Professional Documents

Culture Documents

Ansi C37.50-R2000

Uploaded by

maherianto 29Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansi C37.50-R2000

Uploaded by

maherianto 29Copyright:

Available Formats

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

ANSI C37.50-I989 (R1995,R2000)

AMERICAN NATIONAL STANDARD

Low-Voltage

AC Power Circuit

Breakers Used in Enclosures-

Test Procedures

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Secretariat

lnstitute of Electrical and Electronics Engineers

National Electrical Manufacturers Association

Approved 02/11/O0

American National Standards Institute, Inc.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

S T D - N E M A C37.50-ENGL L989 m 6470247 0524173 3TT m

ANSI C37.50-1989 (R1995)

American Approval of an American National Standard requires verification by ANSI that the

requirements for due process, consensus, and other criteria for approval have been

National met bythe

standards

developer.

Standard Consensus is established when, in the judgment of the ANSI Board of Standards

Review, substantial agreement has been reached by directly and materially affected

interests. Substantial agreement means much more than a simple majority, but not

necessarily unanimity. Consensus requires thatall views and objections be

considered, and thata concerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence

does not in any respect preclude anyone, whether he has approved the standards

or not,from manufacturing, marketing, purchasing, or using products, processes, or

procedures not conforming to the standards.

The American National Standards Institute does not develop standards and will in

no circumstances give an interpretation of any American National Standard.

Moreover, no person shall have the right or authority to issue an interpretation

of an

American National Standard in the name of the American National Standards

Institute. Requests for interpretations shall be addressed to the secretariat or

sponsor whose name appears on the title page of this standard.

CAUTION NOTICE: This American National Standard may be revised or withdrawn

at any time. The procedures of the American National Standards Institute require

or withdraw this standard no later than five

that action be taken to reaffirm, revise,

years from the dateof approval. Purchasers of American National Standards may

receive current information on all standards by calling or writing

the American

National Standards Institute.

Published by

National Electrical Manufacturers Association

1300 N. 17th Street, Rosslyn, Virginia 22209

CopyrightO 2000 National Electrical Manufacturers Association

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

All rights reserved.

No patt of this publication maybe reproduced in any

form, in an electronic retrieval

system or otherwise,

without prior written permission of the publisher.

Printed in the United States of America

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

Foreword (This Foreword is not part of American National Standard C3750-1989.)

This standardwas first published in 1973 as a replacement for Section9 (Test Require-

ments) of American National Standard forLow-Voltage AC Power Circuit Breakers (600-

Volt Insulation Class), ANSI C37.13-1969. In 1975 a supplement, American National

Standard Test Procedures forLow-Voltage AC Integrally Fused Power Circuit Breakers,

ANSI C37.50a-1975, was published as a replacement for Section8 (Test Requirements)

of ANSI C37.28-1969 and Section8 of ANSI C37.13a-1975. The contentsof ANSI

C37.50-1973 and C37.50a-1975 were combined in ANSI C37.50-1981 in accordance

with the IEEE Low-Voltage Switchgear Devices Subcommittee revision and combination

of ANSI C37.13-1969 andANSI C37.13a-1975 into ANSIIIEEE C37.13-1981. This

(1 989)revision of the 1981 standardwas developed t o clarify miscellaneous areas of

interpretation within the document.

This standard was originally written as a description of design test requirements andthe

performance criteria outlinedestablished the basis for certification of low voltage ac-

power circuit breakersused in enclosures for use in nonutility installations subject to

regulation by public authorities and similar agencies concerned withlaws, ordinances,

regulations, administrative orders,and similar instruments. It was established as a sepa-

rate document to facilitate its use by test laboratories and itstimely revision based on

experience. This revision supports that original proposition.

Experience has also indicated that there have been misinterpretations regarding the

testing requirements for fielddesign-change modifications. This has resulted in circuit

breaker modifications by manufacturers other than the original manufacturer without

sufficient testingto properly recertify themodified products. Any change to a basic

design should be coordinated with theoriginal manufacturer. Otherwise, the original

certifcation responsibility cannotbe continued.

This revision was prepared by the NEMA Power Switchgear Assemblies, Low-and

Medium-Voltage Power Circuit Breaker, Medium-Voltage Load-Interrupter Switches

Technical Committee,NEMA/SG/V, which has assumed responsibility for its maintenance.

Suggestions for improvement ofthisstandard will be welcome. They shouldbe sent to:

NationalElectricalManufacturersAssociation, 2101 L Street, W ,Washington, IX 20037.

The standard wasprocessed and approved for submittal t o ANSI by Accredited Standards

Committee on Power Switchgear, C37. Committee approvalof the standard doesnot nec-

essarily imply that all Committee members voted for its approval. At the time it approved

t h i s standard, the C37 Committeehad the following members:

W.E. Laubach, Chair

A. K. McCabe, Executive Vice-Chair, HV Standards

S.H. Telander, Executive Vice-Chair, LV Standards

D. L. Swindler, Executive ViceChair, IEC Activities

C. H. White, Secretary

M. B. Williams, Program Administrator

Organizations Represented Name of Representative

Association of Iron and Steel Engineers ...................... J. M. T han

Electric Lght and Power Group. . . . . . . . . . . . . . . . . . . . . . . . . . . .R. L. Capra (Chair)

M. J. Eckelkamp

K. D. Hendrix

J. H. Provanzana

D. E. Soffrin

D. T. Weston

G. R. Brandenberger (Alt)

T. E. Bru& (Alt)

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

Organization Represented Name of Representative

Institute of Electrical and Electronics Engineers ................. H.W.Mikulecky, Chair

R. W. Haas

W. F. Hoenigmann

D. M. Larson

E.W. Schmunk

C. A. Schwable

S. C. Atkiison (Alt)

D. G. Kumbera (Alt)

National Electrical Manufacturers Association . . . . . . . . . . . . . . . . . . R. A. McMaster (Chair)

T. C. Burtnett

R. H. Miller

R.O. D. Whitt

H.L. Miller (Alt)

Tennessee Valley Authority ............................. R. B. Rotton

Testing Laboratory Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L. Frier

W. T. O'Grady

R. W. Seelbach (Alt)

U.S. Department of Agriculture,

Rural ElectrZcation Administration. ...................... H. L. Bowles

U.S. Department of the A m y ,

Office of the Chief of Engineers ......................... W. M. Jones

US. Department of the Interior,

of Bureau Reclamation. .............................. J. W. Reif

U.S. Department of theNavy,

Naval Construction Battalion Center. ...................... R. L. Clark

Western Area PowerAdminstration. . . . . . . . . . . . . . . . . . . . . . . . . G. D. Birney

The Power Switchgear Assemblies, Low- and Medium-Voltage Circuit Breaker, Medium-

Voltage Load-InterrupterSwitches Technical Committee(NEMA/SG/V) of the NEMA

Switchgear Section, which developed this standard, had the following members:

S. H. Telander, Chair P. Clickner

C. White, Secretary N. Davies

H. Keating

W.Laubach

S. Roberts

T. Robirds

G. Sakats

D.Swindler

A. Tomeo

C. Welter

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

STD.NEMA C37-50-ENGL L989 m b470247 052413b O09 m

Contents SECTION PAGE

1.General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Sc0pe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 References to American National Standards . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 . General Test Conditions and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 . Design Test Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Specific TestRequirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 TestConditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Trip-Device Calibration Check Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 AC Dielectric Withstand-Voltage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 ContinuousCurrent Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Overload Switching Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.8 Endurance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.9 Short-circuitCurrent Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.10 Short-Time Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 . Accessory Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Alarm and Auxiliary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Undervoltage Trip Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Mechanical Accessory Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 . Treatment of Failures within Test Sequences ............................. 19

6 . Production Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Control, Secondary Wiring, and Devices Check Test . . . . . . . . . . . . . . . . . . . . . 19

6.4 AC Dielectric Withstand Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.5 No-Load Operation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.6 Open-Fuse Trip Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 . Production Monitoring and Product Retest Requirements . . . . . . . . . . . . . . . . . . . . . 20

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Production Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3 ProductRetestRequirements ................................... 20

Tables

Test Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Table 1 9

Table 2 Copper Conductors for Use in Continuous-Current Tests . . . . . . . . . . . . . . . . 11

Table 3 Short-circuit Current Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4 Overload TestConditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 5 Endurance Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6 Retest Series (Unfused Breakers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix Guide for Methods of Power-Factor Measurement

for Low-Voltage Test Circuits .................................. 23

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

-

S T D * N E M A C37-50-ENGL L989 b 4 7 0 2 4 7 0524377 T 4 5 m

American National Standard

for Switchgear -

Low-Voltage AC Power Circuit Breakers

Used in Enclosures -

Test Procedures

This standard constitutes Section 9of American National Standard forLow-Voltage AC Power Circuit Breakers Used

in Enclosures, ANSI/IEEE C37.13-1981.

