Professional Documents

Culture Documents

JS 6000 Grip

JS 6000 Grip

Uploaded by

Alfonso Lopez toroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JS 6000 Grip

JS 6000 Grip

Uploaded by

Alfonso Lopez toroCopyright:

Available Formats

JS1000, JS6000

Joystick Grips

Technical

Information

520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

Revisions

Revisions Revisions

Date Page Changed Rev.

24 Jun, 2013 21 Grip Button Color Options table HA

15 Jan, 2010 25 A Grip Front Plate Diagram illustration GA

17 Dec, 2009 10 - 11 Pro grip recommendation, IP rating FA

02 Sep, 2008 Cover obsolete joystick removed, replaced with ball grip EA

04 Jan, 2008 Various Content update DA

06 Dec, 2005 9 Operating and storage temperature updated C

© 2013 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer -Danfoss reserves the right to alter its products without prior notice. This also applies to products already

ordered provided that such alterations can be made without affecting agreed specifications. All trademarks in

this material are properties of their respective owners. Sauer-Danfoss, the Sauer-Danfoss logotype, the Sauer-

Danfoss S-icon, PLUS+1™, What really matters is inside® and Know-How in Motion™ are trademarks of the Sauer-

Danfoss Group.

2 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

Contents

General Information Introduction...................................................................................................................................................... 5

JS1000, JS6000 Grip Selection Guide....................................................................................................... 5

Grip Options and Joystick Base Compatibility................................................................................ 5

Product Configuration Model Code.................................................................................................... 6

JS1000 Grips JS1000 Grip Product Configuration Model Code................................................................................. 7

PRO Grip...........................................................................................................................................................10

Product Overview....................................................................................................................................10

Model Code Nomenclature..................................................................................................................10

Specifications............................................................................................................................................10

Connector Pin Assignments.................................................................................................................11

Front Plate Model Code Designations..............................................................................................12

Dimensions................................................................................................................................................13

Grip with Rocker Switch/Grip with Banana Switch...........................................................................14

Product Overview....................................................................................................................................14

Model Code Nomenclature..................................................................................................................14

Specifications............................................................................................................................................14

Grip with Rocker Switch..............................................................................................................................15

Connector Pin Assignments.................................................................................................................15

Dimensions................................................................................................................................................15

Grip with Banana Switch............................................................................................................................16

Dimensions................................................................................................................................................16

Ball Grip.............................................................................................................................................................17

Product Overview....................................................................................................................................17

Model Code Nomenclature..................................................................................................................17

Specifications............................................................................................................................................17

Connector Pin Assignments.................................................................................................................17

Dimensions......................................................................................................................................................18

JS6000 Grips JS6000 Grip Product Configuration Model Code...............................................................................19

JS6000 Grip Function Connector Pin.....................................................................................................22

JS6000 Grip Function Connector Pin Assignments.....................................................................22

A Grip.................................................................................................................................................................23

Product Overview....................................................................................................................................23

Model Code Nomenclature..................................................................................................................23

Front Plate Model Code Designations..............................................................................................25

Rocker Switch Profiles............................................................................................................................25

Rocker Switch Specifications...............................................................................................................26

Rocker Switch Wiring Details...............................................................................................................27

Push Button Specifications...................................................................................................................28

Push Button Wiring Details...................................................................................................................28

Connector Pin Assignments.................................................................................................................29

Dimensions................................................................................................................................................32

MG Grip.............................................................................................................................................................33

Product overview.....................................................................................................................................33

Model Code Nomenclature..................................................................................................................34

Specifications............................................................................................................................................34

Connector Pin Assignments.................................................................................................................35

Switch Wiring Details..............................................................................................................................36

Dimensions................................................................................................................................................36

520L0872 • Rev HA • Jun 2013 3

JS1000, JS6000 Joystick Grips

Technical Information

Contents

JS6000 Grips HKN Grip...........................................................................................................................................................37

(continued) Product Overview....................................................................................................................................37

Model Code Nomenclature..................................................................................................................37

Specifications............................................................................................................................................37

Dimensions................................................................................................................................................37

Grip and Joystick Base Service Part Information.............................................................................................................................38

Service Parts

4 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

General Information

Introduction Sauer-Danfoss joysticks offer mobile machine product engineers a wide array of grip

designs. Each of the grip designs outlined in this document meets the demanding

conditions typically found in mobile equipment environments.

The many available grip features provide OEM engineers with options offering a high

degree of protection from chemicals, high-pressure wash, shock, vibration and EMC

exposure. Sauer-Danfoss grips are appropriate for both in-cabin and out of cabin

applications and feature ergonomic forms that minimize machine operator fatigue.

This publication provides technical information required to specify the grip portion of

JS1000 and JS6000 joysticks. Sauer-Danfoss JS1000 Joystick Base Technical Information

manual 520L0826 and JS6000 Joystick Base Technical Information manual 520L0760

provide technical information required to specify joystick bases.

JS1000, JS6000 Grip Options and Joystick Base Compatibility

Grip Selection Guide Use the following table to determine which joystick base mates with specific

Sauer-Danfoss joystick grips.

JS1000, JS6000 Grip Options and Joystick Base Compatibility

Grip functionality (maximum number)

Compatible with Proportional inputs

Grip designation JS1000 base JS6000 base Momentary switches Rocker Banana Roller Operator presence

PRO X X (6) X (2)

Grip with Rocker Switch X X (1)

Grip with Banana Switch X X (1)

Ball X

A X X (8) X (2) X (1)

MG X X (2) X (1)

HKN X

JS1000, JS6000 Joystick Grips

Grip with rocker switch/

PRO grip Grip with banana switch Ball grip

see pages 10 − 13 see pages 14 − 16 see pages 17− 18

A grip MG grip HKN grip

see pages 23 − 32 see pages 33 − 36 see page 37

520L0872 • Rev HA • Jun 2013 5

JS1000, JS6000 Joystick Grips

Technical Information

General Information

JS1000, JS6000 Product Configuration Model Code

Grip Selection Guide A product configuration model code (model code) is used to specify particular features

(continued) when ordering JS1000 or JS6000 joysticks. The model code begins with the product

family name and the remaining fields are filled in to configure the product with the

desired features.

JS1000 and JS6000 model codes contain information relating to both base features and

grip features.

6 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

JS1000 Grip JS1000 grip product configuration model code example – base part - A, B, C, D and E1

Product Configuration A B C D E F G H J

Model Code

J S1000 XY A J 331 T

1 2 3 1

A Product Family

Code Description

JS1000 JS1000 joystick base with Deutsch® connector, spring return to center

B Single or Dual Axis

Code Description

XY Dual axis function, forward and reverse with left and right, with guided axis

(force is increased in the corners)

NY Single axis function, forward and reverse

NG Dual axis function, without guided axis feel (free moving in all directions)

C Center Return Spring

Code Description

A Standard spring

B Heavy spring

D1 Electrical Interface Options D2 Joystick CAN Source Address

Code Description Code Description

J CAN with J1939 message protocol None—use with analog output

NN

S Analog voltage output (when D1=S)

33 Source address = 33 (hex)

34 Source address = 34 (hex)

D3 Joystick Output Type 35 Source address = 35 (hex)

Code Description 36 Source address = 36 (hex)

None—use with analog output

N

(when D1=S)

1 CAN full scale output = 1000 counts

E1 Grip Mounting Options

Code Description

B Bottom mount (from below the panel, no boot retainer included, boot is captured between panel

and housing) with vent plug*

C Bottom mount (from below the panel, no boot retainer included, boot is captured between panel

and housing) without vent plug*

T Top mount (from above the panel, includes boot retainer for attaching boot to joystick housing)

with vent plug*

U Top mount (from above the panel, includes boot retainer for attaching boot to joystick housing)

without vent plug*

* Vent plug is a Gore-Tex® moisture barrier. If the plug is not present, Ingress Protection below the base is unrated.

PRO grip option top mount only.

520L0872 • Rev HA • Jun 2013 7

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

JS1000 Grip JS1000 grip product configuration model code example – joystick part - E2 and F

Product Configuration A B C D E F G H J

Model Code

(continued)

J S 1 0 0 0 XY A J 3 3 1 T PRO R 3 R L

2 1 2 3 4

E2 Grip Mounting and Handle Options

Code Description

PRO PRO grip, CAN output. Complete section F, G, H, J

PR1 PRO grip, with no switch or proportional functions, CAN output.

