Professional Documents

Culture Documents

DTC P0106, P0107, P0108 4.13: General

Uploaded by

Keith ChoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTC P0106, P0107, P0108 4.13: General

Uploaded by

Keith ChoiCopyright:

Available Formats

7

HOME

DTC P0106, P0107, P0108 4.13

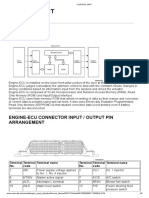

GENERAL 7351

MAP Sensor

See Figure 4-24. The manifold absolute pressure sensor

(MAP sensor) is supplied 5 volts from the ignition control

module and sends a signal back to the ignition control mod-

ule. This signal varies in accordance with engine vacuum and

atmospheric barometric pressure. Changes in barometric

pressure are influenced by weather and altitude.

Table 4-15. Code Description

DTC DESCRIPTION

P0106 MAP sensor rate-of-change error

P0107 MAP sensor failed open/low

P0108 MAP sensor failed high

Figure 4-24. MAP Sensor

DIAGNOSTICS Diagnostic Notes

The reference numbers below correlate with the circled num-

Diagnostic Tips bers on the Test 4.13 flow charts.

● DTC P0106 will set if the MAP sensor signal fluctuates 1. Connect BREAKOUT BOX (Part No. HD-42682)

faster than normal operation. between wire harness and ignition control module. See

4.6 BREAKOUT BOX: ICM.

● With the MAP sensor disconnected, the ignition control

module should recognize a low voltage. If low voltage is 2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

observed, the ignition control module and harness are 41404), gray pin probes and patch cords.

not at fault.

● Gently place a jumper wire across MAP Sensor connec-

tor [80B] Terminals B and C using HARNESS CONNEC-

TOR TEST KIT (Part No. HD-41404), gray male probes

and patch cord. With the jumper in place, the ignition

control module should recognize a high voltage.

● MAP sensor output check. Using the VACUUM PUMP

(Part No. HD-23738A), apply a vacuum to the pressure

port of the MAP sensor. The signal voltage should lower

as the vacuum is applied.

2004 Touring: Engine Management (Carbureted) 4-33

HOME

s0587a8x

Manifold

absolute

pressure

sensor

(MAP)

[80A]

[80B]

BK/W

R/W

V/W

To vehicle

speed sensor

(VSS)

BK/W

V/W

R/W

[10B]

[10A]

Sensor power

Sensor ground

MAP signal

Ignition control module

Figure 4-25. MAP Sensor Circuit

Table 4-16. Wire Harness Connectors in Figure 4-25.

NO. DESCRIPTION TYPE LOCATION

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[80] Manifold Absolute Pressure Sensor (MAP) 3 - Place Packard Top of Intake Manifold

4-34 2004 Touring: Engine Management (Carbureted)

HOME

Test 4.13 (Part 1 of 2)

MAP SENSOR: DTC P0106, P0107, P0108

With ignition ON, measure voltage

1 between Breakout Box terminal 11 (+)

and terminal 4 (-). With key ON,

engine OFF, voltage must be between

4.2 and 4.95 volts. With key ON,

engine running, voltage must be

between 1.5-3.0 volts at hot idle.

Does voltage fit specifications?

YES NO

Perform 4.7 WIGGLE TEST

to check for intermittents.

Intermittents present?

STOP

Go to Test 4.13

(Part 2 of 2).

YES NO

To identify the source of inter- Replace MAP sensor. See the Touring Ser-

mittents, start with box marked vice Manual. Clear diagnostic trouble codes.

by Bold Asterisk under Test See 4.5 SPEEDOMETER SELF DIAGNOS-

4.13 (Part 2 of 2). Wiggle har- TICS. Road test. Did check engine lamp illu-

ness while watching DVOM. minate and set Code P0106, P0107 or

YES NO

Install original MAP sensor. System

Replace ignition control module now OK.

and road test again to verify.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal pro-

gression through the chart brings

you to this location.

2004 Touring: Engine Management (Carbureted) 4-35

HOME

Test 4.13 (Part 2 of 2)

MAP SENSOR: DTC P0106, P0107, P0108

Continued from Test 4.13 (Part 1 of 2).

Check the 5 volt reference supply at

the MAP sensor connector [80B]. With

2 ignition ON, measure voltage between

terminal C (R/W) and terminal A (BK/W).

Is voltage approximately 5.0 volts?

YES NO. NO.

Greater Less

than 6V. than 4.5V.

Connect Breakout Box. Disconnect ignition

1 control module from Breakout Box.

OPEN CHECK: Measure resistance Locate short to 12 volts on R/W Disconnect ignition control module from

2 between MAP connector [80B] Terminal B wire in wire harness. Repair as

1 Breakout Box.

and Breakout Box connector [10] necessary. Check continuity between MAP connector

terminal 11. Is resistance less than 1 ohm?

2 [80B] Terminal C and Breakout Box

connector [10] terminal 3. Then measure

continuity between MAP connector [80B]

Terminal A and Breakout Box connector [10]

terminal 4.

Continuity present?

YES NO

SHORT CHECK: Measure Locate and repair

2 resistance between MAP con- open on V/W wire.

nector Terminal B and chassis

ground. Is resistance greater

than 1 meg ohm? YES NO

With MAP sensor connector Repair

[80] disconnected, check open wire.

resistance between Break-

YES NO out Box terminal 3 and 5

(black). Is it greater than 1

megohm?

Replace MAP sensor. See the Locate and repair

Touring Service Manual. grounded V/W wire.

YES NO

Replace ICM. Locate and repair

Reprogram and short between

learn password. R/W wire and

ground.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal pro-

gression through the chart brings

you to this location.

4-36 2004 Touring: Engine Management (Carbureted)

HOME

DTC P0562, P0563 4.14

GENERAL DIAGNOSTICS

Battery Voltage Diagnostic Notes

The ignition control module monitors battery positive voltage. The reference numbers below correlate with the circled num-

The normal operating range is between 8-16 volts while bers on the Test 4.14 flow charts.

engine is running.

1. Was battery allowed to discharge? Was battery drawn

NOTE down by a starting problem?

When either a diagnostic trouble code P0562 or P0563 is set, a. Yes. Charge battery.

the battery icon in the speedometer will illuminate.

b. No. See charging system troubleshooting.

● A DTC P0562 is set if the ignition module detects battery

positive voltage less than 8 volts while the engine is run- 2. Connect BREAKOUT BOX (Part No. HD-42682)

ning. between wire harness and ignition control module. See

4.6 BREAKOUT BOX: ICM.

● A DTC P0563 is set if the ignition module detects battery

positive voltage greater than 16 volts. 3. The ignition control module is monitoring voltage at igni-

tion control module connector [10] (black) Pin 1.

