Professional Documents

Culture Documents

Physical Property

Physical Property

Uploaded by

hamdany danyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Physical Property

Physical Property

Uploaded by

hamdany danyCopyright:

Available Formats

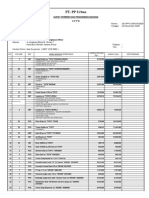

Nylon6/Unreinforced

Standard

Property Test Condition Test Method ISO Units CM1017

>PA6<

Dry 3.5%water

Physical property

Water Absorption 24hrs. in 23℃ water ISO 62 % 1.8 -

Water Absorption 23℃ in water ISO 62 % 10.5 -

Density 23℃ ISO 1183 kg/m 3 1130 -

Mechanical property

Tensile strength -40℃ ISO 527-1,2 MPa 120 115

Tensile strength 23℃ ISO 527-1,2 MPa 85 40

Tensile strength 80℃ ISO 527-1,2 MPa 30 20

Elongation at Yield 23℃ ISO 527-1,2 % 1.5 -

Elongation at Break 23℃ ISO 527-1,2 % 38 50

Flexural Strength -40℃ ISO 178 MPa 145 140

Flexural Strength 23℃ ISO 178 MPa 120 45

Flexural Strength 80℃ ISO 178 MPa 50 30

Flexural Modulus -40℃ ISO 178 GPa 3.9 3.6

Flexural Modulus 23℃ ISO 178 GPa 3 1

Flexural Modulus 80℃ ISO 178 GPa 0.8 0.4

C om pressive Strength 23℃ ISO 604 MPa 85 -

C oefficient of friction(Without lubrication) Vs m etal Suzuki Method - 0.15〜0.2 -

Shear Strength 23℃ ASTM D732 MPa 75 70

Rockwell Hardness 23℃ ISO 2039-2 R Scale 119 90

Rockwell Hardness 80℃ ISO 2039-2 R Scale 83 -

Taper Abrasion ISO 9352 m g/1000tim es 3〜4 -

C harpy Im pact Strength(V-notched) -40℃ ISO 179 kJ/m 2 2.5 11.5

C harpy Im pact Strength(V-notched) 23℃ ISO 179 kJ/m 2 4 31

C harpy Im pact Strength(Unnotched) -40℃ ISO 179 kJ/m 2 破断せず -

C harpy Im pact Strength(Unnotched) 23℃ ISO 179 kJ/m 2 破断せず -

Heat property

Melting Point DSC Method ℃ 225 -

Specific Heat - J/g・℃ 1.9 -

Therm al C onductivity - W/m ・℃ 0.25 -

C oef of Linear Therm al Expansion ISO 11359-2 ×10 -5 /℃ 8 -

Heat Deflection Tem p Low Load 0.45MPa ISO 75-1,2 ℃ 190 -

rank/thickness m

Flam m ability UL94 V-2(1/32") V-2(1/32")

mt

Electrical property

Volum e Resistivity IEC 60093 Ω・m 10 12 〜10 13 10 9〜10 10

Dielectric Strength IEC 60243-1 MV/m 20 -

Dielectric C onstant 23℃、60% RH、50Hz IEC 60250 - 4.1 9

Dielectric C onstant 23℃、60% RH、1KHz IEC 60250 - 3.9 8

Dielectric C onstant 23℃、60% RH、1MHz IEC 60250 - 3.4 4.5

Dissipation Factor 23℃、60% RH、50Hz IEC 60250 - 0.07 0.1

Dissipation Factor 23℃、60% RH、1KHz IEC 60250 - 0.06 0.11

Dissipation Factor 23℃、60% RH、1MHz IEC 60250 - 0.03 0.13

IEC Tracking Index(C TI) UL-746B - 600 -

Arc resistance Tungsten Electrode UL-746A sec. 120 -

Molding property

Mold shrinkage(Machine Direction) 80×80×3m m t Toray Method % 1.0〜1.6 -

Mold shrinkage(Transverse Direction) 80×80×3m m t Toray Method % -

Mold shrinkage(Machine Direction) 80×80×1m m t Toray Method % 0.5〜1.0

These values are typical data for this product under specific test

conditions and not intended for use as limiting specifications.

