Professional Documents

Culture Documents

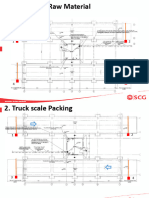

20-1 Transport-Bucket Eleva

20-1 Transport-Bucket Eleva

Uploaded by

maherianto 290 ratings0% found this document useful (0 votes)

110 views47 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

110 views47 pages20-1 Transport-Bucket Eleva

20-1 Transport-Bucket Eleva

Uploaded by

maherianto 29Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 47

Bucket Elevator

1. Introduction

| bucket elovator for vertical cesent conveying consists of a serles of buckets mounted on an

endless chain or belt, operating over head and foot pulleys or sprockets. Take-ups are

provided as a neans of coupensating for variations in length of chain or bolt due to

Venverature changes, ateossher ic conditions, or wear.

A steel cas

dusting, venting of the elevator Is done by comecting the hoad section with a dust collector

ing usually encloses the bucket line, and the head and foot machinery. To prevent.

Buckets, mounted at spaced Intervals, are loaded by scooping up saterial fros the elevator's

hoot. Material is discharged vken the bucket passes over the head vbee!.

2. General inforsation on bucket elevator

2-1. Type of bucket elevator

(1) Chain type

A Continuous type

Low speed type + 10 - 33 n/see [Daido NE type }

for courso nater iol

High speed type + 80 - 70 n/see [Daido NSE tyre 7

for povdery saterial

B. Contrifural discharee type

C. Internal discharge type

for sticky material (eypsim, rav coal)

‘ack Senter octet Bovter

(2) Belt type

Seoed is high as 220e/nin, and conveying heleht Is high as 100n In aaximua. Accordingly

construction is compact and price is low compared with chain type bucket elevator. Thore

{is limitation for tenperature, such as 60°C for standard belt and 120°C for heat resistant

bolt.

) Chain strand

Double chain strand type : standard

Single chain strand type + for seller type

Chain is equipped at the back of bucket.

Chain speed is less than 250/sin.

eT)

ies

ee

2-2. Comparison of chain type and belt type

Conparison of chain type and belt type is as follows.

Advantage Disadvantage 1

Tiara is — cae

eee fae

ee

4, lo restriction for transport neterial | 4. Lover for transportation height

= lusp saterial / povdery aaterial -

TE Comact and lish wee T Dificae Tor wfateanca

Belt tyne |2. attr for auxin temerortation = cantering of belt

teieht |2. tosricton for transport material

| 2. Holetass operation + tours steril only

2-3 Bucket type

SD type Is used for lov speod bucket elevator, NE type.

S type, vhich Is the largest for transportation capacity, Is used for high speed bucket

elevator HSE type and low speed bucket elevator.

© trpe is special one vhich is edoptad for sincle chain type bucket elevator having a fix

bolts for conveyor chain at back side,

4 bucket Is attached to at evory 4 pitch for hich speed bucket olevator instead of 2 pitch

ee

: om

e.~

L we

2-4. Drive

There are two kinds of drive for bucket elevator, roller chain drive and reducer direct drive,

Comparison of these two kinds is as follovs.

Advantage:

Disadvantage

Roller chain & spocket,

1, Easy to erection and saintenance

= Yueh vibration

Direct érive with

sear reducer

1. Loss vibration

2. Simple structure

Larger reduction ratio is

requested for gear reducer

. Hore precise in erection

2-5. Backstop dovico

‘A cam clutch type backstop device is eavipred on drive shaft.

3. Design infornation for planning

(1) Norsel ond asxinun capacity

(2) Lifting height

) Material propert

+ feparent spect

ic aravity

+ Granularity, size of material

+ Angle of repose

+ Torperature snd noisture

+ Adhesion, sbrasion, fludity

+ Corrosion

4, Bosic celeulation for planning

(1) Selection of bucket elevator type

(2) Selection of transportation speed

) Selection of buckot size

(4) Caleulation and solection of

+ Drive power and drive unit

+ Shaft dianotor and bearing size

* Chain tension and chain size for conveyor chain

+ Chain tension and chain size for poxor transaisston

+ Backstop dovico

LUCKEL BLBULOR

Master bearing Conveyor sprocket Wheel

Takeups

Secowadjusted

“Tokeups

Gravity

Takeups

Backstops

Roller type Band type

Design criteria

1, Selection of bucket elevator type

‘Type of bucket elevator

Lump aaterial

+ Raw saterial Continous type, Lav speed type

= 25 on

+ Clinker

Fine material

+ Raw eaterial

+ Conont: Continuous type, High speed type

+ Cireulation mater

for raw ail

and conent

2. Dedusting air a'ty

20 w/ain/s? for casing sectional area

50 wein/n® for opening area

Calculation Hethod

and

Calculation Examplo

Calculation of bucket elevator (1/5)

Calculation equation

Exaaple

1. Transportation speed

Saki mPa BL

whore,

$+ Transportation speed arin

Ya + Actual motor speed roe

(lip 3, generally)

1+ Reduction ratio of gear

| n+ Efficiency of trensission

| 0.955 for fluid coupling

| 1.0 for other type

| P+ Conveyor chein pitch ®

| Nz = No. of tooth of spocket for conveyor

1m, # No, of teeth of driver spockst for transwission

ne No, of tooth of driven spockot for transeission

2. Power required

Taf ay RMB sco) es ee

[\ lege aalvoge * 8" CF Go)

ee

| \ 2B Cix to)

| i :

| shore,

KW + Power required Ww

Q + Maxisun cépacity wh

$+ Transportation speed Wain

1H Center distance height a

Co + Equivalent height of power of scoop a

and Lifting at discharge end

2n for Lov speed bucket elevator

‘3m for high speed bucket elevator

Y Driving efficiency of gear and chain

0.8 as standard

+ Safty factor for wotor

1.15 ag standard

KK-4 + 06-88-51

Daido series no + NSEAOOS (High speed tyne)

| Casing dimension 1820 x 1140 nm

| Capacity + max 420 t/h

Center distance height + 27.00

Material + raw noal

9 2 0T

8Bu pass 90%

ov

0.5% moisture

Notor + SSK x SP x 50lz x 970rpm

Reducer 1/20,25 reduction ratio

Conveyor chain + DI3SZI25NAPC4

strongth

40,000 ke

Unit veleht 20.7 ke/n

Chain pitch 125 na

Conveyor sprocket 24T / 2¢T

957.7 an6/057.7 meg

Driving systen + Fluid coupling

Driving chain + DID240-1

Tenet

Tonsile streneth

51,100 ke

Driving sprocket : 16T / 30T

300.50 mn /728.20 me 6

+ NSE 5055 (t = 4.5 am)

Voight 40.3. ke/sot

08537 n°

+ 500 aa

Bucket,

Bucket pitch

<& Cheek >>

1

DB

= 73,39 w/in > 73 a/nin

8 = 970 * * 0,085 x 0.125 « 24 « I

~10-

Calculation of bucket elevator (2/5)

[ Calculation ecuation

Brasple

3. Capacity efficiency

axe,

Ko gusia ay * 100

K + Capacity offietency

+ Maxtaun capacity

Bucket pitch”

Transportation speed

+ Specific eravity

+ Volune of bucket in 100% filling,

4, Tension of conveyor chain

Po = (1MO*D + vos Ye) (H+ Co)

there,

Pe + Tension of conveyor chain

+ Maximum capacity

S_ + Transportation speod

Conter distance height

at discharge end

2n for lov speed bucket: elevator

3a for high speed bucket. elevator

Desigh criteria :

Safety factor for conveyor chain Se

Pe

unit veight of conveyor chain x no. of strand

(unit veight of bucket) / (pitch of bucket)

Equivalent height of pover of scoop and lifting

= average tensile strength * no. of strand

420 x 0. _

We TT x 0.7 xf0.casm] * 10?