● Low voltage generally indicates a loose wire, corroded

4. This checks for voltage drops in the ignition control mod-

connections and/or a charging system problem.

ule circuit.

● A high voltage condition may be caused by a faulty volt-

a. Place (+) probe to battery positive terminal.

age regulator.

b. Place (-) probe to terminal 1 on Breakout Box.

Table 4-17. Code Description 5. Remove Breakout Box at ICM, reconnect ICM. Insert

Breakout Box at connector [22] (BK). On FLHR/S models

DTC DESCRIPTION (6-place connector), install Breakout Box adapters (HD-

42962).

P0562 battery voltage low

P0563 battery voltage high

2004 Touring: Engine Management (Carbureted) 4-37

HOME

R/BK To Ignition Switch Ignition Control Module

[83B]

7

A Y \ BE Rear Coil

B

6

C BE \ O Front Coil

5

15 Amp BK Ground

Ignition Fuse W

Ignition \

B

Coil K

GY

1

W \ BK Key ON Power

To TSM/TSSM

[10B] [10A]

[8A] To

1 2 3 4 5 6 7 8 9 10 11 12 [8B] Data Link

Ground Stud

[1B]

1 2 3 4 5 6 7 8 9 10 11 12

[1A]

FLHT/C Only

GY

Engine Stop Switch W \ BK

6-Place on FLHR/S

[22B]

1 2 3 4 5 6 7 8 9 10 11 12

[22A]

Figure 4-26. Battery Voltage Circuit

Table 4-18. Wire Harness Connectors in Figure 4-26.

NO. DESCRIPTION MODEL TYPE LOCATION

[1] Main to Interconnect Harness FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Bracket

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

Inner Fairing-

Interconnect to Right FLHT/C 12-Place Deutsch

[22] Right Fairing Support Brace

Handlebar Switch Controls

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

[83] Ignition Coil All 3 - Place Packard Below Fuel Tank (Left Side)

4-38 2004 Touring: Engine Management (Carbureted)

HOME

Test 4.14 (Part 1 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Perform charging system tests.

1 Charging system OK?

YES NO

2

With ignition ON, measure voltage drop Repair

between battery positive (+) terminal charging system.

3 and Breakout Box connector [10] (black)

Pin 1 (-). Is voltage drop greater

than 0.5 volt?

4

YES NO

With ignition ON, measure voltage drop Check for voltage drop between battery

5 between battery positive (+) terminal negative (-) terminal and Pin 5 (+) on

and connector [22A] Pin 4 (-). Is voltage connector [10B] (black) on Breakout Box.

drop greater than 0.5 volt? Is voltage drop greater than 0.5 volt?

YES NO YES NO

With ignition ON, measure voltage drop Repair or replace Locate and repair Problem is intermittent.

between battery positive (+) terminal W/BK wire or bad connection. Perform 4.7 WIGGLE

and connector [22A] Pin 3 (-). Is voltage terminals. TEST.

drop greater than 0.5 volt?

YES NO

Inspect connector [22] for

corrosion or loose wires. If

STOP above conditions are not

present, replace engine stop

switch.

Go to Test 4.14

(Part 2 of 2).

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (Carbureted) 4-39

HOME

Test 4.14 (Part 2 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Continued from Test 4.14 (Part 1 of 2). With

ignition ON, measure voltage drop between

battery positive (+) terminal and GY terminal

on 15 amp ignition fuse (-). Is voltage

drop greater than 0.5 volt?

YES NO

With ignition ON, measure voltage drop Repair or replace GY

between battery positive (+) terminal and wire or terminals.

R/BK terminal on 15 amp ignition fuse. Is

voltage drop greater than 0.5 volt?

YES NO

With ignition ON, measure voltage drop Replace fuse or

between battery positive (+) terminal and fuse terminals.

terminal A of maxi fuse (-).

Is voltage drop greater than 0.5 volt?

YES NO

With ignition ON, measure voltage drop Replace ignition

between battery positive (+) terminal and switch or terminals.

terminal B of maxi fuse (-).

Is voltage drop greater than 0.5 volt?

YES NO

High resistance between maxi Replace maxi fuse.

fuse and battery. Replace wire or

terminals.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-40 2004 Touring: Engine Management (Carbureted)

HOME

DTC P1009, P1010 4.15

GENERAL

Password Problem

The ICM and TSM/TSSM exchange passwords during opera-

tion. An incorrect password or missing password will set a

diagnostic code.

NOTE

If the TSM/TSSM is not connected to the wiring harness, the

vehicle will not start.

Table 4-19. Code Description

DTC DESCRIPTION

P1009 Incorrect password

P1010 Missing password Figure 4-27. TSM/TSSM

DIAGNOSTICS 6924

Diagnostic Notes 3

4

The reference numbers below correlate with the circled num-

bers on the Test 4.15 flow charts.

2

1. DTC P1009 may be set if a recent ICM or TSM/TSSM

replacement did not follow the correct password assign-

1

ment procedure. See 3.24 PASSWORD LEARN for

details.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

1. Terminal 2: ground (BK)

41404), black socket probes and patch cord.

2. Terminal 3: serial data (Lt GN/V)

3. Connect BREAKOUT BOX (Part No. HD-42682) 3. Terminal 4: power (GY)

between wire harness and ICM. See 4.6 BREAKOUT 4. Protective cap

BOX: ICM.

4. See the Touring Service Manual for TSM/TSSM replace- Figure 4-28. Data Link Connector

ment. See PASSWORD LEARNING under 3.24 PASS-

WORD LEARN for the password learning procedure.

2004 Touring: Engine Management (Carbureted) 4-41

HOME

f2208z8x

[156B] [156A]

Main to Interconnect

6 6 Harness

5 5

4 4

3 3 GY

BK

2 2 BK

LtGN/V 1 1 LtGN/V

O

1 2 3 4 5 6 7 8 9 10 11 12 [30B]

BN/GY 1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY

TSM/TSSM

[39B] GY BK

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [39A]

1 2 3 4 5 6 7 8 9 10 11 12 [8B]

Speedometer 1 2 3 4 5 6 7 8 9 10 11 12

[108B] 1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Ignition

[108A] Tachometer Harness

15A [1B] [1A]

Accessory

Fuse 1

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

2

Main to Interconnect 3

[2A] 1 2 3 4 5 6 7 8 9 10 11 12 Harness 4

[2B] 1 2 3 4 5 6 7 8 9 10 11 12

Data Link

[91A]

Main to Interconnect 15A

Harness Ignition

Fuse

LtGN/V

12

15A [10B]