COPYRIGHT © TORAY INDUSTRIES,INC

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Earthmoving Materials OperationsDocument26 pagesEarthmoving Materials OperationsDimash RayimbekovNo ratings yet

- Cantilever Retaining Wall DesignDocument6 pagesCantilever Retaining Wall DesignAgha Sikander0% (1)

- 03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFDocument12 pages03455-Glass Reinforced Concrete (GRC) - Rev.0 PDFMithun UdayanarayanaNo ratings yet

- CMPM CompilationDocument80 pagesCMPM CompilationTrisha MaeNo ratings yet

- Zinq - AnalysisDocument116 pagesZinq - AnalysisAimiNo ratings yet

- Unit-5: Partition and Cavity Wall Partition and Cavity WallDocument15 pagesUnit-5: Partition and Cavity Wall Partition and Cavity Wallसमिर भण्डारीNo ratings yet

- 22 - Sanitary Toto & GroheDocument2 pages22 - Sanitary Toto & GroheYon Galang FebriawanNo ratings yet

- Chillerft WFC SC SH 30 enDocument2 pagesChillerft WFC SC SH 30 enKristina BožićNo ratings yet

- 001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewDocument10 pages001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewSwati KulkarniNo ratings yet

- Engr. Yoshiaki C. Mikami, Bsce Msce-Ste RMP: Prepared byDocument30 pagesEngr. Yoshiaki C. Mikami, Bsce Msce-Ste RMP: Prepared byDenzel NgNo ratings yet

- Chapter 1. IntroductionDocument57 pagesChapter 1. Introductionsisay gemNo ratings yet

- Fabrication of Process Analyzer Packages-MSDocument24 pagesFabrication of Process Analyzer Packages-MSAhmed ElghmatiNo ratings yet

- Acrobat Document2 PDFDocument15 pagesAcrobat Document2 PDFKhepa BabaNo ratings yet

- Steel (181-190) - Gupta & GuptaDocument25 pagesSteel (181-190) - Gupta & GuptaKalaiselvi PalaniNo ratings yet

- Head Loss Calculator by Fadi YasinDocument8 pagesHead Loss Calculator by Fadi YasinYasser ShehataNo ratings yet

- M2509 111 Fact Sheet Diaphragm Wall InstallationDocument1 pageM2509 111 Fact Sheet Diaphragm Wall InstallationkurtaustinNo ratings yet

- Proper Sizing of Boiler Feedwater SystemsDocument3 pagesProper Sizing of Boiler Feedwater SystemsCarlos WayNo ratings yet

- Alat BM 2023Document5 pagesAlat BM 2023candraNo ratings yet

- What Is Vapor Intrusion Mitigation? How Does It Work?Document2 pagesWhat Is Vapor Intrusion Mitigation? How Does It Work?ul84No ratings yet

- Jurnal Perencanaan Rumah SakitDocument12 pagesJurnal Perencanaan Rumah SakitMitha AuliaNo ratings yet

- Referat Engleza FandacheDocument10 pagesReferat Engleza FandacheLoredana CondreaNo ratings yet

- FOB at Nekarikallu StationDocument16 pagesFOB at Nekarikallu StationsandeepNo ratings yet

- Assessments of Geotechnical Conditions and Slope Stability Analysis: Case Study in Gedo Town, EthiopiaDocument10 pagesAssessments of Geotechnical Conditions and Slope Stability Analysis: Case Study in Gedo Town, EthiopiaFrances Dixy AceraNo ratings yet

- RCC Design of Anganwadi FootingsDocument28 pagesRCC Design of Anganwadi FootingsD.V.Srinivasa RaoNo ratings yet

- 03 - Stormwater MSMA 2nd 2012 - Quality Design FundamentalsDocument19 pages03 - Stormwater MSMA 2nd 2012 - Quality Design Fundamentalsang.xicongNo ratings yet

- Wind and Seismic LoadsDocument4 pagesWind and Seismic LoadssnsatyanarayanaNo ratings yet

- Flow Singularity ModelingDocument6 pagesFlow Singularity ModelingsaruthanNo ratings yet

- TR-2-82 Connections For Precast BuildingsDocument310 pagesTR-2-82 Connections For Precast BuildingsBundit LeeNo ratings yet

- (Theory) 2012. (TiAl, I) Advances in Gamma Titanium Aluminides and Their Manufacturing TechniquesDocument16 pages(Theory) 2012. (TiAl, I) Advances in Gamma Titanium Aluminides and Their Manufacturing TechniquesNgọc Minh LêNo ratings yet

- CR ElevationDocument1 pageCR Elevationiamslime11No ratings yet