3 yaczre

+(20.72) + 45.3 year+)

+ no. of chain strand

40.3 + unit weight of bucket kg

+ pitch of bucket .

OK

Caleutation of bucket elevator (3/5)

Calculation equation

vinere,

N+ Revolution spced of shaft or spocket ron

+ Transportation speed wain

P : Conveyor chain pitch 8

Ne # No, of teeth of conveyor spockot

T+ Hotor torque keren

We # Hotor power w

Po = Po + Po

= (BLO 4 yo + ve) + Co) 2 x Ho + Ho) CH + 3)

= Pet xe 7

Mos pend

Fie

|e! + Total conveyor ctain tens vet

| Be + Conveyor chain tension (ratertal side) tat

Po + Conveyor chain tension (no uaterial side) kei

Ho = Bonding eonent keen

4 + Distant between bearing and spockot ca

Case A +

Result of torsion and bonding

i

| Total torge = T? + H*

i

|

Earle |

5. Drive shaft dianoter (at besrins point) al

s TB x ob |

ets HOt eecrie \

T= 97,300 x T= 97,300 x 85, = 220,226.4 ke-en

6543 + 2

10203 ke

2

10203 « 31,2. = 189,776 ke-ca

+ 40.3.) « (2769

29.7 + 49:3.) x (2709) |

-12-

Caloulation of bucket elevator (4/5)

[ Calculation equation

ase

= 3 flexi

ae ae fants

ssfusltew

where,

1 + Shearing stress In fatigue losd

for carbon steel = 240 ~ 450 ke/cu®

t = 2D?

2 + Wosent Inertia of shaft = 20

| by + Shaft dianeter cn

| at bearing point

| Case B

Bending nonent only

ost

t

x De?

500 «

@ # Allovable tensile stress in fatigue load

= 300 ~ 00 ke/ea?®

500 ke/ex? as standard

Wo + Bonding sonent keen

De + Shaft dionoter at bearing point co

-1g-

= 14.87 en

2s [2x

7 ¥ 500

= 15.606 ce < NDISO OK.

Calculation of bucket elevator (5/5)

Calculation ewation

Ezanole

©. Tail shaft diasoter (ot hearing point)

Depend on capacity (not depend on heisht)

Selection of standard is es follows.

[Daido bucket elevator standard J

Type (S8Gf85 ) Tell shaft diaveter

we 15 BT SU > ( 50 am dianeter at

NE 30 BT SOV bearing point )

HE 50 ot By

XE 100 BT 8

HE 150 er 75

ME 200 Bt 73

HE 300 BT 75

NE 400 BT 90

NE 500 BT 90

NE 600 81 1004

NE 700 BT 1004

1. Roller chain tension for power transaission

+, 100

pon = AEB AD x + Go)

P= (100) at + Co) x PRD

where,

F + Roller chain tension

Q + Maxima capacity

S + Transportation speed

PCD(C) : Pitch circle dlazeter of conveyor sprocket

PCD(R) + Pitch cirele diameter of driving sprocket

Desisn criteri

Safety fnetor for roller chain SFco

= inalle-strent} of roller chain. > yg

|

|. Backstoo

| tee (Age 2) x BRO

| shee,

| Th = Toreue for backstop ke

Selection of size of backstop

yet = 18.1. X0 x POD)

Design criteria +

Safety factor for backstop SFr

= -tacaue (feom mpker inforeation) 2

ETSY CS aad at boarine)

pen = 1000. $20 39

= 782.5 be

P= oma. SET sea te

sug. «

sro * SBQ = 1247 > 12 on.

te «2809 « 20D = 1209 ken

Backstop device + CHCI60

rated torque

2800 ken

= 2800. =

She = 3800 = 2.03 > 2.0 O.K.

-u-

High speed type bucket elevator

(NSE type)

iting fevet :

fst, 998 the dlagtem and follow the

of transpextation capacity 500

High spoed type bucket elevator

(NSE type)

12) JD NSE Type Bucket Elevater

[Diagram of Standard 1 sions i

EE We [NSE me | NSE We [NEE wr [NSE wo] NSE Go [NOE TO [NSE wo [wa Bio |

[hain Patch io | 100 Fr 5 12s 150 10 15, i

Buckst No. | NS E40 | NSBaaso | NS E5005 | NS E5060 | NS Eos | NSEser | NS Bem | NS E700 i

Yad baat 2" 2% m u % % x “ 1

Pek ASpeaet | 765.2 oT 7.7 oa | ma? | mee | 07 1

‘Section Type 1 fot 1 T 7 7 z |

fect 780 a0 | eo 30 30 180 100, !

5 1525 1525 1525 1525 1525, 1525, 1525 1

: 7 a

—z 2350 2700 7700 ‘ae00 | 00 2900 “3200 _—| t

F 1200 { iso [1800 1750 | 1150 2000

c | 50 450 550 350 650 650, 750,

7 1600 1708 1700 1850 1950 2090 | 280 2280 |

x [ee | ante ase | a0 |e i

L | __800 a0 | 1100 we | Mss 1s 1

My 450 500 700 100 #00

My eo 750 30 | i

EEE 250 350, Ex) 3350 |

: i os See ;

; = = [fe

® 3050 "3050 S00 3300 3500 |

i s = 3050 won| soo | 3080

Fer {es

Toe | os

Fat 1200, 1350, 1850 1600 1650

45643 55574 e075, 20/6 20/6. 90/7 1020/8

High speed type bucket elevator

(NSE type)

_ Wid NSE ype Bucket Elevator

High speed type bucket elevator

(NSE type)

Bi

NSE Type Bucket Elevator

Chain

Gan na Pc wa S| =e

Pe | SE ao ae |

DRRONNOT| We [Haaser wal wert = [we [ara woe [aos |e | | 808

DewON=G.| wo [Sef sos lee [eal ser] 3 |] w3[ iw [oo [ep as | eto

DE soNTOaEG, | 10 To [ 05

De sonemes. LWT rg [se [osu | oe.2| s7a] 9 | os | 3 OET ae | os | soto

DR NTE, [es mL] —]

(Cpe renters, [ae] ora fea.s|aurs| se |r | ae | ae fis» Pasepae] as | a | 1500

[ncemrars, Fis 15 [ie

DRG, [es is ie ie |

pevponisan, [50] 7 | 70 [as | sol ssa] as | oo fua.s [oF] Ta] 0.000

DR WONTTENS, [HE ie ia |

DEI, [1 T [we |e [

(Cpaneowarewc, [ae] 5 | 75 [28s | sss] oe | os | tm [ist Cire Pa] |

BRIONTSOEE, [0 i ee '

BRON LL To larrs| oo] oa] ae [us fins TAT Toe i

(Coienrses, [are fons [a fens [iio fiona] aoe [esas Die |e | te |

EBucket

i

Dimensions td

/ |

j scam fafeafelxl) ye chain Uses oS

oe ic

[wsEeare om a oe

Te eate us |s.3 $2) seo | sos | ae | ateou sero, sonoest oem.

