Professional Documents

Culture Documents

001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art Review

Uploaded by

Swati KulkarniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art Review

Uploaded by

Swati KulkarniCopyright:

Available Formats

Journal of Structural Engineering

Vol. 39, No. 5, December 2012 - January 2013 pp. 393-402 No. 39-51

Behavior of reduced beam section moment connection with reference to

continuity plates: state – of – the – art review

Kulkarni Swati Ajay*, and R. Vesmawala Gaurang*

Email: swatiakulkarni@gmail.com

*Department of Applied Mechanics, Sardar Vallabhabhai National Institute of Technology, Surat - 395007, Gujarat, INDIA.

Received: 12 May 2011; Accepted: 20 September 2011

Welded flange bolted web, are the most commonly used connections for the seismic resistant design of a steel structures.

During Post Northridge (1994) and Kobe (1995) earthquake for damaged beams and columns, observations indicated

that, connections suffered damages due to brittle fracture. After this event, extensive research has been carried out

worldwide to address the unexpected damage to welded steel moment resisting frames. Various methods were proposed

for modifying the cyclic performance of the conventional connection for new construction and to retrofit of steel

moment frames. Reduced beam section (RBS) is one of the several connection types pre-qualified for use in new steel

moment frames in seismic zone. To form reduced section, some portion of the beam flanges at a short distance from

column face is removed, so that the yielding and plastic hinge occurs within the trimmed area of flanges. This paper

summarizes the recent studies and visualizes the scope for further study in research developments of RBS connection

with reference to continuity plates.

Keywords: Steel structures; beam-to-column moment connections; reduced beam section; rigid connections; continuity

plates.

After the incidences of Northridge (1994) and Kobe considerable research has been carried out worldwide.

(1995) earthquakes, out breaking of brittle fracture of Three general approaches were followed in improving

beam-to-column connections (Fig. 1) in a wide variety connection detail: 1) improving unreinforced connections

of welded specially moment frame steel structures /toughening schemes; 2) strengthening approach:

challenged the previous thought about seismic behavior strengthening connection by addition of cover plates, ribs

of special moment frames (SMF) and other types of steel or haunches; 3) weakening approach: locally weakening

seismic resisting systems. Post-earthquake observations the beam away from the column face by reduced beam

indicated that a wide spectrum of brittle connection section (RBS) or slotted web.

damage was occurred, ranging from minor cracking to The RBS connection is one of the most well-known

completely severed beams and columns1,2. Therefore, details in ‘flange reduction methods’ (Figs. 2, 3). In RBS

welded flange and bolted or welded web connection (the connection, the strategic trimming of beam flanges at a

‘pre-Northridge’ connection) became an unacceptable short distance from column flange is planned to promote

connection for use in areas of high seismicity, because stable yielding at trimmed portion as well as to protect

it was observed that such connection cannot develop welded joint. In comparison with reinforced connections,

sufficient beam ductility in the beam, before fracture RBS connections are more efficient and economical,

occurs at the joint. To access the unexpected damage because they do not require extra field welding and

Journal of Structural Engineering 393

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

performing complex details. Use of RBS connection is L/2

found to be advantageous due to: a) the shear force in the

panel zone is reduced; b) the force demand in column

continuity plate is reduced; and c) strong-column –

g/c bf

weak-beam requirement is satisfied. Although reducing

the beam member section reduces the global stiffness of

the structure, this reduction is only about 5 to 7 percent a b

and has a little effect on final detailing of the structure.

According to these characteristics, RBS connection is

potentially the most popular type among post-Northridge

connections. Nonetheless, some typical deficiencies are

introduced in the structure, when this connection is used. ds

Many of these are related to stability based problems

and plastic hinge instability like as: a) lateral torsional

buckling at plastic hinge location; b) beam web local a b

buckling; c) beam flange local buckling; and d) column

e

twisting sensitivity.

Fig. 3 Reduced beam section geometry details (plan, elevation)

Column

Prequalified RBS connection details are described

CJP weld in various codes like, Federal Emergency Management

Shear tab Academy (FEMA) 350-353,355D3-7 and American

Beam Institute of Steel Construction (ANSI/AISC), 341-05-

Continuity

plate Seismic provisions for structural steel buildings8, ANSI/

AISC 358-05-Prequalified connections for special

and intermediate steel moment frames for seismic

applications9, ANSI/AISC 360-05-Specifications

for structural steel buildings10, National Institute of

Weld access standards and Technology-NEHRP Seismic Design

hole Technical Brief No. 211 and AISC Steel design guide

Fig. 1 Typical pre-Northridge beam-to-column moment series – 1312.

connection Some of the main design limitations based on the

range of available successful testing and prequalification

CJP weld are: for beams: 1) use in only flexurally controlled beam

Reduced flange geometry spans. L/d ≥ 5 for intermediate moment frames (IMF)

and L/d ≥ 7 for SMF; 2) no more than 50% flange

Shear tab reduction; 3) symmetry relative to both the left and

Beam

right sides of the beam and the top and bottom beam

flanges; 4) standard wide flange sections 5) beam depth

Panel yone is limited to W36 (W920) for rolled shapes; 6) depth of

built-up sections shall not exceed the depth permitted

for rolled wide-flange shapes; 7) beam weight is limited

Weld access hole to 300 lbs/ft (447 kg/m), 8) beam flange thickness is

limited to 13/4 in. (44.5 mm); 9) the protected zone

Continuity Plates consists of the portion of beam between the face of

Column the column and the end of the reduced beam section

Fig. 2 Typical reduced beam section connection cut farthest from the face of the column. For columns:

Journal of Structural Engineering 394

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

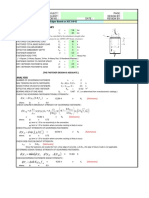

1) standard wide flange sections; 2) the beam shall be strength Eqns. (1, 2) and limitation on panel zone

connected to the flange of the column; 3) there is no (column web) slenderness Eqn. (4).

limit on the weight per foot of columns; 4) there are no

additional requirements for flange thickness. ANSI/AISC (360-05)10

Besides above mentioned prequalification limits of When, Pr £ 0.75 Pc

RBS, FEMA and AISC codes provides other related

é 3bcf tcf2 ùú

guidance on fabrication, beam lateral bracing, reduced R n = (0.6 Fycw d c tcw )´ êê1 +

(1)

stiffness effects and gravity load considerations for êë db d c tcw úúû

new constructions.

