Professional Documents

Culture Documents

Ms Refurbishment of Side Cladding Wall at Inc1 Shedder Area

Uploaded by

Afiq JamalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ms Refurbishment of Side Cladding Wall at Inc1 Shedder Area

Uploaded by

Afiq JamalCopyright:

Available Formats

ZIA PRIMA ENTERPRISE

METHOD STATEMENT – WALL CLADDING

FOR KUALITI ALAM SDN BHD

JOB TITLE: REFURBISHMENT OF SIDE CLADDING WALL AT INC 1

SHREDDER AREA

Project Doc. No: KAWMC/L&I-BQ/2023/006 Rev. No: - Page -

METHOD STATEMENT

JOB TITLE: REFURBISHMENT OF SIDE CLADDING WALL AT INC 1 SHREDDER AREA

A. PREPARATION FOR ALUMINIUM AND CLADDING WORKS

1. Ensure works areas , all floors slabs, parapets if any, shll be complete, clear and kept

clear from all trades prior to start of work.

2. Control point,benchmarks and datum line will be prepared.

B. ALUMINIUM INSTALLATION

1. Total station will be used to mark coordinates and auto level will be used for levelling.

2. Areas where aluminium will be installed, will be surveyed and checked to ensure

squarness and plumbness of concrete/ plaster for aluminium fabrication.

3. Support system in the form of brackets or angles and primary support will be installed

with proper alignments.

4. Rockwool or other insulation, along with the back pans, shall be installed at all

spandrel areas.

5. Curtain wall frame and internal unit frames will be installed on site level and plumb,

using aluminium shims or adjustable brackets to pack out any irregular areas of

concrete or block work.

6. Ensure squareness prior to start glass installation. (if applicable)

C. ALUMINIUM CLADDING INSTALLATION

1. Cladding sub-frames, angles runners must be installed with proper alignment.

2. Fix aluminium composite panels to the runners ensuring horizontal and vertical

alignment.

3. Apply silicon to perimeter, panel joints and terminal joints. Backing rod will be used if

necessary.

D. GLASS INSTALLATION (IF APPLICABLE)

1. Install pressure plates and cover, bar- closes or other fasteners to safely secure the

glass in place.

2. Installation of hardware will be according with manufacturer’s instructions.

3. Preparation and Finish of Mild Steel Surface

E. SEALANT APPLICATION

1. Ensure the surface to be sealed is sound, dry and free from any dirt or contaminants.

2. Joints and spaces to be sealed shall in case be less than 6mm deep or more than

12mm deep, and should exceed 2o mm in width.

3. Joints will fill to within 10mm of the surface with backup material.

4. After completion of work inspection request to ber raised and ensure its approval from

the consultant.

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Method Statement CladdingDocument2 pagesMethod Statement CladdingAfiq JamalNo ratings yet

- Method Statement CladdingDocument2 pagesMethod Statement CladdinggeorgekahuhakogiNo ratings yet

- Method Statement CladdingDocument2 pagesMethod Statement Claddingasrihamid77% (26)

- Plot A 007: Curtain Wall and Glazed AssembliesDocument6 pagesPlot A 007: Curtain Wall and Glazed AssembliesRACHED ABBOUDNo ratings yet

- Steel Door MSDocument2 pagesSteel Door MSMichael TugawenNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- SECTION 08520 Aluminum Windows Part 1 - General 1.1 General RequirementsDocument6 pagesSECTION 08520 Aluminum Windows Part 1 - General 1.1 General RequirementsIm ChinithNo ratings yet

- Method Statement For ENBD & EIB WorksDocument38 pagesMethod Statement For ENBD & EIB WorksDarius AdeNo ratings yet

- Aluminium Work Method StatementDocument4 pagesAluminium Work Method StatementChezy629100% (3)

- Mos For Pilling Foundation - SucDocument9 pagesMos For Pilling Foundation - SucEngr Muhammad Azam ThaheemNo ratings yet

- Method of State-WPS OfficeDocument8 pagesMethod of State-WPS OfficeAsif SafiNo ratings yet

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Document7 pages4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNo ratings yet

- Method of Statements - Precast WallDocument17 pagesMethod of Statements - Precast WallEd Salanga100% (3)

- Sop Magnesium Anode Installation - ThiessDocument10 pagesSop Magnesium Anode Installation - ThiessbonnicoNo ratings yet

- Mos For Gypsum PartitionsDocument8 pagesMos For Gypsum PartitionsCamlockNo ratings yet

- Manhole Construction AwarenessDocument14 pagesManhole Construction AwarenessparseNo ratings yet

- General: Insulated Aluminium CladdingDocument5 pagesGeneral: Insulated Aluminium Claddingeccos3338No ratings yet

- De635 Suggested SpecificationDocument2 pagesDe635 Suggested Specificationqpuc198No ratings yet

