Professional Documents

Culture Documents

Anyload TN001 v2 Load Cell Force Transducer How It Works

Uploaded by

maherianto 29Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anyload TN001 v2 Load Cell Force Transducer How It Works

Uploaded by

maherianto 29Copyright:

Available Formats

Load Cell and Force Transducer – How It Works

Load cells and force transducers are essential S-Beam or S-Type

devices in weighing or measurement Single Point

applications. There are no clear definitions of Canister and Disk

load cell and force transducer, but they are all Planer

sensors; usually load cell measures weight, Load Pins

while force transducer measures force or Load Buttons

torque. Tension Links

They are used in variety of industries such as

packaging, transportation, food, farming, Sensing Electronics:

agriculture, construction, medical, high tech,

The key part of sensing electronics for a load

test and measurement, and many others.

cell is the strain gauge. The strain gauge, as the

The major components of any load cell or force name implies, can measure the strain on a piece

transducer are: of metal when is it bonded to it.

1. Sensor Element, and A strain gauge is a thin precision resistor

2. Sensing electronics component that changes its resistance value

when it is under tension or compression.

Sensor Element:

The Sensor Element in a load cell or force

transducer, often called “spring element”, is a

precisely machined piece of metal commonly

made from high strength alloy steel, or stainless

steel with heat treatment, or high strength

aluminum alloy.

The sensor element is made in such a way that

if a load is applied to it in a certain direction and

orientation, it will develop strain that is

proportional to the load that is being applied. A

load cell’s accuracy is highly dependent on the

sensor element design and material, as well as Figure 1: Strain Gauges in Compression, Normal, and

Tension (change of shape is exaggerated).

workmanship.

To turn this change in resistance into a usable

Sensor Elements come in different shapes and

voltage output, four (or groups of four) strain

sizes that correspond to the relevant

gauges are attached to a sensor element in a

application and load rating. Anyload provides

wheat stone bridge arrangement.

variety of load cells as follows:

Single Ended Shear Beam

Double Ended Shear Beam

www.anyload.com Tech Note: #101, V1 Page 1

Load Cell and Force Transducer – How It Works

transducers is at most about 0.1 mm to 1 mm at

full scale.

Figure 4: Single point load cell under load

Figure 2: Strain gauge wiring diagram In most cases, strain gauges are bonded to the

The strain gauges are bonded to the sensor sensor element at the locations where most

element in such a way that when a load is strain will occur.

applied to the load cell, R1 and R3 will be under

When the load cell or force transducer is in

compression and R2 and R4 will be under

unloaded and normal condition, all the strain

tension.

gauge resistance values are equal or close to

equal and the voltage output of the wheat

How Does It Work? stone bridge is zero or close to zero.

To show how a load cell actually works, we will When a load is applied to the sensor, the strain

demonstrate using a single point load cell. The gauges are under compression or tension

sensor element of a single point load cell will according to the schematic below:

look similar to this illustration:

Figure 5: Strain Gauge wiring under load

Figure 3: Single Point Load Cell Model

In this condition, the strain gauges under

When a load is exerted on the load cell or force compression have lower resistance and the

transducer at the loading point, the sensor ones under tension have higher resistance. This

element will produce strain according to the change in resistance will cause the voltage

following simulation (refer to Figure 4). The output to deviate from zero or close to zero by

change in shape of the sensor element is an amount that is proportional to the load

exaggerated for illustration purposes. The applied.

actual deflection of most load cells or force

www.anyload.com Tech Note: #101, V1 Page 2

Load Cell and Force Transducer – How It Works

Milli-Volt per Volt Output

A sensor’s output voltage with respect to the

excitation or supply voltage is presented in

mV/V in the specification sheet of the load cell

or transducer. This value is stated for the full

scale output of a load cell and commonly they

are 1, 2, 3, 4 mV/V, or other numbers lower or

in between.

The term “full scale output” means the voltage

output of a load cell when the load cell is at full

Figure 6: Example of wheat stone bridge on a load cell

rated mechanical load.

There are different resistive components other

For example, for a load cell or force transducer than the four main strain gauges that make up a

with 2 mV/V full-scale output, it means if the wheat stone bridge circuit. They are

excitation voltage is 10 VDC, then at full scale

the output voltage will be 20 mV according the Zero balance compensation

following equation: Temperature compensation on zero

Sensitivity compensation

Temperature compensation on

sensitivity

Load Cell or Force Transducer Zero Balance Compensation

Since not all strain gauges are of exactly equal

Compensation

values and their value might change by a small

Ideally a load cell with a simple wheat stone

amount after the bonding process to the sensor

bridge circuit has an output of zero when it is

element, the zero balance resistive components

unloaded. However, in reality, several resistive

will help to counter this change or difference.

components have to be added to the wheat

The goal of zero balance is to make all strain

stone bridge circuit to minimize the

gauges bonded to a sensor element almost

temperature change effects and achieve zero

equal in value.

balance in unloaded condition. A real example

of a wheat stone bridge in a load cell will look Temperature Compensation on

similar to the following schematic:

Zero

The sensor element, as well as strain gauges will

naturally expand and contract depending of the

environment temperature. This can lead to false

load value reading in different temperatures.