Neeene=i6 [as [583] aso | 15 | woo | ae [HT Tomo 0.0685 !

NS Es0e0—16 oe woo [ae [atin soon ase oT 6.0682

Nsesnis=ie_| ats |21s.3| 759] 125 SOHTZSM.7sH12591 100H125M.120H TN | 0.1119 i

NSEs050=16 8 STEER TEE YEN TE oer 036

NSE60o—16 5 Las [tsiisoe

SERRE seo sor | son | aso | 1

WSECOsO— % [ae frookrisent, 1am oH oe

[CNsers=ie 1s | sHsM. |

[Fis eroesman | ors |ase.2} ase | 1s | 100 [722 | soonrren oe e281

(ws rss2 [as frente separa

-19-

Low speed type bucket

(NE type)

elevator

Sele

0 ‘retaperaton sped

‘ne oraant Ghats mde vp oh cow:

ibe ee

respec onelgeneagnc ot pe & mh

clase at 604 van

Serecie neue

ee eee

Stat Sheets ovenware vale

Hise sree oe

ec

‘eat eats et at tho ef he

ia

Weta ace H

Low speed type bucket elevator

(NE type)

BUCKET ELEVATOR,

Diagram of Standard Dimensions

Tk conse

scare Spout ane set

ote Pred oa

Low

(WE

speod

typo)

type

bucket

elevator

58 UN POR

i ante] WETS | GH | WEED | Heieo | ENG | ene | WH | WA | ei [ea ee

ion on [Tyas yer Tyrer | aves rvres| wrens | vPes|TVFEs| ares FMS [ WS

# ie [ew [as [ae [es | er

200| “a6 | 309 [aw [so | aw [me | be |

I | [ia [ ram aa ef

i Es

} sof { a5 | ae [an | om | er [|

i | aan ar maf ale ele | He af

ER a

Te | ho | na [ee ee

=> epee |e

676 | a7 | 78 78 Ce Es

wa [ as | a oe zen| 300 | ass

is || st | oa | |

a |p| a | |e [oe

F rn sen [3e0_| aa]

i a [0 |

eae [a | iss | |

j ore || vas | [a0]

: wae ||| we [ae [a

= 700, a ‘i790_| 7080 | 3310.

aoe [a | a se] |e

; ao [se | | a ze | yor | we

30 | x0 [ae [0 | am | 8

2 sso | 00 [x0 | 2080 ‘3300 | 3a0 | 70

i sis [asia [aw | Br [ore | axe | ris | ois | rors | wore

se [sn [sn [aos | oni | wert [won [nr [ine [posto

: a

5 wa || an} or] fat Tata

i u0_| gua | a0 | aes0 | ons0 | soo | 00 | aso | ss00 | ano

ate a | Le

gp te me [ 0 || ae [a | ae |

ES [Trine ate [nee [ae ae Tae [ee

[tw [te | 08 | “es [ase |_| toe [wre [ a | ae Te

Ze | wo [o> | e2 [oem | ie [ me [a [ae [ane |

2 [ wa [ | ea] ae | es [ie | sw | | | | a

ze [ eo [te | tm mm [ ee | oe | [ofa

Low

(NE

speed

type)

type bucket

elevator

BUCKET ELEVATOR

Table of Standard Sizes of NE Type Bucket Elevators

Sins om)

Elevator Luinsannt a — aster ‘Stave

be — feetmsfecima ening | BANOO | trey

weowat | ren | ooae | om [SRS el ‘ee

we 1s | wrse,| rors | sco | cas | oso | 1, | WE, | 7% | S75] or sow

100 excrio *

wei | sorus,| rsa | seme | coo | oxo | le | By 885 | aw

wes | erm. rsa | sea | sao | corse Bo as

Be 7509 wm Jom | gus | ogee

wero’ | Se | am | HBB | soe | ono | iy |, | HE | SE | or oow

serous, 300 oie | SS8 |

e150 | me | BBE | samo | cour | hy | is BIS | or 250

iXaore, B38 a

exo a | 22 | sao | oom | BE | io SES | ar a50

esto ve | BR | sim | ome | hy | Bo ‘Siege |

‘e400 p00 | BER | seovo | anvze | Wen | Tan | 32088 | SBE | ar sow

reso am | ise | som | oxs | Blas | las | Sue | Sta | ar vow

age Sis | Ses

weso0 oe | Bae | srerm] cous | Hoa | haa | Seat | SES | ereow

23 Sie | hess

a wef um | Pues | SEB

veawo | 1eeecs: | seo | G88 | crow | osm | Hiss | Blas | Base | S88 | ercow

Houssts, 3:38 Hm | Siete

= 23-

Low speed type bucket elevator

(NE type)

BUGKEL BhEYCO8

x] «| wane ft fale] elo] Zz] |e | wenn] % | oF] om

c-as | 22) 22] 2| ae] aes] ns Blows

cm | aa) 22] soo] ae] as] vs + neaxore3es

Toa.

7| ror] 820m | a2] 2a] aofie.s| 0] 0) oe no firs] ve | a | “hacen

cs sk : 0 bw hs $s

ool wy Bwa [wale [a | Mansons

7] “ 7 awe |= [w|o |- Mevessnes

ve we | 42| co] am) ats] 20) 0 aww | |e | as | anaes

rao| wa] 8% suo | as] 4s] ao] ats] as) ms] m0 pou | [ow | |. rassassaaes

vo1e} too] gts | 45] 4.5] seo] a1s| aes] 275| aofonr] ame | m | w | as | - aeiocstems

veo | 9 awe | [w | 6 | - mene

4s| smo] v7] seo] 25] ms] 01

vero 9 7 Bim [zs| |» | Menranus

wal elas al sal asl walowsl wal ow] an[ on Pm [= Le [o | weresres

ne [wor] 857 : pwn [as| a | = |- Monsicus

27 | 7 Bw [ms a | ss [- Mewes

$e] 1s] 45] olans| os] sv} an fone

[an] sb awa [ms| a | [> sams

wor] we awe [na[ a | # | > Mewrsxus

soe | a5] 45] ueo}eo.s| 70 | 100 25 /ex2

va] ae] $2 awa [as] a | | sanonns

Taprely i ese irene

~~

Low

(NE

speed

type)

type bucket ale

vator

VER Tap SAV GAA yD

SUGIEV Glee URS

Diagram showing Relation between Chain and Buckets

eee wg oe ae

Tes omar oae

aching uaa uae

evferyerienmne ier

Seater ericecset

Sa cieas wae aan ee

peeled nema

er ea alone ie

ae

lel hee eee

a apart] | *le

= i “orAOzaNeKs wt || as] aa] oa] os |e “Tel”* ad

veo |e Po tt |e] x] uo | os] us

=| = BEEEECE| | EERE

oa rg

we300 | —— 20 oe ee a0 | ao yo} 1s faa | 7s] 4s

Somme] [eal oepeeL mele De

See apts T ale

eae ‘peremaconc. |” [Foo] 70] esa] ooa[ieo | os [uo] v0 | 22 fae | as] 7s

wo | EE SERRE ee | ERR

| SH EESEREE seeps

vem | 2 = :