- Site Construction Methodology Gypsum BoaDocument75 pagesSite Construction Methodology Gypsum BoaLhiee Ziur100% (2)

- Concepcion SpecificationsDocument7 pagesConcepcion SpecificationsMark Daniel RodajeNo ratings yet

- 8.29.18 Appx 3 BLDG Envelope Design GuideDocument6 pages8.29.18 Appx 3 BLDG Envelope Design GuideireneNo ratings yet

- Covered Walkways SpecificationsDocument5 pagesCovered Walkways SpecificationsErnesto LopezNo ratings yet

- SECTION 07920 Sealants and Calking Part 1 - General 1.1 SummaryDocument5 pagesSECTION 07920 Sealants and Calking Part 1 - General 1.1 SummaryIm ChinithNo ratings yet

- Tekton Construction Corp. Construction MethodologyDocument11 pagesTekton Construction Corp. Construction MethodologyTekton Construction Corp.No ratings yet

- 04 20 00 - Unit Masonry PDFDocument13 pages04 20 00 - Unit Masonry PDFmasoodaeNo ratings yet

- Concrete Foundation Installation MethodDocument11 pagesConcrete Foundation Installation MethodAung Naing Latt AungNo ratings yet

- Division 07 50 00 - Membrane Roofing & Roofing AccessoriesDocument7 pagesDivision 07 50 00 - Membrane Roofing & Roofing AccessoriesrheriNo ratings yet

- Mitchell Metals Specifications Gabled CanopyDocument5 pagesMitchell Metals Specifications Gabled Canopyjegan kalaperumalNo ratings yet

- Exterior planting specifications for 8th Gate Financial DistrictDocument6 pagesExterior planting specifications for 8th Gate Financial DistrictAhmad SaadeldinNo ratings yet

- General: Preformed Metal Cladding - Aluminium - Single SkinDocument5 pagesGeneral: Preformed Metal Cladding - Aluminium - Single Skineccos3338No ratings yet

- 09 25 13 - Acrylic Plastering PDFDocument8 pages09 25 13 - Acrylic Plastering PDFmasoodaeNo ratings yet

- Cast Iron Manhole Cover & GratingsDocument4 pagesCast Iron Manhole Cover & GratingsttshareefNo ratings yet

- 1.6.1 Curtain Wall Installation MethodDocument12 pages1.6.1 Curtain Wall Installation Methodmohadly90100% (5)

- Diaphragm Wall Specifications R 0Document10 pagesDiaphragm Wall Specifications R 0aomareltayebNo ratings yet

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- 10 26 13 Wood and Door Protection Corner GuardsDocument4 pages10 26 13 Wood and Door Protection Corner GuardscamilleNo ratings yet

- Section 09250Document9 pagesSection 09250Im ChinithNo ratings yet

- 60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Document3 pages60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Eng Victor FidelisNo ratings yet

- Parapet Wall Extension - MethodologyDocument2 pagesParapet Wall Extension - MethodologyRabnawaz ImamNo ratings yet

- The Rise Resort Skim Coating ProjectDocument10 pagesThe Rise Resort Skim Coating ProjectMin Luo100% (1)

- Aluminium Cladding Method StatementDocument4 pagesAluminium Cladding Method StatementGirithar M Sundaram100% (2)

- Architectural-Walkway-Canopy SpecificationsDocument5 pagesArchitectural-Walkway-Canopy SpecificationsErnesto LopezNo ratings yet

- College of Engineering: General Specification Single Attached (Core Type) Residential BuildingDocument5 pagesCollege of Engineering: General Specification Single Attached (Core Type) Residential BuildingCIELO OLEANo ratings yet

- Architectural Specifiactions CVCDocument18 pagesArchitectural Specifiactions CVCJen AgabinNo ratings yet

- Aluminium and GlazingDocument5 pagesAluminium and GlazingnguyenmainamNo ratings yet

- Cem Kote CW PlusDocument6 pagesCem Kote CW Plusconstruct404No ratings yet

- Method of StatementDocument23 pagesMethod of StatementDeepan TravellerNo ratings yet

- Civil Works-MethodologyDocument11 pagesCivil Works-MethodologyMarvilou Gomez100% (1)

- BICOPD-23-022-003 (450) BIC Notification of Works-MergedDocument19 pagesBICOPD-23-022-003 (450) BIC Notification of Works-MergedFariz Fatahillah AlbugisiNo ratings yet

- Site Works and Earthworks GuideDocument6 pagesSite Works and Earthworks GuideKayla ManguladNo ratings yet

- Installation of Aluminium Cladding Method StatementDocument4 pagesInstallation of Aluminium Cladding Method StatementAllan Bryan Sario0% (1)

- The Rise Residence & Resort Project Method StatementDocument16 pagesThe Rise Residence & Resort Project Method StatementMin Luo100% (6)