The temperature compensation component is a

temperature dependant resistor that will

www.anyload.com Tech Note: #101, V1 Page 3

Load Cell and Force Transducer – How It Works

counter the resistance changes of the main

strain gauges.

Sensitivity Compensation

The sensitivity compensation components will

help adjust the load cell sensitivity to a standard

value of 1, 2, 3, 4 mV/V or other numbers lower

or in between, full scale output within a certain

tolerance range.

Temperature Compensation on

Sensitivity

The sensor element, strain gauges, elastic

modulus of the sensor element, will naturally

change depending of the environment

temperature during receiving the loading or

force. This can lead to incorrect load or force

value reading in different temperatures.

The temperature compensation component is a

temperature dependant resistor that will

For load cell products and information please

counter the incorrect reading in different

visit:

temperature.

Online: https://www.anyload.com/

Canada Office and Warehouse:

Anyload Weigh & Measure Inc.

6855 Antrim Avenue, Burnaby, BC, V5J 4M5

Toll Free: 1.855.ANYLOAD (269.5623)

Phone: 604.420.2130

Fax: 1.866.612.9088

Email: info@anyload.com

US Office and Warehouse:

Anyload LLC.

Building 6, Unit # 30R - 1275 Bloomfield Avenue

Fairfield, NJ, 07004

Toll Free: 1.855.ANYLOAD (269.5623)

Fax: 1.866.612.9088

Email: info@anyload.com

www.anyload.com Tech Note: #101, V1 Page 4

You might also like

- Vedic Maths - India's Approach To Calculating!Document4 pagesVedic Maths - India's Approach To Calculating!padmanaban_cse100% (2)

- Ansi C12.1-2001Document118 pagesAnsi C12.1-2001maherianto 29100% (2)

- BudgetingForecastingCoursePresentation 1547839506611Document91 pagesBudgetingForecastingCoursePresentation 1547839506611ikakkos100% (2)

- PC200-8 SM - 013 Troubleshooting by Failure Code Part-3Document50 pagesPC200-8 SM - 013 Troubleshooting by Failure Code Part-3t5442071100% (2)

- 23 Seriesand Parallel CircDocument7 pages23 Seriesand Parallel CircAshley O'Neal50% (2)

- Load CellDocument9 pagesLoad Celladalberto soplatetasNo ratings yet

- Electronic Scale ArduinoDocument8 pagesElectronic Scale ArduinoKathryn WorkmanNo ratings yet

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- Protection of MV LV Substation Transformers PDFDocument37 pagesProtection of MV LV Substation Transformers PDFmatanveerNo ratings yet

- Electrical Transmission and Distribution Reference Book of WestinghouseDocument832 pagesElectrical Transmission and Distribution Reference Book of WestinghouseAlexis Fernandez Cordova94% (31)

- Calibration of Load CellDocument3 pagesCalibration of Load Cellpammy313100% (1)

- Chapter5 - Sensor & TransducerDocument36 pagesChapter5 - Sensor & Transducerkmthong33% (6)

- en Bearing Damage and Failure AnalysisDocument106 pagesen Bearing Damage and Failure Analysisacicuencano100% (5)

- Load CellsDocument24 pagesLoad CellsKevinAngeloMaNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- Strain Gauge Load CellDocument6 pagesStrain Gauge Load CellSaraswantoNo ratings yet

- Crankcase Pressure SM019901095211 - en PDFDocument5 pagesCrankcase Pressure SM019901095211 - en PDFDavy GonzalezNo ratings yet

- Ingersoll RandDocument56 pagesIngersoll RandDavid Yucra0% (1)

- CFC-201 User's MunualDocument214 pagesCFC-201 User's Munualmaherianto 2950% (4)

- MECH826 Week05 MachineVibrationStandardsandAcceptanceLimitsDocument78 pagesMECH826 Week05 MachineVibrationStandardsandAcceptanceLimitsDefinal ChaniagoNo ratings yet

- 4-Day Hands-On Python ProgrammingDocument3 pages4-Day Hands-On Python ProgrammingÃmåñûēl DïrïbãNo ratings yet