Smee] [asleep ale [hs eter

weno mT melee [el Po

+ Frese arnt Hoty ‘Sturdy chain is employed

=e bat Ome ans ees nat

4 For ante sande Gat

=a

het aay corre Ove sco eens wth spec

bes apthat aban igor sl teeta, resating lo long hae

Tein Fete nove. chin i agai ode fer Hype oa concted

‘ested Fora ng Hore i xed Kr stachmat efor Gola sande

Belt Type Bucket Elevator

( Rexnord )

= 26 -

Cea

bucket elevators

selection

guidelines

chain or belt

The selection of a belt or chain type bucket elevator

for a particular application is both a science and an

arl, combining measurable factors with the experi-

ence of a material handling expert. Except for a few

specific materials (as shown in the chart at the right)

there is no direct method of determining which type

of bucket elevator is best. Some general guidelines

a5 {0 which type of elevator will Dest fil your needs

are listed below.

Materials

Certain bulk materials, because of their inherent

characteristics, are handled best in a particular typo

of elevator. A general guide to typical materials

handled by bucket elevators is shown at the right.

The type of elevator, chain or belt, best sulted to the

handing of a specific material is also shown.

Centers

Maximum elevator centers are limited by allowable

chain pull or belt construction. Usually, where other

factors are not a consideration, belt iype elevators

ate capable of greater height.

‘Temperature

Modern steel chains are capable of operation in

significantly higher temperatures than an equivalent

belt type unit. Belts are limited by carcass and cover

constuction. For operating temperature in excess of

150°F, selection should be relerred to Rexnord

engineers.

Speed

‘The siandard models of both chain and belt type

elevators listed in this bulletin are designed for

optimum operation at speeds as listed for a specific

model. Speed variations of + 10% are permitted

without affecting operation. Design modifications can

be incorporated to permit a wider range of speeds.

in which case the belt type unit can outpace the

chain elevator. Any such modification should be

referted to Rexnord engineers.

-27-

Typical materials handled in Rex

1200 and 1600 series mill duty

bucket elevators: .

Density! Recommended

LosiPer "elevator

Material Curt: series

‘Aluminum oxide (Alumina). 1200

‘Ashes, coal - wel. 1600

‘Ashes, coal diy... 1600

Baw : 1600

Bentonite, fine - ary +800

Borax, powdered 1600

Calcium chloride 1600

Cement, cinker 1600

Cement, Portland. +600

Gement rock, crushed +1600

Clay, ground - dry. 1600

Coal antivacite, fines 1600

Coal, bituminous ~ sack. 1600

Coat, ignite 1600

Coke breeze. 2. 1200

Goke; petroleum... 1600

Coke, loose....... + 1200

Dolomite, crushed 1600

Feldspar, round 1600

Flue dust” 1600

Fluorspar. 1600

Gravel, screened 1600

Gypsum, calcined” 1600

Gypsum, crushed 1600

Gypeum, powdered? 1600

non pyrites, fines... 1600

Lime, grouns 1600

Lime, pebble < 1600

Limestone, crushed. 22... 1600

Limestone, pulverized +1600

Limestone, 1600

Limestone, agricultural. 1600

Magnesia, fines. 1600

1600

+1600

7 1600

Phosphate, tsp. 1600

Phosphate sands. 1200

Potash 1600

Raw meal 1609

Satt, 1600

Salt, rock - course. 1600

Sand, damp 310-130 1200

Sand, dey. 90-100 1200

Shale, ervshed. 85-90 1600

Seg, fumace « 6065 1600

‘Slag, crushed Ho 85.80 1600

Slate, crushed .. 2) 80-90 1600

Soda ash, heavy” 55-65 1600

Urea... sees. 4050 1609

Wood chips. 15-25 1200

“Buckets musi be cies onthe bottom fr ae wens Yo conte

‘enkapped ain order cbtan ried capactles,

‘Densities shown aro “as hancles” values

Rex 1200 series

mill duty

belt elevator

features

Commercially available elevator belting selected

{or individual application.

@ Rex Style “AC” fabricated steel elevator buckets

in single or staggered double rows, secured to

bell with flat head Huck type or common elevator.

bucket fasteners,

@ Welded stee! head pulley with lagging and taper

lock hubs.

© Heavy-duty spherical roller bearing pillow blocks.

@ Twelve-gauge stee! split upper head section. a

© Sub cischarge spout with adjustable rubber

peeler lip and two inspection doors.

Headshaft bearing supports integral with lower

head section.

@ Lower head section of 14" steel plate.

@ Intermediate casing of heavy gauge steel with

deep beaded crimps for stiffness." #10 ga. for

single leg construction; #7 ga. for double eg

construction. (Attach to adjoining structures at

approximately 20 foot centers for lateral suppor).

Generous clearance between casing and belt

edges.

@ Sett-supporting comer angle constiuction.~

@ Intermediate hinged type inspection door

(optional).

@® Boo! section of ‘A" steel plate.

@ Front and rear cleanout access panels with quick

acting latches. a

@ Iwo bolted access doors for removal of takeup

foot pulley

@® Flanged bottom with flat base for complete

beating on foundation.

@ Welded steel wing type foot pulley with taper

lock hubs,

@ feex counterweighted extemal gravity takeup with

adjustable channel frame for single point belt

training adjustment.

@ Flanged inlet opening for easy connection to

leading chute.

@ Externally mounted Rex flanged block bearings

with closed end shield,

@ First intermediate above boo! has three large

access doors for installation of splice and

buckets."

“Construction varies for double leg casing.

15

CEI)

bucket elevators

mill duty belt elevator selection

select the Rex mill duty bucket

elevators you need from

these simple tables

Using information ftom the chart pn the following

pages you can quickly select and develop

Specifications for a mill duty belt type elevator to fit

your requirements. While the charts cover a broad

fange of capacity and center capabilities, other

combinations of belting, buckels, speed, service

factors, etc. permit higher centers or models nol

listed - consult Rexnord Inc.

How to read belt elevator -

model numbers

‘The example below exptains the technical

makeup of a specific belt elevator model no.

1242 - 1810 A

Se ae an

BELT TYPE fe Peete

i

Ae ee Sanu

see

mgm) [agar bee

mere) (Seam | ee

- Fieve] [SEron| [2

{A NUMBER 1 EXCESS OF 20 INDICATES DOUBLE ROW OF BUCKETS,

AXP w= ALLOWABLE BELT TENSION IN LBSINCH OF WIDTH

selection example

Required: A belt type bucket elevator to handle

finished cement in a marine transfer terminal.