1 . General ANSI/IEEE C37.09-1979 (R1989),Test Procedure for

AC High-Voltage Circuit Breakers Rated on a Symmet-

1.1 Scope. This standard covers the test procedures rical Current Basis

for enclosed low-voltage ac power circuit breakers as

follows: ANSI/IEEE C37.13-1981, Low-Voltage AC Power

Circuit BreakersUsed in Enclosures

(1) Stationary or drawout circuit breakers of two-

or three-pole construction, withone or more rated ANSI/IEEE C37.26-1972 (R1978), Guide for Methods

maximum voltages of 635 (600 for units incorporating of Power-Factor Measurement for Low-Voltage Induc-

fuses), 508, and 254 V for application on systemshav- tive Test Circuits(see Appendix)

ing nominalvoltages of 600,480, and 250 V.

(2) (a) Unfused circuit breakers ANSI/UL 198C-1986, High Interrupting-Capacity

(b) Fused circuit breakers Fueses, Current-Limiting Types

(3) Manually operated or power-operated circuit

breakers withor withoutelectromechanical or solid-

state trip devices.

2. General Test Conditions and Requirements

NOTE: In this standard the words “circuit breaker” shall mean

“enclosed low-voltage ac power circuit breaker,” either fused The conditions prevailing at the test site during tests

or unfused. The words ‘bfused circuit breaker’’ shall mean

a “circuit breaker without integral fuses” and the words “fused on circuit breakersshall be as stated in Section 2 of

circuit breaker” shall mean a “circuit breaker incorporating ANSI/IEEE C37.13-198 1, except that continuous-

current-limiting fuses as an integral part of the unit.” current testsand trip-device calibration checktests

shall be conducted at an ambient air temperature be-

1.2 Referenced American National Standards. This tween 10°C (50°F) and 40°C (104°F).

standard is intended for use with thefollowing Ameri-

can National Standards.When these standards are super-

seded by a revision approved by theAmerican National

3. Design Test Requirements

Standards Institute, Inc, therevision shall apply.

ANSI C37.16-1988, Switchgear - Low-Voltage Power 3.1 General. Design tests are performed on representa-

Circuit Breakers and AC Power Circuit Protectors - tive circuit breakers to demonstrate the capability of a

Preferred Ratings, Related Requirements, andAppli- particular frame size of a circuit breaker to meet its

cation Recommendations assigned ratings andto operate under service conditions

given in Section 2 of ANSI/IEEE C37.13-1981.

ANSI C37.17-1979 (R1988), TripDevices for AC and

Although the tests described in this standard cover

General-Purpose DC Low-Voltage Power Circuit

the performance of completelow-voltage power circuit

Breakers

breakers, it should be recognized that they may not

ANSIlIEEE 4-1982, Techniques forHigh-Voltage cover some of the component parts of circuit breakers

Testing such as wire, insulation materials, and the like. Addi-

7

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

S T D * N E M A C37.50-ENGL 1989

AMERICAN NATIONAL STANDARDC37.50-1989

tional evaluation in accordance with applicable stan- 3.3 Test Conditions

dards covering these components maybe necessary. 3.3.1 Test Enclosure. All tests listed in 3.2, with

When major design changes (such as contact struc- the exception of the trip-device calibration check test

ture) are made, a complete sequence retest shall be and the ac dielectric withstand-voltage test,shall be

made. Minor design changes that affect only aspecific made with a drawout circuit breakerin its test enclo-

area shall be retested within theapplicable sequence sure.

(for example, an electrical operator change needs only The test enclosure for circuit breakersof a particular

an endurance test, or an arc chute change needs only frame size shall be the minimum-dimension single-unit

an interrupting test). enclosure with the smallest electricalspacings recom-

mended by the manufacturer and with enclosure ter-

3.2 Specific Test Requirements minals exposed to the ambient air. The manufacturer’s

3.2.1 Test Requirements for Unfused Circuit test enclosure description shall include minimum clear-

Breakers. Each circuit breaker frame size, including ance t o ground, location of ventilationopenings and

functional components as listed in Table 1 of ANSI/ their effective area, total enclosure dimensions, and

IEEE C37.13-1981 and accessory devices as givenin configuration of connections for the enclosure terminals.

Section 4 of this standard, with which it is equipped, 3.3.2 Circuit Breakers Using Only One Type of

shall successfully complete all of the following tests, Trip Device. Circuit breakers that are designed to be

utilizing the applicable sequences as outlined in Table l equipped only with solid-state, direct-acting trip de-

of this standard. vices (or only electromechanicaldevices) shall be com-

(1) Trip-device calibration check test (see 3.4) pletely tested in accordance with the test sequences

(2) AC dielectric withstand-voltage test (see 3.5) given in Table 1;that is, test sequencesI-IV for unfused

(3) Continuous-current test (see 3.6) circuit breakers andthe additional test sequence V for

(4) Overload switching test (see 3.7) fused circuit breakers.

(5) Endurance tests (see 3.8) 3.3.3 Circuit BreakersUsing More than One Type

(6) Short-circuit current tests (see 3.9) of Trip Device. Circuit breakers that are designed t o be

(7) Short-time current test (see 3.10) equipped with morethan one type of direct-acting trip

device, either electromechanical or solid-state, shallbe

NOTE: Where there is close similaritybetween frame size de- tested in accordance with the requirementsgiven in

s i g n s or where duplicate ratings (such as shortcircuit current)

exist, certain tests may be combined in order to obviate dupli- 3.3.3.1,3.3.3.2, and 3.3.3.3.

cate testing. 3.3.3.1 Each circuit-breaker frame size, with the

3.2.2 Test Requirementsfor Fused CircuitBreakers.

electromechanical trip device installed, shall be tested

The circuit breaker elementof the fused circuit breaker for all applicable tests in accordance with the test

shall have met the test requirements of3.2.1 for un- sequences I, II, III, and IV of Table 1.

fused circuit breakers.Each fused circuit breaker frame NOTE: Contingent upon review of construction differences

between circuit breakers using alternate tripping devices, test 3

size shall be equipped with direct-acting tripdevices of sequence II(c) may be omitted for the alternate configura-

with long-time-delay and instantaneous elements. The tions, based on successful testing of one of theconfigurations.

trip device may be either electromechanicalor solid-

3.3.3.2 Each circuit-breaker frame size, with the

state as required by the circuit-breakerdesign except

solid-state trip device installed, shall be tested in accor-

that when the circuit breakerdesign will accept either

type, the solid-state typeshall be used. When power dance with test sequenceII given in Table 1, except

and manually operated fused circuit breakers have that under (c), only short-circuit current test 3 needbe

performed.

storedenergy closing mechanisms that differ only in

When the basic design of the solid-state trip device

the means of supplying the energy to be stored, the

does not vary substantially between framesizes, the

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

sequence of tests shall be performed as outlined on the

required tests just mentioned need be performed only

power-operated fused circuit breaker only.

