Professional Documents

Culture Documents

TSB-1045 102200 Regulator Installation

Uploaded by

xavier marsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSB-1045 102200 Regulator Installation

Uploaded by

xavier marsCopyright:

Available Formats

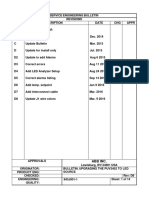

Technical Service

Bulletin

Source: Leece-Neville Heavy Duty Systems Division - Arcade, NY USA

Date: July 7, 2017

Bulletin No: TSB-1045

Models: 12 Volt JB and LC Style Alternators

Subject: 102200 Voltage Regulator Installation

These instructions cover the removal and installation of the 102200 voltage regulator which is used on

the 12 volt “JB” and “LC” alternators.

The 102200 regulator has an excite circuit which is used on 12 volt alternators with AC excite, ignition excite, or with a

diode trio, depending on the original configuration of the alternator.

Regulator Removal

1. Disconnect battery ground cable. 5. Disconnect the red and black leads to the

2. Remove and discard four Mounting Screws from the regulator terminals by removing and discarding

regulator cover. the two (2) #6-32 screws holding the leads to the

3. Remove and retain the two #10-32 nuts from the terminals. See Figure 4.

Excitation Terminal on the Regulator Holder. See Figure 1.

Figure 1 Figure 4

Excitation Mounting

Terminal Screws (4) Black Lead

#10-32 Nuts Terminal (-) Red Lead

(2) Terminal (+)

#6-32

Screw (2) Brushes

Regulator (Note

Holder Orientation As

Spring and You Remove)

Shunt Leads

If the regulator holder has Remote Sense Terminal, do not remove

these nuts. See Figure 2.

Remote Sense

Figure 2 Terminal

6. Remove the brushes, noting their

orientation so that they can be reinstalled in

(DO NOT REMOVE

NUTS)

the same way they were removed. Reinstalling

the brushes in the same orientation will match

Figure 3 the alternator slip ring wear on the ends of the

Excitation

#10-32 brushes. Visually inspect the brushes. If the

4. Slowly tilt the regulator Square Head brushes appear burned, cracked, damaged, or

up and remove and retain the Screw less than 3/8 inches long the brushes must be

Excitation #10-32 square head Regulator replaced. Inspect the springs and the shunt

screw to disconnect the regulator Terminal lead within the spring for damage. Replace if

blue lead (may be white with a blue necessary.

tracer). Note the orientation of the 7. Inspect the Red and Black leads which

Regulator Blue wire terminal inside were disconnected from the regulator. If insulation

the regulator holder so it can be Regulator

Blue Lead

is damaged so bare wire is visible, then the

reinstalled in the same manner. See alternator should be disassembled and the leads

Figure 3. replaced.

Important: The information contained in this bulletin is intended for use by trained, professional technicians who have the proper

tools, equipment, and training to perform the required maintenance described above. This information is NOT intended for ‘do-it-

yourselfers’, and you should not assume that this information applies to your equipment. If you have any questions regarding this

information please visit our website at www.prestolite.com, or contact our technical service department at:

Leece-Neville Heavy Duty Systems

400 Main Street Phone: (844) 492-4062

Arcade, NY 14009 Page 1 webmail@prestolite.com

Technical Service

Bulletin

Date: July 7, 2017

Bulletin No: TSB-1045

Regulator Installation Figure 6

1. If the brushes are to be reused, clean both

brushes with a spray electrical contact cleaner of the

type that does not contain silicone. Silicone attacks the Black Lead in

brushes and will cause short brush life. Clean brush Regulator Holder

Groove

contact caps with #600 grade (or finer) sand paper.

2. Insert a brush in each of the two brush openings

Red Lead in

in the original orientation noted in step 6 above. Regulator Holder

Compress the springs and retain with a pin inserted Groove (Not

through the Access Hole in the Regulator Holder. A applicable to

remote sense

suitable pin can be made of a 1/16” drill or brazing wire.

models)

See Figure 5.

Figure 5

6. Apply a small amount of downward pressure on the

regulator and REMOVE RETAINING PIN (see Figure 5) from

Access Hole to release the brush springs. Hold down the

regulator and secure it with four (4) #8-32 screws supplied.

Torque to 11-13 LB-IN.

CAUTION: The pin used to retain the brushes during

the regulator assembly MUST BE REMOVED before

the regulator is secured to avoid regulator damage.

WARRANTY IS VOID ON ANY REGULATOR RETURNED

WITH ‘PIN’ DAMAGE!!