Number of analytical and experimental studies When, Pr ³ 0.75 Pc

have been performed on RBS moment connection to é 3bcf tcf2 ùú çæ 1.2 Pr ö÷

examine: flange cut reduction geometry, beam web R n = (0.6 Fycw d c tcw )´ êê1 + ´çç1.9 - ÷ (2)

êë

ú

db d c tcw úû çè Pc ÷÷ø

to column flange connection detail, behavior of panel

zone, requirement of continuity plate, lateral and local Ru £ Rn , = 1 (3)

instability of beam, effect of composite slab, and

usefulness for retrofitting. ANSI/AISC (341-05)8

Substantial work has been reported on the all

(d z + wz )

parameters described in above paragraph but very limited t³ (4)

literature has been found on the absolute necessity of 90

the continuity plates (CP) requirement. In the referred ANSI/AISC (358-05)9

research literature SMF are considered to study the

Equations used to calculate probable peak plastic hinge

cyclic behavior of RBS with respect to CP and panel

moment and maximum moment at the face of the

zone. As and when RBS connection is provided, due to

column are as below Eqns. (5-8)

the formation of the plastic hinge at the reduced flange

area, the amount of shear and axial force generated at M f = M pr + VRBS ´ S h (5)

the column interface are less than the full beam cross-

section. Therefore, use of RBS moment connection, Sh = a + b (6)

2

reduces the force demand in column panel zone and M pr = C pr Ry Z e Fy

(7)

CP. In an effort to gain an insight into the behavior of

RBS connections with reference to continuity plates, an Z e = Z x - 2ctbf ( d - tbf ) (8)

attempt is made to study available literature. The codal

provisions related to panel zone behavior and studies Further, required shear strength of PZ when the

are presented to highlight the importance of minimum moment at the reduced beam section reaches the plastic

column web thickness requirement. moment capacity can be calculated using the following

equation.

CODAL PROVISIONS – PANEL ZONE BEHAVIOR åM f

Ru = - Vc (9)

The panel zone (PZ) is the portion of the column within ( db - tbf )

the depth of the connecting beams in a moment resisting FEMA -350 (2000)3

steel connection as shown in Fig. 2. The transfer

of moments between beams and columns causes a Moment-resisting connections should be proportioned

complicated state of stress and strain in the panel zone. such that either shear yielding of the panel zone

Under the action of forces, the panel zone deforms in initiates at the same time as flexural yielding of the

three modes: axial, shear, and bending. Only the shear beam elements or all yielding occurs in the beam.

deformation of the panel zone has a significant effect Calculation of thickness of PZ (Eqn 10, 11) that results

on the behavior of steel frames13. in simultaneous yielding of the panel zone and beam is

Recent ANSI/ AISC seismic provisions include as given below.

design equations to calculate panel zone design shear

Journal of Structural Engineering 395

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

æ h - db ö÷ ANSI/AISC (358-05)9 and FEMA-350 (2000)3

C y M c çç

çè h ÷÷ø Continuity plates need not be provided when the column

t pz = (10)

( 0.9 )0.6 Fyc Ryc d c ( db - tbf ) flange thickness, tcf, is greater than or equal to the value

given by either of the following values (Eqn 12,13).

1

Cy = (11) Fyb Ryb

Z be tcf ³ 0.4 1.8bbf tbf (12)

C pr

Sb Fyc Ryc

If tpz, as calculated above, is greater than the thickness tcf ³ bbf / 6 (13)

of the column web, doubler plates are provided, or the

column size is increased to a section with adequate web where CP are required, the thickness of the plates shall

thickness. As the thickness of web in this particular be determined as: For one-sided (exterior) connections,

region of column varies, column PZ may be considered continuity plate thickness shall be at least one-half of the

as weak, balanced or strong. thickness of the beam flange. For two-sided (interior)

connections; the continuity plate thickness shall be at

CODAL PROVISIONS - CONTINUITY PLATES (CP) least equal to the thicker of the two beam flanges on

REQUIREMENT either side of the column.

Continuity plates are the stiffeners that provide a load ANSI/AISC (360-05)10 and AISC Steel Design Guide

path for the flanges on both sides of the column. When Series-13(1999)12

stiffeners are required, it is normal to place a full-depth

transverse stiffener on each side of the column web. Further, as per current AISC specifications for structural

The stiffener also serves as a boundary to the very steel buildings the non-seismic provisions that govern

highly stressed panel zone. the design of continuity plates are based on four column

limit states: (1) local flange bending Eqn. (14), (2) local

Post-Northridge studies have shown that even web yielding Eqn. (15), (3) web crippling Eqn. (16) and

when continuity plates of substantial thickness are (4) web compression buckling Eqn. (17) as discussed

used, inelastic strains across the weld of the beam in detail below:

flange to the column flange are substantially higher

opposite the column web than they are at the flange 1) Local Flange Bending (LFB): The design local

tips. The disproportionate strains can cause the weld flange bending strength fRn is calculated as

stress at the center of the flange to exceed the tensile below

strength prematurely based on a uniform average stress Rn = 0.9 ´ 6.25´ tcf2 Fyc (14)

distribution through the entire weld.

2) Lateral Web Yielding (LWY): The column

ANSI/ AISC (341-05)8 and FEMA-350 (2000)3 resistance for LWY is given by following

equation

When considering the elimination of continuity plates,

Rn = 1´( 5k + N )Fycwtcw (15)

currently as per ANSI/ AISC 341-05 use of CP is

recommended in all cases, unless tests show a given 3) Web Crippling (WC): The column web crippling

connection will work without them based on tests. resistance is given by equation, when the

In addition, FEMA350 states that unless project- concentrated compressive force to be resisted is

specific testing is performed to demonstrate that applied at a distance from the member end that is

continuity plates are not required, RBS moment greater than or equal to by equation below

connections should be provided with continuity plates, é 1.5 ù

when the column flange thickness is below a minimum ê æç 3 N ö÷æç tcw ö÷÷ ú EFycwtcf

2

Rn = 0.75´ 0.8t ê1 + çç ÷÷çç ÷ ú (16)

ê çè d c ÷øçè tcf ÷÷ø ú

cw

value. The required minimum thickness is based tcw

êë úû

primarily on the beam flange width and thickness.