When a manually operatedfused circuit breakeris

cn the 1600-and 3000/320Oampere frame sizes.

3.3.3.3 Each fused circuit breaker frame size

not essentiallythe same as the power-operated fused

shall be equipped with a solid-state tripdevice and shall

circuit breaker or does not have any power-operated

be tested in accordance with sequence Vof Table 1.

equivalent, all test sequences shall also be performed

on the manually operatedfused circuit breaker.

The fused circuit breakershall be equipped with the 3.4 TripDevice Calibration Check Test

functional components listed in Table 1 of ANSI/IEEE 3.4.1 Direct-Acting Overcurrent Trip Devices. Cali-

C37.13-1981 and shall complete all of the tests in bration check testsshall be made on direct-acting over-

sequence V of Table 1 of this standard. current trip devices, both before and after applicable

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

~-

STD.hJENA C37.50-ENGL L987 R b470247 0524179 ALB m

AMERICAN NATIONAL.STANDARD C37.50-1989

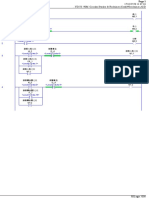

Table 1

Test Sequences

Sequence I (Power-Operated Cicuit Breaker with Selective Trip Device)

(a) TripDevice Calibration Check Test (3.4)

(b) AC Dielectric Withstand-VoltageTest (3.5)

(c) ContinuousCurrent Test (3.6)

(d) Overload Switchmg Test (3.7)

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

(e) Short-circuit Current Tests (Table 3, test 8)

(r) TripDevice Calibration Check Test (3.4)

(g) AC Dielectric Withstand-VoltageTest (3.5)

Sequence II (Power-Operated Circuit Breaker with Dual Trip Deviœ)

(a) TripDevice Calibration Check Test (3.4)

(b) AC Dielectric Withstand-Voltage Test (3.5)

(c) ShortCircuit Current Tests (Table 3, tests 1, 2.3,4,5, and 6 )

(d) TripDevice Calibration Check Test (3.4)

(e) AC Dielectric Withstand-Voltage Test (3.5)

Sequence III (PowerQperated Circuit Breaker with Dual Trip Device)

(a) TripDevice Calibration Check Test (3.4)

(b) AC Dielectric Withstand-Voltage Test (3.5)

(c) Endurance Tests (3.8)

(d) ShortCicuit Current Tests (Table 3, test 7)

(e) TripDevice Calibration Check Test (3.4)

( f ) AC Dielectric Withstand-VoltageTest (35)

Sequenœ IV (Manually Operated Circuit Breaker without Direct-Acting

Trip Device, with Shunt Trip)

(a) AC Dielectric Withstand-Voltage Test (3.5)

(b) Short-Time Current Test (3.10)

(c) ShortCircuit Current Tests (Table 3, test 8)

(d) AC Dielectric Withstand-Voltage Test (35)

Sequence V (Power4perated Fused Circuit Breaker with Dual Trip Device)

(a) TripDevice Calibration Check Test (3.4)

(b) AC Dielectric Withstand-Voltage Test (35)

(c) ContinuousCurrent Test (3.6)

(d) ShortCimit Current Tests (Table 3, tests 9, 10, 11, and 12)

(e) TripDevice Calibration Check Test (3.4)

( f ) AC Dielectric Withstand-VoltageTest (35)

NOTES: at the same instant (t 3 ms) as fault-current inception. If the

(1) Power-Operated and Manually Operated Cicuit Breakers total clearing time is 83 ms or less, short-circuit current test 1

When power-operated and manually operated circuit breakers in sequence II (c) may be omitted. In the event that an inda

have stored-energy closing mechanismsthat differ only in the pendent manually operated circuit breaker is not manufac-

means of supplying the energy to be stored, the sequence of tured in a particular frame size, this test sequence is to beper-

tests shall be performed as outlined on the power-operated cir- formed on a power-operated circuit breaker.

cuit breaker only.

When a manually operated circuit breaker is not essentially (S) Sequence V. Use one new or rebuilt circuit breaker per

the same as thepower-operated circuit breaker or does not frame size to perform as many short-circuit duty cycles per set

have any power-operated equivalent, all test sequences shall of contacts as the manufacturer chooses. Contacts and arc

also be performed on the manually operated circuit breaker. chutes may be dressed 01cleaned between short-circuit tests

(d) provided that test (f) is performed before arc chutes are

(2) Number of Samples. Use one circuit breaker per frame dressed and cleaned. The manufacturer may rebuild or provide

size, either new or rebuilt, to complete each test sequence: I, a new circuit breaker after any short-circuit test provided that

III, and N. tests (e) and (r) are performed prior to rebuilding or replacing

the circuit breaker. All tripdevice calibration check tests and

(3) Sequence II. Use one new or rebuilt circuit breaker dielectric withstand tests shall be performed on each new or

per frame size to perform as many short-circuit duty cycles per rebuilt circuit breaker.

set of contacts as the manufacturer chooses. Contacts and arc

chutes may be dressed or cleaned between short-circuit tests (6) When a rating is to bechanged subsequent to complet-

(c), provided that test (e) is performed before arc chutes are ing sequences in Table 1 only those tests needed to demon-

dressed and cleaned. The manufacturer may rebuild or provide strate thechanged rating need to be performed. For example:

a new circuit breaker after any short-circuit test provided that Increased 635-V instantaneous short-circuit rating can be

tests (d) and (e) are performed prior to rebuilding or replacing demonstrated by performing Sequence II of Table 1with short-

the circuit breaker. All tripdevice calibration check tests and circuit current tests 1 and 4 of Table 3 at theincreased rating.

dielectric withstand tests shall be performed on each new or Increased shortcircuit current ratings with selective trip d a

rebuilt circuit breaker. vices can be demonstrated by performing sequence I at the in-

creased rating.

(4) Sequence IV. The direct-acting trip device is to be Increased short-time or nonautomatic short-circuit current

made inoperative or removed ifthis is the construction used ratings (both ratings shall b e of equal value) can be demon-

when the circuit breaker is supplied without a directacting strated by performing sequence IV at thedifferent current and

trip device. For test (c), the shunt trip circuit is to be energized voltage rating.

9

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

S T D * N E M A C37.50-ENGL 1989

AMERICAN NATIONAL STANDARDC37.50-1989

test sequencesas givenin Table 1to demonstrate the sta- setting is applied to the tripdevice. The test current

bility of the tripdevices. Tests shall be conducted on shall be initiated and maintained at the testvalue for

the tripdevices usinga 60-Hz current supply ofsinu- the time necessary to establish performance criteria.

soidal wave shape at any appropriate voltage. Tests on In addition, each short-time-delay tripelement is

trip devices may be conducted with the tripdevice(s) to be tested io determine that it will not trip the cir-

removed from the circuitbreaker. cuit breaker when a currentless than the pickup setting

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Solid-state trip devices may betested as described in (minus the allowable tolerance)is applied. This current

3.4.1.lY3.4.1.2,and 3.4.1.3,or, alternatively, by apply- should not be maintained for longer than 1 second.

ing directly t o the solid-state tripdevices current or 3.4.1.4 Alternate Test Method. If the calibrating

voltage values equal to the output of the overcurrent test currents specified in3.4.1.1 and 3.4.1.3 are not

sensing device for the specified value of primary test readily available, test currents as low as 150% of the

current. The trip device shall function to open the cir- pickup setting may beused.

cuit breaker within thespecified time limits. When the

alternate method is employed, the overcurrentsensing 3.5 AC Dielectric Withstand-Voltage Test

device(s) shall be checked separatelyto verify that its 3.5.1 General. Dielectric withstand tests shall be

output is within the manufacturer’s standards. conducted on completely assembled circuit breakers,