- Ansi C37.51-1989Document26 pagesAnsi C37.51-1989YogialkNo ratings yet

- Lab Report of Strain Gauges and Load Cells PDFDocument11 pagesLab Report of Strain Gauges and Load Cells PDFAamnaNo ratings yet

- Testing Power Transformer MeasurementsDocument126 pagesTesting Power Transformer MeasurementsAnonymous EKVfZYQiegNo ratings yet

- Teachers Book - Smarty 4 PDFDocument77 pagesTeachers Book - Smarty 4 PDFFlorenciaRivichini50% (2)

- Nema VSD GuideDocument81 pagesNema VSD GuideSeahlkNo ratings yet

- Holderbank: Binder 1 Materials Technology IDocument2 pagesHolderbank: Binder 1 Materials Technology IlatiefNo ratings yet

- Datasheet 3133Document4 pagesDatasheet 3133Alfian van JansenNo ratings yet

- CZL616C Micro Load Cell DatasheetDocument4 pagesCZL616C Micro Load Cell DatasheetAlexandru ArcireNo ratings yet

- Datasheet: 3133 - Micro Load Cell (0-5kg) - CZL635Document4 pagesDatasheet: 3133 - Micro Load Cell (0-5kg) - CZL635HamdanRizqiNo ratings yet

- Getting Started With Load CellsDocument6 pagesGetting Started With Load Cellssupport ubicuoNo ratings yet

- Chapter 3Document15 pagesChapter 3qalbeessaashiboNo ratings yet

- Unit2 - Overview of Sensors - Transducers - Characteristc Ic - SpecificationDocument25 pagesUnit2 - Overview of Sensors - Transducers - Characteristc Ic - SpecificationgudduNo ratings yet

- Force Transducer Calibration and Failure TestingDocument6 pagesForce Transducer Calibration and Failure TestingMuthoka Vincent0% (2)

- Load CellDocument4 pagesLoad CellTeja SanthoshNo ratings yet

- Lesson 10Document25 pagesLesson 10Mohammad KhazaalNo ratings yet

- Spring 2019 - Lab 6 - Force Transducer HWDocument9 pagesSpring 2019 - Lab 6 - Force Transducer HWMuthoka VincentNo ratings yet

- CPS - Load CellsDocument7 pagesCPS - Load CellsAshok (B20CI015)No ratings yet

- Unit 3. Signal ConditioningDocument17 pagesUnit 3. Signal Conditioningjose joseNo ratings yet

- Title: Load Cells in Force Sensing Analysis - Theory and A Novel ApplicationDocument5 pagesTitle: Load Cells in Force Sensing Analysis - Theory and A Novel ApplicationduvanNo ratings yet

- Force Displacement MeasurementDocument39 pagesForce Displacement MeasurementVarad Date0% (1)

- 1.105 Solid Mechanics Laboratory Fall 2003: Experiment 3 The Tension TestDocument13 pages1.105 Solid Mechanics Laboratory Fall 2003: Experiment 3 The Tension TestSuman.SNo ratings yet

- Determine Voltage Drops in Series CircuitsDocument15 pagesDetermine Voltage Drops in Series CircuitsMartin GeorgievNo ratings yet

- Measurement Lect 7 - 2018Document55 pagesMeasurement Lect 7 - 2018Abdelhay Mohamed HassanNo ratings yet

- Unit 2Document29 pagesUnit 2nikhill kundarNo ratings yet

- Ee 101 Lexp 3 ConclusionDocument3 pagesEe 101 Lexp 3 Conclusionystine95No ratings yet

- Aic Rep NewDocument10 pagesAic Rep Newj.k.boseNo ratings yet

- Transformer TestingDocument33 pagesTransformer Testingiamketul6340No ratings yet

- EE305 Instrumentation and Measurement Teaching Assistant Šejla DžakmićDocument15 pagesEE305 Instrumentation and Measurement Teaching Assistant Šejla DžakmićFrank WhiteNo ratings yet

- Module 2: Resistive, Capacitive & Inductive Transducer: Resistance PotentiometerDocument38 pagesModule 2: Resistive, Capacitive & Inductive Transducer: Resistance PotentiometerSAKSHI CHIKSHENo ratings yet

- How Is Temperature Affecting Your Strain Measurement Accuracy?Document3 pagesHow Is Temperature Affecting Your Strain Measurement Accuracy?Gabor VatoNo ratings yet

- Measurement of Force, Torque and SpeedDocument18 pagesMeasurement of Force, Torque and SpeedErxDNo ratings yet

