Professional Documents

Culture Documents

ESM 4450 Owner's Manual Installation Guide

Uploaded by

PRIMA PUTRA JAYAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESM 4450 Owner's Manual Installation Guide

Uploaded by

PRIMA PUTRA JAYACopyright:

Available Formats

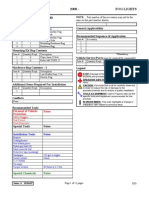

ESM 4450 OWNER’s MANUAL 2.

1 GENERAL DESCRIPTION:

Please read the following information before using and thank you

very much for buying Emko products.

Mounting Clamp Terminal cover

The safety requirements are classified as "warning" or "caution"

according to the following explanations:

WARNING: Suggests that the user' s mishandling can result in

personal death or serious injury.

CAUTION: Suggests that the user' s mishandling can result in

personal injury or damage to the property.

Packing List: Label

One unit.

Two fixing clamps.

One owner’s manual. Front Panel

NEMA 4X

1. INTRODUCTION:

ESM series process controllers can be adapted easily to all applications and automation Enclosure max 5mm thick

systems to control heating, cooling or any process parameters. They are mainly used in the

glass, plastics, petrochemical, textile, automotive and machine production industries. 2.2 DIMENSIONS:

ESM series products are highly developed offering sensitive control schemes by means of

selectable control forms including ON/OFF, P, PI, PD, PID, Auto-tune and Self-tune.

2. INSTALLATION:

WARNING: A visual inspection of this product for possible damage during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, the user

shall provide the unit with an appropriate external protective circuit.

The unit is normally supplied without a power switch or a fuse. Use power switch and fuse as

required (fuse rating is 1A@250VAC)

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble with

the unit can be prevented. 2.3 PANEL CUT-OUT:

Never attempt to disassemble, modify, or repair this unit. Tampering with the unit may result

in malfunction, electric shock, or fire. 65mm (2.56in)

Do not use the unit in combustible or explosive gaseous atmospheres.

During installation into a metal panel, care should be taken to avoid injury from metal burrs

65mm (2.56in)

which might be present. The equipment can loosen from vibration and become dislodged if

installation parts aren't properly tightened.

WARNING: Before beginning installation of this product: 46mm (1.81in)

Disconnect all electrical power to the machine.

Make sure the machine cannot operate during installation.

Follow all safety warnings of the machine manufacturer.

CAUTION: Forbidden Conditions: Corrosive and explosive atmospheres, Home application.

This unit is for industrial applications, only.

Carefully read and follow all installation instructions.

46mm (1.81in)

Installing / Replacing I/O Modules

2.4 PANEL MOUNTING:

Inserting into Panel:

WARNING: During installation into

ΠRemove power from unit. Firmly grip the facia, push a metal panel, care should be taken to

the locking tabs top and bottom and pull the unit

avoid injury from metal burrs which

from its case.

might be present. The equipment can

Insert the module(s) into the cavity(ies as shown). loosen from vibration and become

dislodged if installation parts aren't

Ž Carefully reinsert properly tightened.

the unit into its ! Prepare panel cut-out.

housing. Make ! Check front panel gasket position.

certain that the ! Insert the device through the cut-

communications out.

port lines up with Installing the Fixing Clamp:

the hole at the back The unit is designed for panel

of the housing and mounting. Fixing is by mounting

snap into place. clamps.

Insert the unit in the panel cut-out

Plug-in Modules Product Code from the front.

Relay 3A@250Vac EMO-400

second Input Outputs

Insert the mounting clamps from the

SSR 20mA@18Vdc EMO-410 rear side of the device and tighten the

Transistor 40mA@18Vdc EMO-420 fixing screws to secure the unit

Volt/Current (0 to 20mA, 0 to 10V) EMO-430 against the panel.

Digital switch (NPN, PNP, Contact) EMI-400

0 to 20 mA Current EMI-410 Removing from panel:

0 to 5AAC Current Transformer EMI-420 1) Loosen screws.

TC Input EMI-430 2) Pull the fixing clamps from the device while holding the unit in place.

RTD Input EMI-440 3) Pull the unit through the front of the panel.

0-10vdc Input EMI-450

ESM 4450 v10R7 1-877-798-7287 P.1

3 ELECTRICAL CONNECTIONS: 3.51 CURRENT OUTPUT TRANSDUCER:

WARNING: You must ensure that the controller is correctly configured for your

application. Incorrect configuration could result in damage to the process being

controlled, and/or personal injury. It is your responsibility, as the installer, to ensure

that the configuration is correct. The controller may either have been configured

when ordered, or may need configuring now.

WARNING: This equipment does not contain any parts and material related to

users. Only qualified personnel and technicians trained specially should work on

this equipment. This equipment contains internal circuits with voltage dangerous to

human life. There is severe danger for human life in the case of unauthorized

intervention.

WARNING: Be sure to use the rated power supply voltage and a 1 amp fuse to

protect the unit against damage and to prevent failure. 3.6 VOLTAGE OUTPUT TRANSDUCER: 3.61 VOLTAGE INPUT:

WARNING: Keep the power off until all of the wiring is completed so that electric Transmitter

shock and trouble with the unit can be prevented.

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTIONS:

1 2 3 4 5 6

C NO

Universal M3 screw terminals

Proces Input

OUTPUT - 3

Sensor or Transmitter 5A@250V ~ 6mm/0.23in note 2

Supply Voltage

wire size: Max. 50mA

Communication

Socket

18AWG/1mm2

solid/stranded Note 2: Auxilliary power supply for external transmitter;

Torque 0.5Nm please specify 12 or 24 vdc at time of order

MODULE-1 MODULE-2 Supply Voltage

Input

0.8 x 3mm

RS-232 Terminal Definitions RS-485 Terminal Definitions

1 RX 1 D-

7 8 9 10 11 12

2 TX 2 D+

3.2 POWER SUPPLY:

3 GND 3

Note-1

Note-1 :

N L Internal fusible flameproof resistor. 4. TECHNICAL SPECIFICATIONS AND RATINGS

11 12 External 1 amp fuse must be used in circuit.

Equipment use: Process controller equipment

External 100-240V ~ (-15%;+10%) 50/60Hz - 6VA Housing & Mounting: 48mm x 48mm x 105mm 1/16 DIN 43700 Plastic

Fuse

housing for panel mounting.

~

(1 A T) 24 V ~ (-15%;+10%) 50/60Hz - 6VA Panel cut out: 46x46mm.

Power Protection: NEMA 4X (IP65 front, IP20 rear).

Switch

24V --- (-15%;+10%) - 6W

Weight: Approximately 0.15 Kg.

12 V --- (-15%;+10%) - 6W Environmental rating: Standard, indoor at an altitude of less than 2000 meters

Supply with non condensing humidity

3.3 PT100 INPUT: Polution degree: II, Normal office or workplace, non conductive pollution

Mode of operation: Continuous

Supply voltage: 100 to 240 VAC 50/60 Hz.

24Vac/dc 50/60 Hz

Process Inputs: User selectable (TC, RTD, DC Voltage/Current)

Accuracy: ± 0,25% of FS for thermocouple, thermoresistance,

voltage and + 0,70% of FS for current measurement.

Sampling Cycle: 3 samples per second.

Input Filter: Adjustable from 0.0 to 900.0 Seconds.

Control Form: Programmable ON/OFF, P, PI, PD or PID.

Standard Relay Output: 1 rated 5A@250Vac (Programmable control or

alarm output)

Plug-in modules: optional, 2 max.