7. Reconnect ground cable to battery.

Retaining Pin Access Hole

Regulator Test

3. Orient the regulator with respect to the alternator

as shown in Figure 1 using the regulator label as a 1. “Flash” field as follows:

reference. With the engine off, connect a short jumper to the alternator

4. Attach Red wire to (+) regulator terminal and NEGATIVE output terminal and to a piece of stiff wire or

Black wire to the (-) regulator terminal using the two #6-32 1/16” drill. Insert the drill in the access hole as far as it will go

screws supplied (see Figure 4). Torque to 10-12 LB-IN. for 1 to 2 seconds. This will restore the residual magnetism in

Connect the regulator blue lead to the Regulator Holder the rotor.

using the excite #10-32 square head screw and two #10-32

nuts in the same manner it was removed, (see Figure 3), 2. Connect an accurate voltage meter across the alternator

Torque Nuts to 17-20 LB-IN. terminals and run engine at 1000 to 1200 RPM. The voltage

5. Place regulator in Regulator Holder. Assure that shall be between 14.0 and 14.4 volts.

the Black and Red leads are seated in the groves in the

Regulator Holder. See Figure 6.

Important: The information contained in this bulletin is intended for use by trained, professional technicians who have the proper

tools, equipment, and training to perform the required maintenance described above. This information is NOT intended for ‘do-it-

yourselfers’, and you should not assume that this information applies to your equipment. If you have any questions regarding this

information please visit our website at www.prestolite.com, or contact our technical service department at:

Leece-Neville Heavy Duty Systems

7585 Empire Drive Phone: (844) 492-4062

Florence, KY 41042 Page 2 webmail@prestolite.com

You might also like

- AR Series ACB UVT RemovalDocument3 pagesAR Series ACB UVT RemovalGeorgios MariolisNo ratings yet

- Vibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Remove - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Cross Bar Replacement ITF - SM - 5825274-1EN - 3Document6 pagesCross Bar Replacement ITF - SM - 5825274-1EN - 3service iyadMedicalNo ratings yet

- TSB 1062 4000 Series Solid Lead FrameDocument10 pagesTSB 1062 4000 Series Solid Lead FrameJoao SilvaNo ratings yet

- Instructions: Headlamp Visor KitDocument2 pagesInstructions: Headlamp Visor KitPaco JonesNo ratings yet

- Instruction Manual-Smc 33KVDocument9 pagesInstruction Manual-Smc 33KVRAKESH CHANDRA PATRANo ratings yet

- Samsung UE65HU7500L Chassis U8GADocument68 pagesSamsung UE65HU7500L Chassis U8GALuiz Roberto Honório Alves FilhoNo ratings yet

- F Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesDocument6 pagesF Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesAnonymous GbfoQcCNo ratings yet

- XR700 and XR3000: Ignition InspectionDocument20 pagesXR700 and XR3000: Ignition InspectionDevine LightNo ratings yet

- Samsung A330Document48 pagesSamsung A330cipcozianu_297765774No ratings yet

- Cdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFDocument87 pagesCdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFMilciades MurilloNo ratings yet

- Aiwa Tvc2121Document43 pagesAiwa Tvc2121Safran NuhNo ratings yet

- 3114 Entrance-Door-Sensor 10 18 18Document5 pages3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaNo ratings yet

- Homelite HL-EH-LR Rebuild Kit Tech Bulletin Rev ADocument8 pagesHomelite HL-EH-LR Rebuild Kit Tech Bulletin Rev AAMWATSON6754No ratings yet

- TV CN202Document33 pagesTV CN202jama35No ratings yet

- V LogoDocument3 pagesV LogoAdrián CasarrubiasNo ratings yet

- User Instructions For R1100S Gear Switch IndicatorDocument17 pagesUser Instructions For R1100S Gear Switch Indicatorbuzzz57No ratings yet

- Crestline Dampening Systems: Installation InstructionsDocument73 pagesCrestline Dampening Systems: Installation InstructionsSergey PhilippovNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- 03 Disassembly and ReassembleDocument5 pages03 Disassembly and ReassembleEduardo HernandesNo ratings yet

- Replacing Adjusting Engine High-Low Speed ActuatorDocument7 pagesReplacing Adjusting Engine High-Low Speed ActuatorMarco GutiérrezNo ratings yet

- Duc256 WWDocument32 pagesDuc256 WWalexNo ratings yet

- Ajuste Mecanismo z32Document20 pagesAjuste Mecanismo z32Freddy Lucas VeraNo ratings yet