K01 Ball grip Do not complete F, G, H, J

LSW Grip with analog rocker switch, 1.15 to 3.75 V DC range. Do not complete F, G, H, J

LSB Grip with banana switch, 1.15 to 3.75 V DC range. Do not complete F, G, H, J

PRO grip available with CAN option only. Grips with switches available with analog

option only.

F1 PRO Grip Function Layout F2 PRO Grip Function Layout

Code Description Code Number of switches on the front plate

R... Right handed grip .0.. No switches

L... Left handed grip .1.. 1 switch

.2... 2 switches

F3 PRO Grip Function Layout .3.. 3 switches

Code Type of proportional function .4.. 4 switches

..R. Roller or wheel, not sealed .5.. 5 switches

..N. None

F4 PRO Grip Function Layout

Code Position of proportional function

...N No proportional function required

Vertical proportional function on the

...R

Right-hand side

Vertical proportional function on the

...L

Left-hand side

Horizontal proportional function on the

...B

Bottom

Vertical proportional functions on both

...D

the left and the right-hand sides

Horizontal proportional functions as

...S

dual set on the top and the bottom

...T Horizontal proportional function on top

8 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

JS1000 Grip JS1000 grip product configuration model code example– joystick part - F, G, H and J

Product Configuration A B C D E F G H J

Model Code J S 1 0 0 0 X Y A J 3 3 1 T P R O R 3 R L R Y Y N R N G N

(continued)

1 2

F Grip Function Layout Examples

R0NN Right handed, 0 switches, No roller, No position R2RL Right handed, 2 switches, Roller, Left positioned

R1NN Right handed, 1 switches, No roller, No position R3RL Right handed, 3 switches, Roller, Left positioned

R2NN Right handed, 2 switches, No roller, No position R0RB Right handed, 0 switches, Roller, Bottom positioned

R3NN Right handed, 3 switches, No roller, No position R1RB Right handed, 1 switches, Roller, Bottom positioned

R4NN Right handed, 4 switches, No roller, No position R2RB Right handed, 2 switches, Roller, Bottom positioned

R5NN Right handed, 5 switches, No roller, No position R3RT Right handed, 3 switches, Roller, Top positioned

R0RR Right handed, 0 switches, Roller, Right positioned R0RD Right handed, 0 switches, 2 Roller, Dual positioned

R1RR Right handed, 1 switches, Roller, Right positioned R1RD Right handed, 1 switches, 2 Roller, Dual positioned

R2RR Right handed, 2 switches, Roller, Right positioned R0RS Right handed, 0 switches, 2 Roller, Stacked positioned

R3RR Right handed, 3 switches, Roller, Right positioned R1RS Right handed, 1 switches, 2 Roller, Stacked positioned

R0RL Right Handed, 0 switches, Roller, Left positioned R2NR Right handed, 2 switches, No roller, Right positioned

R1RL Right Handed, 1 switches, Roller, Left positioned R2NL Right handed, 2 switches, No roller, Left positioned

G1 PRO Grip Side Switch Orientation G2 PRO Grip Side Switch Color

Code Description Code Description

R. Right handed PRO Grip .R Red side switch

L. Left handed PRO Grip .Y Yellow side switch

.B Black side switch

.G Grey side switch

.N No side switch

H PRO Grip Front Plate Switch Color Selection Examples

Code Description

NNNNN No switches (diagram 0NN*)

Position 1 switch Red, position 2 switch Yellow, position 3 switch Black, position 4 switch Grey,

RYBGR

position 5 switch Red (diagram 5NN*)

YYYYY 5 Yellow switches (diagram 5NN*)

Position 1 switch Red, No position 2 switch, No position 3 switch, position 4 switch Red, position

RNNRB

5 switch Black (diagram 3NN*)

Position 1 switch Yellow, Position 2 switch Red, No position 3 switch, No position 4 switch, No

YRNNN

position 5 switch (diagram 2RL*)

* See PRO Grip front panel diagram, page 10. Number refers to button location on grip front panel. Select one

color code for each switch specified.

J Operator Presence Switch Option Not Available

Code Description

N No: operator presence switch option not selected

520L0872 • Rev HA • Jun 2013 9

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

PRO Grip

PRO Joystick Grip

Product Overview

The PRO grip is a patented ergonomic joystick grip that is designed to minimize operator

fatigue in operations requiring repetitive, precision movement over extended periods

of time. The grip is available in right and left hand versions. The profile of the PRO

grip ensures that the operators fingers are close to input functions thus maximizing

functional control. The hand rest at the base of the grip and soft feel elastomeric palm

insert contributes to a comfortable feel and provides additional protection for the

joystick boot.

A unique feature of the grip is the intelligent embedded electronics that allows joystick

input information to be multiplexed into a two-wire serial signal communicating with

base electronics. The intelligent electronics facilitate the compact design of the grip by

eliminating the need to pass large numbers of discrete wires through the joystick shaft.

The PRO grip is available with a maximum of six switch inputs or two proportional

inputs, or a mix of switch and proportional inputs.

The PRO grip is not recommended in an open cab environment.

Model Code Nomenclature

Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Grip Product Configuration Model Code, pages 7

to 9.

The PRO grip uses all portions of the model code. Other JS1000 grips use only the E2

portion of the model code.

Specifications

PRO grip switches and proportional rollers are internally wired to a microcontroller

located in grip. Grip information is included in joystick base CAN messages.

Electrical Specifications

Description Specification

Switch action Momentary

Switch type Single pole, NO

Switch mechanical life 1 million cycles

Environmental Specifications

Description Specification

Operating temperature -30°C to 75°C [-22°F to 167°F]

Storage temperature -40°C to 85°C [-40°F to 185°F]

Environmental sealing (without proportional roller) IP 43

10 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

PRO Grip Specifications (continued)

(continued)

Proportional Roller Specifications

Description Specification

Roller action Spring return to center

Roller electrical output ±1000 counts from null

Roller mechanical life 5 million cycles

Environmental sealing IP 40

Proportional rollers are not to be used in no cabin or open cabin joystick applications.

Connector Pin Assignments

PRO grips mounted on JS1000 joystick bases that have user inputs—switches,

proportional inputs or a mix of both—must use the CAN electrical output option

to transmit grip switch and proportional function information. Refer to the JS1000

Joystick Base Technical Information manual 520L0826 for grip CAN message details and

connector pin assignments.

520L0872 • Rev HA • Jun 2013 11

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

PRO Grip Front Plate Model Code Designations

(continued)

PRO Grip Front Plate Diagram

0 Prop Right Prop Left Prop Bottom/Top Prop Dual Prop Stacked Prop

0NN 0RR 0RL 0RB 0RD P4

0 switches P4 P3 P3 P4

P3

P3

0RS

1NN 1RR 1RL 1RB 1RD

3

4 P4 P3 1 P3 P4

1 switch

5 P3

5

2NN 2RR 2RL 2RB 2NR 2NL

3 2 3 2 3 2

2 switches 4 1 P4 P3

4 1 4 1

P3

3NN 3RR 3RL

3 2 P4 Front Plate Configuration Example

4 1 P4 P3

3 switches 3RT 1

4 1 4

5 5 5 5

3

4NN

3 2 Legend: P3 Position 6

4 switches Prop = Proportional function in grip

4 1

R1RB - RY

Pushbutton colors:

5NN R = Red

3 2

Y = Yellow F1 G2

5 switches B = Black

4 1 F2 G1

5 G = Grey

F3

N = None

F4

P005301E

12 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

PRO Grip Dimensions

(continued)

Pro grip dimensions in millimeters [inches].