when it is less than d/2 then in above equation: a)

for N / d c £ 0.2 factor 0.8 changes to 0.4, b) for

Journal of Structural Engineering 396

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

N / d c > 0.2 factor 0.8 changes to 0.4 and term 3N/d the Eqns. (1-9). The required PZ strength and thickness

changes to 4N/d – 0.2. is compared to the design PZ shear strength and column

4)Web Compression Buckling (WCB): When a pair of web thickness. Then as per design requirement doubler

compressive flange forces coincide on opposite plates are provided on both sides of the PZ, or the

sides of the column web subjected to compression column size is increased to a section with adequate

buckling, the web must have its slenderness ratio web thickness. The doubler plates are plug-welded to

to avoid the possibility of out-of-plane buckling. the column web to prevent local buckling as well as to

achieve web thickness for weak, medium and strong

é 24t 3 EF ù PZ. In Table.1, for all connections CP equal in thickness

Rn = 0.9 ´ êê

cw ycw ú

ú (17) to the beam flange were provided and PZ required shear

êë Tc úû

strength is compared with design strength.

The web compression buckling provision (Eqn 17) Behavior and performance of RBS moment

applies only when there are compressive forces on both connection significantly depends on the behavior

flanges of a member at the same cross-section, such as of column PZ. General consideration for specimens

that might occur at the bottom flange of two back-to- with ‘balanced’ panel zone strength is that specimens

back moment connections under gravity loads. Its use are designed to promote yielding in both PZ and in

in the case of external beam-to-column connection is the beams. Specimens with ‘strong’ PZ are designed

conservative. But the importance of the web stiffness so that virtually all yielding would occur within the

t3cw/Tc can be studied to observe the torsional restrain beams, with panel zone remaining essentially elastic.

to column flange. In this case beam lateral torsional buckling (LTB),

The required strength, Ru, for the various continuity beam flange local buckling (FLB) and beam web local

plate limit states is based on the force delivered to the buckling (WLB) will be observed. Finally, specimens

connection by the beam flange. This equation (Eqn 18) with ‘weak’ PZ are designed so that virtually all yielding

considers the beam flange reduction. occur in the panel zone, with the beams remaining

essentially elastic.

1.1Ry Fy Z b + Vb S h

Ru = (18) Apart from Eqns. (1-9), which are generally used,

db - tbf

following equations are also used by some researchers.

When the required strength exceeds the available Equations (19-21) are the equations used to calculate

strength as determined for the column PZ and CP listed panel zone design shear strength by Oskouei and

above, stiffeners and/or doublers shall be provided and Gerami14 (Uniform Building Code15), Lee, et

shall be sized for the difference between the required al.16,17 (Krawinkler18), and by Gilton and Uang19,

strength and the available strength for the applicable respectively.

limit state. Equations (22-24) are the equations used to calculate

panel zone required shear strength when the moment at

RESEARCH ON RBS CONNECTIONS WITH the reduced beam section reaches the plastic moment

REFERENCE TO CONTINUITY PLATES capacity by von Mises yield criterion, Roeder20, Tabar

RBS Connection with Continuity Plates and Doubler and Deylami21-23, respectively.

Plates é 3bcf tcf2 ùú

As mentioned above usually, for one-sided (exterior) R n = (0.55 Fycw d c tcw )´ êê1 + (19)

êë db d c tcw úúû

connections, continuity plate having thickness of at least

one-half of the thickness of the beam flange and for two- é 3bcf tcf2 ùú

sided (interior) connections; the continuity plate having R n = 0.75(0.6 Fycw d c tcw )´ ê1 +

ê (20)

êë db d c tcw úúû

thickness of at least equal to the thicker of the two beam

flanges on either side of the column are provided as v = 0.6 Fyc 2bcf tcf (21)

shown in Fig.4a. Then the panel zone is designed as per

v y = 0.6 Fyc d c tcw (22)

Journal of Structural Engineering 397

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

æL d ö é d ù

æ M RBS ö÷ çç b 2 + c 2 ÷÷ æ db ö ê Lb + c ú

ç ç ÷÷´ç1 - ÷÷ 1 1

VRBS , p = çç ÷´

çè db ÷÷ø ççç Lb - e ÷÷÷ ççè H ÷ø

(23) Vr = b E M p êê - 2 × ú

ú (24)

çè 2 ø ê 0.95db Lb Hú

êë úû

Table 1

Panel zone observations of various RBS studies

Sl. Ref. Author Country Year Type of No. of Tests with Shear tab PZ Observations Observations Remarks

No. No Frame/ Tests (without) connection W/B/S PZ Beam

loading Slab detail

1 24 Jones, S. L., USA 2002 Double sided 8 3(3) Bolted W Severe Fracture of Replacing part of

Fry, G.T., cyclically yielding beam flange beams is easier

and loaded at near weld than the the parts of

Engelhardt,M. top of the B Yielding WLB, FLB column and beam

D. column. therefore Balanced

S No yielding WLB, FLB PZ.

1(1) Welded B Yielding WLB, FLB

2 19 Gilton, C. S., USA 2002 One sided cy- 2 (2) Welded --- --- ---- Since the PZ is com-

and Uang, clically loaded posed of two flanges,

C. M. (weak at the end of the PZ requirement is

axis ) the beam usually satisfied

3 1 6 , Lee, C. H., Korea 2004 One sided 8 (2) Bolted B Yielding Brittle fracture 0 . 7 0 V R P S , p /

17 Jeon, S. W., cyclically across Rn0.90

Kim, J. H., loaded at the Beam flange 0.90 Vr/Rn 1.1

and Uang, end of the at weld access

C.M. beam. hole

S No Yielding LTB

(6) Welded B Yielding FLB

S No yielding LTB

4 2 1 , Tabar, A. M., Iran 2004 One sided 9 (9) Welded W T h o r o u g h l y Susceptible 0.70Vr / Rn

2 2 , and Deylami, cyclically yielded to fracture Vr / Rn 0.85

23 A. loaded at the B Very less WB

end of the yielding

beam.

S No yielding LTB,WB

5 2 5 , Zhang, X., USA 2006 Double sided 3 (3) Welded W S h e a r Large plastic Balanced PZ

26 and Ricles, cyclically distortion strain at

J. M (deep loaded at (Minimal welds /greater

Columns) top of the Column twist) fracture

column. potential FLB

B Shear distor- WLB , FLB

tion reduced

(More Column

twist)

S S h e a r WLB , FLB

distortion

reduced (More

Column twist)

6 14 Oskouei, Iran 2008 Double sided 8 (8) Welded W C o l l a p s e C o l l a p s e VRBS,p / Rn = 0.90

A. G., and cyclically merely occurs merely occurs

Gerami, M. loaded at in PZ and joint in PZ and

top of the area. joint area.

column. B --- ----

S Elastic All

Substructure

energy wasted

in beam.