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- Joint Coating Application & Pipe Coating ProcedureDocument7 pagesJoint Coating Application & Pipe Coating Proceduregst ajahNo ratings yet

- SECTION 07421 Aluminiym Composite Panel Part 1 - General 1.1 Eneral RequirementsDocument6 pagesSECTION 07421 Aluminiym Composite Panel Part 1 - General 1.1 Eneral RequirementsIm ChinithNo ratings yet

- PREFORMED STEEL CLADDING SPECIFICATIONSDocument5 pagesPREFORMED STEEL CLADDING SPECIFICATIONSeccos3338No ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- EN 1.4521 Ferritic Stainless Steel Product InformationDocument1 pageEN 1.4521 Ferritic Stainless Steel Product Informationpipedown456No ratings yet

- Sonam Internship Report-1.0Document36 pagesSonam Internship Report-1.0Sonam TsomuNo ratings yet

- ASTM G 50 - 76 r97 - Rzuwltc2ujk3rteDocument5 pagesASTM G 50 - 76 r97 - Rzuwltc2ujk3rteSamuel EduardoNo ratings yet

- Astm f1545 Plastic Lined PipeDocument8 pagesAstm f1545 Plastic Lined PipesivagulfNo ratings yet

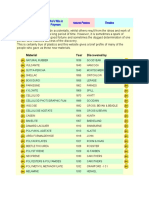

- Price ListDocument33 pagesPrice ListAllen MendozaNo ratings yet

- HYDROTITE & PVC WATERSTOP SPECDocument4 pagesHYDROTITE & PVC WATERSTOP SPECMichael VillaluzNo ratings yet

- Installation Instructions BWC Waterline Shower ChannelDocument4 pagesInstallation Instructions BWC Waterline Shower ChannelBLUCHERNo ratings yet

- Stanley Engineering TB68-1 Corrosion MethodsDocument8 pagesStanley Engineering TB68-1 Corrosion MethodskpNo ratings yet

- Buildings 11 00443Document25 pagesBuildings 11 00443karthicfinconNo ratings yet

- Carbozinc 608 HB-ProductFlyer - 112817Document2 pagesCarbozinc 608 HB-ProductFlyer - 112817Muhammad Prima JayaNo ratings yet

- Screws, Fittings, Seals BucyrusDocument16 pagesScrews, Fittings, Seals BucyrusJhonny ManjarrezNo ratings yet

- Manuals - ExhaustFans - Exhaust O&IMDocument56 pagesManuals - ExhaustFans - Exhaust O&IMDavina FristantryNo ratings yet

- Asme BPVC IxDocument7 pagesAsme BPVC IxNVTVNNo ratings yet

- PSVDocument8 pagesPSVtetiospamNo ratings yet

- Is 13935 Seismic Evaluation & Strengthening of Masonry BuildingsDocument41 pagesIs 13935 Seismic Evaluation & Strengthening of Masonry BuildingslovehackinggalsNo ratings yet

- Haydon Catalog 2013 PDFDocument180 pagesHaydon Catalog 2013 PDFEdgar Bonilla MuñozNo ratings yet

- Details of Measurement (Preliminaries)Document30 pagesDetails of Measurement (Preliminaries)Engr SwapanNo ratings yet

- TDS Conbextra GP2 IndiaDocument4 pagesTDS Conbextra GP2 IndiaAbhay ShrivastavaNo ratings yet

- Who's Who in Polymers Natural Plastics Timeline: Year Discovered byDocument10 pagesWho's Who in Polymers Natural Plastics Timeline: Year Discovered byelsobkiNo ratings yet

- Herz Strömax MDocument10 pagesHerz Strömax MNeoaNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Structural Engineering Thesis TopicsDocument1 pageStructural Engineering Thesis Topicsaleena489% (9)

- 3 - D Printer Carbon Fiber Reinforced WithDocument17 pages3 - D Printer Carbon Fiber Reinforced With19 CH 056 Vaishali VivekNo ratings yet

- Standard Pipe A53 PDFDocument6 pagesStandard Pipe A53 PDFArvindNo ratings yet

- Quantitynotes 180816020109 PDFDocument73 pagesQuantitynotes 180816020109 PDFOm Krish RamNo ratings yet

- Covalence HTLP80: Product Data SheetDocument3 pagesCovalence HTLP80: Product Data SheetJuan Carlos Contreras CherresNo ratings yet

- Astral ProductDocument14 pagesAstral ProductBhagawati InfraNo ratings yet

- Auto ClaveDocument16 pagesAuto ClaveAhmed QomaruddinNo ratings yet

- SikaFiber® PP-12 VNDocument2 pagesSikaFiber® PP-12 VNBuiDucVinhNo ratings yet

- Handbook of Residual Stress and Deformation of SteelDocument477 pagesHandbook of Residual Stress and Deformation of SteelRicardo Martins SilvaNo ratings yet