18o REF 18o REF

18o REF 18o REF

Decreasing Increasing Decreasing

Increasing

X

[6.55 ± 0.04]

X Y

166.0 ± 1

Y

74.2 ± 0.5 DIA

[2.92 ± 0.02]

Orientation

[0.37 ± 0.02]

Feature

9.4 ± 0.5

[0.25 ± 0.02]

Ø59.4 ± 0.5

[2.1 ± 0.02]

6.35 ± 0.5

53.46 ± 0.5

[2.34 ± 0.02]

4 x Ø4.57 ± 0.05

Increasing

[0.180 ±0.002] X Pin 6

R2.0 ± 0.5

[0.08 ± 0.02]

[2.25 ± 0.005]

Increasing

57.15 ± 0.12

Decreasing

[2.75 ± 0.02]

69.85 ± 0.5

Y Y

[1.125 ± 0.005]

[1.38 ± 0.02]

34.92 ± 0.5

28.58 ± 0.12

28.58 ± 0.12

Pin 1

[1.125 ± 0.005]

57.15 ± 0.12

[2.25 ± 0.005]

34.92 ± 0.5

[1.38 ± 0.02]

69.85 ± 0.5

[2.75 ± 0.02]

Decreasing

X

P005 244E

520L0872 • Rev HA • Jun 2013 13

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

Grip with Rocker Switch/

Grip with Banana Switch

Grip with Rocker Switch Grip with Banana Switch

Product Overview

JS1000 grips with switches are intended to provide a simple, flexible and comfortable

operator control that includes a proportional input device at the top of the grip. Two

shapes are available for the proportional input device: V rocker or banana rocker. Both

grips use Hall sensing technology to detect rocker switch position.

The proportional input generates a nominal 0 to 5 Vdc signal that is used as a change of

state (switch) input.

Model Code Nomenclature

Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Grip Product Configuration Model Code, pages 7

to 9.

The grip with rocker switch and grip with banana switch are designated using only the

E2 portion of the code.

Specifications

Top Switch Electrical Specifications

Description Specification

Supply voltage 5.0 ± 0.5 Vdc

Maximum survival voltage 18 Vdc Continuous

Maximum current draw 10 mA

Output at maximum displacement 75% ± 8% of supply voltage

Output at null 50% ± 4% of supply voltage

Output at minimum displacement 23% ± 8% of supply voltage

Top Switch Environmental Specifications

Description Specification

Operating temperature -40°C to 80°C [-40°F to 175°F]

Storage temperature -40°C to 85°C [-40°F to 180°F]

EMI/RFI rating 100 V/m

Mechanical life 6 million cycles

14 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

Grip with Rocker Switch Connector Pin Assignments

Both grip-with-switch options may use either the JS1000 base analog or CAN output

option. Refer to the JS1000 Joystick Base Technical Information manual 520L0826 for grip

CAN message details and connector pin assignments.

Dimensions

Grip with rocker switch dimensions in millimeters [inches].

Decreasing

X

4X Ø 4.57 ± 0.05

[0.180 ± 0.002]

Orientation

69.85 ± 0.50 R2.03 ± 0.50 Feature

[2.75 ± 0.02] [0.08 ± 0.02]

Decreasing Increasing

Y Y

69.85 ± 0.50

[2.75 ± 0.02] Increasing

X

18˚ REF 18˚ REF

18˚ REF 18˚ REF

Decreasing Increasing Decreasing Increasing

Y Y Y Y

110.63 ± 0.50

[4.35 ± 0.02]

3.80 [0.15] Max panel

Feed-through mounting

6.35 ± 0.50 Ø 59.4 ± 0.50

[.25 ±.02] [2.34 ± 0.02]

59.60 ± 0.50

[2.35 ± 0.02]

2234A

520L0872 • Rev HA • Jun 2013 15

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

Grip with Banana Switch Dimensions

Grip with banana switch dimensions in millimeters [inches].

Decreasing switch Decreasing

X Orientation

4X Ø 4.57 ± 0.05

Feature

[.180 ± .002]

Decreasing Increasing

69.85 ± 0.50 Y Y

[2.75 ± 0.02]

R2.03 ± 0.50

[0.08 ± 0.02]

Increasing

X

Increasing switch 18˚ REF 18˚ REF

69.85 ± 0.50

[2.75 ± 0.02] Increasing Decreasing

switch switch

18˚ REF 18˚ REF

Increasing Decreasing

Decreasing Increasing X X

Y Y

115.43 ± 0.50

[4.54 ± 0.02]

3.80 [0.15] Max panel

feed-through mounting

59.60 ± 0.50 Ø 59.4 ± 0.50

6.35 ± 0.50

[2.35 ± .02] [2.34 ± 0.02]

[.25 ± 0.02]

2235A

16 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

Ball Grip

Ball Joystick Grip

Product Overview

The JS1000 Ball grip provides a simple and comfortable operator control. Manufactured

of high impact plastic, the grip is perfectly suited for mobile machine applications

requiring only X-Y control and no switch or proportional input options.

Model Code Nomenclature

Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS1000 joystick base, use code positions E2, F, G and J to

specify grip properties. Reference JS1000 Product Configuration Model Code, pages 7 to 9.

The ball grip is designated using only the E2 portion of the code.

Specifications

Environmental Specifications

Description Specification

Operating temperature -40°C to 80°C [-40°F to 175°F]

Storage temperature -40°C to 85°C [-40°F to 180°F]

Environmental protection IP 66, 67

Connector Pin Assignments

The ball grip has no electrical outputs. It can be mounted on JS1000 bases having either

a CAN or analog output. Refer to the JS1000 Joystick Base Technical Information manual

520L0826 for grip CAN message details and connector pin assignments.

520L0872 • Rev HA • Jun 2013 17

JS1000, JS6000 Joystick Grips

Technical Information

JS1000 Grips

Ball Grip Dimensions

(continued)

Ball grip dimensions in millimeters [inches].

Decreasing

X 4 x Ø4.57 ± 0.05

[0.180 ± 0.002]

Orientation

R2.03 ± 0.5 Feature

[2.75 ± 0.02]

69.85 ± 0.5

[0.08 ± 0.02]

Decreasing Increasing

Y Y

Increasing

X

69.85 ± 0.5

[2.75 ± 0.02]

18o REF 18o REF

18o REF 18o REF

Decreasing Increasing Increasing Decreasing

Y Y

[3.41 ± 0.02]

X

86.61 ± 0.5

X

3.8 [0.15]

Max panel

feed through mounting

[2.35 ± 0.02]

Ø59.4 ± 0.05

59.6 ± 0.5

[0.25 ± 0.02]

6.35 ± 0.5

[2.34 ± 0.002]

P005 243E

18 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

JS6000 Grip JS6000 product configuration model code example – base part - A, B, C, D, E, F and G

Product Configuration

Model Code

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1 A 0 H 0 R V N N N N N N N N

Base Grip

A Product Series

Code Description

JS6000 Series JS6000 Joystick

B Operational Axis Options

Code Description

XY Bi-directional: X and Y axis

NY Uni-directional: Y axis only (required for friction-holding)

C Shaft Position Sensing and Output Options

Code Description

PRR Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

PQQ Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±1.5° neutral threshold

PSS Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±5° neutral threshold

PTT Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±5° neutral threshold

PUU Potentiometer: dual output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

HMM Hall effect: dual sensors per axis; Vs = 5 VDC; Vo = 0.5 to 4.5 VDC

CAN Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B communication, 6 pin connector

CPL Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B communication, 18 pin connector

D Centering Spring Options

Code Description

H Heavy force

M Medium force

L Light force

F Friction-hold (position maintained, center detent)

E Gate Pattern Options

Code Description

S Square, full output at 45 degree

F Mechanical Options

Code Description

NL No mechanical option; spring return to center only

FB Friction-held in Y axis; no X axis; center detent; 1.25 N•m [0.92 lb•ft] friction-hold force;

2.5 N•m [1.66 lb•ft] breakout force

FC Friction-held in Y axis; no X axis; center detent; 1.25 N•m [0.92 lb•ft] friction-hold force;

3.25 N•m [2.40 lb•ft] breakout force

HC Friction-held in Y axis; no X axis; center detent; 2.25 N•m [1.66 lb•ft] friction-hold force;

4.0 N•m [2.95 lb•ft] breakout force

G Direction (Microswitch) Options

Code Description

N No switches

Y Microswitches installed (analog potentiometer option only)

520L0872 • Rev HA • Jun 2013 19

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

JS6000 Grip JS6000 grip product configuration model code example – grip properties - I, J, K, L, M, N, O,

Product Configuration P, Q, R, and S

Model Code

(continued)

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S C L N J 3 3 1 A 0 H 0 R V N N N N N N N N

1 2 3 4

H1 Electrical Interface Options

Code Description

S Analog (voltage output from joystick sensors or switches)

J CAN, SAE J1939 protocol

H2, 3 CAN Source Address*

Code Description

NN None—use with analog outputs when H1 = S

33 Source address = 0x 33

34 Source address = 0x 34

35 Source address = 0x 35

36 Source address = 0x 36

* Consult the factory if additional source addresses are required.