[W: Weak, B: Balanced, S: Strong]

Journal of Structural Engineering 398

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

Properly designed PZ could avoid problems related of ANSI/AISC, the specimens satisfied minimum web

strong or weak PZ and use of expensive doubler plates. and flange thickness requirements, which eliminated

Excessive yielding in weak PZ can lead to low cycle the need for doubler plates and continuity plates. It was

fatigue and brittle fracture of the beam flange to column observed that all specimens reached a total interstory

welds. Strong PZ may induce probability of local and drift angle of 0.05 radians, which satisfied the AISC

lateral buckling in beam. Therefore, a balanced PZ requirements for a special moment frame of a total

strength criterion was proposed by various researchers interstory drift angle of 0.04 radians, with strength not

and to achieve this desired range was also suggested as less than 80 percent of the capacity. Local instability

discussed in Table 1. at high levels of interstory drift; that was attributed to

RBS connection can be classified into two types lateral-torsional buckling of the beam bottom flange

according to the web attachment details: RBS with coupled with local twisting of the connected column

welded web connections and RBS with bolted web flange was observed.

connections. FEMA 3503 permits both RBS bolted and

welded web connections for ordinary moment frames

Continuity plate,

(OMF) and SMF. But as per ANSI/AISC 358-059 RBS top and bottom on both sides

bolted web connection is qualified for intermediate

moment frames (IMF) and should not be used for Doubler plate, on both sides

SMF.

From the observations shown in Table 1, balanced PZ

welded web connection may have an edge over bolted

web connection, due to brittle fracture was observed

near weld access hole in bolted web connection.

Another consideration for PZ strength is the

strain demand around the beam flange-column flange

weldment. PZ deformation and flange weldment

demand appeared nearly proportional. So, weldment in

a very weak PZ specimen must withstand considerably

higher demand than a weldment in a very strong or Fig. 4a RBS connection with continuity plates and doubler plates

balanced PZ specimen.

Further, to learn CP requirements for weak-axis

RBS connections Gilton and Uang19, performed studies

with the presence of continuity plates. It was observed

that, longer the CP stickout and trimming the corners,

reduces the stress concentration at the edge of the beam

flange groove weld. For one sided connections, effect

of adding a CP on the far-side of the column is found

unnecessary.

RBS Connection without Continuity Plates

Fig. 4b RBS connection without continuity and doubler Plates

Generally CP are provided as per the thickness

requirement given by AISC. However, the absolute

necessity of continuity plates in RBS moment Further for W14 and W18 sections, Pantelides28

connections is not bifurcated clearly. To establish a suggested that CP are required if the column web

design procedure for using the RBS beam-to-column thickness is less than the value given by Eqn. (25).

moment connection without CP Adan and Reaveley27, Also, observed that given equation safely limits local

Pantelides28 tested RBS connections as shown in Fig. 4b. web yielding and column flange twist even at higher

Column specimens were designed as per requirements level of inelastic drift.

Journal of Structural Engineering 399

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

1

æ 0.0026( Fyb tbf b f )1.69 ö÷3 Mp = Plastic moment capacity of the

tcw < ççç ÷÷ (25) beam section

çè Fycw ÷÷ø

Mc = Moment at column centerline

based on the beam plastic moment

CONCLUSIONS capacity projected from the beam

plastic hinge; the location of

A summary of behavior of reduced beam section

expected plastic hinge

moment connection with reference to continuity plates is

presented in this paper. Elimination of continuity plates Mpr / MRBS = Probable peak plastic hinge

in RBS moment connections can reduce the material moment

and labour cost for steel moment frame construction. N = length of bearing

It is seen that studies are generally performed with Pr = Required tensile strength

continuity plates and doubler plates. It is observed Pc = Available tensile strength/ yield

that to understand the behavior of RBS connection strength

further study is necessary to learn aspects like a) the

Ryb / Ryc / Ry = The ratio of the expected yield

behavior of column sizes other than W14 and W18

strength of the beam (column)

without continuity plates; b) study of continuity plates

material to the minimum specified

in conjunction with panel zone for more connections;

yield strength, in accordance with

c) absolute necessity and size of the CP on the far-side

the AISC Seismic Provisions.

of the column for weak- axis connections.

Rn / Rv / vy / v = Panel zone design shear strength

NOTATION Ru/VRBS.F / Vr = Panel zone required shear

strength

be = A coefficient , assumption range Rn = Design strength for various limit

1 - 0.85 states

f = Resistance factor Ru = Required strength

Cpr = A factor to account for the peak Sb = the elastic section modulus of

strength, defined as 1.15 for the the beam at the zone of plastic

RBS connection hinging

Cy = Ratio of yield moment capacity Tc = Clear distance between flanges

to the plastic moment capacity of less the fillet or corner radius for

the beam rolled shapes; distance between

E = Modulus of elasticity of steel adjacent lines of fasteners or the

clear distance between flanges

Fycw = Specified minimum yield stress

when welds are used for built-up

of column web

shapes

Fyb (Fyc) = Specified minimum yield stress

VRBS / Vb = Larger of the two values of shear

of the beam (column) flange

force at the centre of the reduced

Fy = The specified minimum yield beam section at each end of the

stress of the material of the beam

yielding element (beam/

Vc = Column shear

column).