The tripping times shall be in accordance with the including secondary control wiring, at voltages and

requirements ofANSI C37.17-1979, and the appro- under the conditions given in 3.5.2 and 3.53.

priate table depending upon whether the device is of All voltages shall be measured in accordance with

electromechanical or solid-state design, as well aswith ANSI/IEEE 4-1982. The potential shall be increased

the manufacturer’s time-current characteristiccurve gradually from zero so as to reach the required test

for the particular device. value in 5 to 10 seconds, and shall be held at that value

3.4.1.1 Long-TheDelay Trip Elements. The for 1 minute,except 3.5.2(4), which is to be a momen-

long-time-delay trip element of the direct-acting trip tary voltage test t o verify the solid-state control

device’s

device shall be set at the 100%long-time pickup setting integral surge-protection features.

and at themarked minimum time setting (band). The The test voltages shall be essentially sinusoidal and

element shall be tested once to determine the time of applied with a minimum crest value equal t o 1.414

operation by applying a test current equalto 150% times the specified values. The frequency of the test

300% of the 100% setting for electromechanical voltage shall be within *20% of the rated frequency

devices, and 200% of the 100%setting for solid-state of the circuit breakerbeing tested. If atest transformer

devices. The test current shall be initiated at the test of less than 500 VA is used, a suitable voltmeter shall

value or shall be increased from a lower value to the be provided to measure the applied output potential

test value as quickly as possible, but notlonger than directly.

5 seconds, and shall be maintained at the testvalue. 3.5.2 Test Voltages. The dielectric withstand test

3.4.1.2 Instantaneous Trip Elements.The in- voltage shall be not less than the following:

stantaneous trip elementof the direct-acting trip (1) 2200 V for the primary circuit of a new, com-

device shall be set at any marked pickup setting and pletely assembled circuit breaker.

shall be tested once t o determine that the element (2) 1500 V for secondary control wiring and con-

operates within theallowable tolerance. Compliance trol devices including current sensors and magnetic

with this requirementmay be determined by initiat- latch, except (3),(4), and (5).

ing the test current at approximately 70% of the in- (3) 1000 V for new motors.

stantaneous trip settingand quickly raising the current (4) 500 V momentary for control devices and cir-

at a uniform rate and as rapidly as consistent with an cuitry operating at 80 V ac rms (110 V dc) or less that

accurate determination of the trip value or by using a are not connected directly to theprimary circuit or ex-

symmetrical currentpulse of such magnitude and dura- ternal secondarycontrol circuits.

tion at bothlimits of the allowable tolerance that oper- (5) Twice rated voltage plus 1000 V for undervol-

ation of the trip element only within theallowable tage trip devices operating at avoltage above 250 V ac.

tolerance can be determined. (6) 60%of the values given in (l), (2), (3), (4), and

3.4.1.3 Short-TheDelay Trip Elements. The (5) after completionof any of the testsequences in

short-time-delaytrip element of the direct-acting trip Table 1.

device shall be set at any marked short-time-delay pick- 3.5.3 Points of Application of Test Voltage

up setting andat the marked maximum time setting 3.5.3.1 With the circuit breaker in theopen

(band) and shall be tested once to determine the time position, apply the primary-circuit test potential be-

of operation when a test current equalto 250% of that tween:

10

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

STDONEMA C37.50-ENGL 1989 m 6470247 0524LBL 476

AMENCAN NATIONAL STANDARD C37.50-1989

(1) The primary circuit, includingboth upper and Table 2

lower terminals, and metal partsthat are normally Copper Conductors for Use in

grounded. Continuowcurrent Tests

(2) The primary circuit and the secondary control

wiring. Bus Bars* per Terminal

Circuit-Breaker

(3) The upper terminals and lower terminals of the Frame Sie Size

primary circuit. (amperes) Quantity (inches)

For convenience, tests (1)and (2) above may be 600 1 1/4X 2 (6.35 X 50.8 mm)

combined by connecting secondary terminals to metal 800 1 1/4 x 3 (6.35 x 76.2 mm)

parts that are normally grounded. 1600 2 114 X 3 (6.35 X 76.2 mm)

2000 2 1/4 X 4 (6.35 X 101.6 mm)

3.5.3.2 With the circuit breakerin the closed 3 1/4X 5 (6.35 X 127.0 mm)

3000/3200

position, apply the primary-circuit test potentialbe- 4000 4 1/4X 5 (6.35 X 127.0 mm)

tween:

(1) The primary circuit and metal parts that are W e r e multiple bus bars are used, they are to bespaced 1/4

normally grounded. inch (6.35 mm) apart. The 4000-ampere group is to be two sets

of two bars with not more than 4 inches (101.6 mm) between

(2) The primary circuit and secondary control pair centers. When testing nonpreferred ratings above4000

wiring. amperes, the bus bar groups and sizes shouldbe adapted to the

(3) Primary terminals of different phases. particular terminal designs, and so may not necessarily have

1/4-iich spacings and may vary from4 inches maximum be-

For convenience, tests (1) and (2) above may be tween sets.

combined by connecting secondaryterminals to metal

parts that are normally grounded.

3.5.3.3 With the circuit breaker in either the a continuous-current rating equalto the fused circuit-

open or closed position, apply the secondary control breaker frame size.

wiring test potential between the secondary control 3.6.2 Duration of Test. The continuous-current

wiring terminals and metal parts thatare normally test shall be performed for such a period of time that

grounded. the temperature rise of the terminals of the test enclo-

If the circuit-breaker control circuitincludes a sure will not have increased by more than 1.O°C (1.8'F)

motor, the motormay be disconnected during the di- during each of two successive 30-minute intervalsas

electric withstand teston the control circuitand sub- indicated by three successive readings.If the tempera-

sequently tested at the potentials specified in 3.5.2(3). ture rise at the end of the second interval is equal to

Undervoltage trip devices operating at a potential the established limits and if the temperature rise has

above 250 V shall be tested separately as specified in increased since the previous reading, the test shall be

3.5.2(5). continued.

3.6.3 Method of Measuring Temperature of the Air

3.6 Continuous-Current Test Surrounding the Enclosure (Ambient). The temperature

3.6.1 General. The continuous-current test is per- of the air surrounding the enclosure (ambient) shallbe

formed to ensure that circuit breakerscan carry 100% determined by one thermometer or thermocouple hav-

of their rated continuous current at rated frequency ing a heat sink attached and placed approximately 12

within a test enclosure withoutexceeding the allow- inches (304.8mm) from the side surface of theenclo-

able temperature limits specified in Table 2 of ANSI/ sure and midway between the top and bottom of the

IEEE C37.13-1981. Circuit breakersshall be equipped enclosure.

with overcurrent trip devices havinga continuous- 3.6.4 Copper Conductors for Use in Continuous

current rating equal to the continuous-current rating Current Tests. Specifications for copper bus bars are

of the circuit-breaker frame size. The overcurrent trip given in Table 2.

device shall be prevented from opening thecircuit Configurations shall be vertical unless the design of

breaker. the test enclosure requires them to be horizontal.

See Section 4 for information concerning accessory The conductors connected to the enclosure terminals

devices. shall be a minimum of 4 feet (1.2 m) long.

Three-pole circuit breakersmay be tested using If the test enclosure terminal configuration isnot

either a three-phase circuit or single-phase circuit (all compatible with the number of bars listed in Table 2,

poles in series) at theoption of the manufacturer. then the test bussize and number may be changed to

The fused circuit breakershall be equipped with match the enclosure terminals, provided that the cross-

the minimum-rating fuse recommended by the manu- sectional area is not increased and a 1/4-inch minimum

facturer for use with an overcurrent trip device having thckness is used.