Process Display: 10 mm Red 4 digit LED display

Set Display: 8 mm Green 4 digit LED display

LED indicators: AT (Autotune, M(Manual Mode), A (Auto Mode)

3.4 THERMOCOUPLE SENSOR: PSET (Process set), ASET1 (Alarm set-1),

Connect the wires with the ASET2 (Alarm set-2), °C (Centigrade LED),

polarity as shown. Always use °F (Fahrenheit LED), V (Other), PO (Process output),

AO1 (Alarm output-1), AO2 (Alarm output-2).

compensation wire

Operating / Storage temperature: -5 °C to +55 °C / -40 °C to +85 °C

corresponding to the Operating / Storage humidity: 90 % max. (non condensing)

thermocouple used. If present, Installation overvoltage category: II, Distribution level, fixed installation

the shield must be connected category

to a proper ground. Thermocouple input types: User selectable (L,J,K,R,S,T,B,E,N,C)

Thermoresistance input type: PT 100 (2 and 3 wires)

DC Voltage input types: User selectable (0 to 50mV, 0 to 5V, 0 to 10V)

DC Current input types: User selectable (0 to 20mA, 4 to 20mA)

Cold Junction Compensation: Automatically ±0.1°C/1°C

3.5 CURRENT OUTPUT TRANSDUCER WITH SEPARATE POWER SUPPLY: Line Compensation: Maximum 10 Ohm

Sensor Break Protection: Within the operating scale.

Sensor Power Supply 12 or 24 vdc 50mAdc maximum

WARRANTY:

We warrant that the products will be free from defects in material and

workmanship for 2 years from the date of purchase.

The warranty above shall not apply for any damage caused by the use of the

product and is limited only to the repair or replacement of the product.

ESM 4450 v10R7 1-877-798-7287 P.2

Abbreviations

ESM 4450 Programming Guide Parameters are listed in the left hand column in bold lettering followed by its

description and available choices. Some abbreviations are defined as follow:

Front Panel Description AT Autotune ST Self Tune

Display & Indicators

ESM-4450 FS Full Scale (or Max. Scale) Su-L Minimum Operating Value

°C °C unit LED

°C HYS Hysteresis Su-u Maximum Operating Value

°F Process & °F °F unit LED

Parameter PV Process Value SV Process Set Value or PSET

OP1 Display An LED indicator for units other than °C and °F

OP2

Process Set Value, Output1(Process or Alarm) LED

OP3

REMOTE RAMP MAN AUTO

Alarm Set Value &

OP1 Programming Mode - Main Menus

Parameter display OP2 Output2(Process or Alarm) LED

Process Controller °C °C °C

OP3 Output3(Process or Alarm) LED

SET

AUTO Automatic operation LED (for process output)

MAN Manual operation LED (for process output)

Keyboard AUTO AUTO AUTO

RAMP LED for Ramp&Soak operations

Access all menus and to move SET SET

REM LED for operation with remote set value

up to another menu.

Access process set value and OK SV Process set value LED see operator see technıcıan factory settıngs

SET

button when in the program mode. parameters parameters

AT Autotune LED

Increase the parameter values Parameters

and access the program menus.

Decrease the parameter values OPERATOR PARAMETERS

and access the program menus.

Process and Alarm Set Value Parameters (SET LIST)

PSET This is the device’s process set value. If there isn’t any extra module in the device,

Table-1 (Process Input Type and Scale selection) this parameter is used for Output-3.

Process Input Type(TC) Scale(°C) Scale(°F) ALr1 Module-1’s alarm set value when installed & configured as an alarm output.

0 L(FeConst DIN43710) -100°C 850°C -148°F 1562°F

ALr2 Module-2’s alarm set value when installed & configured as an alarm output.

1 L(FeConst DIN43710) -100.0°C 850.0°C -148.0°F 999.9°F

2 J(FeConst IEC-584) -200°C 900°C -328°F 1652°F ALr3 Output-3’s alarm set value when configured as an alarm output.

3 J(FeConst IEC-584) -199.9°C 900.0°C -199.9°F 999.9°F

4 K(NiCrNi DIN/IEC) -200°C 1300°C -328°F 2372°F Tuning and Operating methods (RUN LIST) see p5 for explanation of tuning methods

5 K(NiCrNi DIN/IEC) -199.9°C 999.9°C -199.9°F 999.9°F

tUnn This parameter defines the tuning type.

6 R(Pt13%RhPt DIN/IEC) 0°C 1700°C 32°F 3092°F

NO =Tuning is inactive. ATUN=Only Autotune is active.

7 R(Pt13%RhPt DIN/IEC) 0.0°C 999.9°C 32.0°F 999.9°F

8 S(Pt10%RhPt DIN/IEC) 0°C 1700°C 32°F 3092°F

STUN=Only Selftune is active. AT.ST=Autotune and selftune are active.

9 S(Pt10%RhPt DIN/IEC) 0.0°C 999.9°C 32.0°F 999.9°F

attn NO= Autotune is inactive. YES= Autotune is active.

10 T(CuConst DIN/IEC) -200°C 400°C -328°F 752°F

11 T(CuConst DIN/IEC) -199.9°C 400.0°C -199.9°F 752.0°F AUtO AUTO= Auto process mode. MAN=Manual process mode.

12 B(Pt18%RhPt DIN/IEC) -200°C 400°C -328°F 752°F

13 B(Pt18%RhPt DIN/IEC) -199.9°C 400.0°C -199.9°F 752.0°F rSSL Ramp-Soak Function.

14 E(CrConst DIN/IEC) -150°C 700°C -238°F 1292°F oFF=ramp-soak inactive run=Ramp-Soak is active hold=ramp-soak is paused

15 E(CrConst DIN/IEC) -150.0°C 700.0°C -199.9°F 999.9°F

16 N(NicrosilNisil DIN/IEC) -200°C 1300°C -328°F 2372°F

ULSL If output module 1 is a relay output, then this parameter can be used to define the

17 N(NicrosilNisil DIN/IEC) -199.9°C 999.9°C -199.9°F 999.9°F motorized valve control form. Output 1 to open and Output 3 to close the valve:

18 C(... DIN/IEC) 0°C 2300°C 32°F 4172°F No=inactive HEAt=operates with heating PID CooL=operates with cooling PID

19 C(... DIN/IEC) 0.0°C 999.9°C 32.0°F 999.9°F bpLt Bumpless Transfer

Process Input Type(RTD) Scale(°C) Scale(°F) NO=bumpless transfer is inactive. YES=Bumpless Transfer is active.

0 PT 100 -200°C 650°C -328°F 1202°F

LtCC High Limit Latch Cancelling. If an Alarm output was configured as a latched

1 PT 100 -199.9°C 650.0°C -199.9°F 999.9°F

output and that output is not in the latched condition, it can be returned to a

Process Input Type(DC Voltage and Current) Scale non latching alarm output by entering YES. Once cancelled LtCC=NO

0 0...50 mV Configurable

1 0...5 V Configurable Display Parameters (DISP LIST)

2 0...10 V Configurable

tdSP Defines the function of the top display.

3 0...20 mA Configurable

0=PV , 1= SV-PV, 2=2nd analog input’s measured value (if unit is fitted with this option)

4 4...20 mA Configurable

bdSP Defines the function of the bottom display.

Entering Process Set Value and Parameters Note: If device is running in manual mode, the bottom display shows % Power.