Ze / Zbe = Plastic section modulus at center

H = Column height

of the reduced beam section

Lb / Lb / 2 = Beam length from column face

Zx = Plastic section modulus for full

to beam tip

beam cross-section

Mf = Probable maximum moment at

face of column

Journal of Structural Engineering 400

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

a = Horizontal distance between a 5. FEMA-352., “Recommended post-earthquake

column flange (face) and the start evaluation and repair criteria for welded, steel

of an RBS cut moment frame buildings”. Federal Emergency

Management Agency, Washington DC, USA,

b = Length of an RBS cut

2000.

bf = Width of beam flange

6. FEMA-353., “Recommended specifications and

bcf = Width of column flange quality assurance guidelines for steel moment

c = Depth of cut at the center of the frame construction for seismic applications”.

reduced beam section Federal Emergency Management Agency,

dc = Overall depth of column Washington DC, USA, 2000.

dz = Overall panel zone depth between 7. FEMA-355D., “State of the Art Report on

continuity plates Connection Performance”. Roeder C, Team

db = depth of beam Leader. Federal Emergency Management Agency,

h = The average story height of the Washington DC, USA, 2000.

stories above and below the 8. ANSI/AISC 341-05., “Seismic Provisions for

panel zone. Structural Steel Buildings- Including Supplement

k = Distance from outer face of the No. 1”. American Institute of Steel Construction,

flange to the web toe of the fillet Inc., Chicago, IL.2005.

t = Thickness of column web or 9. ANSI/AISC 358-05., “Prequalified Connections

doubler plate for Special and Intermediate Steel Moment Frames

for Seismic Applications including Supplement

tcf = Thickness of column flange

No.1”. American Institute of Steel Construction,

tcw = Column web thickness Inc., Chicago, IL. 2005.

tbf = Thickness of beam flange 10. ANSI/AISC 360-05., “Specification for Structural

tpz = Thickness of panel zone Steel Buildings”. American Institute of Steel

wz = Width of panel zone between Construction, Inc.,Chicago, IL. 2005.

column flanges 11. Hamburger, R. O., Krawinlker, H., Malley, J.

M. and Adan, S. M., “Seismic Design of Steel

REFERENCES Special Moment Frame- A Guide for Practicing

Engineers”. NEHRP Seismic Design Technical

1. Miller, D. K., “Lessons learned from the Northridge

Brief No. 2, USA, 2009.

earthquake”. Engg., Struct., Vol. 20,1998, pp 249–

260. 12. AISC Steel Design Guide Series-13, “Stiffenening

of Wide-Flange Columns at Moment Connections:

2. Nakashima, M. and Chusilp, P., “A partial view

Wind and Seismic Applications” American Institute

of Japanese post-Kobe seismic design and

of Steel Construction, Inc.,Chicago, IL.1999.

construction practices”. Earthquake Engineering

and Engineering Seismology, Vol. 4, pp 1–13. 13. Jin, J. and Tawil, S.E., “Evaluation of FEMA-

350 seismic provisions for steel panel zones”.

3. FEMA-350., “Recommended seismic design

Jl of Struct. Engg., ASCE, Vol.131, No.2, 2005,

criteria for new steel moment frame buildings”.

pp 250–258.

Federal Emergency Management Agency,

Washington DC, USA, 2000. 14. Oskouei, A. G. and Gerami, M., “Study of stiffness

effect of panel zone on ductility of RBS joint”.

4. FEMA-351., “Recommended seismic evaluation

Intl. Jl. of Sustainable Construct. Engg. and Tech.

and upgrade criteria for existing welded steel

Vol.1, 2010, pp 1–8.

moment frame buildings”. Federal Emergency

Management Agency, Washington DC, USA, 15. UBC1997, Uniform Building Code.

2000. 16. Lee, C. H., Jeon, S. W., Kim, J. H. and Uang, C.M.,

Journal of Structural Engineering 401

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

“Effect of panel zone strength and beam web of reduced beam section moment connections”.

connection method on seismic performance of Proceedings: 14th World Conf. on Earthquake

reduced beam section steel moment connections”. Engg., Beijing, China, 2008.

Jl of Struct. Engg., ASCE, Vol.131, No.12, 2005, 24. Jones, S. L., Fry, G.T. and Engelhardt, M. D.,

pp1854–1866. “Experimental evaluation of cyclically loaded

17. Lee, C.H., Jeon, S. W., Kim, J. J. and Uang, C.M., reduced beam section moment connections”. Jl

“Seismic performance of reduced beam section of Struct. Engg., ASCE, Vol.128, No.4, 2002,

steel moment connections: effects of panel zone pp 441–451.

strength and beam web connection method. 25. Zhang, X. and Ricles, J. M, “Seismic behavior of

Proceedings: 13th World Conf. on Earthquake reduced beam section moment connections to deep

Engg., Canada, 2004. columns”. Jl of Struct. Engg., ASCE, Vol.132,

18. Krawinkler,H., “Shear in beam-column joints in No.3, 2006, pp 358–367.

seismic design of steel frames”. Engg. Jl., AISC, 26. Zhang, X., Ricles, J. M., LU, L. W. and Fisher,

Vol. 15, No.3, 1978, pp 82–91. J. W., “Analytical and experimental studies on

19. Gilton, C. S. and Uang, C. M., “Cyclic response seismic behavior of deep column-to-beam welded

and design recommendations of weak-axis reduced beam section moment connection”.

reduced beam section moment connections”. Jl Proceedings: 13th World Conf. on Earthquake

of Struct. Engg., ASCE, Vol.128, No.4, 2002, pp Engg., Canada, 2004.

452–463. 27. Adan, S. M. and Reaveley, L. D., “The reduced

20. Roeder, C. W., “General issues influencing beam section moment connection without

connection performance”. Jl of Struct. Engg., continuity plates”. Proceedings: 13th World Conf.

ASCE, Vol. 128, No.4,2002, pp 420-428. on Earthquake Engg., Canada, 2004.

21. Tabar, A. M. and Deylami, A., “Instability of beams 28. Pantelides, C. P., Reaveley, L. D. and Adan, S. M.,

with reduced beam section moment connections “Chapter 23 - Analysing Steel Moment-Resisiting

emphasizing the effect of column panel zone Connections using Finite Element Modelling”. in

ductility”. Jl of Construct. Steel Research, Vol. 61, Papadrakakis, M., Charmpis, D. C., Lagaros, N.

2005, pp 1475-1491. D. and Tsompanakis, Y., (Eds), Computational

22. Deylami, A. and Tabar, A. M., “Effect of column Structural Dynamics and Earthquake Engineering

panel zone characteristics on instability of (pp 363-376), CRC Press, Taylor and Francis

beams with RBS moment resisting connections”. Group, UK, 2009.