11

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMERICAN NATIONAL STANDARD C37.50-1989

If continuous current ratings other than those listed The open-circuitvoltage of the supply circuit shall

in Table 2 are tested, determine the test bussize by be not less than 100% or more than 105% of the rated

interpolation using the nearest standard bus barsizes. maximum voltage of the circuit breaker, except that a

For example, thesize for a 2500-A breaker rating is higher voltage may be employed at theoption of the

found as follows: manufacturer. The maximum fault current available

at the circuit-breaker terminalsshall not exceed the

2000A: 2 X l / 4 X 4 = 2 i n 2

rated short-circuit currentof the circuit breaker.

3000 A: 3 X 1/4 X 5 = 3.75 in2 The closed-circuit voltage as measured at the test

terminals to which the supplyside of the circuit

2500 A: 2 + (3

= 2.875 in2 breaker is connected shall be not less than 65% of the

rated maximum voltage for which the circuit breaker

3.6.5 Method of Measuring Device Temperatures. is being tested.

Thermocouples shall be used to measure the tempera- The enclosure and the frame of the circuit breaker

tures on the circuit breaker. shall be insulated from grouna and shallbe connected

Thermocouples used for measuring the temperature through a 30-ampere fuse of adequate interrupting

of insulation shall be located on the current-carrying rating to the supply side of the phase judged least

member or other metal part at a pointas close as prac- likely to strike to the enclosure. As an alternate con-

tical to the accessible junction of the insulationand the figuration, at the manufacturer's option, the 30-ampere

current-carrying member or other metal part. fuse may be replaced by a minimum No. 10 AWG cop-

Thermocouples used for measuring the temperature per wire. The configuration may be changed at any

of the test enclosure terminal connectionsand other time during the test. Metallic contact between the cir-

conducting joints shall be located approximately 112 cuit-breaker frame and the enclosureshall be considered

inch (12.7 mm) from the terminal or otherconducting a connection.

joints on the current-carrying member. 3.7.3 Rate of Operation. Rate of operation shall be

Thermocouples may be used to determine the air not less than one operation every minute for a group of

temperature of the areas within the circuit breaker five operations. Groupsof operations maybe separated

where accessory devices are mounted as a means of by intervals of up to 15 minutesmaximum.

establishing the required ambient temperature for 3.7.4 Opening of Circuit Breaker. The circuit

separate accessory device testing. breaker shall be opened by a separatelyenergized shunt

Thermocouples shall be held in intimate contact trip device.

with the conductor surface bysuch methods as weld- 3.7.5 Duration of Current. The circuit breaker shall

ing, drilling andpeening, or cementing. carry the current for not less than one cycle before

3.6.6 Performance. Circuit breakers shall be con- opening for each operation.

sidered to have passed this test if the limits of observ- 3.7.6 Number of Operations. Circuit breakers in

able temperature rise specified in Table 2 of ANSIIIEEE each frame size shall make and break the circuit not

C37.13-1981 are not exceeded. less than the numberof times given in Table 3 of ANSI

C37.16-1988. For frame sizes not listed in Table 3, the

tests shall be conducted based on the values specified

3.7 Overload Switching Test for the next-lower preferredframe-size rating.

3.7.1 General. The overload switching test shall be

3.7.7 Performance. At the conclusion of this test,

performed at notless than the rated maximum voltage,

any rated control voltage, and at a current level no less the circuit breaker shall be in a condition to continue

than 600% of rated continuous current of the circuit- the applicable test sequence without repair or replace-

breaker frame size. ment of parts, and thegrounding means (eitherwire or

3.7.2 Test Circuit. The three-phase test circuitshall fuse) mentioned in 3.7.2 shall not have opened.

have a maximum power factor of 50% lagging with X 3.8 Endurance Tests

and R in series connection. The frequencyof the test 3.8.1 General. All endurance tests shall be per-

circuit shall be 60 Hz k 20%.The power factor shall be formed on the same circuit breaker to determine com-

determined in accordance withANSI/IEEE C37.26- pliance with specified mechanical and electrical require-

1972.' ments as givenin Table 4 of ANSI C37.16-1988. Ser-

vicing shall be permitted at the intervalsgiven in the

table.

'ANSIlEEE C37.26-1972has been withdrawn as an Ameri- For frame sizes not listed h Table 4, the testsshall

can National Standard (pending review or reaffirmation), but

is reproduced in the Appendix to aid in the completion of the be conducted based on thevalues specified for the next-

requirements of ANSI C3750-1989. lower preferred frame-size rating.

12

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMERICAN NATIONAL STANDARD C37.50-1989

3.8.1.1 Power-operated circuit breakersshdl be and enclosure shall be considered a connection.

subjected to all endurance tests. For circuit breakers forwhich the overload switch-

3.8.1.2 Manually operated circuit breakers hav- ing test is required, the 30-ampere fuse or alternate

ing storedenergy mechanisms that differ from the ground connection may be omitted.

power-operated equivalent only in the means of sup- 3.8.4 Mechanical Endurance Test. Themechanical

plying the energy to be stored need not be subjected endurance test shall be performed at no load and at

to endurance tests. any rated control voltage.

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

3.8.1.3 Manually operated circuit breakers,not 3.8.5 Performance. At the conclusion of these tests,

essentially the same as power-operated circuit breakers the circuit breakers shall be in a condition to continue

or not having any power-operated equivalent,shall be the applicable test sequence without repair or replace-

subjected to all endurance tests except that thenum- ment of parts that affect short-circuit performance,

ber of mechanical endurance operations performed charging of the mechanism, opening of the breaker,

shall be 50% of the number specified in Table 4 of or closing of the breaker, and the groundingmeans

ANSI C37.16-1988. (either wire or fuse) mentioned in 3.8.3.1 shall not

3.8.2 Rate of Operation. The rate of operation shall have opened.

be one operation every 2 minutes. At the option of the 3.9 Short-circuit Current Tests

manufacturer, the ratemay be increased. During each 3.9.1 General. Short-circuit current tests as de-

operation, the circuit breakershall remain closed for scribed in 3.9.2 and given in Table 3, shall be performed

no less than 116 second. on circuit breakers to determine their abilityto close,

Due to the large total numberof operations required, carry, and interrupt currents within theirratings, and

both electrical and mechanical endurance tests may be to demonstrate that fused breakers withmaximum-

conducted in groups at the optionof the manufacturer. rated fuses will provide short-circuit interruption at

However, at least one group shall consist of not leSS current values at and above ratings given for the600-V

than 120 electrical endurance operations. system nominal voltages given in Table 1 of ANSI

3.8.3 Electrical Endurance Test. The electrical en- C37.16-1988. Short-circuit current ratingsare given in

durance test shall be performed with not less than ANSI C37.16-1988, Tables1and 2 forunfused breakers

rated continuous current,at not less than rated maxi- and Table 17 for fused breakers. For frame sizes not

mum voltage, and at any rated controlvoltage. listed in these tables, theratings shall be based on the

3.8.3.1 Test Circuit. The test circuit shall have a n e x t - m e r preferred frame-size rating or the maxi-

maximum power factor of 85% lagging with the X and mum-preferred frame-size rating, whichever is less.

R in series connection. The frequencyof the test cir-

cuit shall be 60 Hz 2 20%.The power factor shall be de- 3.9.2 Types of Tests. Typesof short-circuit current

t e h e d in accordance withANSI/IEEE C37.26-1972.' tests are described in 3.9.2.1 through 3.9.2.4.