H4 Joystick Output Type

Code Description

N None—use with analog outputs when H1 = S

1 CAN full scale output = 1000 counts

I, J, K Grips, grip proportional rocker output and style

For grips designed to mate with the JS6000 joystick base, use code positions, I through S to specify grip

properties. Refer to Front Plate Model Code Designation, page 25 for rocker switch location examples.

I Grip switch details

Code Description

T Top switch

Handle type D Operator presence switch

Number of buttons B Both top and operator switch

0 No top switch, no operator presence switch

L Left rocker location (vertical orientation)

R Right rocker location (vertical orientation)

B Both left and right (vertical orientation)

H Horizontal rocker location

0 No rocker switch

J A grip proportional rocker output K A grip proportional rocker style

Code Definition Code Definition

R Potentiometer, 10% to 90% Vs S Wave style

Q Potentiometer, 25% to 75% Vs V V style

N None N None

20 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

JS6000 Grip L, M, N, O, P, Q, R, S Grip options

Product Configuration For A grips use code positions L, M, N, O, P, Q, R, and S to specify grip button colors.

Model Code

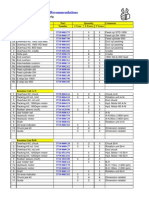

(continued) Grip Button Position to Model Code Conversion

Grip front plate button position* Corresponding master model code

1 L

2 M

3 N

4 O

5 P

6 Q

7 R

8 S

See A Grip Button Position Designations, pages 29 to 32.

Grip Button Color Options

Code Description

R Red

B Black*

G Green*

Y Yellow*

L Blue*

N No push button switch

* The red colored push-button switch is considered the default color. There is a five-piece order minimum

each time the other color options are ordered.

520L0872 • Rev HA • Jun 2013 21

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

JS6000 Grip Function JS6000 Grip Function Connector Pin Assignments

Connector Pin Pin assignments for the JS6000 connector that contains grip outputs are dependent

on the type of joystick shaft position sensor (potentiometer or Hall) and the electrical

output option (analog or CAN) selected for the joystick base. Analog base grip pin

assignments are found on pages 29 to 32 and page 35 of this manual. Pin assignments

for other analog base functions are found in the JS6000 Joystick Base Technical

Information manual 520L0760.

Grip pin assignments for joystick bases that have analog outputs depend on whether

a potentiometer or Hall sensor is used to measure the position of the joystick shaft. If a

potentiometer is used, the 12 pin connector on the joystick base is used for grip outputs.

If a Hall sensor is used, the 16 pin connector is used for grip outputs.

If the CAN electrical output option is selected, a 6 or 18 pin Deutsch® connector is

provided in the base and input information from the grip is broadcast in a J1939

message format. Refer to the JS6000 Joystick Base Technical Information manual

520L0760 for details on J1939 CAN grip messages and Deutsch connector pin

assignments.

22 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Multi-function Grip

Push Button Switch

Left Rocker

A Joystick Grip Top Switch

Operator Presence Switch

Product Overview 2265

The A grip is a multi-function, ambidextrous ergonomic grip designed for a comfortable

user interface and maximum functional control. The grip features a modular design that

allows switch and proportional rocker location flexibility.

The A grip is available with combinations of up to eight switches and up to two

proportional inputs. One of the optional switches can be used to provide an operator

presence function on the grip. Available button colors are red, black, green, yellow, and

blue.

Model Code Nomenclature

Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I through S to

specify grip properties. Reference JS6000 Grip Product Configuration Model Code, pages

19 to 21.

Model Code for A Grip Front Plate Options

I Number of momentary Number, location of proportional Number, location of momentary

Code switches—grip front plate rocker switches—grip front plate switches—back of grip

A000 0 0 0

A00T 0 0 T

A00D 0 0 D

A00B 0 0 B

A0L0 0 L 0

A0LD 0 L D

A0R0 0 R 0

A0RD 0 R D

A0B0 0 B 0

A0BD 0 B D

A0H0 0 H 0

A0HD 0 H D

A0RB 0 R B

A0RT 0 R T

A0LB 0 L B

A0LT 0 L T

A100 1 0 0

A10T 1 0 T

A10D 1 0 D

A10B 1 0 B

A1L0 1 L 0

A1R0 1 R 0

A1H0 1 H 0

520L0872 • Rev HA • Jun 2013 23

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Model Code for A Grip Front Plate Options (continued)

(continued) I Number of momentary Number, location of proportional Number, location of momentary

Code switches—grip front plate rocker switches—grip front plate switches—back of grip

A1LD 1 L D

A1RD 1 R D

A1HD 1 H D

A1RT 1 R T

A1LT 1 L T

A1RB 1 R B

A1LB 1 L B

A200 2 0 0

A20T 2 0 T

A20D 2 0 D

A20B 2 0 B

A2L0 2 L 0

A2R0 2 R 0

A2H0 2 H 0

A2LD 2 L D

A2RD 2 R D

A2HD 2 H D

A2RB 2 R B

A2RT 2 R T

A2LB 2 L B

A2LT 2 L T

A300 3 0 0

A30T 3 0 T

A30D 3 0 D

A30B 3 0 B

A3R0 3 R 0

A3RD 3 R D

A3L0 3 L 0

A3LD 3 L D

A3RT 3 R T

A3LT 3 L T

A400 4 0 0

A40T 4 0 T

A40D 4 0 D

A40B 4 0 B

A500 5 0 0

A50D 5 0 D

A50B 5 0 B

A50T 5 0 T

A600 6 0 0

A60D 6 0 D

A60B 6 0 B

A60T 6 0 T

24 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Front Plate Model Code Designations

(continued)

A Grip Front Plate Diagram

A000 A0B0* A1R0 A200 A2H0

3 2

A00T A1RT A20T A2HD

X Y 3 Y 3 2

A00D A1RD A20D

X

A00B A1RB A20B

A0R0 A0H0 A1L0 A2R0 3 A300 3 2

A0RT Y A0HD A1LT X 1 A2RT Y A30T

A0RD X A1LD A2RD 4 A30D 1

A0RB A1LB A2RB A30B

A0L0 A100 A1H0 A2L0 A400

2 2 3 2

A0LT A10T A1HD A2LT A40T

X X

A0LD A10D A2LD 1 A40D 4

1 1

A0LB A10B X A2LB A40B

A3R0 3 A3L0 2 A500 3 2 A600 3 2

A3RT Y A3LT X A50T 5 A60T 5

5 6 4 1 4 1

A3RD A3LD A50D A60D

4 1 6

A3RB A3LB A50B A60B

* For CAN and CAN+ output models, include grip configurations: A0BD, A0BB, A0BT.

2247B

Rocker Switch Profiles

Profile of Wave Rocker Switch Option Profile of V Rocker Switch Option

2248

520L0872 • Rev HA • Jun 2013 25

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Rocker Switch Specifications

(continued) The optional grip rocker switches use a conductive plastic potentiometer to generate

an analog output that is proportional to switch position. The wipers that run across the

potentiometer track are driven by the thumb operated rocker mechanism. Rocker switch

action is spring return to center.

Mechanical Specifications

Description Specification

Breakout force 5 N [1.12 lbf ]

Operating force 15 N [3.37 lbf ]

Maximum applied force 50 N [11.24 lbf ]

Mechanical angle of movement ± 12°

Electrical angle of movement ± 9°

Expected life >5 million operations

Environmental Specifications

Description Specification

Operating temperature -40°C to 70°C [-40°F to 158°F]

Storage temperature -40°C to 80°C [-40°F to 176°F]

Environmental sealing IP 65

Electrical Specifications

Description Specification

Maximum load current Potentiometer wiper*

Directional switches: 200 mA

Maximum power dissipation 0.25 W at 25° C [77° F]

Output voltage ranges 25 to 75% Vs

10 to 90% Vs

Center tap voltage 50% Vs ± 2%

Center tap angle 1.5° either side of center

Directional switch operating angle 2.5° either side of center

Directional switch maximum supply voltage 36 Vdc

Directional switch current rating 5 mA

• Center tap has an angle of ± 1.5°

• 50% of the Vs is supplied at the center position

• The track also has a directional switch with a center off switch

• The direction switch changes state after a movement of 2.5° in each direction

• The switch current rating is 5 mA

* The rocker is only to be used as a potentiometer and not as a variable resistor.