- Aiwa Tv-c1400 Chassis Cp-005aDocument27 pagesAiwa Tv-c1400 Chassis Cp-005apetricabogdanNo ratings yet

- 4725 0200 AA Screen PDFDocument4 pages4725 0200 AA Screen PDFjavier gutierrez pizaNo ratings yet

- NKF-770 TD Exchange Procedure (JLN-550Ver1 0)Document11 pagesNKF-770 TD Exchange Procedure (JLN-550Ver1 0)Abel Francisco Villadiego CaballeroNo ratings yet

- LCD-TV: ServiceDocument79 pagesLCD-TV: ServiceHasan AK0% (1)

- Vibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Inst Headers Install TitianDocument3 pagesInst Headers Install TitianhuntersgreenNo ratings yet

- Service Manual KTS440RCDocument39 pagesService Manual KTS440RCMuhammad Fatham WidiastonoNo ratings yet

- Alignment Light AdjustmentDocument11 pagesAlignment Light AdjustmentNooruddin DeroNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- PLX102 Maintenance ManualDocument8 pagesPLX102 Maintenance ManualJairo Manzaneda100% (4)

- Samsung La37c630 La60c650 Chassis N84aDocument94 pagesSamsung La37c630 La60c650 Chassis N84ajpcmansoNo ratings yet

- Contactor 3TS47, 3TS48: Operating InstructionsDocument7 pagesContactor 3TS47, 3TS48: Operating Instructionsemilce RiveraNo ratings yet

- WheelHorse 8-0814 - 803930Document2 pagesWheelHorse 8-0814 - 803930Kevins Small Engine and Tractor ServiceNo ratings yet

- T 220Document54 pagesT 220Claudio RussoNo ratings yet

- Eclipse 90-99 ElectricalDocument540 pagesEclipse 90-99 ElectricalManuel VizaNo ratings yet

- Service Manual: DEH-3400RDocument73 pagesService Manual: DEH-3400RДианка РусалкаNo ratings yet

- (Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocument170 pages(Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIAngelo RuedaNo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- Motorised Unit: Changeover Switch Installation and Operation GuideDocument20 pagesMotorised Unit: Changeover Switch Installation and Operation GuideStalin Paul Rodriguez LeonNo ratings yet

- All-Products Esuprt Electronics Accessories Esuprt Electronics Accessories Monitor Esuprt Monitor P Series Dell-P2419h-Monitor User's-Guide8 En-UsDocument25 pagesAll-Products Esuprt Electronics Accessories Esuprt Electronics Accessories Monitor Esuprt Monitor P Series Dell-P2419h-Monitor User's-Guide8 En-UsDeeGordon77No ratings yet

- Erbe ICC-200 - Instruction ManualDocument8 pagesErbe ICC-200 - Instruction ManualFrancisco AvilaNo ratings yet

- Rans S6ES Assembly Manual PDFDocument346 pagesRans S6ES Assembly Manual PDFG.L. ZortmanNo ratings yet

- ULC-900 Service ManualDocument20 pagesULC-900 Service ManualEslam ElsayedNo ratings yet

- General Motors Universal External Wire Harness Repair Kit & Test Harness General Motors Universal External Wire Harness Repair Kit & Test HarnessDocument1 pageGeneral Motors Universal External Wire Harness Repair Kit & Test Harness General Motors Universal External Wire Harness Repair Kit & Test Harnessdavid100% (1)

- Getting Started With ATV310: DangerDocument4 pagesGetting Started With ATV310: DangerAdnan Naeem MalikNo ratings yet

- TVF2100NH - 09 008 432 1R2 PDFDocument39 pagesTVF2100NH - 09 008 432 1R2 PDFEfra Lan PeñaNo ratings yet

- Maintenance: OS030EC (C801) OS/SS030BE (D826)Document10 pagesMaintenance: OS030EC (C801) OS/SS030BE (D826)Hector PuacNo ratings yet

- Points Eliminator: Conversion Part No. 2030Document2 pagesPoints Eliminator: Conversion Part No. 2030masakpNo ratings yet

- Allen Bradley AC ContactorsDocument21 pagesAllen Bradley AC ContactorsbryanvdzNo ratings yet

- Denon DN-S3500Document60 pagesDenon DN-S3500Tevel ComNo ratings yet

- TV-C1421 C1422Document43 pagesTV-C1421 C1422gusy180662No ratings yet

- Bulletin: Technical ServiceDocument3 pagesBulletin: Technical ServiceMiguel Contreras PezoaNo ratings yet

- Vibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Document2 pagesVibration Damper and Pulley - Remove - Pulleys Without Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- 3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFDocument14 pages3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFAris Bodhi RNo ratings yet