- Measurement TipsDocument14 pagesMeasurement TipsFarah DianaNo ratings yet

- Strain Gauge: Load CellDocument33 pagesStrain Gauge: Load CellPrashant ShahNo ratings yet

- Stain Gage Measurements YsDocument9 pagesStain Gage Measurements YsAnonymous RJtBknNo ratings yet

- BioMechanics Lab Report Guidelines ExampleDocument4 pagesBioMechanics Lab Report Guidelines ExampleFrederick MartinezNo ratings yet

- TransducerDocument42 pagesTransducerShreyash SargarNo ratings yet

- WheitStone Bridge For Temperature MeasurementDocument6 pagesWheitStone Bridge For Temperature MeasurementrajeshNo ratings yet

- Electrical and Electronics Measurement 4th Sem B.Tech.Document41 pagesElectrical and Electronics Measurement 4th Sem B.Tech.Saksham KumarNo ratings yet

- Cha:4 Potentiometers: Principal of D.C. Potentiometer Crompton's Potentiometer Application of DC PotentiometerDocument16 pagesCha:4 Potentiometers: Principal of D.C. Potentiometer Crompton's Potentiometer Application of DC PotentiometerNirav ChauhanNo ratings yet

- Complex Rational Function Frequency: Voltage DividerDocument5 pagesComplex Rational Function Frequency: Voltage DividerEugenio PulidoNo ratings yet

- Yarmolenko Lab1Document8 pagesYarmolenko Lab1yarmolenkonazar1309No ratings yet

- Load & Pressure GuideDocument4 pagesLoad & Pressure GuideIvette RamírezNo ratings yet

- Potentiometer: 1. Construction and Working of Basic DC PotentiometerDocument11 pagesPotentiometer: 1. Construction and Working of Basic DC PotentiometerKumar SanNo ratings yet

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument20 pagesMeasurement Systems: Application and Design by Ernest O. DoebelinAlhji AhmedNo ratings yet

- Losses 123Document10 pagesLosses 123parasathyaNo ratings yet

- 2-Unit-I PPTs-02-02-2021 (02-Feb-2021) Material - II - 02-Feb-2021 - Resistive-Sensors-AnalogDocument45 pages2-Unit-I PPTs-02-02-2021 (02-Feb-2021) Material - II - 02-Feb-2021 - Resistive-Sensors-Analognatsu dragneelNo ratings yet

- Praise Be To The Lord of All Worlds: in The Name of Allah, The Merciful, The BeneficentDocument49 pagesPraise Be To The Lord of All Worlds: in The Name of Allah, The Merciful, The BeneficentMahrukh ChaudharyNo ratings yet

- Principle of The Strain GaugeDocument6 pagesPrinciple of The Strain Gaugeapi-3706095100% (1)

- Lab Assignment: Strain GaugeDocument5 pagesLab Assignment: Strain GaugeReal MadridNo ratings yet

- Episode 118 - Potential DividersDocument14 pagesEpisode 118 - Potential DividersAshley kennedyNo ratings yet

- Measurement of Force, Torque and Strain: Prepared by DrrrshahDocument84 pagesMeasurement of Force, Torque and Strain: Prepared by DrrrshahKantha RaoNo ratings yet

- Load Cell & Its Application in TextileDocument27 pagesLoad Cell & Its Application in TextileSoumyajit Sarkar100% (1)

- Electronic Pressure SensorsDocument5 pagesElectronic Pressure Sensorsmcbmcb159No ratings yet

- Why The Voltage Divider Formula Is ImportantDocument5 pagesWhy The Voltage Divider Formula Is ImportantjackNo ratings yet

- Breakdown Analysis From Vcs Controller of z2p23 MV DriveDocument7 pagesBreakdown Analysis From Vcs Controller of z2p23 MV Drivemaherianto 29No ratings yet

- AS Standard LV&MV Cable BruchureDocument49 pagesAS Standard LV&MV Cable Bruchuremaherianto 29No ratings yet

- KPS Belt Inspection A1-J07 W23-07-2018Document8 pagesKPS Belt Inspection A1-J07 W23-07-2018maherianto 29No ratings yet

- NPL100-12 DatasheetDocument1 pageNPL100-12 Datasheetmaherianto 29No ratings yet

- THW, Mea Type A: 750 V 70 C PVC Insulated, Single CoreDocument2 pagesTHW, Mea Type A: 750 V 70 C PVC Insulated, Single Coremaherianto 29No ratings yet

- Auto Barrier Gate SystemDocument3 pagesAuto Barrier Gate Systemmaherianto 29No ratings yet

- Truck Scale Barrier Gate SystemDocument2 pagesTruck Scale Barrier Gate Systemmaherianto 29No ratings yet