Wiper load must be resistance greater than 100 kΩ.

26 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Rocker Switch Wiring Details

(continued)

Left Rocker

Black

Blue/orange Switch track Green

Left blank

Centre tap - yellow/red

0V Potentiometer track 5V

Forwards Backwards

White/red Pink Pink/grey

(V+) (V-)

Right Rocker

Black

Blue Switch track Yellow

Left blank

Centre tap - yellow/red

5V Potentiometer track 0V

Backwards Forwards

Pink/grey White White/red

(V-) (V+)

Horizontal Rocker

Black

Blue Switch track Green

Left blank

Centre tap - yellow/red

0V Potentiometer track 5V

Left Right

White/red Pink Pink/grey

(V+) (V-)

2249

520L0872 • Rev HA • Jun 2013 27

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Push Button Specifications

(continued)

Push Button Electrical Specifications

Description Specification

Switch action Momentary

Switch type Single pole, NO

Contact rating 200 mA at 50 Vdc - person present switch

100 mA at 50 Vdc - top and front plate switches

Contact resistance 50 MΩ maximum

Mechanical life 1 million cycles

Push Button Environmental Specifications

Description Specification

Operating temperature -40°F to 70°C [-40°C to 158°F]

Storage temperature -40°F to 80°C [-40°C to 176°F]

Environmental sealing IP 66

Operating force 3 N [0.674 lbf ]

Push Button Wiring Details

Push Button Switches

1 Blue Black

2 Yellow

3 Yellow/Orange

4 Green

5 Red

6 Violet

Top Switch

Pink with Black

marker sleeve

Operator Presence Switch

Red/Green Blanck/White

2250

28 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Connector Pin Assignments

(continued)

Warning

Potential uncommanded machine movement. JS6000 base and grip pinout

specifications are a function of joystick base measurement sensor type and electrical

output (analog or CAN). For joysticks with analog output, the pinout assignments for the

12 and 16 pin connectors depend on whether a potentiometer or Hall sensor is used to

measure the position of the joystick shaft. If a potentiometer sensor is used, the 12 pin

connector is used for grip outputs. If a Hall sensor is used, the 16 pin connector is used

for grip outputs and pins 13 through 16 are not used. Refer to the Rocker Switch Wiring

Details, page 27 for information regarding the switch nomenclature used below. Refer

to Front Plate Model Code Designation, page 25 for information regarding the location

nomenclature for push button switches.

A Grip Button Position Designations

• Pins 13 to 16 are not used on the 16 pin connector

• Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A000

A00T Top Common

switch

A00D Operator Common Operator

presence presence

A00B Top Operator Common Operator

switch presence presence

A0L0 Switch Switch VoutL Center tap V+ V- Common

out L out L

A0LD Switch Switch VoutL Center tap V+ Operator V- Common Operator

out L out L presence presence

A0LT Switch Switch VoutL Center tap V+ Top V- Common

out L out L switch

A0LB Switch Switch VoutL Center tap V+ Operator Top V- Common Operator

out L out L presence switch presence

A0R0 Switch Switch Center tap V+ VoutR V- Common

out R out R

A0RD Switch Switch Center tap V+ Operator VoutR V- Common Operator

out R out R presence presence

A0B0 Switch Switch Switch Switch VoutL Center tap V+ VoutR V- Common

out L out L out R out R

A0BD Switch Switch Switch Switch VoutL Center tap V+ Operator VoutR V- Common Operator

out L out L out R out R presence presence

A0H0 Switch Switch VoutH Center Tap V+ V- Common

out H out H

A0HD Switch Switch VoutH Centertap V+ Operator V- Common Operator

out H out H presence presence

520L0872 • Rev HA • Jun 2013 29

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Connector Pin Assignments (continued)

(continued)

A Grip Button Position Designations

• Pins 13 to 16 are not used on the 16 pin connector

• Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A0RT Switch Switch Top Center tap V+ VoutR V- Common

out R out R switch

A100 PB1 Common

A10T PB1 Top Common

switch

A10D PB1 Operator Common Operator

presence presence

A10B PB1 Top Operator Common Operator

switch presence presence

A1L0 Switch Switch PB1 VoutL Center tap V+ V- Common

out L out L

A1R0 PB3 Switch Switch Center tap V+ VoutR V- Common

out R out R

A1H0 Switch PB2 Switch VoutH Center top V+ V- Common

out H out H

A1LD Switch Switch PB1 VoutL Center tap V+ Operator V- Common Operator

out L out L presence presence

A1RD PB3 Switch Switch Center tap V+ Operator VoutR V- Common Operator

out R out R presence presence

A1HD Switch PB2 Switch VoutH Center top V+ Operator V- Common Operator

out H out H presence presence

A1RT PB3 Switch Switch Top Center tap V+ VoutR V- Common

out R out R switch

A1LT Switch Switch PB1 VoutL Center tap V+ Top V- Common

out L out L switch

A1RB PB3 Switch Switch Top Center tap V+ Operator VoutR V- Common Operator

out R out R switch presence presence

A1LB Switch Switch PB1 VoutL Center tap V+ Operator Top V- Common Operator

out L out L presence switch presence

A200 PB3 PB2 Common

A20T PB3 PB2 Top Common

switch

A20D PB3 PB2 Operator Common Operator

presence presence

A20B PB3 PB2 Top Operator Common Operator

switch presence presence

A2L0 Switch Switch PB2 PB1 VoutL Center tap V+ V- Common

out L out L

30 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Connector Pin Assignments (continued)

(continued)

A Grip Button Position Designations

• Pins 13 to 16 are not used on the 16 pin connector

• Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A2R0 PB4 PB3 Switch Switch Center tap V+ VoutR V- Common

out R out R

A2H0 Switch PB3 PB2 Switch VoutH Center tap V+ V- Common

out H out H

A2LD Switch Switch PB2 PB1 VoutL Center tap V+ Operator V- Common Operator

out L out L presence presence

A2RD PB4 PB3 Switch Switch Center tap V+ Operator VoutR V- Common Operator

out R out R presence presence

A2HD Switch PB3 PB2 Switch VoutH Center tap V+ Operator V- Common Operator

out H out H presence presence

A2RB PB4 PB3 Switch Switch Top Center tap V+ Operator VoutR V- Common Operator

out R out R switch presence presence

A2RT PB4 PB3 Switch Switch Top Center tap V+ VoutR V- Common

out R out R switch

A2LB Switch Switch PB2 PB1 VoutL Center tap V+ Operator Top V- Common Operator

out L out L presence switch presence

A2LT Switch Switch PB2 PB1 VoutL Center tap V+ Top V- Common

out L out L switch

A300 PB3 PB2 PB1 Common

A30T PB3 PB2 PB1 Top Common

switch

A30D PB3 PB2 PB1 Operator Common Operator

presence presence

A30B PB3 PB2 PB1 Top Operator Common Operator

switch presence presence

A3R0 PB4 PB3 Switch Switch Center tap V+ PB5 VoutR V- Common

out R out R

A3RD PB4 PB3 Switch Switch PB5 Center tap V+ Operator VoutR V- Common Operator

out R out R presence presence

A3L0 Switch Switch PB2 PB1 VoutL Center tap V+ PB6 V- Common

out L out L

A3LD Switch Switch PB2 PB1 VoutL Center tap V+ Operator PB6 V- Common Operator

out L out L presence presence

A3RT PB4 PB3 Switch Switch Top Center tap V+ PB5 VoutR V- Common

out R out R switch

A3LT Switch Switch PB2 PB1 VoutL Center tap V+ PB6 Top V- Common

out L out L switch

A400 PB4 PB3 PB2 PB1 Common

520L0872 • Rev HA • Jun 2013 31

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

A Grip Connector Pin Assignments (continued)

(continued)

A Grip Button Position Designations

• Pins 13 to 16 are not used on the 16 pin connector

• Blank = Pin not used

Pin number

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A40T PB4 PB3 PB2 PB1 Top Common

switch

A40D PB4 PB3 PB2 PB1 Operator Common Operator

presence presence

A40B PB4 PB3 PB2 PB1 Top Operator Common Operator

switch presence presence

A500 PB4 PB3 PB2 PB1 PB5 Common

A50D PB4 PB3 PB2 PB1 PB5 Operator Common Operator

presence presence

A50B PB4 PB3 PB2 PB1 Top Operator PB5 Common Operator

switch presence presence

A50T PB4 PB3 PB2 PB1 Top PB5 Common

switch

A600 PB4 PB3 PB2 PB1 PB5 PB6 Common

A60D PB4 PB3 PB2 PB1 PB5 Operator PB6 Common Operator

presence presence

A60B PB4 PB3 PB2 PB1 Top PB5 Operator PB6 Common Operator

switch presence presence

A60T PB4 PB3 PB2 PB1 Top PB5 PB6 Common

switch

Dimensions

A grip dimensions in millimeters [inches].