Battery 12

Fuse

[10A] Ignition Control Module

Serial data

Figure 4-29. Serial Data Circuit (FLHT/C)

Table 4-20. Wire Harness Connectors in Figure 4-29.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

4-42 2004 Touring: Engine Management (Carbureted)

HOME

f2208y8x

BK GY

LtGN/V LtGN/V BK

BN/GY

O 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

1 2 3 4 5 6 7 8 9 10 11 12 BK

[39B]

1 2 3 4 5 6 7 8 9 10 11 12 [39A] GY

Speedometer

1 2 3 4 5 6 7 8 9 10 11 12 [8B] Ignition

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

15A

Battery

Fuse 15A

Accessory

Fuse 1

2

3

4

Data Link

[91A]

15A

LtGN/V

Ignition

Fuse

12

[10B]

[10A] Ignition Control Module 12

Serial data

Figure 4-30. Serial Data Circuit (FLHR/S)

Table 4-21. Wire Harness Connectors in Figure 4-30.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

2004 Touring: Engine Management (Carbureted) 4-43

HOME

Test 4.15

PASSWORD PROBLEM: DTC P1009, P1010

Which diagnostic trouble

code was set?

DTC P1009. DTC P1010.

1 Bad password. No password.

Reprogram password. Are there any

See 3.24 PASSWORD U-codes set?

4 LEARN.

DTC P1009 still exist?

YES NO YES NO

Replace TSSM and System Troubleshoot Remove ICM connector [10]. Check

4 relearn password. OK. lowest U-code. for continuity to ground at data

System OK? connector [91A] Terminal 3. 2

6701 Continuity present?

YES NO YES NO

System Repair short Check for battery voltage on Pin 3.

Reinstall original TSSM.

OK. to ground. Battery voltage present?

Replace ICM.

5 Reprogram and relearn

6702 6704

password.

6703

YES NO

Repair short Test data connector [91A] 2

to voltage. Terminal 3 against Breakout Box Pin

12 for continuity. Continuity present?

6705 3

YES NO

Inspect terminals

for damage or repair

Replace TSM/TSSM and relearn

4 password. System OK? 2 opens as necessary.

6706

YES NO

System Reinstall original TSSM.

OK. Replace ICM.

4 Reprogram and relearn

6707

password.

6708

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-44 2004 Touring: Engine Management (Carbureted)

HOME

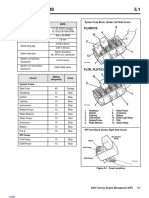

DTC P1351, P1352, P1354, P1355 4.16

GENERAL 7863

Ignition Coil

Ignition coil codes will set if the ignition coil primary voltage is

out of range. This could occur if there is an open coil or loss of

power to the coil. If front and rear codes are set simulta-

neously, it is likely a coil power failure or a coil failure.

The coil receives power from the engine run/stop switch. The

ignition control module is responsible for turning on the coils

by providing the ground to activate the coils, which in turn

powers the coils.

Table 4-22. Code Description

DTC DESCRIPTION Figure 4-31. Ignition Coil Circuit Test

P1351 Front ignition coil open/low

s0592x8x

P1352 Front ignition coil high/shorted Coil tower

P1354 Rear ignition coil open/low

P1355 Rear ignition coil high/shorted

DIAGNOSTICS

C

Diagnostic Notes B

The reference numbers below correlate with the circled num-

bers on the Test 4.16 flow charts. A

1. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probes and patch cord.

CAUTION Figure 4-32. Ignition Coil Connector Terminals

Gently connect test lamp to connector [83B]. Forcefully

inserting test lamp will result in ignition connector termi-

nal damage. 4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray socket probes and patch cord.

2. See Figure 4-31. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box. Table 4-23. Coil Terminal Description

Note that cranking the engine with test lamp in place of

the ignition coil can sometimes cause a DTC P1351, TERMINAL DESCRIPTION WIRE COLOR

P1352, P1354 or P1355. This condition is normal and

does not by itself indicate a malfunction. Codes must be A Rear coil Y/BE

cleared if this condition occurs.

B Power W/BK

3. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ICM. See 4.6 BREAKOUT C Front coil BE/O

BOX: ICM.

2004 Touring: Engine Management (Carbureted) 4-45

HOME

R/BK To Ignition Switch Ignition Control Module

[83B]

7

A Y \ BE Rear Coil

B

6

C BE \ O Front Coil

5

15 Amp BK Ground

Ignition Fuse W

Ignition \

B

Coil K

GY

1

W \ BK Key ON Power

To TSM/TSSM

[10B] [10A]

[8A] To

1 2 3 4 5 6 7 8 9 10 11 12 [8B] Data Link

Ground Stud

[1B]

1 2 3 4 5 6 7 8 9 10 11 12

[1A]

FLHT/C Only

GY

Engine Stop Switch W \ BK

6-Place on FLHR/S

[22B]

1 2 3 4 5 6 7 8 9 10 11 12

[22A]

Figure 4-33. Battery Voltage Circuit

Table 4-24. Wire Harness Connectors in Figure 4-33.

NO. DESCRIPTION MODEL TYPE LOCATION

[1] Main to Interconnect Harness FLHT/C 12-Place Deutsch Inner Fairing- Right Fairing Bracket

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch (Black) Under Right Side Cover

Inner Fairing-

Interconnect to Right FLHT/C 12-Place Deutsch

[22] Right Fairing Support Brace

Handlebar Switch Controls

FLHR/S 6-Place Deutsch Inside Headlamp Nacelle

[83] Ignition Coil All 3 - Place Packard Below Fuel Tank (Left Side)

4-46 2004 Touring: Engine Management (Carbureted)

HOME

Test 4.16 (Part 1 of 2)

IGNITION COIL: DTC P1351, P1352, P1354, P1355

Disconnect connector [83].

Measure voltage on Terminal B

of coil. Equal to battery voltage

1 after key ON?

YES NO

Use Breakout Box and test light for the

2 next inspection.

Repair open wire or

Front coil codes: Check between ICM Pin connection on W/BK wire.

3 6 and ICM Pin 1.

Rear coil codes: Check between ICM Pin

7 and ICM Pin 1.

Does test lamp flash when engine is

cranked?

YES NO

Measure coil resistance. Replace ICM.

4 Reprogram and

Front coil codes: Check between perform password learn.

coil Terminal B and Terminal C.

Rear coil codes: Check between

coil Terminal B and Terminal A.

Resistance 0.5-0.7 ohms?

YES NO

Replace coil.

STOP

Go to Test 4.16

(Part 2 of 2).

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (Carbureted) 4-47

HOME

Test 4.16 (Part 2 of 2)

IGNITION COIL: DTC P1351, P1352, P1354, P1355

Continued from Test 4.16 (Part 1 of 2).