- Remove 785 Damper SIS 2.0Document9 pagesRemove 785 Damper SIS 2.0isaac989No ratings yet

- Arduino 2wd Smart Robot Car Kit enDocument8 pagesArduino 2wd Smart Robot Car Kit enJeyson GuanoluisaNo ratings yet

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- LensesDocument31 pagesLensesDejaunae LawsonNo ratings yet

- Članak o Zvijezdama PDFDocument28 pagesČlanak o Zvijezdama PDFLejla BajrektarevićNo ratings yet

- The Absolute BEST Dungeons, Dragons and SpaceShuttles Ti-Con MaterialsDocument42 pagesThe Absolute BEST Dungeons, Dragons and SpaceShuttles Ti-Con MaterialsCristiano LimaNo ratings yet

- Q4 Science 9 - Module 1Document23 pagesQ4 Science 9 - Module 1Danilo Saliog67% (6)

- Dielectric AbsorptionDocument4 pagesDielectric AbsorptionbookbumNo ratings yet

- Prev Year Questions: Chapter: TrigonometryDocument10 pagesPrev Year Questions: Chapter: TrigonometrySumit KumarNo ratings yet

- Padeye8t (Without Cheek Plate)Document2 pagesPadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- A Periodic Table of The Elements at Los Alamos National LaboratoryDocument3 pagesA Periodic Table of The Elements at Los Alamos National Laboratoryروشان فاطمة روشانNo ratings yet

- CertificateDocument40 pagesCertificateHery MukhlisNo ratings yet

- Proposal - Shortcut - LNKDocument11 pagesProposal - Shortcut - LNKJohn kinder BasilioNo ratings yet

- 3.3 Catalogo Tem3Document18 pages3.3 Catalogo Tem3Deison F. Arango A.No ratings yet

- Cable CatologueDocument69 pagesCable CatologueJyoti ShekharNo ratings yet

- Class 2 Lever Effort Force CalculationDocument10 pagesClass 2 Lever Effort Force CalculationvenkateswaranNo ratings yet

- Chemistry 9th Edition Zumdahl Test BankDocument25 pagesChemistry 9th Edition Zumdahl Test BankCarolineAvilaijke100% (55)

- DLL - Science 6 - Q3 - W3Document6 pagesDLL - Science 6 - Q3 - W3Annelyn AmparadoNo ratings yet

- Hyo Sung EbaraDocument33 pagesHyo Sung Ebaraduongbk24 luu quang duongNo ratings yet

- Disha Super 10 Mock Tests For JEE Main 2022Document248 pagesDisha Super 10 Mock Tests For JEE Main 2022Ausuh NamaNo ratings yet

- Lecture - 1.1.9Document17 pagesLecture - 1.1.9akhil nigamNo ratings yet

- Module 2Document12 pagesModule 2Azeezan AlessaNo ratings yet

- Key Features:: Single 8" Two-Way 90° X 50° Full-Range Loudspeaker SystemDocument4 pagesKey Features:: Single 8" Two-Way 90° X 50° Full-Range Loudspeaker SystemRafRouf SehiliNo ratings yet

- MedusaDocument2 pagesMedusaCoolProphetNo ratings yet

- LECTURE 1 ARO 3011 Fall 2021 VVDocument54 pagesLECTURE 1 ARO 3011 Fall 2021 VVRukiezillaNo ratings yet

- Chemistry General Sem IV Part 1Document10 pagesChemistry General Sem IV Part 1Cristiano RonaldoNo ratings yet

- Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%Document2 pagesPressure Transmitter With Ceramic Sensor, Accuracy 0,5%essameldinNo ratings yet

- Sample - Solutions Manual Photonics 2nd Edition by SalehDocument1 pageSample - Solutions Manual Photonics 2nd Edition by Salehhadi farzinNo ratings yet

- Index Transforms - S B YakubovichDocument261 pagesIndex Transforms - S B YakubovichsalembensalemNo ratings yet

- Functions and Graphs 1-1 Introduction. Previous To The Seventeenth Century, Algebra andDocument21 pagesFunctions and Graphs 1-1 Introduction. Previous To The Seventeenth Century, Algebra anddahlai dahlia oktaviani ginting100% (1)

- Colloids and Surfaces, 427-438 427Document12 pagesColloids and Surfaces, 427-438 427Dila DjannahNo ratings yet

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012No ratings yet

- Lab Report Marcet BoilerDocument8 pagesLab Report Marcet BoilerAnis Thuraiya100% (1)