Proceedings: 13th World Conf. on Earthquake

(Discussion on this article must reach the editor before

Engg., Canada, 2004. March 31, 2013)

23. Deylami, A. and Tabar, A. M., “Experimental

study on the key issues affecting cyclic behavior

Journal of Structural Engineering 402

Vol. 39, No. 4, OCTOBER - NoveMBER 2012

You might also like

- Drift Control Deep Beam-To-Deep Column Special Moment Frames Dengan Sambungan RbsDocument8 pagesDrift Control Deep Beam-To-Deep Column Special Moment Frames Dengan Sambungan RbsAyulestariSimamoraNo ratings yet

- Cyclic Tests of Steel Moment Connections Rehabilitated With RBS or Welded Haunch - Uang Et Al - ASCEDocument12 pagesCyclic Tests of Steel Moment Connections Rehabilitated With RBS or Welded Haunch - Uang Et Al - ASCEkostas formulagrNo ratings yet

- 008-Reduced Beam Section Moment Connection With Reference To Bolted Web State of The Art ReviewDocument5 pages008-Reduced Beam Section Moment Connection With Reference To Bolted Web State of The Art ReviewSwati KulkarniNo ratings yet

- SEISMIC DESIGN OF NEW RBS MOMENT CONNECTION WITH CORRUGATED WEBDocument9 pagesSEISMIC DESIGN OF NEW RBS MOMENT CONNECTION WITH CORRUGATED WEBt7acarraNo ratings yet

- Lecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesDocument20 pagesLecture 10 (B) - DR S K Garg On Ductile Detailing of Steel BridgesSulabh GuptaNo ratings yet

- Experimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024Document13 pagesExperimental Study On Seismic Behavior of RC Column-Steel Beam Joints With Whole Column-Section Diaphragm - 2024KRISHNA MURARINo ratings yet

- Stress Analysis of Reduced Beam Section ConnectionsDocument10 pagesStress Analysis of Reduced Beam Section Connectionskukuh kurniawan dwi sungkonoNo ratings yet

- RBS 1Document12 pagesRBS 1Imam Usamah Abdul Shidiq 20 314No ratings yet

- ANSI-AISC 358-20 - C7SB - InglésDocument7 pagesANSI-AISC 358-20 - C7SB - InglésmanuelNo ratings yet

- Engineering Structures: Alireza Bagheri Sabbagh, Mihail Petkovski, Kypros Pilakoutas, Rasoul MirghaderiDocument16 pagesEngineering Structures: Alireza Bagheri Sabbagh, Mihail Petkovski, Kypros Pilakoutas, Rasoul MirghaderiSohini MishraNo ratings yet

- 2023, Yu Et Al., Seismic Behaviour of CFRPDocument23 pages2023, Yu Et Al., Seismic Behaviour of CFRPÁlvaro MendozaNo ratings yet

- ContentServer AspDocument11 pagesContentServer AspSantiago GonzalezNo ratings yet

- Norma Aisc 341 (Capítulo E)Document22 pagesNorma Aisc 341 (Capítulo E)ElmerNo ratings yet

- Effect of Serviceability Limits On Optimal Design of Steel Portal Frames by Phan 2013Document11 pagesEffect of Serviceability Limits On Optimal Design of Steel Portal Frames by Phan 2013fahmi aballiNo ratings yet

- 1 s2.0 S0263822312001092 MainDocument19 pages1 s2.0 S0263822312001092 Mainasaad biqaiNo ratings yet

- ER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame ConnectionDocument6 pagesER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame Connectioncancery0707No ratings yet

- Aparte Del Aisc 358Document4 pagesAparte Del Aisc 358Cristian SandovalNo ratings yet

- Monthly Steel Quiz Tests Your KnowledgeDocument2 pagesMonthly Steel Quiz Tests Your KnowledgeRajed MaglinteNo ratings yet

- Beam - Column Joint EC2Document11 pagesBeam - Column Joint EC2undf25No ratings yet

- Strengthening of Reinforced Concrete Columns by Steel Jacketing: A State of ReviewDocument10 pagesStrengthening of Reinforced Concrete Columns by Steel Jacketing: A State of Reviewsefatwrdk21No ratings yet

- Steel Column Tree PDFDocument9 pagesSteel Column Tree PDFDario P. YanezNo ratings yet

- Finite Element Modelling of Castellated Steel Beams Under Lateral-Distortional Buckling ModeDocument15 pagesFinite Element Modelling of Castellated Steel Beams Under Lateral-Distortional Buckling Modevijaykrishna kotapatiNo ratings yet

- Technical Column: Fretting (Inner Ply) PotentialDocument1 pageTechnical Column: Fretting (Inner Ply) PotentialRose Mary ChackoNo ratings yet

- Reinforced Concrete Exterior Wide Beam-Column-Slab Connections Subjected To Lateral Earthquake LoadingDocument10 pagesReinforced Concrete Exterior Wide Beam-Column-Slab Connections Subjected To Lateral Earthquake LoadingklheirosNo ratings yet

- Experimental Si Numerical Investigation PBRBDocument16 pagesExperimental Si Numerical Investigation PBRBmocanuNo ratings yet

- Design of Slab-Column Junctions in Flat Slabs: N. K. Subedi and P. S. BaglinDocument13 pagesDesign of Slab-Column Junctions in Flat Slabs: N. K. Subedi and P. S. BaglinalmeidavaleNo ratings yet

- Concrete Columns PDFDocument9 pagesConcrete Columns PDFAnne Karollynne CastroNo ratings yet

- Journal of Constructional Steel Research: Mohamad A. Morshedi, Kiarash M. Dolatshahi, Shervin MalekiDocument15 pagesJournal of Constructional Steel Research: Mohamad A. Morshedi, Kiarash M. Dolatshahi, Shervin MalekiSantiago GonzalezNo ratings yet

- Installation of Steel Framing Members To Receive Screw-Attached Gypsum Panel ProductsDocument9 pagesInstallation of Steel Framing Members To Receive Screw-Attached Gypsum Panel ProductsINARQ1979No ratings yet

- Base Plate and Anchor Rod Design 2nd PDFDocument8 pagesBase Plate and Anchor Rod Design 2nd PDFAmol JdvNo ratings yet

- Trahair (2009) - Buckling Analysis Design of Steel FramesDocument5 pagesTrahair (2009) - Buckling Analysis Design of Steel FramesGogyNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Shamass 2019Document15 pagesShamass 2019LeonardoMadeira11No ratings yet

- Optimal Design of CFS Portal FramesDocument14 pagesOptimal Design of CFS Portal FramesTito MuñozNo ratings yet