0=SV 1=%power 2=ramp-soak dısplay

Setting the process values: 3 = 2nd sensor’s measured value 4 = CT input measured value

When the ! button is pressed, the SV LED, next to the process value on the bottom Ramp / Soak Parameters (rmP SoA)

display, flashes. Adjust the desired process set value using the ! and !buttons. StrA From 0 to 99h 59min. (Inactive if 0.0)

rStO From 0 to 50% of SV. (Inactive if 0). If rSto or ramp & soak functions have

Press the ! button again to save the new value to memory. If, instead, the !

been selected, then (set value-rSto)<starting temp<(set value+rSto). The

button is pressed, the new set value isn’t saved to memory and the unit exits the

unit operates within this range for the duration selected.

setting mode. You can't change the SV value when the AT LED is lit.

rSty Ramp-Soak type 0=1-4 segment 1= 5-8 segment 2=1-8 segment

Setting the alarm values:

All outputs on the device can be configured as alarms. Alarm set values are shown PU-1to 8 Target SV (SU-L to SU-U)

as ALr1, ALr2 and ALr3 in the SET LIST menu. To access the Set Lıst menu press the Tr-1 to 8 Ramp segment time (from 0 to 99h 59min.)

! button then the ! button. Pressing the ! button agaın allows you to TS-1 to 8 Soak segment time (from 0 to 99h 59min)

access and change the values of PSEt, ALr1, ALr2 and ALr3.

Notes on Ramp and Soak

Observing and changing parameter values:

The parameters have been divided into three groups: Operator, Technician and There are three options: you can have two independent 4 segment processes (essentially

Calibration. The calibration parameters can be accessed by the manufacturer only. giving you two recipes) or one 8 segment process.

The operator can not access the parameters for running mode and configuration. If you want only one Ramp, use the Stra parameter. You do not have to use the Pu, Tr and TS

Whenever you want to enter either the operator’s or technician’s parameter groups, parameters.

the device will require a password. The default value of the user-changeable By using the Stra you are defining the amount of time the controller will take to get the

passwords ıs “0”. To enter new passwords, you must first access the technician’s temperature to the Set Value (time becomes the overriding factor).

If you want more than one R & S, make sure that Stra = 0.

parameters and scroll to “PASS ConF”. After entering the password press the ! Then choose rsty according to the number of segments desired.

button to save it to memory. If you want the controller to shut down after it has gone through all the R & S segments, it

You can access the main titles of the menu by using the ! and must be running in the Manual Mode (Operator Parameters – Run List).

! buttons. Press If this parameter is defined as AUTO, then, at the end of the final segment, the controller will

the ! button to move to the next level of any menu. Change the value of your work to keep the temperature at the final target value. See p7 for graphic representation.

To run the R & S, Rssl in the Operator’s Parameters must be set to RUN via the front

chosen parameter by using ! and ! buttons. The new value is saved to

mounted touch pad

memory by using the ! Button. OR

via an input module, EMI-400, which can be plugged into the controller. This is further

explained on page 4.

ESM 4450 v10R7 1-877-798-7287 P.3

Parameters Parameters

Technician’s parameters (PınP) PID parameters (cont’d)

ıSSL Configuration for process input type. PoFS PID output offset. Added to PID output. -100.0 to 0 for cooling PID

0=TC, 1=RTD, 2=DC Voltage/Current 0.0 to 100.0 for heating PID

TC Input (issl=0)

tCSL TC input type selection for thermocouple and scale (ref. Table-1) -100.0 to 100.0 for heating/cooling PID.

unıt Configuration for unit of measure (°C, °F) PoSS SV offset for PID. Added to PID output (PoSS * PSET / FS)

LPAd Low point adjustment used together with uPAd to correct sensor error. -100.0 to 0 for cooling PID

eg. reading is 26 (low) and 320 (high) but should read 25 and 325 0.0 to 100.0 for heating PID

LPAd = -1 and uPAd=5 -100.0 to 100.0 for heating/cooling PID.

uPAd Upper point adjustment Strn Stability value. Adjustable from 1 to max scale. If tunn=no or Stun, oscillation might

LOL Minimum value of operation scale occur. PSEt-Strn#PSEt#PSEt+Strn

UPL Maximum value of operation scale O-db Proportional band shifting. Adjustable from +50.0% of FS. This value is added to

PUOF Process offset ±10% of FS. Added to process value & expressed in degrees. PSET value for cooling. If SV for heating =PSEt+SuoF then SV for

ıFLt Input signal filtering time. (0.0 to 900.0 seconds) cooling=PSEt+SuoF+o-db

CjnC NO = cold junction compensation is inactive. YES = active.

Sbou Control output value for duration of Sensor break error

-100.0 to 0 for cooling PID

rtdS RTD input type selection for thermoresistance and scale (Ref. Table-1)

R TD In p ut ( is s l= 1 )

0.0 to 100.0 for heating PID

unıt Configuration for unit of measure (°C, °F)

-100.0 to 100.0 for heating/cooling PID

LPAd Low point adjustment used together with uPAd to correct sensor error.

To continue controlling the process if sensor breaks, enter a value. Inactive if 0.0

eg. reading is 26 (low) and 320 (high) but should read 25 and 325

LPAd = -1 and uPAd=5 Input/Output Modules Configuration (MODULE-1/MODULE-2) ıoP1 & ıoP2

uPAd Upper point adjustment out1 / out2 Output configuration (heat, cool, Lout)

LOL Minimum value of operation scale

Con1 / Con2 Control type (ON/OFF or PID)

UPL Maximum value of operation scale

PUOF Process offset ±10% of FS. Added to process value & expressed in degrees. HYS1 / HYS2 Hysteresis value 0% to 50% of FS (expressed in degrees)

ıFLt Input signal filtering time. (0.0 to 900.0 seconds) HYn1 / HYn2 Mode of Hysteresis [0=SV+(HYS/2) and SV-(HYS/2)]

Input type selection for voltage and current (Table-1) [1=SV and SV+HYS or SV and SV-HYS]

UASL

D CVo l t a g e / C u r r e n ( i s s l = 2 )

tm1 / tm2 Minimum OFF time (0.0 to 100.0 Seconds)

dPnt Decimal point position on the displays

0=0000 1=000.0 2=00.00 3=0.000 Lou1 / Lou2 0=Alarm output 1=Manual/Automatic 2=Sensor break alarm

UCAL Dual or multi-point calibration 0=Lol is -1999 & Upl is 9999) (Loutputs) 3=PV is out-of-range 4=Ramp/Soak finished

1=Dual point (adjust Lol & Upl to suit) 5=Sensor break alarm for analogue input module

6=PV is out-of-range for analogue input module

2=Multi-point (up to 16 points P000 to P016)

ALS1 / ALS2 Alarm sensor selection 0 = Process input sensor (on terminals 1,2,3)

P000 1 = Analogue module (1 or 2) sensor

to Calibratiton points for multi-point configuration

P016 Used for non-linear calibration ALt1 / ALt2 0=Process high alarm 1=Process low alarm

(alarm types) 2=Deviation high alarm 3=Deviation low alarm

CoEF Input coefficient. Used to scale input. eg. If sensor input = 40mV, a coefficient 4=Deviation band alarm 5=Deviation range alarm

of 1.25 (50mV÷40mV) is used to get a Full Scale deflection (Upl). 6=Heater failure alarm (CT input module must be installed)

unıt Configuration for unit of measure ALH1 / ALH2 Alarm hysteresis 0% to 50% of FS (expressed in degrees)

°C=Centigrade °F=Fahrenheit U=other - =none Aon1/ Aon2 Alarm delay from fault 0.0 to 9999 seconds

Lol Minimum value of operating scale AoF1/ AoF2 Alarm reset from fault 0.0 to 9998 seconds. For high limit with manual reset

only, select 9999. Display will read LtCH to indicate latch feature selected.