Using Breakout Box, measure resistance between

ICM and coil terminals as follows.

DTC COIL BREAK-

TERMINAL OUT BOX

TERMINAL

P1351/ C

6

P1352 (BE/O wire)

P1353/ A

1 P1354 (Y/BE wire)

7

3 Resistance less than 0.5 ohms?

YES NO

Perform 5.8 WIGGLE TEST Repair open wire

to check for intermittents. or connection.

Intermittents present?

YES NO

Repair Check for continuity to ground.

intermittent.

Front coil codes: Check

Breakout Box Pin 6.

Rear coil codes: Check

Breakout Box Pin 7.

Continuity present?

YES NO

Repair short Check for voltage.

to ground.

Front coil codes: Check

Breakout Box Pin 6.

Rear coil codes: Check

Breakout Box Pin 7.

Voltage present?

YES NO

Repair short Replace ICM.

to voltage. Reprogram and

learn password.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-48 2004 Touring: Engine Management (Carbureted)

HOME

DTC P0373, P0374 4.17

GENERAL

f2256x8x

Crank Position Sensor

See Figure 4-34. A DTC P0373, P0374 will set if the crank-

shaft position sensor (CKP) signal is weak or absent.

Table 4-25. Code Description

DTC DESCRIPTION

P0373 Crankshaft position sensor intermittent

Crankshaft position sensor not detected or

P0374

cannot synchronize Stator

Connector [46]

Crankshaft

DIAGNOSTICS Position Sensor

Connector [79]

Under Voltage Regulator

Diagnostic Notes

Figure 4-34. Voltage Regulator (Left Side View)

1. Connect BREAKOUT BOX (Part No. HD-42682) to igni-

tion control module wire harness only, leaving ignition

control module disconnected. See 4.6 BREAKOUT BOX:

ICM.

2. One megohm is very high resistance. Some meters will

read infinity, OL, etc.

3. Use HARNESS CONNECTOR TEST KIT (Part No. D-

41404), brown socket probes and patch cords.

4. For testing purposes, install sensor without running wir-

ing along normal path. Disconnect and route wiring prop-

erly if system is now OK.

2004 Touring: Engine Management (Carbureted) 4-49

HOME

f2208w8x

Crankshaft

Position

Sensor

BK

R

[79A]

[79B] 1 2

BK

BK

R

[10B]

[10A]

Crank Sensor (+)

Module Ground

Crank Sensor (-)

Ignition Control Module

Figure 4-35. Ignition Circuit

Table 4-26. Wire Harness Connectors in Figure 4-35.

NO. DESCRIPTION TYPE LOCATION

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[79] Crankshaft Position Sensor 2 - Place Mini-Deutsch Bottom of Voltage Regulator

4-50 2004 Touring: Engine Management (Carbureted)

HOME

Test 4.17

CRANK POSITION SENSOR: DTC P0373, P0374

Leaving ICM disconnected, connect Breakout

1 Box to harness only. Measure resistance

between Pins 8 and 5, and between Pins 9 and 5

on connector [10]. Is resistance more than 1

2 megohm?

YES NO

Check for intermittent connection, pinched Disconnect connector [79]. Leaving ICM

or damaged wires, and loose CKP sensor disconnected, use Breakout Box to measure

fastener. Conditions found? resistance between Pins 8 and 5 on connector

[10]. Also measure resistance between Pins 9

and 5 on connector [10]. Is there still continuity to

ground (less than 1 megohm resistance)?

YES NO

Repair as Connect DVOM to Terminals 8 and 9 at YES NO

necessary. connector [10] on Breakout Box.

Set DVOM to AC volts and crank engine.

Does DVOM read 1 VAC minimum Repair short to Replace CKP

during cranking? ground on R or sensor.

BK wire between

connectors [10B]

and [79B].

YES NO

With DVOM still connected, check for Connect DVOM at Terminals 1

intermittents using 4.7 WIGGLE TEST. 3 and 2 of connector [79A].

Intermittents present? DVOM should read 1 VAC

minimum while cranking.

Does it?

YES NO

YES NO

Repair as Replace CKP

necessary. sensor. Clear

codes and retest. Check for continuity between Replace CKP

Code P0373, Pin 8 [10B] and Pin 1 [79B]. Is sensor.

P0374 set? continuity present?

4

YES NO

YES NO

Repair open on BK wire Repair open on R wire

Reinstall CKP System between Pin 2 [79B] and Pin 9 between Pin 1 [79B] and Pin 8

sensor. Replace OK. on connector [10B]. on connector [10B].

ICM. Reprogram

and perform pass-

word learn.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (Carbureted) 4-51

HOME

DTC P0501, P0502 4.18

GENERAL

7951

Vehicle Speed Sensor

See Figure 4-36. The vehicle speed sensor is powered and

Speed

monitored by the ICM. The ICM processes the vehicle speed Sensor

signal and transmits this signal to the TSM/TSSM and speed-

ometer through serial data.

NOTE

When the vehicle speed signal is greater than 0, the closed

loop idle speed control is inhibited.

Table 4-27. Code Description

DTC DESCRIPTION

Engine Oil Fill

P0501 VSS sensor low Plug/Dipstick

P0502 VSS sensor high/open

Figure 4-36. Vehicle Speed Sensor Location

DIAGNOSTICS

f2183x8x

Diagnostic Notes

The reference numbers below correlate with the circled num-

bers on the Test 4.18 flow charts.

1. The speedometer has a built-in diagnostic mode. See 1

4.5 SPEEDOMETER SELF DIAGNOSTICS.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black pin probe and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and ICM. See 4.6 BREAKOUT

BOX: ICM.

4. Jack up motorcycle and rotate rear wheel with transmis- 2

sion in neutral.

1. Vehicle Speed Sensor Connector [65]

2. P&A Security Siren Connector [142]

Figure 4-37. Electrical Bracket (Inboard Side)

4-52 2004 Touring: Engine Management (Carbureted)

HOME

f2208x8x

Vehicle Speed

Sensor

R A A R/W

W B B W/GN

BK C C BK/W

[65A] [65B]

W/GN

BK/W

R/W

[10B] 3 10

[10A]

Sensor Ground

5v Power

VSS

Ignition

Control

Module

Figure 4-38. Vehicle Speed Sensor Circuit

Table 4-28. Wire Harness Connectors in Figure 4-38.

NO. DESCRIPTION TYPE LOCATION

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[65] Vehicle Speed Sensor 3 - Place Deutsch Under Right Side Cover (Behind Electrical Bracket)

2004 Touring: Engine Management (Carbureted) 4-53

HOME

Test 4.18 (Part 1 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Remove and inspect vehicle speed sensor. Inspect

for debris and clean if necessary. Place speedometer

into diagnostic mode and clear ICM trouble codes.