The open-circuitvoltage of the supply circuit shall 3.9.2.1 Single-phase tests with a line-to-line volt-

be not less than 10W0 or more than 105%of the rated age not less than each rated maximum voltzge applied

maximum voltage of the circuit breaker, exceptthat a across any pole and with theavailable rms symmetrical

higher voltagemay be employed at the option of the current not less than 87%of the applicable rated three-

manufacturer. The maximum fault current available at phase short-circuit current.See Table 3, tests 4,5,and,

the circuit-breaker terminalsshall not exceed the rated 6 for unfused breakers and test 9 for fused breakers.

short-circuit currentof the circuit breaker. 3.9.2.2 Three-phase tests with a line-to-line volt-

The closed-circuit voltage as measured at the test age not less than each ratedmaximum voltage and the

terminals to which the supplyside of the circuit breaker average of the available rms symmetrical components

is connected shall be not less than 80% of therated maxi- of the available three-phase currents notless than the

mum voltagefor which the circuit breaker is being tested. applicable rated short-circuit current.See Table 3, tests

The enclosure and the frame of circuit breakers for 1, 2 , 3 , 7 , and 8 for unfused breakers and test 10 for

which the overload switching test is not required shall fused breakers.

be insulated from ground and connectedthrough a 30- 3.9.2.3 For fused breakers, a three-phase test

ampere fuse of adequate interrupting ratingto the sup- with a line-to-line voltage not less than rated maximum

ply side of the phase judged least likely t o strike to voltage and the average of the available rrns symmetrical

the enclosure. As an alternate configuration, at the components of the available three-phase currents be-

manufacturer's option, the 30-ampere fuse may be re- tween 90% and 100% of the rated short-circuit current

placed by a minimum No. 10 AWG copper .wire. The values given for the 600-V system nominal voltages of

configuration may be changed at any time during the the circuit-breaker elementas listed in Table 1 of ANSI

test. Metallic contact between the circuit-breaker frame C37.16-1988. See test 11 of Table 3 of this standard.

13

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMERICAN NATIONAL STANDARD C37.50-1989

Table 3 sured one-half cycle after inception of the currentflow

Short-circuit Current Tests in the test circuit.This current shall be calculated in ac-

cordance with ANSI/IEEE C37.09-1979.

Rated

Type of Test Maximum For three-phase circuits the symmetrical-current

Test Duty Cycle (No. of Phases) Voltage Current value shall be the average of the phase currents.

1 0-15 S-C-O 3 635 Il 3.9.3.2 The power factor of the test circuit for

2 0-15 S-c-o 3 125 08 unfused circuit breakersshall be 15% lagging or less

3 0-15 S-c-o 3 254 13 (X/Rratio or 6.6 or greater) withX and R in series

4 0-15 S-c-o 1 635 0.8711 connection. Any reactor used in the test circuitshall

5 0-15 S-c-o 508 0.8712

6 0-15 S-C-O 0.8713254 be an air-core reactor. The power factor for fusedcir-

7 0 635 Il cuit breakers shall be 20% lagging or less (X/Rratio of

8 0-15 S-C-O 635 18

4.9 or greater) withX and R in series connection.The

9 0 600

174 O00

10 O+t+C-O 200.000

600 power factor shal be determined in accordance with

11 o 600 See 3.9.2.3 ANSIlIEEE C37.26-1972.'

12 o 600 See 3.9.2.4

3.9.3.3 Transient current characteristicsof the

NOTES: test circuit shall be as given in 3.9.3.3.1 through

(1) O = opening operation; C-O = close-open; t = time neces- 3.9.3.3.4.

sary for the test procedures, including replacement of fuses and

resetting of the open-fuse trip device;ïl = rated short-circuit 3.9.3.3.1 For circuit breakers with instanta-

current at rated maximum voltage of 635 V;12= rated short- neous trip elements therms value of the alternating

circuit current at rated maximum voltage of 508 V ; I s = rated component of the current at the endof three cycles

short-circuit current at rated maximum voltage of 254 V (see

Table 1 of ANSI C37.16-1988;Ig = rated short-circuit current shall be not less than 90% of the value measured at

at rated maximum voltage of 635 V (see Table 2 of ANSI one-half cycle after initiation ofthe current.

C37.16-1988). 3.9.3.3.2 For unfused circuit breakers with-

(2) Tests 1 and 2 are to be performed with opposite termi- out ipstantaneous trip elements therms value of the

nals energized.(For example, if upper terminals are used for

test 1,then lower terminals are used for test 2, and vice versa.) alternating components of the current atthe end of

(3) Test 2 is to be performed in sequence II given in Table 1, 1/2 second shall be not less than 80% of the value mea-

using a circuit breaker equipped with the minimum-rated con-

tinuous-current electromechanical overcurrent trip device for

sured at one-half cycle after initiation of the current.

the circuit-breaker frame size being tested. 3.9.3.3.3 For the first opening operation

(4) Tests 4,5,and 6 may be performed on the same circuit (unfused circuit breakers) on eachduty cycle, the cur-

breaker, one test per pole. rent shall be initiated in the test circuit in such a man-

(5) For tests 9 and 10 the current is in r m s symmetrical

amperes. ner as to ensure that the peak current available would

(6) For tests 11 and 12 see the referenced sections of this be not less than 2.3 times the single-phase rms sym-

standard. metrical value for the single-phasetest and 2.3 times

(7) At the option of the manufacturer, test 11 may be

omitted if the total clearing time of the maximum fuse is equal the three-phase rms symmetrical value in one.phase

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

to or less than the minimum total clearing time of the circuit- for three-phase tests.

breaker element, at the short-circuit test current value. If the 3.9.3.3.4 For the first opening operation

circuit breaker's timecurrent characteristic data are for the

maximum clearing time, subtract 0.016 second to obtain a (fused circuit breakers) on eachduty cycle, the current

value for the minimum total clearing time of the circuit- shall be initiated in the test circuit in such a manneras

breaker element. to ensure that the peak current available would be not

less than 2.16 times the single-phase rms symmetrical

3.9.2.4 For fused breakers, a three-phase test value for the single-phase test and 2.16 times the three-

with a liw-to-linevoltage not less than rated maximum phase r m s symmetrical value in one phase for three-

voltage and the average of the available rms symmetrical phase tests.

components of the available three-phase currents equal 3.9.3.4 The test-circuit voltage prior to the in-

to approximately twice (*lo%) the rated short-circuit ception of current flow shall be not less than the rated

current values given for the 600-Vsystem nominal volt- maximum voltage for the short-circuit current rating

ages of the circuit-breaker elementas listed in Table 1 being verified.

of ANSI C37.16-1988. See test 12 of Table 3 of this 3.9.3.5 The frequency of the test circuit shall be

standard. 60 HZ-+ 20%.

3.9.3 Test Circuit Conditions 3.9.3.6 On three-phase tests, either the power

3.9.3.1 The rms symmetricalcurrent that verifies source or fault connectionsshall be grounded, but not

the short-time or the short-circuit rating shall be deter- both.

mined by calibrating the test circuit with the circuit 3.9.3.7 The power-frequency recovery voltage

breaker short-circuited or omittedand shall be mea- shall be not less than 95% of the rated maximumvolt-

14

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

S T D - N E M A C37.50-ENGL 1989

AMERICAN NATIONAL STANDARD C37.50-1989

age of the circuit breaker when testing with instanta- the opening test of a duty cycle the maximum current

neous trip elements. When testing circuit breakers with- offset shall not exist in the phase to which the fuse is

out instantaneous trip elements, therecovery voltage connected.

shall be not less than 80% of the rated maximum volt- 3.9.3.9 For single-phase testing, the test enclo-

age of the circuit breaker. sure and circuit-breaker frame shall be insulated from

The peak value of the power-frequency recovery ground and shall be connected through a 30-ampere

voltage within the first full half-cycle after clearing and fuse of adequate interrupting rating to the unused

for the next five successive p e a k s shall be not less than phase of the three-phase source. As an alternate con-

1.343 (fi X 0.95) times the rated maximum voltage of figuration, at the manufacturer’s option, the30-ampere

the circuit breaker for tests conducted with instanta- fuse may be replaced by a minimum No. 10 AWG c o p

neous tripelements; and not less than 1.131 (fi X per wire. The configuration may be changed at any