Capacity = 500 TPH

Centers = 175'-0"

«Density = 65 PCF (as handled)

Maximum Lump = 100% Fines

Temperature = Ambient

Step 1: Convert given capacity into cu, fL/hr,

500% 2000 15.385 CFH

16

NOTE: All elevators are volumetric machines

with Constant capacity ratings of any unit in

cubic ithe, The capacity of any unit in tons/

he, varies with density,

Step 2: Refer to Table 4 - Elevator selection on page

17, Read down the left hand column of rated

capacities until a value is reached that

matches or exceeds the cubic ft

requirement

{n this case the 17000 cu. ftJhr. bar meets

the criteria.

Enter the horizontal bar at the figure

representing the material density, in this

case the 65 PCF level. Proceed fo the

horizontally until an imaginary vertical

representing the required center distance is

intersected. Center distance requirements

are indicated in a scale across the top of

Table 4.

Read the model number in the special area

in which the above intersection occurs.

For this case the model number is

1280-32106

Step 3: Proceed to page 18 to develop

specifications,

Step 4: Calculate required drive horsepower from

lables on page 19.

Step 5: For drive selection use tables shown on

Page 23. The headshaft RPM from Table 5

‘and motor horsepower froni Table 6 will

suggest a combination of chain reduction

and teducer output.

Step 6: For elevator dimensions refer to pages 20 &

{or optional platform and access ladder

\ensions refer to page 24. For optional

t frame.dimension reer to page 25,

= 29 -

table 4 - belt elevator selection

“CAPACITY - CUBIC FEET PER HOUR

ELEVATOR CENTERS IN FEET

4700]

500]

7900

aT

e009

1 1009

+2000)

S009

DENSITY = LOS/CU-T.

sas] Saas] Beas] Eeas

7000

as) (8

3009

{22000

28009

3%

2

00

WEREEE Consult Rexnord inc.

“Based on buckets filed to water level

= 30 - 7

[Rex/|//

bucket elevators

mill duty belt elevator specifications

table 5 - specifications

BEER arcs pon ERAT | PoaTSAT eae

ope 7, cn] “areca [Power] ——Jfuiaey] smart ‘ai

RE | cue | mows | seem Pine | frm {S| now [om | “On i

W010 [ABS] 1 [xa | | ae [a | a7 | 90] ame | tent

= [zsos08 [ABC] 1p raxe [10] ais] 90 | 7 | 00 | ome | 20x00

3 [rzsorsos—[asc {1 | exe | 10] sie] 90] 7 | 0] ome | 20xtor

[Tiesorao[ ac [1p aaxi_[i2 | ais _|_a0 | ay 00 | ae] axa

2 [rescreo [ac [1 [texto [ie | ss] a0] a7] 90 | ove] sexe

aad 1230-1810 BC 1 1x10 | 12 315 30 a7 30. The EE

1250-2010 | BC | 1 aoxiof 12] 38] 30] a7 [a0 | ame] ane

om | SE epee] ae ea ee |e

= [lesozeo [8c | 2 | axio || as] 20) 37 | a0 | ame | woxee

2 [eicseo ace prexto [2 | a8] 30] or 00 | ave | sone

# [Trasossio[-ac[ 2] vexio | ie | os] 30} 7] 90 | mm | 50x64

3 [esoaoo [3c {2 | goxi0 | 12 | ais] 30] a7 | a0] ame | eoxen

. 1230-4810" B.C 2 24xt0 | 12 315) 30 | 37 30. The 60x 64

yzsoso0 | 8c [2p wx | 2 | as | ao [ar | a0 | ome Txt

> Lee eee es eS Le ae xa

3 [ees [0] 1 taxi [ie | cos | ae] eof ae ie | ae

[Crane | 0 +] ext [v2 | es] ae fe fae [ome | 80

2 [rezieo| 0 [1] vexio[ 2 | ses] ae] nef a2 ae 32x80

a 1242-2010 oD 1 20x10 | 12 385 aT 3 42 Ea 34x80

wan | 0 [? [eee] me [ele |e] am] «xe

= [ie@zeio [oe raat [aes ae eae 10x90

3 [mesa [0-2 [rex [2 | aes | ae | me] ae |e 3x0

% [Lieaasio |p [2 [texto | ve [oes | ae | oo [a] ae 30x80

3 [eso [0-2 [eax | | aes ae oe ae a Bx 80

3 [razseio | 0] 2 [eax | a2 | aes | ae | oe [ae | ae «0x80

jeazeoro [0] 2 | soxto | | oes | a2 | 03 | @ | am | 70x00

OTE: Al cimentions shown ininchet

“BELT DESIGNATION: = 600RIW, B= 7SDPLW. C= 1000RIM D= 1200PI¥

‘A Guckets ar tla "AC" abricatedot #1092, tee. Cer hicknesses are avaleble upon request, See page 22 for bucket etal

1 Bet speeds ae nomial forthe spocitic putoy same

‘Sa putoys.A 10% Gavaionn speed (nigher of ener)

fefeed to Roxrord engineots

cing "usec" Thus te bat wil operate Gi S15 FPW on 30" dla pulleys and 386 FP on At

rrited. Wider speed ranges ae ease wih cevian cesign alevaons and shou be

specification example

Consider the elevator model selected in the sample One-Rex 1230-3210C bucket elevator with double

problem on page 16. This is the model number row of 16x 10 AC bucket spaced 12” apart on 1000

1230 3210€ elevator. Locate the selected model P.LW. belting operating at a speed of 318 FPM, Unit

number in Table 5. Proceeding to the right horizontally, _will have 30” pulleys and machinery will be

develop specifications as follows: ‘contained in 50" x 64" casing.

-31-

18

mill duty belt elevator

motor horsepower determination

Table 6 contains data which will permit you to

quickly calculate the required horsepower at the

horsepower). Motor HP is then determined by the

application of a factor representing drive losses.

elevator headshait. (Sometimes called BHP = brake Reter to example below for detailed procedure.