Connect all circuits and ride motorcycle for

1 approximately 1.0 mile (1.6 km). Check for newly

logged codes. Codes present?

YES

NO

Check for continuity between socket System OK.

2 A of connector [65B] (R/W wire) and

ground. Continuity present?

YES NO

Repair short to ground. 2 Check for continuity between socket A

of connector [65B] (R/W wire) and pin 3

[10] of breakout box. Continuity

3 present?

YES NO

Check for continuity between socket C Repair open on R/W wire

of connector [65B] (BK wire) and between connectors [10B]

ground. Continuity present? and [65B].

YES NO

Repair open on BK wire

STOP between connector [65B]

and ground.

Go to. Test 4.18

(Part 2 of 2)

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-54 2004 Touring: Engine Management (Carbureted)

HOME

Test 4.18 (Part 2 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Continued from Test 4.18 (Part 1 of 2).

2

Check for continuity between socket B of connector

3 [65B] and Pin 10 [10] of breakout box. Continuity

present?

YES NO

Check for voltage on W/GN wire of connector

[65B] while connected. Meter should read 4-6 Repair open on W/GN

wire between connectors

4 volts when gear tooth absent and 0-1 volts

[10B] and [65B].

when gear tooth is present. Does it?

YES NO

Replace ICM. Reprogram

and learn password.

4-6 volts present. 4-6 volts present but no

fluctuation from 0-1 volts

Replace ICM. Reprogram Replace vehicle

and learn password. speed sensor.

2004 Touring: Engine Management (Carbureted) 4-55

HOME

DTC P0602, P0603, P0604, P0605, P0607 4.19

GENERAL DIAGNOSTICS

ICM Failure DTC P0607 Test

All of the following codes indicate an internal failure which 1. Power down the vehicle.

requires replacement of the ignition control module. See the

Touring Service Manual for replacement procedures. 2. Clear codes using speedometer self-diagnostics.

3. Replace ICM if codes reappear.

● DTC P0602 - Calibration memory error

● DTC P0603 - EE PROM failure

● DTC P0604 - RAM failure DTC P0602, P0603, P0604, P0605 Test

● DTC P0605 - Program memory error 1. Power down the vehicle.

● DTC P0607 - A to D converter error 2. Clear codes.

3. Using Digital Technician, reprogram ICM using the cor-

rect calibration. See your dealer.

4. Restart vehicle. If code reappears, replace ICM. Repro-

gram and perform password learn.

4-56 2004 Touring: Engine Management (Carbureted)

HOME

DTC U1064 4.20

GENERAL

Loss of TSM/TSSM Serial Data

The serial data connector provides a means for the ICM and

TSM/TSSM to communicate their current status. When all

operating parameters on the serial data link are within specifi-

cations, a state of health message is sent between the com-

ponents. A DTC U1064 indicates that the TSM/TSSM is not

receiving this state of health message.

Table 4-29. Code Description

DTC DESCRIPTION

U1064 Loss of TSM/TSSM serial data

Figure 4-39. TSM/TSSM

DIAGNOSTICS 6924

Diagnostic Notes 3

4

The reference numbers below correlate with the circled num-

bers on the Test 4.20 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682) as fol- 2

lows: 1

a. Mate black socket housing on Breakout Box with

speedometer connector [39] using SPEEDOMETER

HARNESS ADAPTER (Part No. HD-46601).

1. Terminal 2: ground (BK)

b. Mate black pin housing on Breakout Box with speed- 2. Terminal 3: serial data (Lt GN/V)

ometer harness connector [39B] using SPEEDOM- 3. Terminal 4: power (GY)

ETER HARNESS ADAPTER (Part No. HD-46601). 4. Protective cap

c. Mate gray socket housing on Breakout Box with

TSM/TSSM connector [30A]. Figure 4-40. Data Link Connector

d. Mate gray pin housing on Breakout Box with har-

ness connector [30B].

2004 Touring: Engine Management (Carbureted) 4-57

HOME

f2208z8x

[156B] [156A]

Main to Interconnect

6 6 Harness

5 5

4 4

3 3 GY

BK

2 2 BK

LtGN/V 1 1 LtGN/V

O

1 2 3 4 5 6 7 8 9 10 11 12 [30B]

BN/GY 1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY

TSM/TSSM

[39B] GY BK

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [39A]

1 2 3 4 5 6 7 8 9 10 11 12 [8B]

Speedometer 1 2 3 4 5 6 7 8 9 10 11 12

[108B] 1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Ignition

[108A] Tachometer Harness

15A [1B] [1A]

Accessory

Fuse 1

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

2

Main to Interconnect 3

[2A] 1 2 3 4 5 6 7 8 9 10 11 12 Harness 4

[2B] 1 2 3 4 5 6 7 8 9 10 11 12

Data Link

[91A]

Main to Interconnect 15A

Harness Ignition

Fuse

LtGN/V

12

15A [10B]

Battery 12

Fuse

[10A] Ignition Control Module

Serial data

Figure 4-41. Serial Data Circuit (FLHT/C)

Table 4-30. Wire Harness Connectors in Figure 4-41.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

4-58 2004 Touring: Engine Management (Carbureted)

HOME

f2208y8x

BK GY

LtGN/V LtGN/V BK

BN/GY

O 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

1 2 3 4 5 6 7 8 9 10 11 12 BK

[39B]

1 2 3 4 5 6 7 8 9 10 11 12 [39A] GY

Speedometer

1 2 3 4 5 6 7 8 9 10 11 12 [8B] Ignition

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

15A

Battery

Fuse 15A

Accessory

Fuse 1

2

3

4

Data Link

[91A]

15A

LtGN/V

Ignition

Fuse

12

[10B]

[10A] Ignition Control Module 12

Serial data

Figure 4-42. Serial Data Circuit (FLHR/S)

Table 4-31. Wire Harness Connectors in Figure 4-42.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

2004 Touring: Engine Management (Carbureted) 4-59

HOME

Test 4.20

LOSS OF TSM/TSSM SERIAL DATA: DTC U1064

Can you read TSM/TSSM hardware P/N?

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

NO or “No Rsp”

YES

Install Breakout Box on speedometer.

1 Install Breakout Box on speedometer. 1 Check for continuity between terminal 3

While wiggling harness, check for continuity (gray) and terminal 2 (black) of Breakout

between terminal 3 (gray) and terminal 2 Box

(black) of Breakout Box Continuity present?

Continuity present?