60 [2.36]

Push Button Switch

Left Rocker

131.51 [5.18]

Top Switch

Operator

Presence Switch

110 [4.33]

2251

32 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

MG Grip

MG Joystick Grip

Product overview

The MG multi-function grip is designed to provide an ergonomic solution to grip

applications requiring an operator presence function. The profile of the MG grip ensures

that the operators fingers are always close to the buttons to minimize operator fatigue

and maximize functional control. An optional hand rest feature is also available to further

minimize operator fatigue and provide additional protection for the joystick boot.

The grip is available with or without an operator presence lever switch, as well as up to

two low current switches at the top of the grip. If two top switches are present, they are

actuated through a rocker assembly.

0 Switch Option with 1 Switch Option with

Operator Presence Lever Operator Presence Lever

2 Switch Option with Grip with Hand

Operator Presence Lever Rest Option

520L0872 • Rev HA • Jun 2013 33

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

MG Grip Model Code Nomenclature

(continued) Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I, J and K to

specify grip properties. Reference JS6000 grip product configuration model code, pages 18

to 19.

MG grip model codes do not use model code positions J through S.

Model Code for MG Grip Switch Positions

Code Switch position* Operator presence lever Hand rest

MG00 No switches No lever No hand rest

MG01 Switch 1 No lever No hand rest

MG02 Switch 1, 2 No lever No hand rest

MG03 Switch 1,2 Included No hand rest

MG04 Switch 1,2 Included Included

MG05 Switch 1 Included Included

MG06 Switch 1,2 No lever Included

MG07 Switch 1 No lever Included

MG08 Switch 1 Included No hand rest

MG09 No switches Included Included

MG10 No switches No lever Included

MG11 No switches Included No hand rest

*Refer to Dimensions, page 36, for definition of switch locations.

Specifications

Electrical Specifications

Description Specification

Contact resistance 50Ω

Contact bounce 1 ms

Insulation resistance >100 MΩ at 50 Vdc

Dielectric strength 500 V (50 Hz, 1 min.)

Switching current Max: 100 mA

Min : 10 µA

Switching voltage Max: 30 Vdc

Min: 2 Vdc

Electrical life 1 million cycles at maximum voltage

Environmental Specifications

Description Specification

Operating temperature -25°C to 75°C [-13°F to 167°F]

Storage temperature -30°C to 80°C [-22°F to 178°F]

Ingress protection IP 67 (operator presence lever may not operate in icing

conditions)

34 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

MG Grip Connector Pin Assignments

(continued)

Warning

Potential uncommanded machine movement. JS6000 base and grip connector pin

assignments are a function of joystick base shaft measurement sensor type and base

electrical output (analog or CAN). For joysticks with analog output, the pin assignments

for the 12 and 16 pin base connectors depend on whether a potentiometer or Hall

sensor is used to measure the position of the joystick shaft. If a potentiometer sensor

is used, the 12 pin connector is used for grip outputs. If a Hall sensor is used, the 16 pin

connector is used for grip outputs.

12 Pin Connector MG Grip Pin Assignments

Pin number Description

1 Not used

2 Not used

3 Switch 2

4 Operator presence

5 Operator presence

6 Switch 1

7 Not used

8 Not used

9 Not used

10 Not used

11 Not used

12 Common for switch 1, 2

16 Pin Connector MG Pin Assignments

Pin number Description

1 Not used

2 Not used

3 Switch 2

4 Operator presence

5 Operator presence

6 Switch 1

7 Not used

8 Not used

9 Not used

10 Not used

11 Not used

12 Common for switch 1,2

13 Not used

14 Not used

15 Not used

16 Not used

520L0872 • Rev HA • Jun 2013 35

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

MG Grip Switch Wiring Details

(continued)

1 Switch Option 2 Switch Option

Switch 1 Switch 1 Switch 2

Blue Black Blue Green

Black

Operator Presence Switch

Operator presence

Yellow Blue/Orange

2255

Dimensions

MG grip dimensions in millimeters [inches].

ø40 [ø1.57]

54 [ 2.13 ]

28 [ 1.1 ]

14 [ 0.55 ]

Height from

JS6000 Flange

188 [ 7.4 ]

114 [ 4.5 ]

ø50 [ø1.97]

2256

36 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

JS6000 Grips

HKN Grip

HKN Joystick Grip

Product Overview

The HKN grip is a plain, high impact plastic knob grip that has no electrical interface. It is

designed to provide a comfortable grip for extended machine operation.

Model Code Nomenclature

Grip and grip options are specified using the Sauer-Danfoss joystick model code. For

grips designed to mate with the JS6000 joystick base, use code positions I, through S to

specify grip properties. Reference JS6000 Grip Product Configuration Model Code, pages

19 to 21.

The HKN does not use master model code positions J through S.

The master model code for HKN grips is HKN0.

Specifications

Environmental Specifications

Description Specification

Operating temperature -40°C to 80°C [-40°F to 176°F]

Storage temperature -40°C to 85°C [-40°F to 185°F]

Environmental sealing IP 66

Dimensions

HKN Grip Dimensions

Maximum height above flange Maximum diameter

45 mm [1.76 in] 34.6 mm [1.36 in]

520L0872 • Rev HA • Jun 2013 37

JS1000, JS6000 Joystick Grips

Technical Information

Grip and Joystick Base Service Parts

Service Part Information Service part availability for JS1000 joystick is a function of joystick base and grip

specifications. Refer to the JS1000 Base Technical Information manual 520L0826 for

mating connector part information. Refer to the table below for service part information.

JS1000 Joystick Grip and Base Service Parts

Grip type Part description Replacement part ordering number

JS1000 ball grip Boot 10103388

Ball grip 10101913

Grip fastening screw 10101782

JS1000 grip with switch, Rocker switch cover 10101816

rocker and banana Banana switch cover 10103337

JS1000 PRO grip No replacement parts available

38 520L0872 • Rev HA • Jun 2013

JS1000, JS6000 Joystick Grips

Technical Information

Notes

520L0872 • Rev HA • Jun 2013 39

• Bent Axis Motors Sauer-Danfoss is a global manufacturer and supplier of high-

quality hydraulic and electronic components. We specialize in

• Closed Circuit Axial Piston Pumps

providing state-of-the-art technology and solutions that excel in

and Motors

the harsh operating conditions of the mobile off-highway market.

• Displays Building on our extensive applications expertise, we work closely

with our customers to ensure exceptional performance for a broad

• Electrohydraulic Power Steering

range of off-highway vehicles.

• Electrohydraulics

We can help speed up system development, reduce costs and bring

• Hydraulic Power Steering

your vehicles to market faster. Sauer-Danfoss – Your Strongest

• Integrated Systems Partner in Mobile Hydraulics.

• Joysticks and Control Handles

• Microcontrollers and Software

Go to www.sauer-danfoss.com for further product information.

• Open Circuit Axial Piston Pumps

• Orbital Motors

• PLUS+1™ GUIDE

Wherever off-highway vehicles are at work, so is Sauer-Danfoss.

