - CATERPILLARpevare85% (27)

- Synopsis On Training & DevelopmentDocument6 pagesSynopsis On Training & DevelopmentArchi gupta86% (14)

- Syllabus - EU Institutions and Comparative Political System - 2023springDocument10 pagesSyllabus - EU Institutions and Comparative Political System - 2023springreif annieNo ratings yet

- Time May Not Exist - Tim Folger in DiscoverDocument3 pagesTime May Not Exist - Tim Folger in DiscoverTrevor Allen100% (5)

- Basic Instructions: A Load (Contact) SymbolDocument3 pagesBasic Instructions: A Load (Contact) SymbolBaijayanti DasNo ratings yet

- Comprehensive Exam SchedDocument16 pagesComprehensive Exam SchedMark ErvinNo ratings yet

- Math Lesson on Completing PatternsDocument7 pagesMath Lesson on Completing PatternsJazmyne Obra100% (1)

- DTS Letter of Request To IndustryDocument3 pagesDTS Letter of Request To IndustryJohn Paul MartinNo ratings yet

- METAPHYSICAL POETRY A SummaryDocument3 pagesMETAPHYSICAL POETRY A Summaryrcschoolofenglish1No ratings yet

- A Phenomenological Research Design IllustratedDocument15 pagesA Phenomenological Research Design IllustratedMATEI100% (1)

- Research Article: Noise-Cancelling CMOS Active Inductor and Its Application in RF Band-Pass Filter DesignDocument8 pagesResearch Article: Noise-Cancelling CMOS Active Inductor and Its Application in RF Band-Pass Filter DesignAbhay S KochharNo ratings yet

- A Guide For School LeadersDocument28 pagesA Guide For School LeadersIsam Al HassanNo ratings yet

- Infineon IKCM30F60GD DataSheet v02 - 05 ENDocument17 pagesInfineon IKCM30F60GD DataSheet v02 - 05 ENBOOPATHIMANIKANDAN SNo ratings yet

- Pressure Variation in Tunnels Sealed Trains PDFDocument258 pagesPressure Variation in Tunnels Sealed Trains PDFsivasankarNo ratings yet

- ARC JMK-Research June-2021Document6 pagesARC JMK-Research June-2021Karthik SengodanNo ratings yet

- Gathering Statistical DataDocument8 pagesGathering Statistical DataianNo ratings yet