table 6 - horsepower

wr. wPCF WREF TORGE

Terme | AA Tea | APIA Tore] RBar RT

wow | “ne” | centre | RM | eles | Tra | ee. | ype | Se

v2o0-t208_| 286 | 128 | ave | x08 | as? | —202-| sea a

1290-1408 [849 [152 | 448] —108| ~sai| 200] ee} ot

a iee0-1608_|[~403-| 176 | 814] ear | —25-| Bre] te | 3a

ai 290-1410 | _445_[ 197} 570 | 258] 698 [ ao] ast | ae

Buckets | s2ao-1610_ | sor | 22 | sa | 208 | Tae see} 30}

vea0-ier0 | —568_| 251 | 727 | m8 | aay [Sa | hoo} as

w2a0-2010_| “e2a-[ 277] 799 | 368] 875 —aae| 208 | sa

ieooe0_| 7a? [3S 3s] ae a] as

ves0-2610 | a80_| 360] 1129[ 06 | tare | a} | art

pe 200-2210 [S92 aes izva} sit] as 5] 603 [ “tae

ow ¥9003610_| thes | 503 | taae | eae | tree] res | prae}—ae

Buckets [7230-2010] 12.36 553_[ 1688 713 | i9.40_|__873_[ 28.08 | 1.086

1250-4810 _|15.02_| 672 1930 | eer easo | “Toe | aa56 | T3ee

1230-6010 | 1858 | s02 | e389 | 10m | ais | Fae] sear ta

eee [ee | | T_T

ea Taaziaio_| 7.39 | 209 gat_| aio tes] aro] tee] a

now waez-i6i0_| 628 [a7] ios | aie] toa | aa} tor} ah

Buckets | auzeieig_[636_| — sor | yaad | — see tas] aes tf

2i22o10 | 1027 | 338 i52—} aa | ete | Ss | aor | set

Tae | es [aor |] S| ae res

wzezze0 | 1481 [as] veer] a1 | eee [Ta | gas}

Et eae weaes@io_ [16.35 [si 2104] —e08 | 25.75 abe] sree] Te

ew ie@3510_| 1055 [615 | 2588] 790] 2020-| — aro | sear | Tar

Buckets 1242-4010 20.38 ‘676 26.25 B72 32.41 1.067 39.93, 1.327

v2ie-a510_|24.76 | 22 | “915¢| 1060 | “sa0e| ideo] au se-] TSG

ie@soio | s0ee [1018 | sosi | 1313] aeas~| Teer} eas] Sone

horsepower calculation example

Consider the elevator model selected in the sample

problem on page 16. This is a model no. 1230-32100

elevator. The elevator centers are given as 175"-0"

1 Locate the selected model number in Table 6. In

this case itis found on the third line down in the first

“double row" bucket category.

2 Proceed to the right horizontally until the 65 PCF

column values are reached,

9 Terminal HP under the 65 P.C.F. column is read as.

: eee 12.73

4 HPIM x centers = 0.571 x 175 99.93

5 Total BHP = (3)+(4) = 2112.66

6 Assuming drive losses at 10% motor HP,

112.66 x 1.10 = : + 123.86

7 Use next largest standard motor size = .. 125 HP

19

| Rex_| |] mill duty belt

bucket elevators €

(—nIVE can BE MounTED eeR SIDE 3-6 On ¢-6 verENowe

LEFT HAND SHOWN ‘on neOUGER Size

yk “ we

a 4 insPEcTON oooRs

m Nsnes

Ht dy |--+ sme srour

m 2»

optMuM muer

conta euccer |

cenrens

[NTERMEDATE SECTIONS AS AEQURED

pean a

i OTK

j——— «<3 014, ancnon aours

‘min 3 proscenon REMOVABLE CLEANOUT D00RS

adhe fs th (or ommeAs) on ox | fon NSers

FOOT SHAFT ASSEMBLY CLEARANCE

FOR REMOVAL single leg

SES ‘CASNG OMENSONS — mCHES EADSHAFT OMENSIONS —

axe lefole|rele]» [«lelu[n|*|ale]+[u]v[w| [Maman [oa [om] melo

[eexson | zolee [oon |sa]erlea] vom [ae [am|seles fam fadsen| w [am|ecn [am] | scanne na, SET couAR

‘sexee_ [reo] 54] eve [sa] [oa] vere | zon | ae [oe] m1 [esm|sr| mn [arn] son] ave[ ae] [TEEARNGOA | @vu | Dre [ove [oe

40x64 | 120/54 | 41% {58 [ae] 49] 21% | 28% | a2 |6a| 20 | 25% | 57] 36m | 37% | a0 | 3018 | 20 x ort sf $s

v=geusa | io | 2 | 2 |

soxee_ | 20] 54a fsa] oe] a] zoe | ann | ae [oe] os [20m |sr| son [7 | | co [ou

ages Te Lo Te |e IC

eae | a0] s4| ee fsa] se] a] avo | ape | we [oe] sv0| sm [or] ex ar | se |e [on

roxee_[roo|se rm sa] [ea] som [ame | we [ee|ras| am] 7] seu [arn |oon eon [ar] ALAPPROXMATE WAXMUR DIMENSIONS

NOTE: Dimensions subject o change. Cetiied dimensions o! order

20 : -3-

| natal urisned on request

elevator dimensions

ORWVE CaN BE MOUNTED EITHER SIDE

‘LEFT HAND DRIVE SHOWN

‘gery mer

onchange ty aucKeT

3°6° 08 4-6 DEPENDING

‘ouneoUcen size

INSPECTION BOORS

sowereR FoR

‘STWUe 2 SPOUT

ITE SECTIONS

centers

AS REDURES

usr

FOOT SHAFT ASSEMBLY CLEARANCE

4:3 DIA, ANCHOR BOLTS

‘REMOVABLE CLEANOUT DOORS.

MS&FS.

mcnes

om [elon [7 Lae

SET COLLAR

2s | 6 | ao |

wlelele

ole [Fle i v

co] an | |oo| s n [sn [arm [aon

ea | a | 05 on |e |e

eo] eo |e [0 [5 ealonl an

EIICIEIE Pes

eo] san | [so] | 181 | om | ee

Belt Type Bucket eleator

(AUMUND )

/A\ OLMIS)

Technische Unterlagen

Technical Data

Documentation Technique

TU11

Gurtbecherwerk

Belt Bucket Elevator

Elévateur 4 Godets sur Courroie

Cat

ER

juwnoco ssi. . AuMNesTmUTONAL TD,

SSiigeagas USS saelvesen Or Conte

Noueece TG MELE aca

R5Esre Timer tnoa

Sea ee aaah

‘ALMLND-CORPORATION,

{abrrracety sates

News ca S00

ios

BW-G

f | Becher theoretische Férderleistung

Z| bucket theoretical capacity m/h

Hie [sett debit theorique

CEL [iene foray Tinie foramaig] tec ttng

8h | wiatn yrotrusion | volume eit bucket spacing =

BEgE [lerceur Fattiie” |votume Freed pas des godets

fap |e i Messe

2 Lm = a 2 0

4 a at Z wis z00_| a see | mf a 450 _| 20. 69.

He 315. 220 Se] 1928 i 3 83 |

ae ‘400 14,5 200] 780,

soo} 260 [yay 1538 243| 224 |

630. 29. ~402_| 365 [335

goo | 320 [37 154 e 513 | 466 | 427

7000 | 3@) (58 oe 906831 |_767

1250) 73 payee eee ee Ti4i_[ 1046 [965

1400. 99 Ee ae saz) 1418 [1309 | i216]

1600] 400 ate [4780 [1633 [1507 | 1400

(ED) vorzussgrisen / preferred sizes / chotsir de preference

Die angagebenen Furderleistungen entsprachen 100 % SecherfUl lung (KesserfUTTung).

‘The indicated conveying capacities correspond to a 100 £ bucket Filling (water FiT1ing).