YES

YES NO NO

Clear trouble codes. Repair intermittent Replace TSM/TSSM. Repair open on

Test Ride. Does U1064 on LtGN/V wire. Learn password. LtGN/V wire.

return?

YES NO

Replace TSM/TSSM. No trouble found.

Perform password learn

procedure.

Clear codes using speedometer self diagnostics.

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

4-60 2004 Touring: Engine Management (Carbureted)

HOME

DTC U1097 4.21

GENERAL f2191x8x

Loss of Speedometer Serial Data

The serial data connector provides a means for the speedom-

eter, ICM and TSM/TSSM to communicate their current sta-

tus. When all operating parameters on the serial data link are

within specifications, a state of health message is sent

between the components. A DTC U1097 indicates that the

speedometer is not capable of sending this state of health

message.

Table 4-32. Code Description

DTC DESCRIPTION

Loss of all speedometer serial data

U1097 Ignition Control Module

(state of health)

Connector [10]

Figure 4-43. Electrical Bracket (Under Right Side Cover)

DIAGNOSTICS 6924

3

Diagnostic Notes 4

The reference numbers below correlate with the circled num-

bers on the 4.21 flow chart. 2

1

1. Connect BREAKOUT BOX (Part No. HD-42682)

between wire harness and speedometer using SPEED-

OMETER HARNESS ADAPTER (Part No. HD-46601).

See 2.5 BREAKOUT BOX: SPEEDOMETER. 1. Terminal 2: ground (BK)

2. Terminal 3: serial data (Lt GN/V)

2. Connect BREAKOUT BOX (Part No. HD-42682) (black) 3. Terminal 4: power (GY)

as follows: 4. Protective cap

a. Mate black socket housing on Breakout Box with

speedometer connector [39A] (at the back of the Figure 4-44. Data Link Connector

speedometer) using INSTRUMENT HARNESS

ADAPTERS (Part No. HD-46601).

b. Mate black pin housing on Breakout Box with wire

harness connector [39B] using INSTRUMENT HAR-

NESS ADAPTERS (Part No. HD-46601).

2004 Touring: Engine Management (Carbureted) 4-61

HOME

f2208z8x

[156B] [156A]

Main to Interconnect

6 6 Harness

5 5

4 4

3 3 GY

BK

2 2 BK

LtGN/V 1 1 LtGN/V

O

1 2 3 4 5 6 7 8 9 10 11 12 [30B]

BN/GY 1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY

TSM/TSSM

[39B] GY BK

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [39A]

1 2 3 4 5 6 7 8 9 10 11 12 [8B]

Speedometer 1 2 3 4 5 6 7 8 9 10 11 12

[108B] 1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Ignition

[108A] Tachometer Harness

15A [1B] [1A]

Accessory

Fuse 1

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

2

Main to Interconnect 3

[2A] 1 2 3 4 5 6 7 8 9 10 11 12 Harness 4

[2B] 1 2 3 4 5 6 7 8 9 10 11 12

Data Link

[91A]

Main to Interconnect 15A

Harness Ignition

Fuse

LtGN/V

12

15A [10B]

Battery 12

Fuse

[10A] Ignition Control Module

Serial data

Figure 4-45. Serial Data Circuit (FLHT/C)

Table 4-33. Wire Harness Connectors in Figure 4-45.

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

4-62 2004 Touring: Engine Management (Carbureted)

HOME

f2208y8x

BK GY

LtGN/V LtGN/V BK

BN/GY

O 1 2 3 4 5 6 7 8 9 10 11 12 [30B]

1 2 3 4 5 6 7 8 9 10 11 12 [30A]

BN/GY TSM/TSSM

1 2 3 4 5 6 7 8 9 10 11 12 BK

[39B]

1 2 3 4 5 6 7 8 9 10 11 12 [39A] GY

Speedometer

1 2 3 4 5 6 7 8 9 10 11 12 [8B] Ignition

1 2 3 4 5 6 7 8 9 10 11 12 [8A] Harness

15A

Battery

Fuse 15A

Accessory

Fuse 1

2

3

4

Data Link

[91A]

15A

LtGN/V

Ignition

Fuse

12

[10B]

[10A] Ignition Control Module 12

Serial data

Figure 4-46. Serial Data Circuit (FLHR/S)

Table 4-34. Wire Harness Connectors in Figure 4-46.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

[30] Turn Signal/Security Module 12-Place Deutsch

Battery Box (Under Seat)

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

2004 Touring: Engine Management (Carbureted) 4-63

HOME

Test 4.21

LOSS OF SPEEDOMETER SERIAL DATA:

DTC U1097

Can you read ECM/ICM hardware part number?

See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

YES NO or “No Rsp”

Install Breakout Box on speedometer. Install Breakout Box on speedometer. Check conti-

1 While wiggling harness, check continuity

1 nuity between terminal 2 (black) of Breakout Box

between terminal 2 (black) of Breakout and terminal 12 of connector [10B].

Box and terminal 12 of connector [10B]. Continuity present?

2 Continuity present?

2

YES NO

YES NO

Repair open on

Repair intermittent Replace speedometer. Lt GN/V wire.

Clear codes. Test ride. on LtGN/V wire.

Does DTC U1097

return?

Clear codes using speedometer self diagnostics.

YES NO See 4.5 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Replace ICM. No trouble found.

Reprogram and learn

password.

4-64 2004 Touring: Engine Management (Carbureted)

You might also like

- DTC P0107, P0108 5.19: GeneralDocument52 pagesDTC P0107, P0108 5.19: GeneralKeith ChoiNo ratings yet

- Manual Handbook Maintenance-2017Document87 pagesManual Handbook Maintenance-2017Elliza IshakNo ratings yet

- Service Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentDocument116 pagesService Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentMario Garcia100% (1)

- Air Compressors XHP 1070 and 1170 Electrical Manual PDFDocument120 pagesAir Compressors XHP 1070 and 1170 Electrical Manual PDFJean Dubois100% (2)

- E-ECU MID128 Engine Control Unit, Active Measuring ConditionsDocument5 pagesE-ECU MID128 Engine Control Unit, Active Measuring ConditionsrohmanNo ratings yet

- Service Manual For Electrical/Electronic: Portable Power P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028Document105 pagesService Manual For Electrical/Electronic: Portable Power P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028Matt SchroederNo ratings yet

- ESP CodesDocument3 pagesESP CodesAudwin CainesNo ratings yet

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Document2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"heartofdixieNo ratings yet

- Instruction Instruction Instruction Instruction Instruction: Manual Manual Manual Manual ManualDocument36 pagesInstruction Instruction Instruction Instruction Instruction: Manual Manual Manual Manual ManualadsogalletaNo ratings yet