- LCs With FDs As A Technique For Seismic Retrofit of Steel MRFs - Draft - For - RG PDFDocument8 pagesLCs With FDs As A Technique For Seismic Retrofit of Steel MRFs - Draft - For - RG PDFborisbelevNo ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- Capacity loss of steel bridges from corrosionDocument6 pagesCapacity loss of steel bridges from corrosionFaisalNo ratings yet

- Analysis of RC Beam Project Report CoverDocument21 pagesAnalysis of RC Beam Project Report CoverYashvanth KadurNo ratings yet

- SECTION 6 .Steel NSCP-commentaryDocument49 pagesSECTION 6 .Steel NSCP-commentaryJyrus Jyles CadienteNo ratings yet

- Fatigue of Deformed Welded-Wire ReinforcementDocument15 pagesFatigue of Deformed Welded-Wire ReinforcementMridul HasanNo ratings yet

- Advantages of Bundling FRP Rebar: Steven E. Williams, PEDocument5 pagesAdvantages of Bundling FRP Rebar: Steven E. Williams, PELuis Guillermo González EcheniqueNo ratings yet

- Minimum Exural Ductility Design of High-Strength Concrete BeamsDocument11 pagesMinimum Exural Ductility Design of High-Strength Concrete BeamsLordgie AgtucaNo ratings yet

- Garai Et Al 2024 Simulation Based Fracture Assessment of Seismic Moment Frame Connections With Box ColumnsDocument16 pagesGarai Et Al 2024 Simulation Based Fracture Assessment of Seismic Moment Frame Connections With Box ColumnsGUSTAVO ANDRÉS NIÑO BAUTISTANo ratings yet

- سوراخدارDocument14 pagesسوراخدارh.ezatisazehNo ratings yet

- Irjet V8i1007Document5 pagesIrjet V8i1007Diwakar Singh RajputNo ratings yet

- Engineering Structures: Cristopher D. Moen, B.W. SchaferDocument13 pagesEngineering Structures: Cristopher D. Moen, B.W. SchaferFabio Saraiva BoxNo ratings yet

- Performance Based Evaluation of Response Reduction Factor of Steel Staging Water TankDocument9 pagesPerformance Based Evaluation of Response Reduction Factor of Steel Staging Water TankCHETAN JAIPRAKASH CHITTENo ratings yet

- Steel Interchange: Tension-Only OCBFDocument2 pagesSteel Interchange: Tension-Only OCBFhector diazNo ratings yet

- Global Optimization of Cold-Formed Steel Channel SectionsDocument8 pagesGlobal Optimization of Cold-Formed Steel Channel SectionsGogyNo ratings yet

- Srividya College of Engineering and Technology Question BankDocument6 pagesSrividya College of Engineering and Technology Question BankAravindNo ratings yet

- Investigations On The Influence of Angular and Linear Misalignment On The Fatigue Strength of HFMI-treated Structural Steel Butt JointsDocument14 pagesInvestigations On The Influence of Angular and Linear Misalignment On The Fatigue Strength of HFMI-treated Structural Steel Butt JointsengineeringNo ratings yet

- Shear Connection in Composite Bridge Beams - SteelconstructionDocument12 pagesShear Connection in Composite Bridge Beams - Steelconstructionpatricklim1982No ratings yet

- Guidance Note Shear Connectors No. 2.11: ScopeDocument4 pagesGuidance Note Shear Connectors No. 2.11: ScopeDesigns3 ShreeprefabNo ratings yet

- Purlins 3 PDFDocument35 pagesPurlins 3 PDFrajNo ratings yet

- Capitulo 6 (358-10)Document5 pagesCapitulo 6 (358-10)tzawar mishkeNo ratings yet

- End Plate ConnectionsDocument9 pagesEnd Plate ConnectionsJohn PetterNo ratings yet

- Pre-Qualified Seismic Moment Connection: January 2010Document6 pagesPre-Qualified Seismic Moment Connection: January 2010Lucas HoodNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Manuscript Challenges in Engineering Education in India During The Time of Corona Virus Pandemic and The Consequent Total LockdownDocument10 pagesManuscript Challenges in Engineering Education in India During The Time of Corona Virus Pandemic and The Consequent Total LockdownSwati KulkarniNo ratings yet

- Ijaret 12 03 032Document8 pagesIjaret 12 03 032Swati KulkarniNo ratings yet

- 019-Study of Reduced Beam Section Profiles Using Non-Linear Finite Element AnalysisDocument10 pages019-Study of Reduced Beam Section Profiles Using Non-Linear Finite Element AnalysisSwati KulkarniNo ratings yet

- Study of Special Moment Frame & Reduced BeamDocument11 pagesStudy of Special Moment Frame & Reduced BeamSwati KulkarniNo ratings yet

- 013-Comparative Study of Steel Beam Column Connection With and Without Reduced Beam Section Moment Connection For Indian ProfilesDocument9 pages013-Comparative Study of Steel Beam Column Connection With and Without Reduced Beam Section Moment Connection For Indian ProfilesSwati KulkarniNo ratings yet

- 007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateDocument7 pages007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateSwati KulkarniNo ratings yet

- Ijaret 12 03 032Document8 pagesIjaret 12 03 032Swati KulkarniNo ratings yet

- 007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateDocument7 pages007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateSwati KulkarniNo ratings yet

- 001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewDocument10 pages001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewSwati KulkarniNo ratings yet

- Topic Simple BeamDocument7 pagesTopic Simple BeamSwati KulkarniNo ratings yet

- Topic Simple BeamDocument7 pagesTopic Simple BeamSwati KulkarniNo ratings yet

- 006-A Software Solution To Help Design Steel Beam To Column Connection PDFDocument11 pages006-A Software Solution To Help Design Steel Beam To Column Connection PDFSwati KulkarniNo ratings yet

- Ijaret 12 03 032Document8 pagesIjaret 12 03 032Swati KulkarniNo ratings yet

- 03-Modern Strengthening Strategies For Steel Moment ResistingDocument9 pages03-Modern Strengthening Strategies For Steel Moment ResistingSwati KulkarniNo ratings yet

- 002-Study of Steel Moment Connection With and Without Reduced Beam SectionDocument7 pages002-Study of Steel Moment Connection With and Without Reduced Beam SectionSwati KulkarniNo ratings yet

- 007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateDocument7 pages007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateSwati KulkarniNo ratings yet