Le debits indiqués correspondent & un renplissage des godets de 100 £ (remplissage en eau)

{a'hud pace ete) aos fo srosesaton ond

vai the tabi por domeges

‘ering. Netcoprat reproduction veniee

Copyright

Enpfohlener FUNungsgrad:

recomended fi11ing degree: 4

tux de remplissage recomanda:

Urieberrecht an dieser Zeichnesng verstelet wis,

net vom Unesor grochmite Barn

Seana toe mach rebaenaranchin

jersetationg.Uneraasug an rie

OX

Férderleistungen zum AUMUND-Gurtbecherwerk

Capacities for AUMUND-Belt Bucket Elevator

Debits d' Elevateur AUMUND 4 Godets sur Courroie

AUMUND “2

Mi be

3

H

i ‘Suit change mou notce

C

N

[ekecrthton et maere wetave teroeuevon

Antrieb links

Commande d geucne

Left-hand drive Aight-hond drive

onto ec) et vanmsestotonentc

So cootaecinette

ropes protigee

Einlayt,

Entrée

tet

coor

Geet comes an

Soe hae acre as

Phare iteataly

Firderhane, Noutour de levase;

if

Q

HI

u

BB

h

as

fi

Bw h v

750 208 Ea

315 i 7e a]

600) 36 730]

500 om) 50]

630) 0] hao}

800 fi 700] [210]

F000 [rose a0 rr)

1250 1200 | ool i150) vo

1400 1450 300 eso

1600 1050 ) ao

Anserungen vorohaten Subject to change witout note ‘Sous reserve de nodteaons

Doppelschlot zum AUMUND-Gurtbecherwerk

Double Casing for AUMUND-Belt Bucket Elevator

Gaines Jumelées pour Elévateur AUMUND 3 Godets sur Courroie

AUMUND “a

ane

me

ei

Nat

Ku

tum,

3.03.86

INormatausfihfung

Istandard bucket

lexécution stapda

(copyright reproduction. vansey

‘Sind paras ‘te lane Yo roseevion and

‘main be hay 1 por damenee

\Verschleinfeste Ausfihrung

lwear resistant desion

lexécution anti-usure

tere

Gurt-Klemmverbindung

Belt clamping method

i Joint de courroie

Avstbrwneen

Mermalausfrung, aus Staibech geschve

Te

il

ih

i

i Versetateste AusfCiung, aut Sfaiblec ge-

h sche, ib Schéptantenersicking.

ae af Bet Des:

Aintgerutnes States? it Lehi

Seats sholnigr! od Sond bucha,wlded tat plate

ey ptaagaph of sta rated bet ear eetant buch, wed tel

ivonigsaen of Sore ae plate sin rentered wear ees

Street eg tergtogal sod

insane ac :

Poloraie 8 rayne X Cone emersie

S'se"asblgee ave canigration xition anid tile cr suet

de persage zeees

hale abiatges en eecton tngosate coon tarred sutte

Sieve Svc ranere es horde de ooze

Bs

3

eae

8] 8] 8] Aasorangon vrbenaten Subject to change wihout notice Sout résere de modiaions

Becherstrang zum AUMUND-Gurtbecherwerk

ai Bucket Strand for AUMUND-Belt Bucket Elevator

Trongon de Godets d'Elévateur AUMUND 8 Godets sur Courroie ~ 3° ~

ee

AUMUND == aa

i

i

i

A

i

5

B

2

t

3

¢

}

i

é

teopyig ered racer

(ened Batis teh Isto protection Sd

tea the oy py damages

Cond

erlang.

Unsbarechta closer Zihrang versions

ve

“aoc vom Ueneber generis Banutsang

onieigeng. Uoetornng an item)

EP"aratar ahd mach schadeneresapnen.

Name

Datum *

Antriebseinheit mit Kriechantrieb

Orive unit with creep drive

Groupe de commande avec groupe

de virage

Die Kraft wird von einer Trommel durch Reib-

Schluf ibertragen. Ein 3-, 4~-bzw. 5-teiliger,

rautierter Reibbelag ist absolut sicher rund um|

die Trommel verschraubt.

Power transmission from pulley is effected by|

means of friction. A 3-, 4~ and/or S-partite

shombic friction lining is bolted all around the

pulley in an absolutely safe manner.

Transmission de force d'un tambour par frictio

Une garniture de friction rhombique en trois,

quatre et/ou 5 parties est boulonnée tout

autour du tambour d'une maniére sire.

Andetungen vorbohatien. ‘Subject to change without notice. ‘Sous réserve de modifications.

Antrieb zum AUMUND-Gurtbecherwerk

Drive for AUMUND-Belt Bucket Elevator

Commande-Elévateur AUMUND a Godets sur Courroie

AUMUND

Fordererbau GmbH

Maschinenfabrik

Rhelnberg

Becherbefestigung,

bucket attachment.

Anderungen vorbenatin

Die hohe Ausreinfestigkeit des Gurtes in Verbindung mit der Becherform erméglicht eine sictere

The high tensile strength of belt in connection with the shape of buckets allows for a safe

La résistance élevée 3 la rupture de [a courroie en combinaison avec la forme des godets permet

une fixation sire des godets,

Subject to enange winout notice, ‘Sous résonve de modifications.

Cir a und Becherstrang zum AUMUND-Gurtbecherwerk

Irive pulley and Bucket Strand for AUMUND-Belt Bucket Elevator

fambour de Commande et Trongon de Godets d'Elévateur AUMUND & Godets sur Courroie|

Der mehrteilige Reibbetag kann schnell und problem

los auf der Trommel montiert werden. Dadurch kommt

es nur zu sehr kurzem Stillstand des Becherwerkes.

The multipart friction lining can be mounted fast on

the pulley and without any problems. Consequently

stillstand of bucket elevator is very short,

La garniture de friction & plusieurs parties peut étre|

montée vite sur le tambour et sans problémes. Par

conséquent Uarrét d'élévateur est seulement dune

durée tres courte,

Die Betriebssicherheit des Gurtes wird weitgehend

von der Gite der Klemmverbindung bestimmt,

The operating reliability of belt is mainly determined

by the quality of clamp connection.

La fiabilité de ta courroie est principalement deter-

minge par la qualité du raccord de serrage,

-4-

AUMUND

Fordererbau GmbH

Maschinentabrik

Rheinberg

Becherverksfull / bucket elevator boot / pied d'élévateur 3 gode

Parallelspanneinrichtung

paraltel tensioning device

ispositif de tension paraltéle

Spanngewicht

counterweight

contre-poids

Spanntrommet

take-up pulley

tambour de tension

Hate side

grew PW-G-02

Sous reserve de mositeations

Anderungen vorbehaton Subject o change without notice

Spanneinrichtung zum AUMUND~Gurtbecherwerk

Tensioning device for AUMUND-Belt Bucket Elevator

Dispositif de Tension pour UElévateur AUMUND & Godets sur Courroie

FSrdererbau GmbH

AUMUND ===

ane

&

u Becherwerkskopf_/ bucket elevater head /

fe

Hy :

Ci Z

i

a

us AO

ia

‘Aer trent ol copy pecoducten ante.

tebe prise ely ene fo proven and

‘ht he aby 6 pay enmape

Copyright pa.

Becherwerksfufi / but wator boot /

pled délévateur 3 godets

: T

A

arabe hd ach sthadenersasotcnas

{iterbtatigung. Uoeaeang an Brest)

\ ae ment rom Urneber gonenmisie Beng

(C surhederrecht an cioser Zeichmunguorblaitt ves.