- VR6 - Nenr2480-03Document75 pagesVR6 - Nenr2480-03PhamVan CaNo ratings yet

- Cartilla de Reparacion Corolla Negro KINALDocument10 pagesCartilla de Reparacion Corolla Negro KINALNico ArtNo ratings yet

- Manual de Uso Del Vatimetro Analogico Telewave 44ADocument21 pagesManual de Uso Del Vatimetro Analogico Telewave 44AGeovanny Merino0% (1)

- 21 FINAL TEST Bendix TXRXDocument36 pages21 FINAL TEST Bendix TXRXLeonard Edward MichaelsNo ratings yet

- RLC4PCINGDocument5 pagesRLC4PCINGKaiser IqbalNo ratings yet

- GLine Pump MS Setup W VT5041 (Rexroth 3X BFB A11-152) HPN 5577580Document12 pagesGLine Pump MS Setup W VT5041 (Rexroth 3X BFB A11-152) HPN 5577580Алексей ЧаусовNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC PO713 Transmission Fluid Temperature Sensor Circuit High InputDocument5 pagesDiagnostic Trouble Codes (DTC) : DTC PO713 Transmission Fluid Temperature Sensor Circuit High InputBROCHIERNo ratings yet

- Fast Charge Controller For Nicd/Nimh Batteries: DescriptionDocument17 pagesFast Charge Controller For Nicd/Nimh Batteries: DescriptioncorticalisNo ratings yet

- Doosan ES XP1000 Electronic Service ManualDocument123 pagesDoosan ES XP1000 Electronic Service Manualgabriel100% (1)

- Orca Share Media1670890579197 7008223039891606441Document112 pagesOrca Share Media1670890579197 7008223039891606441Joshua Jay Luton100% (1)

- Experiment No. 6 (Manifold Absolute Pressure Sensor) (MAP) : ObjectivesDocument7 pagesExperiment No. 6 (Manifold Absolute Pressure Sensor) (MAP) : ObjectivesMustafa AliNo ratings yet

- PED DIGI Um EN June02Document27 pagesPED DIGI Um EN June02Mamadou Djibril BaNo ratings yet

- Datasheet Amp Meter AutonicsDocument9 pagesDatasheet Amp Meter AutonicsArifin Jr.No ratings yet

- A-798-Z-014-0 Voltage Sensor Panel TroubleshootingDocument11 pagesA-798-Z-014-0 Voltage Sensor Panel TroubleshootingFrancisco ReyesNo ratings yet

- TMP 01Document16 pagesTMP 01flo0909rinNo ratings yet

- Pon Power AB - Service Craelius 2Document19 pagesPon Power AB - Service Craelius 2Алексей100% (1)

- Integrated Silicon Pressure Sensor Manifold Absolute Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument10 pagesIntegrated Silicon Pressure Sensor Manifold Absolute Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and Calibratedmas madNo ratings yet

- SAILOR Battery Panel BP4680Document16 pagesSAILOR Battery Panel BP4680Md Sanaul Karim ShohelNo ratings yet

- Sevice Manual For BFM8 Diesel Parte 3Document55 pagesSevice Manual For BFM8 Diesel Parte 3wilmerNo ratings yet

- Extech 380926 ManualDocument10 pagesExtech 380926 ManualRafael Jimenez PerezNo ratings yet

- User's Manual For Digital Panel Meter Quasar Class 1.0 - L & TDocument51 pagesUser's Manual For Digital Panel Meter Quasar Class 1.0 - L & TAtanu PanditNo ratings yet

- MT MZ 42PZ40!41!42 43 Chassis RF 02RA Service ManualDocument28 pagesMT MZ 42PZ40!41!42 43 Chassis RF 02RA Service ManualJamoussi MohamedNo ratings yet

- DesignCommissioningTips PDFDocument16 pagesDesignCommissioningTips PDFDon Roseller DumayaNo ratings yet

- Model 44A/AP: Broadband RF Watt MeterDocument25 pagesModel 44A/AP: Broadband RF Watt MeterAgdael DominguezNo ratings yet

- 8-101 8-117 Embrague Camioneta JMCDocument18 pages8-101 8-117 Embrague Camioneta JMCRusonegroNo ratings yet

- ARBO SA. COMMISSIONING - ARBO SE-WLS220-2,1-08 ElektronikaDocument8 pagesARBO SA. COMMISSIONING - ARBO SE-WLS220-2,1-08 ElektronikaTBF1DNo ratings yet

- Electronic Service Manual: Compressor ModelsDocument116 pagesElectronic Service Manual: Compressor ModelsAtaa AssaadNo ratings yet

- Mazda B2600 PDFDocument166 pagesMazda B2600 PDFluis sanchez100% (3)

- Manual Rapido de Variador Gk3000Document8 pagesManual Rapido de Variador Gk3000juan serranoNo ratings yet

- Service Manual: TA-FB930RDocument24 pagesService Manual: TA-FB930RMaikel Borges IglesiasNo ratings yet

- New EhtcDocument4 pagesNew EhtcRamakrishnan NatarajanNo ratings yet

- 01 MDocument2 pages01 MGuilherme ZoboliNo ratings yet

- TB6560 Mach3 CNC Stepper Motor Controller Operation InstructionDocument19 pagesTB6560 Mach3 CNC Stepper Motor Controller Operation InstructionCornel BordeiNo ratings yet

- LG Chassis MC 049a RT 29fd15Document31 pagesLG Chassis MC 049a RT 29fd15Alana Clark100% (2)

- Cupiagua CPF Time Delayed Overcurrent: Function Test CertificateDocument2 pagesCupiagua CPF Time Delayed Overcurrent: Function Test CertificatesushantNo ratings yet

- RF 4800Document16 pagesRF 4800Edgar LeonNo ratings yet

- An1643 6 CH Volume Controller Plus Sam261 Bash Amplifier StmicroelectronicsDocument7 pagesAn1643 6 CH Volume Controller Plus Sam261 Bash Amplifier StmicroelectronicsAhmad SukijoNo ratings yet

- Generators Control Panel: Service ManualDocument34 pagesGenerators Control Panel: Service Manualtopsi kretsNo ratings yet

- LG Mc049b Chassis Rz21ca85mxDocument29 pagesLG Mc049b Chassis Rz21ca85mxSeminarski RadoviNo ratings yet

- 414 DatasheetDocument4 pages414 DatasheetAhmad HamoudaNo ratings yet

- Satya Catalog 2023Document52 pagesSatya Catalog 2023Tashmeet SinghNo ratings yet

- Manual de Servicio LG 21fx5reeDocument29 pagesManual de Servicio LG 21fx5reemaoh80No ratings yet