Upl Maximum value of operating scale If Module 1 or 2 is EMO-430

Puof Process offset ±10% of FS. Added to process value & expressed in degrees.

oAt1 / oAt2 Output scale 0= 0...20mA (connect parallel 500 ohm for 0-10VDC)

ıFLt Input signal filtering time (display refresh rate 0.0 to 900.0 seconds) . 1= 4...20mA

PID parameters oua1 / oua2 Output type: Heat / Cool / Retransmission

ret1 / ret2 Rt.pr=Retransmission of PV Rt.er=Retransmission of error

P-Ht Proportional band for heating (0.0% to 999.9% of FS.) Rt.pu=Retransmission of SV

I-Ht Integral time for heating (0 to 3600 seconds) If Module 1 or 2 is EMI-400

D-Ht Derivative time for heating (0.0 to 999.9 seconds)

LIN1 / LIN2 0=Manual / Automatic when logic input closed, changes AUTO program

parameter, if MAN changes to AUTO, if AUTO changes to MAN

Ct-H Control period for heating (1 to 150 seconds)

For Relay module: 30 seconds 1=Start Stop the AT when logic input closed, changes ATTN program

For SSR driver module: 1 or 2 seconds. parameter, if NO changes to YES, if YES changes to NO

2=Run / off Ramp/Soak RSSL program parameter,when logic input is closed,

oLLH Min. control output for heating.(0.0 to ouLH).Inactive ın Heating/Cooling mode. changes RUN or HOLD to OFF, if OFF changes to RUN)

3=Run / hold Ramp/Soak RSSL program parameter when logic input is closed,

oULH Maximum control output for heating. (oLLH to 100%). changes RSSL program parameter, if RUN changes to HOLD, if HOLD

changes to RUN)

oLtH Min. output time for heating. (0.0 to Ct-H or 50 miliseconds when = 0.0) 4=Cancel Alarm Latching when logic input is triggered, unless the alarm

CCoE Cooling proportional band coefficient. (0.0% to 100.0%). If heating and cooling condition still exists.

PID are used, tunning is performed by the heating output. Therefore (P-CL=P- If Module 1 or 2 is EMI-420

HT * CCoE/100) eg. If P-Ht=10.0% and CCoE=50 then P-CL= Hb1 / 2 Heater break alarm set value = (Amps without failure + amps with heater failure)/2

10.0*50/100=5.0%. If value is 0.0, coefficient is inactive. For correct measurements, heating output must be active for at least 0.2 sec.

Recommendation: CCoE=100 when cooling with air; 80 with oil; 40 with water

Ctr1 / 2 Current transformer ratio can be adjusted from 0 to 100.

P-CL Cooling proportional band. (0.0% to 999.9% of FS.) eg. If uPL= 1000EC, eg. For a 100:5A CT this parameter would read 0020 (100/5)

LoL=0EC and P-CL=50% then in temperature P-CL=(1000-0)*50/100=500EC

I-CL Integral time for cooling. (0 to 3600 seconds)

If Module 1 or 2 is EMI-410, EMI-430, EMI-440 or EMI-450

d-CL Derivative time for cooling. (0.0 to 999.9 seconds)

ISL1 / ISL2 Configuration for second sensor input type: 0=TC 1=RTD 2=DC volt/current

Ct-C Cooling control period. (1 to 150 second) tSL1/2 TC input type selection for thermocouple and scale (ref. Table-1)

Recommendation: Use an SSR output for control periods shorter than 30s. UNT1/2 °C=Centigrade °F=Fahrenheit

These are much better suited for frequent on/off operation than relay outputs.

If ISL1= or ISL2= 0

LoL1/2 Minimum value of second sensor input range

oLLC Min. control output for cooling.(0.0%- ouLC). Inactive in Heating/Cooling mode. uPL1/2 Maximum value of second sensor input range

ouLC Maximum control output for cooling. (oLLC - 100.0%). IPu1/2 Module’s display offset value ±10% of Fs1. Added to process value in degrees.

iFL1/2 Module’s input signal filtering time. (From 0,0 to 900,0 seconds)

oLtC Minimum output time for cooling. (0.0 to Ct-C or 50 miliseconds if value is 0.0) CJn1/2 Analogue input Module’s cold junction compensation setting

Ar Anti-Reset Windup (0% to 100% of FS). During PID operation if PSEt - NO = cold junction compensation is inactive YES = active

Ar#PSEt#PSEt+Ar then an integral value is calculated otherwise the last rES1/2 Analogue input remote selection. Determines whether the measured value is the

calculated integral value is used. See p6 for graphic example. result of the input on terminals 1,2, 3 or from the input module. Visible only when

If ot.Ar is selected, then proportional band is used in PID process instead of Ar

decimal point and unit parameters are the same for both inputs.

value.

SuoF Offsets the proportional band from the SV in the PID calculations ("50% of FS)

ESM 4450 v10R7 1-877-798-7287 P.4

Parameters Explanations

If Module 1 or 2 is EMI-410, EMI-430, EMI-440 or EMI-450 (continued)

STEP RESPONSE TUNING (Self Tune)

RTS1 / 2 Selection of sensor type and scale (see Table 1) Firstly, the control form must be PID in order for this tuning method to operate.

UNT1 / 2 °C=Centigrade °F=Fahrenheit

If ISL1 or ISL2= 1

Process

If the tunn parameter is

LoL1 / 2 Minimum value of second sensor input range PID coefficients are determined Stun or At.St, step response

Value

uPL1 / 2 Maximum value of second sensor input range and system becomes stable. tuning is selected. When

IPu1 / 2 Module 1 / 2 PV offset ±10% of FS1. Added to the input reading in degrees Process Set the device is first

iFL1 / 2 Module 1 / 2 Input signal filtering time. (From 0,0 to 900,0 secs) Value ( ) energized, the actual value

rES1 / 2 Determines whether the measured value is the result of the input on is compared to the set

terminals 1,2, 3 or from the input module. Visible only when decimal point value. If the set value is

and unit parameters are the same for both inputs. If YES, then analogue Start Value + [ ( Set Value) ] greater than the actual

2

input module’s value is used as the Set Value. If NO, then SV=PSET Stun value, the process output is

Start enegized until the

UAS1 / 2 Selection of sensor type and scale. (See Table1) Value start value+((set value)/2)

DPN1 / 2 Analogue input module decimal point position Time

is reached. The process

0 = 9999 1 = 999.9 2 = 99.99 3 = 9.999 Process output is reduced to 0% and

ICA1 / 2 Analogue input module calibration type Output

the device ensures that the

If ISL1= or ISL2= 2

0 = None 1 = Dual point temperature has begun to

ICL1 / 2 Minimum value for dual point calibration 100%

fall. The PID coefficients

ICH1 / 2 Maximum value for dual point calibration are calculated and saved to

uNT1 / 2 °C=Centigrade °F=Fahrenheit U=Other units memory. If the tuning is

LoL1 / 2 Minimum value of second sensor input range Time completed successfully,

uPL1 / 2 Maximum value of second sensor input range the tunn parameter is

Ipu1 / 2 Module 1 / 2 PV offset ±10% of FS1. Added to the input reading. changed from Stun to NO or At.St to Atun depending on the original choice.

iFL1 / 2 Module 1 / 2 Input signal filtering time. (From 0.0 to 900.0 secs) If the set value is less than

rES1 / 2 Determines whether the measured value is the result of the input on Process

Value Start Value - [ ( Set Value) ]

the actual value and the

terminals 1,2, 3 or from the input module. Visible only when decimal point cooling PID is selected, the

2

and unit parameters are the same for both inputs. If YES, then analogue Stun process output is energized

input module’s value is used as the Set Value. If NO, then SV=PSET Start

Value

until the

PID coefficients are determined start value-((set value)/2)

and system becomes stable.