Induktiver Néherungsschalter

11 inductive proxinity switch -

| détecteur de proximité inductit

Febritat / make / febriqut par : Peppert & Fuchs

Zugfeder

2. tension spring

ressort de traction

Gunmi-Platte

Ps 3. rubber plate

plaque en caoutchouc

earbeitet

gepratt

Anderungen vorbetaton.

Schieflaufwachter zum AUMUND-Gurtbecherwerk

Drift limit device for AUMUND-Belt Buckef Elevator

Contréteur de Déport pour {'Elévateur AUMUND & Godefs sur Courroie

AUMUND ==

‘Subject to change without otic.

GC

==

i 3

fe-Up/Fension|

spainweg7

i

Spanntager

1 ‘take-up bearing

palier de tension

Schmiernippel

2 Whricating nipple

graisseur

Induktiver Naherungsschalter

3 inductive pre

détecteur de proximeté inductit

bat /aaka/fabive par:

Peppet & Fuchs

Andeningen voroenaten ‘Sunject to change witout novce ‘Sous réserge de modiicatvons

Drehzahliiberwachung zum AUMUND-Gurtbecherwerk

Speed Control for AUMUND-Belt Bucket Elevator

Contréle de Vitesse pour l'Elévateur AUMUND 8 Godets sur Courroie ~ “4 ~

AUMUND ="

Becherwerksfufl / bucket elevator boot / pied délévateur 3 godets

aww

&

Fabrikat / make / fabrigué par : Endress & Hauser

Tye / type / type : Nvoconpact FTHZ3®

Gace Sehvngatel

Ja feltroainats satay fori

fear eelote

Versus

5 ww

ie

fouverele fernebure

casiog

Ta electronic insert

a ncertatctreique

Ansehuptaneeh

eng ve 6 crc Rage

eae bride de raceré

3] |x Einschenubetek

3). : Kabelschalthasten mit Kefrudte

3/3 3 mete 17 able switch box sith control lap

: Bolte de transpesiin are lamoe de catele

8] 8] Ansrnoen reranaten. ‘Subject to change without noice Sous eben ce modtiatons.

~~ Fillstandsgrenzschalter zum AUMUND-BW-Z, BW-G, BW-L

7 Level Indicator for AUMUND-BW-Z, BW-G, BW-L

Indicateur de Niveau pour Elévateurs AUMUND-BW-Z, BW-G, BW-L ~- 4 -

ee

UMUND “SS

ee

Becherwerksfull / bucket elevator boot / pied d° étévateur & godets

BW-Z:

Cr arrecan eh mate mere eprom

Prose protege

puiable de doomsger mist,

a

Forties setoleconih weredsction rant

(Sd farce ste fate to prosecution te

‘ote abi 0 pey cranes

oor,

Fabriat / make / fabriqué

Sip 7 type 7 type SFA TS

3 }—2

ia THE 1 Bb

4 4

Le

1 carton serra

2 StiDel 2 cow

1 Rbaatreder contd age

€¢ Miroschalter verschiebbarer Flansch

1 eam 3 vost ange

vc See sate

& ‘eaélusting sing Membrane

4 inane

sonar

Kabelschaltkasten wit Kotrollewdte

cable sich Bex it control iano

bofte de transposition avec lange de contrtle

i

i

| 3

i

t

i

Name

Datum |

‘Aacierangen vorsenaten = Subject change without novee Sous rtserve de mostheavont

9

Filllstandsgrenzschalter zum AUMUND-BW-Z, BW-G, BW-L

Level Indicator for AUMUND-BW-Z, BW-G, BW-L ete

Indicateur de Niveau pour Elévateurs AUMUND-BW-Z, BW-G, BW-L

eae

AUMUND = :

Rheinberg O/ G/F

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ansi C12.1-2001Document118 pagesAnsi C12.1-2001maherianto 29100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Air SlideDocument26 pagesAir Slidemaherianto 29No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- en Bearing Damage and Failure AnalysisDocument106 pagesen Bearing Damage and Failure Analysisacicuencano100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CFC-201 User's MunualDocument214 pagesCFC-201 User's Munualmaherianto 2950% (4)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- ABB Motor Manual 89Document76 pagesABB Motor Manual 89maherianto 29No ratings yet

- KPS Belt Inspection A1-J07 W23-07-2018Document8 pagesKPS Belt Inspection A1-J07 W23-07-2018maherianto 29No ratings yet

- Truck Scale Barrier Gate SystemDocument2 pagesTruck Scale Barrier Gate Systemmaherianto 29No ratings yet

- 6 Presentation 6 VSD - BahasaDocument4 pages6 Presentation 6 VSD - Bahasamaherianto 29No ratings yet

- Slip RingDocument2 pagesSlip Ringmaherianto 29No ratings yet

- NPL100-12 DatasheetDocument1 pageNPL100-12 Datasheetmaherianto 29No ratings yet

- THW, Mea Type A: 750 V 70 C PVC Insulated, Single CoreDocument2 pagesTHW, Mea Type A: 750 V 70 C PVC Insulated, Single Coremaherianto 29No ratings yet

- Hitung Arus Hubung SingkatDocument22 pagesHitung Arus Hubung Singkatmaherianto 29No ratings yet

- AS Standard LV&MV Cable BruchureDocument49 pagesAS Standard LV&MV Cable Bruchuremaherianto 29No ratings yet

- Breakdown Analysis From Vcs Controller of z2p23 MV DriveDocument7 pagesBreakdown Analysis From Vcs Controller of z2p23 MV Drivemaherianto 29No ratings yet

- Materi HoseDocument5 pagesMateri Hosemaherianto 29No ratings yet

- Auto Compressor PackingDocument2 pagesAuto Compressor Packingmaherianto 29No ratings yet

- Auto Barrier Gate SystemDocument3 pagesAuto Barrier Gate Systemmaherianto 29No ratings yet

- P2-03 - Slipring and Brush For Wound Rotor Induction MotorDocument60 pagesP2-03 - Slipring and Brush For Wound Rotor Induction Motormaherianto 29No ratings yet

- 150438H enDocument4 pages150438H enmaherianto 29No ratings yet

- Anyload TN001 v2 Load Cell Force Transducer How It WorksDocument4 pagesAnyload TN001 v2 Load Cell Force Transducer How It Worksmaherianto 29No ratings yet

- Bag Filter Trainer Revise 2 17-9-2556Document55 pagesBag Filter Trainer Revise 2 17-9-2556maherianto 29No ratings yet

- Open & Challenge: Safety - Quality First and Happy Work PlaceDocument39 pagesOpen & Challenge: Safety - Quality First and Happy Work Placemaherianto 29No ratings yet

- 20-2 Transport-Belt ConveyorDocument173 pages20-2 Transport-Belt Conveyormaherianto 29No ratings yet

- Reclaimer CircularDocument21 pagesReclaimer Circularmaherianto 29No ratings yet

- VFinal - APBNKITA April 23Document86 pagesVFinal - APBNKITA April 23maherianto 29No ratings yet

- Tridge Market Report - CinnamonDocument18 pagesTridge Market Report - Cinnamonmaherianto 29No ratings yet

- AReviewon Amomumsubulatumand Elettaria CardamomumDocument7 pagesAReviewon Amomumsubulatumand Elettaria Cardamomummaherianto 29No ratings yet