0.800) times the rated maximum voltage of the circuit time during the test.

breaker for tests conducted withoutinstantaneous trip 3.9.4 Circuit-BreakerDirect-Acting TripDevice

elements. Each of the peaks shall be displaced not Settings

more than ? 10 electrical degrees from the peaks of 3.9.4.1 Ratings and settings of unfused circuit-

the open-circuit voltage wave prior to current flow. breaker direct-acting trip devices that shall be used for

When making this comparison, it will be necessary all test sequences except sequence II(c), test 2, are spec-

to compensate for any frequencychange that may oc- ified in 3.9.4.1.1 and 3.9.4.1.2.

cur during the test.This may be done bycomparing 3.9.4.1.1 For test sequences II and III, circuit

the positions of the zero crossing points of thevoltage breakers shall be equipped with direct-acting trip de-

wave when referred t o a timing wave, before and after vices with long-time-delay and instantaneous elements.

the test. For tests performed at 60 Hz, the average of The continuous-current rating of the trip device shall

the instantaneous value of the recovery voltage of each be equal to the circuit-breaker frame size being tested.

of the first six half-cycles measured at the 45-degree The long-time-delay element’s pickup and time setting

and 135-degree points on thewave shall be not less may be set as desired by the manufacturer, but the

than 85% of ther m s value of the recovery voltage. The instantaneous settingshall be set at themarked maxi-

instantaneous value of therecovery voltage measured mum setting.

at the45-degree and 135degree points of each of the 3.9.4.1.2 For test sequence 1, circuit breakers

first six half-cycles shall be not less than 75% of the shall be equipped with direct-acting trip devices with

rms value of the recovery voltage. long-time-delay and short-time-delay trip elements. The

For tests performed at SO Hz (which are intended continuous-current rating of the tripdevices shall be

to establish a 60-Hzrating) the instantaneous value of equal to the circuit-breaker frame size being tested.

recovery voltage measured at the 45degree and 135- The long-timedelay element’s pickup and time setting

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

degree points of each of the first six half-cycles may be set as desired by the manufacturer, but the

shall be not less than 90% of the rms value of the short-timedelay elementshall be set at the marked

recovery voltage. maximum pickup setting andmaximum time setting.

If, in a test circuit that employs secondary closing, 3.9.4.2 Ratings and setting of unfused circuit-

there is no attenuation of phase displacement of the breaker direct-acting trip devices that shall be used for

first full cycle of the recovery-voltage wave when com- test sequence II(c), test 2, to demonstrate withstand-

pared with the open-circuit secondary-voltage wave ability of the minimum-rated tripdevices are specifEd

before current flows, the detailed measurement of the in 3.9.4.2.1 and 3.9.4.2.2.

recovery-voltage characteristics indicated in the preced- 3.9.4.2.1 The circuit breakers shall be

ing paragraphs is not required. equipped with direct-acting trip devices with long-time-

3.9.3.8 For three-phase testing, the enclosure delay and instantaneous tripelements. The continuous

and the frame of the circuit breaker shall be insulated rating of the trip device shall be the minimum continu-

from ground andshall be connected through a 30-am- ous-current rating at 480 V for the circuit-breaker

pere fuse of adequate interrupting rating to the line frame size being tested. The long-time-delay element’s

side of the phase judged least likely to strike to the pickup and time setting may be set as desired by the

enclosure. As an alternate configuration, at the manu- manufacturer, but the instantaneous element shall be

facturer’s option, the 30-ampere fuse may be replaced set at the marked maximum pickup setting.

by a minimum No. 10 AWG copper wire. The configu- 3.9.4.2.2 Where no change of the integral

ration may be changed at any time during the test. series conductor is involved, only the maximum rating

Metallic contact between the circuit breaker frame and of the frame size need be checked as stated in 3.9.4.1 .l.

the enclosure shall be considered a connection. During However, for solid-state trip devices, t h e lowest-ratio

15

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMERICAN NATIONAL STANDARD C37.50-1989

current-transformer (sensor) shall be used. front of the circuit-breaker enclosure andshall be lo-

3.9.43 For solid-statetrip devices an additional cated 1 inch (25.4 mm) from, and parallel to, the front

interrupting test (not requiredto be part of Sequence I) door of the circuit-breakerenclosure. The cheesecloth

shall be conducted as indicated in Table 3, Test 8, with may be displaced as necessary to accommodate projec-

the lowest-ratio current-transformer (sensor), short time- tions such as handles.

delay element setat maximum pickup and maximum 3.9.8 Performance

time-delay, to demonstrate the thermal capabilityof the 3.9.8.1 The unfused circuit breaker at the con-

solid-state trip-device system with themaximum energy clusion of each test shall be in a condition to continue

input during Test Duty Cycle 8. If the actual energy the applicable test sequence without repair or replace-

input to thetrip device at another voltage rating is ment of parts, except as permitted in Note 3 of Table 1,

greater than 635 volts,the test shall be conducted at and the emission indicators shall not have ignited.

that rating. This test is requiredfor solid-state trip de- Scorching of the cheesecloth shall not be considered as

vice qualification and is in addition to Table l . After ignition. The groundingmeans (either wire or fuse)

this test the tripdevice shall be in a conditionto con- mentionedin 3.9.3.8 and 3.9.3.9 shallnot have opened.

tinue any test without repair or replacementparts. of 3.9.8.2 The fused circuit breaker at the conclu-

3.9.4.4 Fused circuit breakers shall be equipped sion of each test shall be in a conditionto complete the

with direct-acting tripdevices with long-time-delay and test sequence (tests (e) and ( f ) of sequence V, Table 1)

instantaneous elements. Thelong-time-delay element’s without repairs or replacement of parts other than

pickup and time settingmay be set as desired by the the primary fuses and open-fuse trip-device trigger fuses

manufacturer, but the instantaneous settingshall be set if applicable, exceptas stated in Note5 of Table l . The

at the marked maximum setting. The continuous- emission indicator shall not have ignited. Scorchingof

current rating of the trip device shall be equal to the the cheesecloth shall not be considered as ignition. The

fused circuit-breaker framesize being tested. The fuses grounding means (either wire or fuse) mentioned in

shall be the maximum current rating supplied by the 3.9.3.8 and 3.9.3.9 shall not have opened.

manufacturer for the circuit-breakerframe size. The open-fuse trip device shall have functioned t o

3.9.4.5 When a solid-statetrip device of new de-

open the fused circuit breaker. The fusesshall show no

sign is added to existing qualified circuit breakers, the evidence of arcing on their exterior orthat molten

following testsshall be conducted : metal wasexpelled. They shall not be cracked or charred

(1) Sequence I(e) with 1600- and 3000/3200-ampere

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

and shall not have damaged the supporting means.

frame sizes 3.9.9 Making Current. A circuit breaker’s making-

(2) Sequence II(c), Table 3, Test 2, with 1600- and current capability is demonstrated by its ability to pass

3000/3200ampere frame sizes the three-phase short-circuit current duty cycle test de-

(3) Maximum energy input as indicatedin 3.9.4.3 scribed in 3.9.5.