- 006-A Software Solution To Help Design Steel Beam To Column Connection PDFDocument11 pages006-A Software Solution To Help Design Steel Beam To Column Connection PDFSwati KulkarniNo ratings yet

- 007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateDocument7 pages007-Behavior of Reduced Beam Section Moment Connection With Varying Thickness of Continuity PlateSwati KulkarniNo ratings yet

- A Study of Reduced Beam Section Profiles Using Finite Element AnalysisDocument6 pagesA Study of Reduced Beam Section Profiles Using Finite Element AnalysisOmar Eladel MahmoudNo ratings yet

- 001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewDocument10 pages001-Behaviour of Reduced Beam Section Moment Connection With Refernce To Continuity Plates State Od Art ReviewSwati KulkarniNo ratings yet

- 004-Sutability of Indian Hot Rolled Parallel Flange SectionsDocument14 pages004-Sutability of Indian Hot Rolled Parallel Flange SectionsSwati KulkarniNo ratings yet

- Leopold Matrix Predicts Pulp and Paper Project ImpactsDocument4 pagesLeopold Matrix Predicts Pulp and Paper Project ImpactsSwati KulkarniNo ratings yet

- A Study of Reduced Beam Section Profiles Using Finite Element AnalysisDocument6 pagesA Study of Reduced Beam Section Profiles Using Finite Element AnalysisOmar Eladel MahmoudNo ratings yet

- 002-Study of Steel Moment Connection With and Without Reduced Beam SectionDocument7 pages002-Study of Steel Moment Connection With and Without Reduced Beam SectionSwati KulkarniNo ratings yet

- Basic Civil Engineering FundamentalsDocument40 pagesBasic Civil Engineering FundamentalsSwati KulkarniNo ratings yet

- The Forest (Conservation) Act, 1980 - Arrangement of SectionsDocument2 pagesThe Forest (Conservation) Act, 1980 - Arrangement of SectionsarjunNo ratings yet

- Leopold Matrix Predicts Pulp and Paper Project ImpactsDocument4 pagesLeopold Matrix Predicts Pulp and Paper Project ImpactsSwati KulkarniNo ratings yet

- EN 1993-1-1: 2005 Global Analysis and StabilityDocument9 pagesEN 1993-1-1: 2005 Global Analysis and StabilitySengthai TolaNo ratings yet

- "Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionDocument6 pages"Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionGustavo PaganiniNo ratings yet

- DEC-2018-JAN 2019 - CV-minDocument96 pagesDEC-2018-JAN 2019 - CV-minSujithSujiNo ratings yet

- EB001 CH14 - Placing and Finishing ConcreteDocument55 pagesEB001 CH14 - Placing and Finishing ConcreteJuan MartinezNo ratings yet

- EverComp 47.5 Property SheetDocument1 pageEverComp 47.5 Property SheetSapphire RahimNo ratings yet

- Daily Report Format: Project:-Majestic Tower Location:-Nahur Date:-6/07/2017Document2 pagesDaily Report Format: Project:-Majestic Tower Location:-Nahur Date:-6/07/2017mangeshshinde124No ratings yet

- Supplier, Subcon, Material ApprovalDocument1 pageSupplier, Subcon, Material ApprovalSuyanto Cah PatiNo ratings yet

- Hi SpanDocument54 pagesHi Spangdoyle7282No ratings yet

- PETRAPeikko Group 003 TMAWebDocument34 pagesPETRAPeikko Group 003 TMAWebSales ConstructionNo ratings yet

- Guidelines For WaterproofingDocument49 pagesGuidelines For WaterproofingArbaaz Parvez100% (3)

- Bamboo Reinforcement Concrete - Ghavami - 2004Document13 pagesBamboo Reinforcement Concrete - Ghavami - 2004immortalsky100% (2)

- Steel GirderDocument42 pagesSteel GirderPutri PuttNo ratings yet

- Administration Block - Tender BOQDocument42 pagesAdministration Block - Tender BOQChrispen MachipisaNo ratings yet

- Lect3 - Eqivalent Load - 1151Document17 pagesLect3 - Eqivalent Load - 1151CheongNo ratings yet

- TALAT Lecture 2710: Static Design ExampleDocument82 pagesTALAT Lecture 2710: Static Design ExampleCORE MaterialsNo ratings yet

- Construction of Multi-Purpose Building, Barangay Mahayahay, Iligan CityDocument8 pagesConstruction of Multi-Purpose Building, Barangay Mahayahay, Iligan CityReymon NepomucenoNo ratings yet

- STAAD.Pro V8i Structural Engineering TrainingDocument3 pagesSTAAD.Pro V8i Structural Engineering TrainingAnukool kumarNo ratings yet

- Posi-Strut - Posi Strut Floor Roof Installation ManualDocument32 pagesPosi-Strut - Posi Strut Floor Roof Installation ManualLê Hoàng TháiNo ratings yet

- PLATE KapalDocument11 pagesPLATE KapalRizal HidayatullahNo ratings yet

- Why Midas CivilDocument54 pagesWhy Midas CivilJorge MartinezNo ratings yet

- Single Tension Fastener Away From Edges Based On ACI 318-02Document2 pagesSingle Tension Fastener Away From Edges Based On ACI 318-02civixxNo ratings yet

- Tewodros TesfahunDocument155 pagesTewodros TesfahunMahmoud HegazyNo ratings yet

- CVEN 444 - Homework 5 - Concrete beam and slab design problemsDocument9 pagesCVEN 444 - Homework 5 - Concrete beam and slab design problemsOmar Calisaya RamosNo ratings yet

- Residential Building Drawing MID-Term ExamDocument6 pagesResidential Building Drawing MID-Term ExamRahul SinhaNo ratings yet

- Portal Frame Analysis by Moment Distribution MethodDocument199 pagesPortal Frame Analysis by Moment Distribution MethodNikhilNo ratings yet

- Vertikal Cement MillDocument8 pagesVertikal Cement MillMohamad Taufik (abang topek)No ratings yet

- Indian Standards On Earthquake EngineeringDocument12 pagesIndian Standards On Earthquake EngineeringHari RNo ratings yet

- Seminar Report PDFDocument8 pagesSeminar Report PDFAbdul RafayNo ratings yet

- WWW SefindiaDocument11 pagesWWW SefindiaSUSHANTBIJAMNo ratings yet

- Chpater 82 Piling ProblemsDocument12 pagesChpater 82 Piling ProblemsGan Khai SianNo ratings yet