Output - 3 is reached. The process

out3 Output configuration (heat, cool, Lout) Process Set output is reduced to 0% and

Value ( ) the device ensures that the

Con3Control type (ON/OFF or PID) temperature has begun to

HYS3 Hysteresis value 0% to 50% of FS (expressed in degrees) Time rise. The PID coefficients

Process are calculated and saved to

HYn3 Mode of Hysteresis 0=SV+(HYS/2) and SV-(HYS/2)

memory. If the tuning is

1=SV and SV+HYS or SV and SV-HYS Output

completed successfully, the

tm3 Minimum OFF time (0.0 to 100.0 seconds). Active in on.off control 100% tunn parameter is changed

Lou3 0=Alarm output 1=Manual / Automatic data output from Stun to NO or At.St to

2=Sensor break alarm 3=Output active when PV is outside operating range Atun depending on the

4=Output activates at end of R/S 5=Analog input module sensor break alarm Time

original choice.

6=PV of second input is <LoL1 / 2 or >uPL1 / 2 During tuning, the set value

can not be changed. Step

ALS3 Alarm sensor selection. If output 3 is an alarm output and an analogue module is

response is canceled without changing the PID set values when any of the following conditions

installed: 0 = Alarm in accordance with input sensor (on terminals 1,2,3)

applies: the heating PID is canceled during Heating step response; when the cooling PID is canceled

1 = Alarm in accordance with analogue input module (1 or 2)

during Cooling step response; when there is a sensor break error or when the step response tuning

aLt3 Alarm type: operation can not be completed within 8 hours (the AT LED flashes. The error can be cleared with the

0-Process high alarm 1-Process low alarm 2-Deviation high alarm “SET” button). If the power to the device is removed and reapplied, the device carries out step

3-Deviation low alarm 4-Deviation band alarm 5-Deviation range alarm response tuning again.

6=Heater failure alarm (CT input module must be installed)

NOTE: 2,3,4,5,are not available if Lou3 … 0.

aLH3 Alarm hysteresis. Active if output 3 is alarm output. If ALS3=0 or there is no second LIMIT CYCLE TUNING (Auto Tune)

sensor input, adjustment is 0 - 50% of process input scale (uPL-LoL).

If ALS3=1and an analogue input is present, then it can be adjusted from 0 to 50% of Firstly, the control form must be PID in order for this tuning method to operate.

the input module’s scale. The user can decide at any

If a CT input module is installed and ALt3=0006, adjust from 0.0 to 20.0A. During

time to use this tuning

Atun method by selecting Atun

Aon3 Alarm delay from fault 0.0 to 9999 seconds Process Control is operation or At.St for the tunn

Value unstable

AoF3 Alarm reset from fault 0.0 to 9998 seconds. parameter in the run list.

For high limit with manual reset only, select 9999. Display will read LtCH to indicate After changing the set

Process Set value, if the difference

latch feature has been selected. Value ( ) PID coefficients are between the newly defined

General Configuration (Genn ConF) determined and system

becomes stable. and former set values is

SU-L SV min. limit. Adjustable from min. scale to SU-u value . It’s the minimum value of Time

greater than the

the operation scale. Process proportional band

Output

SU-u SV max. limit. Adjustable from SU-L value to max. scale. It’s the maximum +/-(scale x P-Ht)/1000 if

100% heating or heating/cooling

value of the operation scale.

or +/-(scale x P-CL)/1000

Su-L2Second sensor SV min. limit. Adjustable from min. scale to SU-u2 value .

Time if cooling, the contoller

It’s the minimum value of the operation scale.

will automatically start this

SU-u2Second sensor SV max. limit. Adjustable from SU-L2 value to max. scale. function.

It’s the maximum value of the operation scale. In the event that the actual value moves outside the set value by +/-Strn 3 times while the device is

ULtt Motorized valve travel time can be adjusted from 5 to 600 sec. executing the PID control, the Attn parameter becomes YES and tuning is started.

If the Attn parameter is YES, the device begins tuning from the point where it stands at that moment. If

ULHY Min. activation time of motorized valve and is adjustable from 0.1 to 5.0%. the heating and cooling PIDs are selected together, or if only the heating PID is selected, Heating Limit

eg. If ULtt=100s and ULHY=1.0% then the minimum activation time is (100s*1%) or Cycle is performed; if only the cooling PID is selected Cooling Limit Cycle is carried out. If the Limit

1 second. Cycle operation can not be completed within 8 hours, tuning is cancelled and the Attn parameter

Communication Configuration (Comm Conf) becomes NO. The PID parameters remain as they were before this failed session.

If Heating Limit Cycle is being done, tuning is performed according to set-((set temperature)/4), if

SAdr Slave Address from 1 to 247 cooling Limit Cycle is being done, tuning is performed according to set+((set temperature)/4) .

BAud Baud Rate: 0- 1200 1- 2400 2- 4800 3- 9600 4- 19200 At the end of tuning the Attn parameter becomes NO and the PID parameters are saved to memory.

If a sensor break error occurs, the tuning operation is paused until the sensor connection is re-

Prty Parity 0- none 1- ODD 2-EVEN

established. When the sensor connection returns to normal, the tuning operation is recommenced. If

StPb Stop Bit 0- 1 stop bit 1- 2 stop bit the Limit Cycle tuning operation can not be completed within 8 hours the tuning operation is cancelled

(the AT LED flashes. The error can be cleared with the “SET” button).

Passwords (PASS ConF) While the tuning operation is under way, the Process Set Value (PSEt) can not be changed.

opps Operator password (0 to 9999).

Tcps Technician password (0 to 9999).

Manufacturer’s Calibration Page (PASS CAL) - Factory Set

ESM 4450 v10R7 1-877-798-7287 P.5

PROPORTIONAL BAND SHIFTING o-db ALARM OPTION and OUTPUT FORMS

If > 0 (Dead Band) If < 0 (Overlap Band) Process high alarm

Alarm

Process Process Output Alarm

Output Output Set

100% 100% ON

50%

50%

OFF

0% Process HYS

0% Process

Value

Heating Set Value

Cooling Set Process Value

Value ( ) Cooling Set Heating Set Process low alarm

Value ( + ) Value( - ) Value( )