• Proportional Valves

We offer expert worldwide support for our customers, ensuring

• Sensors

the best possible solutions for outstanding performance. And with

• Steering an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

• Transit Mixer Drives

Members of the Sauer-Danfoss Group

Local address:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-inverter.com

Turolla

www.turollaocg.com

Sauer-Danfoss (US) Company Sauer-Danfoss ApS

2800 East 13th Street DK-6430 Nordborg, Denmark

Ames, IA 50010, USA Phone: +45 7488 4444

Phone: +1 515 239 6000 Fax: +45 7488 4400

Fax: +1 515 239 6618

Hydro-Gear

Sauer-Danfoss GmbH & Co. OHG Sauer-Danfoss-Daikin LTD.

www.hydro-gear.com Postfach 2460, D-24531 Neumünster Shin-Osaka TERASAKI 3rd Bldg. 6F

Krokamp 35, D-24539 Neumünster, Germany 1-5-28 Nishimiyahara, Yodogawa-ku

Phone: +49 4321 871 0 Osaka 532-0004, Japan

Sauer-Danfoss-Daikin Fax: +49 4321 871 122 Phone: +81 6 6395 6066

www.sauer-danfoss-daikin.com Fax: +81 6 6395 8585

www.sauer-danfoss.com

You might also like

- Timberjack 1270BDocument220 pagesTimberjack 1270BMMM-MMM100% (1)

- New Holland CX720 CX740 CX760 CX780 CX820 CX840 CX860 CX880 Combine Harvesters Service Repair ManualDocument31 pagesNew Holland CX720 CX740 CX760 CX780 CX820 CX840 CX860 CX880 Combine Harvesters Service Repair Manualggjjjjotones0% (1)

- Timberjack 1110CDocument278 pagesTimberjack 1110CMMM-MMM100% (3)

- John Deere Fuel EngDocument760 pagesJohn Deere Fuel EngMMM-MMM100% (2)

- Timberjack 1270BDocument190 pagesTimberjack 1270BMMM-MMM100% (1)

- Lcs Troubleshooting Manual - Rev 1Document38 pagesLcs Troubleshooting Manual - Rev 1Andre VPNo ratings yet

- DFP 963D TL WebDocument4 pagesDFP 963D TL WebRicardo Rincon VegaNo ratings yet

- VT650Document454 pagesVT650Alex VNo ratings yet

- Kenwood DNX 9140 Service ManualDocument86 pagesKenwood DNX 9140 Service ManualJessica Nulph0% (1)

- Seiwa Explorer3 User Manual EnglishDocument118 pagesSeiwa Explorer3 User Manual EnglishNomofnamorNo ratings yet

- Service Manual: Loader Control SystemDocument48 pagesService Manual: Loader Control SystemJHONATANNo ratings yet

- Operators Manual Excavator Control GPC ADocument32 pagesOperators Manual Excavator Control GPC AAdam100% (3)

- Input and Output DevicesDocument21 pagesInput and Output Devicesramesh100% (10)

- Contilube II - Spare PartsDocument16 pagesContilube II - Spare PartsWalid AouiniNo ratings yet

- Special ToolsDocument24 pagesSpecial ToolsSuka MuttAstroNo ratings yet

- Manual Instructivo CO 407Document34 pagesManual Instructivo CO 407Juan RafaelNo ratings yet

- Submersible Agitator Pumps: Toyo DPDocument2 pagesSubmersible Agitator Pumps: Toyo DPBasit Edu0% (1)

- LeeBoy Loader Axle 113 Manual 09 2013 PDFDocument104 pagesLeeBoy Loader Axle 113 Manual 09 2013 PDFsimox_softNo ratings yet

- Abs HaldexDocument2 pagesAbs HaldexBom_Jovi_681No ratings yet

- Tiras de Bronze CatDocument8 pagesTiras de Bronze CatPedro Lorenço JorgeNo ratings yet

- Battery and Engine Electrical CircuitDocument4 pagesBattery and Engine Electrical CircuitJean-Claude GONZALEZ100% (1)

- 520L0291 - Rev AA - Juli 07Document12 pages520L0291 - Rev AA - Juli 07Sasko DimitrovNo ratings yet

- Hydrive IOMDocument14 pagesHydrive IOMCristopher PatricioNo ratings yet

- Manitou 1030 SDocument22 pagesManitou 1030 Scornel_lupu100% (1)

- R1600GDocument2 pagesR1600GMellisho Cano J EverNo ratings yet

- Spare Parts List: Forward and Reversible PlateDocument40 pagesSpare Parts List: Forward and Reversible PlatePawelNo ratings yet

- African Commodities - Er800 - 07-2008 32294Document34 pagesAfrican Commodities - Er800 - 07-2008 32294BALANo ratings yet

- Esquema Hidraulico Mc50-70Document7 pagesEsquema Hidraulico Mc50-70jAVIER GARCIA MORIANA100% (1)

- Takeuchi Excavator TB153FR CJ2E000 WM 06860Document686 pagesTakeuchi Excavator TB153FR CJ2E000 WM 06860rok.feleNo ratings yet

- 3000 Product Family Group 16-1846. Detailed Parts Breakdown: Control Valve (1 of 2)Document7 pages3000 Product Family Group 16-1846. Detailed Parts Breakdown: Control Valve (1 of 2)Al BimaNo ratings yet

- F240a 22Document93 pagesF240a 22ניקולאי איןNo ratings yet

- md0000001178202007 PM 221650 RT760E 002 PARTSDocument899 pagesmd0000001178202007 PM 221650 RT760E 002 PARTSDecomaderas SanchezNo ratings yet

- The Daf CF Series: A Winner in Every RespectDocument28 pagesThe Daf CF Series: A Winner in Every Respecthirwa julesNo ratings yet

- Esque MaDocument1,050 pagesEsque MaValter LeiriaoNo ratings yet

- Lista de Partes HM 230Document16 pagesLista de Partes HM 230Veronica MirandaNo ratings yet

- O&K Carraro AxlesDocument10 pagesO&K Carraro AxlesMarek WyszatyckiNo ratings yet

- ECR 35 Schema Imp. IdraulicoDocument3 pagesECR 35 Schema Imp. Idraulicosixin93551No ratings yet

- Nacela Service Manual h14tx h16tpxDocument272 pagesNacela Service Manual h14tx h16tpxGules GheorgheNo ratings yet

- ds511 Specification Sheet EnglishDocument4 pagesds511 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- Pvek DKMHPN500B102Document4 pagesPvek DKMHPN500B102seaqu3stNo ratings yet

- Hydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Document6 pagesHydrostatic Vibratory Plates 365-712 Kilos AVH 5020 / 6020 / 7010Aurelian BogdanNo ratings yet

- Gaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaDocument114 pagesGaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaМихайленко МиколаNo ratings yet

- Operators ManualDocument71 pagesOperators ManualmiguelNo ratings yet

- Pts 1600 Cud S3at3 AppDocument128 pagesPts 1600 Cud S3at3 ApptskumarNo ratings yet

- ServiceManuals/LG/GPS/LN500/LN500 Service ManualDocument31 pagesServiceManuals/LG/GPS/LN500/LN500 Service ManualYonny MunozNo ratings yet

- B30D 4Document150 pagesB30D 4Teknik MakinaNo ratings yet

- Deutz AgrotracDocument2 pagesDeutz AgrotracSilvia De Pedro Camoeiras0% (1)

- Guidetti MEF 520 Parts BOOKDocument17 pagesGuidetti MEF 520 Parts BOOKMichael BochoridisNo ratings yet

- Manitou Mt1436 Mt1440 Mt1840 A B Ep H Ha Privilege Repair ManualsDocument22 pagesManitou Mt1436 Mt1440 Mt1840 A B Ep H Ha Privilege Repair Manualseduardoconner020896jfqNo ratings yet

- Manitou MLT 735 120 LsuDocument2 pagesManitou MLT 735 120 LsugeorgeNo ratings yet

- Apollo 25.6 Step3 190-WpartsDocument230 pagesApollo 25.6 Step3 190-WpartsАлексейNo ratings yet

- McCormick C-MAX RPS Tier 3 (2008-) - RS24 - 100 Tractor Service Repair Manual PDFDocument30 pagesMcCormick C-MAX RPS Tier 3 (2008-) - RS24 - 100 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- SAT318 HarvesterHead SAT318T Harvester Head SAT322 Harvester Head Technical Training Information - UENR0356UENR0356 - SIS PDFDocument122 pagesSAT318 HarvesterHead SAT318T Harvester Head SAT322 Harvester Head Technical Training Information - UENR0356UENR0356 - SIS PDFEDUARDO JAVIER VALENZUELANo ratings yet