- Frequency Inverter: 3Vfmac-Dsp 6PDocument46 pagesFrequency Inverter: 3Vfmac-Dsp 6PMartynas Karkauskas100% (4)

- PIN Out ECM L200Document3 pagesPIN Out ECM L200Norman Valle SáenzNo ratings yet

- 32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen FreeDocument12 pages32-Tap Digitally Programmable Potentiometer (DPP™) Features: Logen Freejorge gerNo ratings yet

- 6E1-12 Engine and Emission Control System (G16 / J20 Engines)Document3 pages6E1-12 Engine and Emission Control System (G16 / J20 Engines)Ronald FerminNo ratings yet

- Meter of Network Parameters Nd20 Type: User'S ManualDocument35 pagesMeter of Network Parameters Nd20 Type: User'S Manualशिवकृष्णतेजा कावूरिNo ratings yet

- Electrical Components in Circuit Diagram / Elektroteile Zum SchaltplanDocument19 pagesElectrical Components in Circuit Diagram / Elektroteile Zum SchaltplanAplesNo ratings yet

- P1 PD CompensatorsDocument13 pagesP1 PD CompensatorsxxshNo ratings yet

- Customer - EPX-Seires Service Manual Rev.E (USA) - 03 - 2017Document96 pagesCustomer - EPX-Seires Service Manual Rev.E (USA) - 03 - 2017Henry Sánchez EstradaNo ratings yet

- Specifications 5.1: FLHR/C/SDocument68 pagesSpecifications 5.1: FLHR/C/SKeith ChoiNo ratings yet

- Harley Davidson ImobilizatorDocument42 pagesHarley Davidson ImobilizatorAli NursetoNo ratings yet

- 2004 Checking For Diagnostic Trouble Codes 2.1: Check Engine LampDocument48 pages2004 Checking For Diagnostic Trouble Codes 2.1: Check Engine Lampjose fermin carrozaNo ratings yet

- Key Fob Signal To TSSM Weak or Fails 3.14: GeneralDocument42 pagesKey Fob Signal To TSSM Weak or Fails 3.14: GeneralKeith ChoiNo ratings yet

- Fe04 TCDocument2 pagesFe04 TCKeith ChoiNo ratings yet

- Fe03 TCDocument2 pagesFe03 TCjose fermin carrozaNo ratings yet

- Specifications 4.1: FLHR/SDocument32 pagesSpecifications 4.1: FLHR/Sjose fermin carrozaNo ratings yet

- Fe05 TCDocument2 pagesFe05 TCKeith ChoiNo ratings yet

- Fe02 TCDocument2 pagesFe02 TCKeith ChoiNo ratings yet

- Thermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10Document11 pagesThermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10orso brunoNo ratings yet

- (Complete) Electrolysis of Copper SulphateDocument4 pages(Complete) Electrolysis of Copper SulphateNoooooNo ratings yet

- Which Is The Best Solid Modelling - Dhyan AcademyDocument3 pagesWhich Is The Best Solid Modelling - Dhyan Academydhyanacademy engineersNo ratings yet

- Question IARDocument4 pagesQuestion IARAryan jay vermaNo ratings yet

- Activating The Standard BI ReportDocument17 pagesActivating The Standard BI ReportlearnsapbwNo ratings yet

- Bates Stamped Edited 0607 w22 QP 61Document6 pagesBates Stamped Edited 0607 w22 QP 61Krishnendu SahaNo ratings yet

- Carel MxproDocument64 pagesCarel MxproPreot Andreana CatalinNo ratings yet

- Fiberlogic CarrierEthernet 842 5300 PresentationDocument41 pagesFiberlogic CarrierEthernet 842 5300 PresentationDuong Thanh Lam0% (1)

- PPF CalculatorDocument2 pagesPPF CalculatorshashanamouliNo ratings yet

- LBX 6513DS VTMDocument4 pagesLBX 6513DS VTMsergiocuencascribNo ratings yet

- Formula Sheet: Basic Trigonometric IdentitiesDocument4 pagesFormula Sheet: Basic Trigonometric Identitieschetan temkarNo ratings yet

- Finches Statistics Student-1Document7 pagesFinches Statistics Student-1api-319172404No ratings yet

- Number System Questions PDFDocument20 pagesNumber System Questions PDFMynur RahmanNo ratings yet

- Guide-to-Proficiency-Testing-Australia 2019Document29 pagesGuide-to-Proficiency-Testing-Australia 2019ffatikatuss100% (1)

- 2018 AniketDocument60 pages2018 Aniketaniket chakiNo ratings yet

- Periodic Table and AtomsDocument5 pagesPeriodic Table and AtomsShoroff AliNo ratings yet

- Chapter 1 IntroductionDocument49 pagesChapter 1 IntroductionGemex4fshNo ratings yet

- List of GHS Hazard Statement & PictogramsDocument33 pagesList of GHS Hazard Statement & PictogramsKhairul BarsriNo ratings yet

- TitleDocument142 pagesTitleAmar PašićNo ratings yet

- Optimization of Decarbonization On Steel IndustryDocument28 pagesOptimization of Decarbonization On Steel Industrymsantosu000No ratings yet

- Power Electronics Circuits Devices and Applications by Muhammad H RashidDocument602 pagesPower Electronics Circuits Devices and Applications by Muhammad H Rashidkartik balojiNo ratings yet

- VFS1000 6000Document126 pagesVFS1000 6000krisornNo ratings yet

- CSC:361-Software Engineering: Semester: Fall2020Document39 pagesCSC:361-Software Engineering: Semester: Fall2020hamsfayyazNo ratings yet

- Wacker Neuson Light Towers LTN 6l Parts Manual 348628422Document23 pagesWacker Neuson Light Towers LTN 6l Parts Manual 348628422kellyholland180884pnc100% (61)

- An4879 Introduction To Usb Hardware and PCB Guidelines Using Stm32 Mcus StmicroelectronicsDocument26 pagesAn4879 Introduction To Usb Hardware and PCB Guidelines Using Stm32 Mcus StmicroelectronicsBulentNo ratings yet

- Flexenclosure Esite Brochure PDFDocument5 pagesFlexenclosure Esite Brochure PDFajdCruiseNo ratings yet

- Fiber SyllabusDocument1 pageFiber SyllabusPaurav NayakNo ratings yet

- Review Skills 1-8Document1 pageReview Skills 1-8TegarNo ratings yet

- CFMDocument16 pagesCFMShoaibIqbalNo ratings yet

- Factors That Affect College Students' Attitudes Toward MathematicsDocument17 pagesFactors That Affect College Students' Attitudes Toward MathematicsAnthony BernardinoNo ratings yet