Alarm

Output Alarm

ANTI-RESET WINDUP AR Set

ON

Process New

Value Integral OFF

Value is HYS

not calculated

New

Process Value

Ar Value Deviation High Alarm

Set Value Integral

Value is

Ar Value calculated Alarm

Output Process

New Set Process Set + Alarm Set

Integral

Value is ON

not calculated

Time

OFF

HYS

PID OUTPUT OFFSET POFS

Added to Output % which is calculated at the end of the PID. Process Value

Process Deviation Low Alarm

Output Alarm

Output Process

100%

Process Set - Alarm Set Set

ON

PoFS = %5.0

50% %5

%5 OFF

HYS

PoFS = -%5.0

Process Value

0% Process

500 Value Deviation Band Alarm

Alarm

OUTPUT OFFSET RELATED TO PID SET POSS Output Process

Process Set - Alarm Set Set Process Set + Alarm Set

Added to the process output calculated at the end of the PID according to the process set

value. * /( - ) ON

eg: PSET = 500°C , uPL = 1000°C , LOL = 0 , PoSS = 5.0%

then 5.0 * 500 /(1000-0) = 2.5%

OFF

HYS HYS

Process

Output Process Value

100% Deviation Range Alarm

Process Alarm

Output Output Process

with Offset Process Set - Alarm Set Set Process Set + Alarm Set

2.5%

50% ON

OFF

HYS HYS

0% Process

500 Value Process Value

ESM 4450 v10R7 1-877-798-7287 P.6

Graphic representation of Ramp and Soak function

Process

Set value

PU-3

PU-6

PU-7

PU-2 PU-5

PU-8

PU-1

PU-4

Start

Time

tr_1 tS_1 tr_2 tS_2 tr_3 tS_3 tr_4 tS_4

4 ramp soak ( = ) 4 ramp soak ( = )

8 ramp soak ( = )

HEATER BREAK ALARM PNEUMONIC REPRESENTATION

Current Transformer

Current transformer ratio for Module-1 Operator Parameters

to Module 1

can be adjusted from 0 to 100.)

eg: For 100:5A type current °C °C

transformer the Ctr 1 parameter would

be 100/5 or 20

Calculating set value for heater failure AUTO AUTO

Set Value = [(Current value without failure Control Output

SET

Ramp/Soak

+ Current value with heater failure )] / 2 Heater menu

eg. A 200V system with three1KW heaters °C °C °C °C

would normally draw 15 amps

[1000 / 200 ]*3 = 5A *3 = 15A 1kW*3

200V ~ AUTO AUTO AUTO AUTO

If one of the heaters is out of order, the CT SET SET SET SET

current draw is now 5A*2 or 10A. The Set

Value must be adjusted to (15+10) /2 process °C

tune

°C

top

°C

soft

°C

or12.5A MODULE-1 set display start

7 8

value

AUTO AUTO AUTO AUTO

MOTORIZED VALVE CONTROL SET SET SET SET

Output-3 alarm 1 °C

auto °C

bottom

°C °C

Closing

Relay set tune display ramp/

EMO-400 relay output module must value

1 2 3 4 5 6 soak

C NO be plugged into Module-1 socket. AUTO AUTO AUTO

tolerance

AUTO

SET

5A@250V ~ SET SET SET

Communication

Module In the RUN LIST grouping of the OPERATOR’s °C

Operation °C °C

(RS-232(standard)/

RS-485(optional))

section, select HEAT or COOL for parameter alarm 2 type ramp/

ULSL. set soak

MODULE-1 MODULE-2

The parameter can be adjusted from value AUTO AUTO

steps AUTO

EMO-400

3A@250V ~ Input/Output 5 to 600 seconds. It defines the time required to SET SET

SET

C Module-2

NO

open the valve completely.To determe this °C

°C °C

7 8 9 10 11 12 parameter correctly, close the valve manually. alarm 3 ramp/soak PU=RS nbr.

Opening N L Be sure the valve is fully closed; then reopen it set control

Relay ~

1A T

Fuse manually without stopping and measure how value tr=ramp time

AUTO AUTO

Supply

long it took to reopen it completely. Add 5% to SET

Switch

this value and enter it for this parameter. SET

motorized tS=soak time

100 ... 240 V ~ 50/60 Hz °C

The parameter determines the valve

Opening

Closing

increments as a percentage of the Ultt control up to 8 R/S

SET

parameter and can be adjusted from 0.1 to 5.0 steps

Max. 3A ~ T

Fuse %. If the valve oscillates while opening or bumpless

°C

SET

Valve

Common Supply closing, INCREASE this parameter’s value! transfer

Input

AUTO

SET

V ~

Opening Closing

alarm °C

latch

M

~ cancelling SET

MOTORIZED VALVE

ESM 4450 v10R7 1-877-798-7287 P.7

Technician Parameters

°C °C °C Process Input Configuration

AUTO AUTO AUTO

SET

°C °C °C °C °C °C °C °C °C °C °C

AUTO

AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO

SET SET SET SET SET SET SET SET SET SET SET SET

see Tech see Tech

°C °C °C

see Tech see Tech °C

°C

°C

PID control I/O-1 I/O-2 output 3

AUTO AUTO REMOTE RAMP MAN AUTO

parameters module module config. AUTO

AUTO

AUTO

SET SET SET

config. config. SET SET SET see operator parameters

°C °C °C

°C °C °C

AUTO AUTO AUTO

AUTO AUTO AUTO

SET SET SET SET

SET SET

°C °C

°C

°C

AUTO AUTO AUTO

AUTO

AUTO

SET SET SET SET

SET

°C °C °C

°C °C °C °C °C

°C

AUTO

AUTO AUTO AUTO AUTO AUTO AUTO AUTO

AUTO

SET SET SET SET SET SET SET SET SET

°C °C °C °C °C °C °C

°C

AUTO AUTO AUTO AUTO AUTO AUTO AUTO

AUTO

SET SET SET SET SET SET SET SET

°C °C °C °C

°C °C °C °C

AUTO AUTO AUTO AUTO

AUTO

AUTO AUTO AUTO

SET SET SET SET

SET SET SET

SET

°C °C °C

°C °C °C

°C

AUTO AUTO AUTO

AUTO AUTO AUTO

AUTO

SET SET SET

SET SET SET

SET

°C °C

°C °C °C °C

°C

AUTO AUTO

AUTO AUTO AUTO AUTO

AUTO

SET

SET SET SET SET SET

SET

°C

°C °C

°C °C

°C °C

AUTO

AUTO AUTO

AUTO AUTO

AUTO AUTO

SET

SET SET SET

SET SET SET

°C °C °C

°C °C

°C

AUTO

AUTO AUTO AUTO

AUTO

AUTO

SET SET

SET SET SET

SET

°C

°C °C

°C

AUTO

AUTO AUTO

AUTO

SET SET

SET

SET

°C

AUTO

SET

ESM 4450 v10R7 1-877-798-7287 P.8

Technician Parameters Technician Parameters

PID Control Parameters Input / Output-1 Module Configuration

°C °C °C °C

AUTO AUTO AUTO

AUTO

SET SET SET SET

°C

°C °C °C

AUTO

AUTO AUTO AUTO

SET

SET SET SET

°C °C °C °C

°C °C °C

AUTO AUTO AUTO AUTO

AUTO AUTO AUTO

SET SET SET SET

SET SET SET

°C °C °C

°C

°C °C °C

AUTO AUTO AUTO

AUTO

AUTO AUTO AUTO SET SET SET SET

SET SET SET °C °C

°C

°C °C °C

AUTO

AUTO

AUTO

SET SET

AUTO AUTO AUTO SET

°C

SET SET SET °C

°C °C °C

AUTO

SET

SET

AUTO AUTO AUTO

°C

SET °C

SET SET

°C °C °C

AUTO

AUTO

SET

SET

AUTO AUTO

AUTO

°C

SET SET SET

°C °C °C AUTO

SET

°C

AUTO AUTO AUTO

SET SET SET

AUTO

SET

ESM 4450 v10R7 1-877-798-7287 P.9

Technician Parameters Technician Parameters

Input / Output Module-2 Configuration Output-3 Configuration

°C °C

AUTO

AUTO

SET SET

°C

°C

AUTO

AUTO

SET

SET

°C °C °C

°C °C °C °C

AUTO AUTO AUTO

AUTO AUTO AUTO AUTO

SET SET SET

SET SET SET SET

°C °C °C

°C °C °C

°C

AUTO AUTO AUTO

AUTO AUTO AUTO

SET SET SET

AUTO

SET SET SET SET °C

°C

°C °C

°C

AUTO

AUTO

SET

AUTO AUTO

SET

AUTO

SET SET °C °C

SET

°C

°C

AUTO

AUTO SET SET

SET °C

°C

SET

°C

°C

AUTO AUTO

AUTO SET SET

AUTO

SET

°C

SET

°C

AUTO

SET

AUTO

SET °C

°C

AUTO

SET

AUTO

SET

ESM 4450 v10R7 1-877-798-7287 P.10

You might also like

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Hitachi Dvp-250e - UDocument57 pagesHitachi Dvp-250e - UHugo Roberto RibeiroNo ratings yet