- Auto Compressor PackingDocument2 pagesAuto Compressor Packingmaherianto 29No ratings yet

- Tridge Market Report - CinnamonDocument18 pagesTridge Market Report - Cinnamonmaherianto 29No ratings yet

- Areca Catechu Betel Nut PDFDocument17 pagesAreca Catechu Betel Nut PDFDania NovitasariNo ratings yet

- AReviewon Amomumsubulatumand Elettaria CardamomumDocument7 pagesAReviewon Amomumsubulatumand Elettaria Cardamomummaherianto 29No ratings yet

- How To InstallDocument1 pageHow To Installmaherianto 29No ratings yet

- Reclaimer CircularDocument21 pagesReclaimer Circularmaherianto 29No ratings yet

- Indoor AC Medium-Voltage Switches For Use in Metal-Enclosed Switchgear - Conformance Test ProceduresDocument23 pagesIndoor AC Medium-Voltage Switches For Use in Metal-Enclosed Switchgear - Conformance Test ProceduresGilberto MejíaNo ratings yet

- Ansi C37.50-R2000Document27 pagesAnsi C37.50-R2000maherianto 29No ratings yet

- RM35JA32MR: Product DatasheetDocument4 pagesRM35JA32MR: Product Datasheetmaherianto 29No ratings yet

- Ansi C37.16-2000Document27 pagesAnsi C37.16-2000maherianto 29No ratings yet

- Interlocking&SF6 PDFDocument3 pagesInterlocking&SF6 PDFmaherianto 29No ratings yet

- Batch RecordDocument11 pagesBatch RecordInes Concepcion TupasNo ratings yet

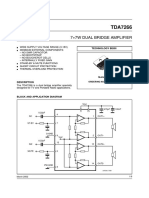

- Tda7266 PDFDocument9 pagesTda7266 PDFRenato HernandezNo ratings yet

- Automobiles Seat ComfortDocument10 pagesAutomobiles Seat ComfortAnushree DeshingeNo ratings yet

- SchoolopeningdocxDocument1 pageSchoolopeningdocxElena BarsukovaNo ratings yet

- Solve Equations and InequalitiesDocument13 pagesSolve Equations and InequalitiesFons Roxas-ChuaNo ratings yet

- Günter Fella: Head of Purchasing AutomotiveDocument2 pagesGünter Fella: Head of Purchasing AutomotiveHeart Touching VideosNo ratings yet

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294No ratings yet

- Work Readiness Integrated Competence Model Conceptualisation and ScaleDocument23 pagesWork Readiness Integrated Competence Model Conceptualisation and ScaleMelly NadiaNo ratings yet

- Agricrop9 ModuleDocument22 pagesAgricrop9 ModuleMaria Daisy ReyesNo ratings yet

- PD083 05Document1 pagePD083 05Christian Linares AbreuNo ratings yet

- Partlist Sym Vf3i 185Document83 pagesPartlist Sym Vf3i 185Jack Wilder100% (1)

- Abdul Jabbar (Mechanical Engineer) AGROFEED KSADocument4 pagesAbdul Jabbar (Mechanical Engineer) AGROFEED KSAftimum1No ratings yet

- Gerunds vs InfinitivesDocument87 pagesGerunds vs InfinitivesDeby NavarroNo ratings yet

- Filipinism 3Document3 pagesFilipinism 3Shahani Cel MananayNo ratings yet

- Oven Nordson ElectronicDocument60 pagesOven Nordson ElectronicDanijela KoNo ratings yet

- Switches Demystified Assembly PDFDocument1 pageSwitches Demystified Assembly PDFkocekoNo ratings yet

- Hydro Distillation Method Extraction of Eucalyptus Oil Lemongrass OilDocument9 pagesHydro Distillation Method Extraction of Eucalyptus Oil Lemongrass OilSIVANESAN JOTHIVELNo ratings yet

- Sleep Hygiene Sleep QualityandDocument8 pagesSleep Hygiene Sleep QualityandVriddhi AgrawalNo ratings yet

- Explorer 7100 ACU ManualDocument78 pagesExplorer 7100 ACU ManualMuhammad Shahroz AfzalNo ratings yet

- Toyota Camry ANCAP PDFDocument2 pagesToyota Camry ANCAP PDFcarbasemyNo ratings yet

- Accident Avoiding Bumper SystemDocument3 pagesAccident Avoiding Bumper SystemDeepak DaineNo ratings yet

- National Institute of Technology Calicut: Department of Computer Science and EngineeringDocument8 pagesNational Institute of Technology Calicut: Department of Computer Science and EngineeringArun ManuNo ratings yet