- 030a 202a enDocument60 pages030a 202a enSunthron Somchai0% (1)

- EDLinkedDocument96 pagesEDLinkedESRANo ratings yet

- Hướng Dẫn Lắp Đặt Máy Treo Tường Cục Bộ FujitsuDocument18 pagesHướng Dẫn Lắp Đặt Máy Treo Tường Cục Bộ FujitsuDoan Tien Do100% (1)

- NewHolland M160 Hydraulic Variable PumpDocument39 pagesNewHolland M160 Hydraulic Variable PumpElena DNo ratings yet

- Spare Parts Manual (HB 3600-3600DP)Document36 pagesSpare Parts Manual (HB 3600-3600DP)drmassterNo ratings yet

- Caixa New HolandDocument286 pagesCaixa New HolandFábio CostaNo ratings yet

- Valve - Clearance Adjustment (6068) (Two-Valve Head) - ctm104 - Service ADVISOR™Document4 pagesValve - Clearance Adjustment (6068) (Two-Valve Head) - ctm104 - Service ADVISOR™Timothee MbambaNo ratings yet

- Komac KB E-CatalogueDocument6 pagesKomac KB E-CatalogueHaitem FarganiNo ratings yet

- Technical Information: JS1000, JS6000 Joystick GripsDocument40 pagesTechnical Information: JS1000, JS6000 Joystick GripsStelian CrisanNo ratings yet

- H1 Bent Axis Variable Motors Technical Information en-USDocument147 pagesH1 Bent Axis Variable Motors Technical Information en-USYllecir XataraNo ratings yet

- Js1 Heavy Duty Joysticks Technical Information En-UsDocument88 pagesJs1 Heavy Duty Joysticks Technical Information En-UskmeNo ratings yet

- Sauer DanFoss Joystick CatalogDocument40 pagesSauer DanFoss Joystick CatalogMichael LinNo ratings yet

- Joystick DanfossDocument44 pagesJoystick DanfossJonny Cristhian Otero BacaNo ratings yet

- Older Generation ModelsDocument6 pagesOlder Generation ModelsMMM-MMMNo ratings yet

- First Generation ModelsDocument8 pagesFirst Generation ModelsMMM-MMMNo ratings yet

- B Series ModelsDocument11 pagesB Series ModelsMMM-MMMNo ratings yet

- Motor GradersDocument7 pagesMotor GradersMMM-MMMNo ratings yet

- G900 Series ModelsDocument28 pagesG900 Series ModelsMMM-MMMNo ratings yet

- First Generation ModelsDocument18 pagesFirst Generation ModelsMMM-MMMNo ratings yet

- ECR First Generation ModelsDocument8 pagesECR First Generation ModelsMMM-MMMNo ratings yet

- G700B Series ModelsDocument28 pagesG700B Series ModelsMMM-MMMNo ratings yet

- John DeereDocument2 pagesJohn DeereMMM-MMMNo ratings yet

- John DeereDocument1,450 pagesJohn DeereMMM-MMM33% (3)

- B Series ModelsDocument10 pagesB Series ModelsMMM-MMMNo ratings yet

- John Deere 724KDocument2 pagesJohn Deere 724KMMM-MMMNo ratings yet

- Microsection 7Document14 pagesMicrosection 7MMM-MMMNo ratings yet

- John DeereDocument2 pagesJohn DeereMMM-MMMNo ratings yet

- John DeereDocument610 pagesJohn DeereMMM-MMM50% (2)

- JS Quickhitch SectionDocument2 pagesJS Quickhitch SectionMMM-MMMNo ratings yet

- Manual Quickhitch: Issue 1Document14 pagesManual Quickhitch: Issue 1MMM-MMMNo ratings yet

- Manual Quickhitch: Issue 1Document23 pagesManual Quickhitch: Issue 1MMM-MMMNo ratings yet

- Compact (English) 239Document131 pagesCompact (English) 239MMM-MMMNo ratings yet

- Earth Drill FlightsDocument2 pagesEarth Drill FlightsMMM-MMMNo ratings yet

- Compact and Medium Hammer BrochureDocument12 pagesCompact and Medium Hammer BrochureMMM-MMMNo ratings yet

- 6hk1xygd01 DGK150D Epa3pDocument79 pages6hk1xygd01 DGK150D Epa3pMMM-MMMNo ratings yet

- JoystickDocument12 pagesJoystickanon_48898060No ratings yet

- Read MeDocument7 pagesRead Mealex najdenovNo ratings yet

- Hyster Joystick EN PDFDocument18 pagesHyster Joystick EN PDFweldsaidiNo ratings yet

- DAC1 27 01 Rev 0Document6 pagesDAC1 27 01 Rev 0vanNo ratings yet

- JoyPad User Manual 2.0 PDFDocument64 pagesJoyPad User Manual 2.0 PDFnelusabieNo ratings yet

- Diamec U6 Spare PartDocument3 pagesDiamec U6 Spare PartJairo Boechat JuniorNo ratings yet

- Combat Flight Simulator 3 Manual Win enDocument20 pagesCombat Flight Simulator 3 Manual Win enmyheart iscoldNo ratings yet

- Technical Information Bulletin: To Ensure Proper NumberingDocument6 pagesTechnical Information Bulletin: To Ensure Proper NumberingBart JohnNo ratings yet

- Gaming Consoles Seminar ReportDocument85 pagesGaming Consoles Seminar ReportPiyush MalhotraNo ratings yet

- Canbus Joystick: A Family of Solutions A Family of SolutionsDocument4 pagesCanbus Joystick: A Family of Solutions A Family of SolutionsasdNo ratings yet

- T8FB (BT) : User ManualDocument44 pagesT8FB (BT) : User ManualalueviadthobbeozhgNo ratings yet

- Joystick Port Interface ProjectsDocument25 pagesJoystick Port Interface Projectsandrei_scNo ratings yet

- Mooring EquipmentDocument195 pagesMooring EquipmentVladimirs Arzeninovs100% (4)

- ABERLINK 3D (Measurement Software) PDFDocument83 pagesABERLINK 3D (Measurement Software) PDFcmm5477100% (1)

- 5 Non Basic Modes PDFDocument8 pages5 Non Basic Modes PDFKunal SinghNo ratings yet

- Optic 6 TutorialDocument25 pagesOptic 6 TutorialgepapaNo ratings yet

- R-Net System R-Net System: Multi-Rehab Powerchair Control SystemDocument4 pagesR-Net System R-Net System: Multi-Rehab Powerchair Control SystemMikel VillanuevaNo ratings yet

- The Danish MD-80 Throttle Part IIIDocument16 pagesThe Danish MD-80 Throttle Part IIIAlejandroNo ratings yet

- InstallDocument2 pagesInstallnameless000No ratings yet

- RTG Konecranes Model ENG Trainee ManualDocument13 pagesRTG Konecranes Model ENG Trainee ManualkongNo ratings yet

- Flanker 2.0 Pilots CardDocument8 pagesFlanker 2.0 Pilots CardIon PopescuNo ratings yet

- Rema Installation ManualDocument53 pagesRema Installation ManualPavlotexNo ratings yet

- Oblivion DDocument250 pagesOblivion DAisyah ComelNo ratings yet

- Thrustmaster - NLR - Honeycomb 5 Juli 2022Document13 pagesThrustmaster - NLR - Honeycomb 5 Juli 2022Nokky SetiawanNo ratings yet

- AMIGA - Barbarian II ManualDocument3 pagesAMIGA - Barbarian II ManualjajagaborNo ratings yet

- Readme Dongle ImportantDocument5 pagesReadme Dongle ImportantMarcos ContrerasNo ratings yet

- VSKYLABS F-19 Pilot Operating HandbookDocument18 pagesVSKYLABS F-19 Pilot Operating HandbookArman TabanovNo ratings yet

- Flight Simulator Cockpit ProjectDocument6 pagesFlight Simulator Cockpit ProjectAviation/Space History LibraryNo ratings yet