- Service Manaul: Wall Mounted Type DC Inverter 1U71Sabfra Model NoDocument73 pagesService Manaul: Wall Mounted Type DC Inverter 1U71Sabfra Model Norehanroy royNo ratings yet

- Czns 4 PDocument14 pagesCzns 4 PВасилий ВасильченкоNo ratings yet

- Service Manual: FOR Whole-Body X-Ray CT ScannerDocument112 pagesService Manual: FOR Whole-Body X-Ray CT Scannerfranky quitianNo ratings yet

- NEC NP-V332X V332W V302H Service Manual (2nd Ed)Document343 pagesNEC NP-V332X V332W V302H Service Manual (2nd Ed)RandyCairo100% (2)

- Installation Manual for Pioneer CD Receivers with RDSDocument32 pagesInstallation Manual for Pioneer CD Receivers with RDStogefip872No ratings yet

- TOA VM-3000 Series Integrated Voice Evacuation System ManualDocument8 pagesTOA VM-3000 Series Integrated Voice Evacuation System ManualKhoá Cửa SamSungNo ratings yet

- Radar Remote Display: Downloaded From Manuals Search EngineDocument35 pagesRadar Remote Display: Downloaded From Manuals Search EngineuliNo ratings yet

- Install Wall-Mounted Wireless AntennaDocument20 pagesInstall Wall-Mounted Wireless AntennaTito SetiajiNo ratings yet

- 2d201 - 063e - e - Service Manual Gantry-Couch Control SectionDocument226 pages2d201 - 063e - e - Service Manual Gantry-Couch Control Sectionkatabalwa eric75% (4)

- MCV902-MCD502 Eng MFL32702807-0411Document20 pagesMCV902-MCD502 Eng MFL32702807-0411WellingtonFerreiraNo ratings yet

- 2d201 - 059e - D - Service Manual Data Transfer SectionDocument99 pages2d201 - 059e - D - Service Manual Data Transfer Sectionkatabalwa eric100% (1)

- Service Manual: FOR Whole-Body X-Ray CT ScannerDocument82 pagesService Manual: FOR Whole-Body X-Ray CT Scannerfranky quitian100% (2)

- Mitsubishi D-Net ManualDocument150 pagesMitsubishi D-Net ManualrobagromocsNo ratings yet

- GPS Compass Operator ManualDocument89 pagesGPS Compass Operator ManualVM ServicesNo ratings yet

- Analog-Digital Converter Module Type AJ65SBT-64AD User's ManualDocument76 pagesAnalog-Digital Converter Module Type AJ65SBT-64AD User's ManualTongminhquy BkhnNo ratings yet

- 2017 CX-9 Bumper RemovalDocument10 pages2017 CX-9 Bumper RemovalGeovanni RodríguezNo ratings yet

- DVD Home Theater System: HT-TXQ120Document36 pagesDVD Home Theater System: HT-TXQ120Mohamad RezazadeNo ratings yet

- Scion XB 2008 - Fog Lights Part Number: PT857-52080: PreparationDocument12 pagesScion XB 2008 - Fog Lights Part Number: PT857-52080: PreparationKiddNo ratings yet

- Manual Zta600aDocument101 pagesManual Zta600aRafael BrandãoNo ratings yet

- Toshiba VTW2887Document105 pagesToshiba VTW2887thomas-stentzelNo ratings yet

- Q64AD2DADocument226 pagesQ64AD2DANguyen Ba TaiNo ratings yet

- Color Monitor: Service ManualDocument23 pagesColor Monitor: Service ManualtaviNo ratings yet

- Toshiba VTW2187 Service ManualDocument101 pagesToshiba VTW2187 Service ManualDavid MaidmentNo ratings yet

- LCD TV Service Manual: MODEL: RZ-20LA60Document26 pagesLCD TV Service Manual: MODEL: RZ-20LA60gmuitaNo ratings yet

- LONMSE 6M230: Installation InstructionsDocument4 pagesLONMSE 6M230: Installation Instructionsnci974No ratings yet

- Vm-5 Series Monitor Model Vm-5S Dual Tachometer Instruction ManualDocument92 pagesVm-5 Series Monitor Model Vm-5S Dual Tachometer Instruction ManualGajanan Patil.No ratings yet

- 32 PD 5000Document101 pages32 PD 5000Mubarak AliNo ratings yet

- Temperature Control Module User's Manual: - Q64TCTT - Q64Tcttbw - Q64TCRT - Q64Tcrtbw - GX Configurator-TC (SW0D5C-QTCU-E)Document178 pagesTemperature Control Module User's Manual: - Q64TCTT - Q64Tcttbw - Q64TCRT - Q64Tcrtbw - GX Configurator-TC (SW0D5C-QTCU-E)soo RenNo ratings yet

- Color Monitor: Service ManualDocument26 pagesColor Monitor: Service ManualAnto PurwantoNo ratings yet

- En SP: GZ-HM50U GZ-HM30UDocument56 pagesEn SP: GZ-HM50U GZ-HM30UgabrielportresNo ratings yet

- LG 22mp55d-hq Chassis Lm14a PDFDocument25 pagesLG 22mp55d-hq Chassis Lm14a PDFWilliam Ariel de SouzaNo ratings yet

- EX-A2X I/O Expansion Module Adapter GuideDocument6 pagesEX-A2X I/O Expansion Module Adapter GuiderosolareNo ratings yet

- EVOline BackFlip Installation Instructions PDFDocument7 pagesEVOline BackFlip Installation Instructions PDFnzNo ratings yet

- Haier 12kbtuDocument70 pagesHaier 12kbtuwarlof26100% (1)

- QJ71DN91 DeviceNet MasterSlave UserManual Hardware IB 0800149 BDocument16 pagesQJ71DN91 DeviceNet MasterSlave UserManual Hardware IB 0800149 BArjun GoudNo ratings yet

- Service Manual: Wall Mounted Type DC Inverter Model NoDocument58 pagesService Manual: Wall Mounted Type DC Inverter Model NoLuncan RaduNo ratings yet

- En SR0 Man DetailedDocument12 pagesEn SR0 Man Detailedrajesh aasvaniNo ratings yet

- ST1DA For Profibus UserManual SH 080444 DDocument148 pagesST1DA For Profibus UserManual SH 080444 DGerman BalderasNo ratings yet

- Digital-Analog Converter Module Type AJ65SBT PDFDocument74 pagesDigital-Analog Converter Module Type AJ65SBT PDFTongminhquy BkhnNo ratings yet

- Onan Service Manual YD Generators and Controls 900-0184Document111 pagesOnan Service Manual YD Generators and Controls 900-0184GreenMountainGenerators67% (9)