Each test may be conducted on aseparate tripde- 3.9.10 Latching Current. Latching-current capabil-

vice. After these tests the trip devices shall be in a con- ity (for a circuit breakernot equipped with an instanta-

dition to continue any test sequence withoutrepairs or neous phase trip element) is demonstratedby theabil-

replacement of parts. ity of the circuit breakert o pass the three-phase short-

3.9.5 Short-Circuit CurrentDuty Cycle. Each duty circuit current duty-cycle testdescribed in 3.9.5.

cycle shall consist of an opening operation followed by

an interval as specified in Table 3 followed by a close- 3.1O Short-Time Current Test

open operation. When short-time-delay trippingdevices 3.10.1 General. The short-time current test shall be

are used, the tripping on each openingshall be delayed performed to verify the ability of the circuit breakerto

by these trippingdevices, except when equipped with perform a short-time current duty cycle at its rated

instantaneous tripping elements effective only during available short-time current and any rated maximum

closing. voltage when applied without direct-acting trip devices

3.9.6 Test Procedure.The circuit breaker shall be (as described in Table 1, Note 4). See Table 2 of ANSI

inserted into the test circuit and the designated short- C37.16-1988. For frame sizes not listed in C37.16-

circuit current tests performed (see Tables 1 and 3). 1988, the ratings shall be based on the next-lower pre-

3.9.7 Emission Indicators for ShortCircuitCurrent ferred frame-size rating.

Tests. An indicator consisting of three layers of cheese- 3.10.2 Test Circuit. The test circuit shall conform

cloth shall be employed to detect any excessive emis- to the requirements given in 3.9.3. A three-pole circuit

sion of flame, hot gases, or molten particlesduring the breaker shall be tested using a three-phase circuit.

short-circuit current test. The cheesecloth shall be 3.10.3 Test Procedure. The circuit breaker shall be

loosely stretched on a frame at least as large as the inserted inthe test circuit,placed in the closed position,

16

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMENCAN NATIONAL STANDARD C37.50-1989

and tested in accordance with test (b) of sequence IV, (1) The maximum number ofswitches that can be

Table1. installed.

3.10.4 Short-Time Current Duty Cycle. The duty ( 2 ) Those switches that controlexternal circuits

cycle shall consist of two periods of 112 second each, and are normally closed when the circuit breaker is

with a 15-second interval of zero current between the closed carrying 50% of their rated continuous current.

112-second periods. (3) Those switches used in the internal control of a

3.10.5 Performance. After a short-time current circuit breaker energized and carrying normal continu-

duty cycle, the circuit breaker shall be in a condition to ous control currents.

continue the test sequence without repairs or replace- Rated continuous currentof a switch rated only in

ment of parts. inductive amperes is the highest rated inductive current

listed.

4.2.2 Overload Test. Alarm and auxiliary swiiches

4. Accessory Devices shall be subjected to an overload test of 50 operations.

4.1 General. Accessory devices, as contrasted with The rate of operation shall be in accordance with 3.7.3.

functional components, are those devices that are not For an alarm switch, this test shall also be proof of the

basically required for proper operation of a circuit endurance capability of the switch.The appropriate

breaker but perform a secondary or minor function as test(s) shall be selected from Table4.

an adjunct or refinement to theprimary function of 4.2.2.1 Performance. At the conclusion of the

the circuit breaker. overload test, an alarm switch shall be capable of mak-

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Functional components are parts of the circuit ing and breaking the test circuit without repairs or re-

breaker required during sequential testing, as outlined placement of parts and shall withstand the dielectric

in 3.3.2, and successful operation of those components test.

throughout all the test sequences shall constitute suffi- An auxiliary switch shall be in a condition to con-

cient proof of theirdesign and that no further testing tinue with the endurance test.

of them is necessary. 4.2.3 Endurance Test - Auxiliary Switch. An auxil-

Available electrical accessory devices, including iary switch that has completed the overload test shall

alarm and auxiliary switches and undervoltage trip be subjectedto thenumber of electrical and mechanical

devices, shall be operationally tested. An accessory de- operations specified in 3.8.1 and at the rate of opera-

vice shall be mounted in its normal place on the circuit tion given in 3.8.2. The endurance test on theauxiliary

breaker during the applicable testing sequence when its’ witch may be performed in conjunction with the en-

installation or operation may affect the performance durance test performed on the circuit breaker. When

of the circuit breaker or if the circuit breaker may af- the design of an auxiliary switch is common to more

fect the operation of the accessory. Servicing of func- than one frame size of circuit breaker; the test may be

tional componentsand accessory devices by cleaning, made only in conjunction with the endurance test of

adjusting, or repositioning the contacts shall be per- the smallest frame size, at the option of the rnanufac-

mitted at theintervals specified in Table 4 of ANSI turer. The appropriate test(s) shall be selected from

C37.16-1988 and in accordance with themanufac- Table 5 .

4.2.3.1 Performance. At the conclusion of the

turer’s established maintenance procedures.

electrical and mechanical endurance test,the switch

4.2 Alarm and Auxiliary Switches shall be capable of making and breaking the test circuit

4.2.1 Temperature Test. An alarm or auxiliary without repairs or replacement of parts and shall with-

switch shall be subjected to a temperature test. With stand the dielectric test.

the circuit breaker and one alarm or auxiliary switch 4.3 Undervoltage Trip Devices

carrying not less than rated continuous current, the 4.3.1 General. An undervoltage trip device shall

switch shall not attain temperatures higher than those operate to open the circuit breaker at 30% or less of

permitted for the materials involved, in accordance the voltage ratings of its trip coil. It shall not operate

with Table2 of ANSI/IEEE C37.13-1981. As an alter- to open the circuit breaker at values above 60% of the

native test procedure at the manufacturer’s option, voltage ratings of its trip coil. However, an undervolt-

temperature tests may be conducted on alarmand age trip device may operate to open the circuit breaker

auxiliary switches separately mounted in an equivalent when the voltage across the trip coil is greater than

ambient temperature determined as described in 3.6.5. 30% but is 60% o r less of the voltage rating of its trip

When more than one alarm or auxiliary switch can be coil.

installed on a circuit breaker, the temperature test shall An electrically reset undervoltage trip device shall

be performed with: pick up, and a mechanically reset undervoltage trip

17

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Kellogg Brown & Root/3262700001

No reproduction or networking permitted without license from IHS Not for Resale, 10/04/2005 15:20:33 MDT

AMERICAN NATIONAL STANDARD C37.50-1989

Table 4

Overload Test Conditions

Test Conditions

Type of Assigned

Contact-Interrupting Power Factor 'ILpe of Load

Rating Voltage Current (ad @c)

assigned

None

Maximum 150%continuous 75%-80%

Resistance

of applicable rating w4wt

range*

Noninductive Maximum 100%75%-80%

assigned

Resistance

of applicable rating laggingt

range*

Inductive Maximum 100%assigned 30%-35% Electromagnet

of applicable rating laggingt

range*

*See Table 23 of ANSI C37.16-1988.

t A t the option of the manufacturer, the power factor may be lower.

Table 5

--`,`,````,,`,,,,,,`,,,,,```,`,-`-`,,`,,`,`,,`---

Endurance Test Conditions

Test Conditions

Type of Assigned

Contact-Interrupting Power Factor Type of Load

Rating Voltage Current (ad (dc)

None assigned Rated* 100%continuous 75%-80% Resistance

rating wangt

Noninductive Rated* 100%assigned 75%-80% Resistance

rating laggingt

Inductive Rated* 100%assigned 45%-50% Electromagnet

rating

*See Table 23 of ANSI C37.16-1988.

?At the optionof the manufacturer, the power factor may be lower.

device shallseal in, at 85%of rated voltage. They may (1) Energize the undervoltage trip device to 85%of

also pick up and seal in at any lower voltage greater the rated voltage of the coil.

than 30% of the voltage rating of-its tripcoil. (2) Close the circuit breaker.

4.3.2 Temperature Test. With the undervoltage trip- (3) Reduce the voltage to 60% of the rated voltage

device coil energized at the maximum voltage of the of the coil. The circuit breakershall not open above

applicable range given inTable 23 of ANSI C37.16- this voltage.

1988, the maximum temperature rise of an undervolt- (4) Reduce voltage to 30% of the rated voltage of

age trip coil shall not be higher than that permitted in the coil, The circuit breaker shall open.

Table 2 of ANSI/IEEE C37.13-1981 for the materials 4.3.4 Endurance Test. An undervoltage trip device

involved, As an alternate test procedureat themanu- shall cause the circuit breakerto trip for 10%of the