- MN Sunpower Solar Panels Safety Installation Guide EuDocument20 pagesMN Sunpower Solar Panels Safety Installation Guide EuDimitris GikasNo ratings yet

- Mazak Detector Alarm MalfunctionDocument182 pagesMazak Detector Alarm Malfunctionzotya54No ratings yet

- Imove 575sDocument13 pagesImove 575sLuis Antonio Hernandez CastroNo ratings yet

- Instrukcja Serwisowa Tundra As18td2hraDocument64 pagesInstrukcja Serwisowa Tundra As18td2hraHuzum ViorelNo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFJOAQUIM GILBERTO SANCHENo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFJOAQUIM GILBERTO SANCHENo ratings yet

- 1794 In092 - en P PDFDocument6 pages1794 In092 - en P PDFhenry avilaNo ratings yet

- SunPower Modules InstallatioDocument24 pagesSunPower Modules InstallatioMatias EspinosaNo ratings yet

- CC-Link System Compact Type Remote I/O Module User's ManualDocument392 pagesCC-Link System Compact Type Remote I/O Module User's ManualLê Đăng HòaNo ratings yet

- Sanyo Dp26671 Service Manual TVDocument76 pagesSanyo Dp26671 Service Manual TVCarlos Jose Solano DelgadoNo ratings yet

- DX200 Options Instructions For Cc-Link Communications FunctionDocument49 pagesDX200 Options Instructions For Cc-Link Communications Functioninyong baik100% (1)

- INVERTER ZVF11-M/S Series User's Manual INVERTER ZVF11-M/S Series User's ManualDocument40 pagesINVERTER ZVF11-M/S Series User's Manual INVERTER ZVF11-M/S Series User's ManualArturo de la VegaNo ratings yet

- LG 24M35H LM14BDocument25 pagesLG 24M35H LM14BSamuel TeixeiraNo ratings yet

- Ceiling Speaker System F-122CU2: Rev. ADocument16 pagesCeiling Speaker System F-122CU2: Rev. ARizal BachtiarNo ratings yet

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)

- SS2 KFT100 0200 00Document12 pagesSS2 KFT100 0200 00PRIMA PUTRA JAYANo ratings yet

- Honda MHRGB3860DJ301323 AllSystemDTC 20230428125840Document2 pagesHonda MHRGB3860DJ301323 AllSystemDTC 20230428125840PRIMA PUTRA JAYANo ratings yet

- Ac450 23 1 PDFDocument120 pagesAc450 23 1 PDFtomtom258No ratings yet

- Precia Molen I40 31110905Document84 pagesPrecia Molen I40 31110905Martin Zhang75% (4)

- PH Module For Abbemat Performance Plus Line PDFDocument2 pagesPH Module For Abbemat Performance Plus Line PDFMauricio CruzNo ratings yet

- Cycle AUDIT 5R Juni 2021 Fix OkDocument2 pagesCycle AUDIT 5R Juni 2021 Fix OkPRIMA PUTRA JAYANo ratings yet

- PPIC Area 5R Checklist DocumentsDocument12 pagesPPIC Area 5R Checklist DocumentsPRIMA PUTRA JAYANo ratings yet

- TechTip 0806 InTouchConnectiontoExcelRemotelyDocument5 pagesTechTip 0806 InTouchConnectiontoExcelRemotelyPRIMA PUTRA JAYANo ratings yet

- MScKabbabe2011 PDFDocument176 pagesMScKabbabe2011 PDFJamal AlshaweshNo ratings yet

- Process EquipmentDocument420 pagesProcess EquipmentFA Ay100% (1)

- Pid Controller Calculus v320Document16 pagesPid Controller Calculus v320Peter UhuleNo ratings yet

- Gpsa Engineering Databook Errata 2004 FPDocument18 pagesGpsa Engineering Databook Errata 2004 FPryan_keller_23100% (1)

- PCS 7 V7.1 User Rights ConfigurationDocument37 pagesPCS 7 V7.1 User Rights ConfigurationrankovicaNo ratings yet

- Fremap SKORPION Process Air HeaterDocument2 pagesFremap SKORPION Process Air HeaterFremap Industries S ANo ratings yet

- EEL - LIEBERT - Environmental Control SystemDocument15 pagesEEL - LIEBERT - Environmental Control SystemJairo FlechasNo ratings yet

- Control of Inverted Pendulum Cart System by Use of Pid ControllerDocument6 pagesControl of Inverted Pendulum Cart System by Use of Pid ControllerDr Saba TareqNo ratings yet

- Danfoss FC 360 Programming GuideDocument158 pagesDanfoss FC 360 Programming Guideerick paredes100% (1)

- PID ArduinoDocument2 pagesPID ArduinoGeorgeNo ratings yet

- Process Instrumentation 2Document8 pagesProcess Instrumentation 2Aditya RasalNo ratings yet

- Modern Process Control WorkshopDocument63 pagesModern Process Control WorkshopIbrahimDewaliNo ratings yet

- PAGV2Document734 pagesPAGV2Leonardo Marín100% (1)

- 3-Phase BLDC Motor Control With PWM ModesDocument33 pages3-Phase BLDC Motor Control With PWM ModesZeynep Emirhan ŞenyüzNo ratings yet

- Precision Incubator Model INE 400: Standard EquipmentDocument2 pagesPrecision Incubator Model INE 400: Standard EquipmentAgus Be PeNo ratings yet

- Inverted Pendulum SystemDocument9 pagesInverted Pendulum Systemمحمد المهندسNo ratings yet

- BMSII O&M Manual - GF-124Document98 pagesBMSII O&M Manual - GF-124Tuan DaoNo ratings yet

- Experiment 2 Level Control System: 1.0 ObjectiveDocument6 pagesExperiment 2 Level Control System: 1.0 ObjectiveElla Iloe IggoNo ratings yet

- Dataforth Corp BrochureDocument16 pagesDataforth Corp Brochurelouiswang1964No ratings yet

- Static Exciter Systems for Pilot and Rotating Exciter ReplacementsDocument24 pagesStatic Exciter Systems for Pilot and Rotating Exciter ReplacementssssduduNo ratings yet

- Proceeding Paper PDFDocument6 pagesProceeding Paper PDFVignesh RamakrishnanNo ratings yet

- Benchmark Temperature Microcontroller For Process Dynamics and CoDocument38 pagesBenchmark Temperature Microcontroller For Process Dynamics and CoTyto Praja Muda NetendNo ratings yet

- Tutorial Sol CH 9Document11 pagesTutorial Sol CH 9Sameer BitthariaNo ratings yet

- PID Tuning - Science, Art or Both?Document4 pagesPID Tuning - Science, Art or Both?Nkosilozwelo SibandaNo ratings yet

- PracticesGuide PID Rev.A enDocument22 pagesPracticesGuide PID Rev.A enveithungengNo ratings yet

- Understanding VSC-HVDC Controller Tuning TechniquesDocument8 pagesUnderstanding VSC-HVDC Controller Tuning TechniqueslalitbickNo ratings yet

- PID-kirjaston tuonti ja saatimen määritysDocument8 pagesPID-kirjaston tuonti ja saatimen määritysSam Fisher LambertNo ratings yet

- TK8070 Temperature & Humidity Controller ManualDocument16 pagesTK8070 Temperature & Humidity Controller ManualDuong PhạmNo ratings yet

- Peter B Andersen ThesisDocument111 pagesPeter B Andersen Thesisfrederic_silvertNo ratings yet