Professional Documents

Culture Documents

2.4 Wheel Shop

2.4 Wheel Shop

Uploaded by

BILAL FAROOQUICopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- C-6.2 HSTDocument38 pagesC-6.2 HSTBILAL FAROOQUI100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

- Building - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoDocument128 pagesBuilding - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoBILAL FAROOQUINo ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- Cga C-8-2017 Last PageDocument2 pagesCga C-8-2017 Last PageBILAL FAROOQUINo ratings yet

- Cga C-6.1 First Page-2019Document2 pagesCga C-6.1 First Page-2019BILAL FAROOQUINo ratings yet

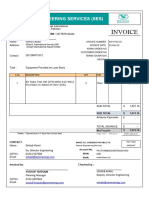

- Inv 0148 22 (Fly Baghdad)Document1 pageInv 0148 22 (Fly Baghdad)BILAL FAROOQUINo ratings yet

- Cga-6.3 - 2019 First PageDocument2 pagesCga-6.3 - 2019 First PageBILAL FAROOQUINo ratings yet

- Cga C-6.1 Last PageDocument1 pageCga C-6.1 Last PageBILAL FAROOQUINo ratings yet

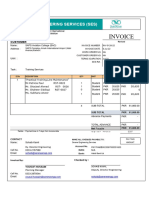

- Inv 0145 22 (Assl)Document1 pageInv 0145 22 (Assl)BILAL FAROOQUINo ratings yet

- INV 0140 22 (Air Sial Limited)Document1 pageINV 0140 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0147 22 (Vision Air)Document1 pageInv 0147 22 (Vision Air)BILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- Inv 0135 22 (Pia)Document1 pageInv 0135 22 (Pia)BILAL FAROOQUINo ratings yet

- INV 0144 22 (Jordan Aviaition)Document1 pageINV 0144 22 (Jordan Aviaition)BILAL FAROOQUINo ratings yet

- Inv 0139 22 (Vision Air)Document1 pageInv 0139 22 (Vision Air)BILAL FAROOQUINo ratings yet

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- C-6.1 HSTDocument24 pagesC-6.1 HSTBILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- C 6 HSTDocument30 pagesC 6 HSTBILAL FAROOQUINo ratings yet

- C-8 HSTDocument10 pagesC-8 HSTBILAL FAROOQUINo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet

2.4 Wheel Shop

2.4 Wheel Shop

Uploaded by

BILAL FAROOQUICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.4 Wheel Shop

2.4 Wheel Shop

Uploaded by

BILAL FAROOQUICopyright:

Available Formats

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

2.4. WHEEL SHOP (C14).............................................................................................................................................. 2

2.4.1. PURPOSE..................................................................................................................................................................2

2.4.2. RESPONSIBILITY....................................................................................................................................................... 2

2.4.3. SCOPE:..................................................................................................................................................................... 2

2.4.4. GENERAL PROCEDURE FOR WHEEL SHOP................................................................................................................2

2.4.4.2. WORK FLOW DIAGRAM OF GENERAL PROCEDURE FOR WHEEL SHOP............................................................5

2.4.5. FORMS IN USE:........................................................................................................................................................ 6

2.4.6. RECORDS OF WORK ACCOMPLISHMENT.................................................................................................................6

Serene Engineering Services (Pvt.) Ltd. Page 1 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

2.4. WHEEL SHOP (C14)

Documents Referred: Forms: SES-SHOP-2403, SES-SHOP-2401, SES-SHOP-2402, SES-EBPO-005, SES-SHOP-

1211, SES-SSPC-1110

2.4.1. PURPOSE

The purpose of this chapter is to define procedure undertaken by wheel shop under C14

component maintenance ratings.

2.4.2. RESPONSIBILITY

1. Prime responsibility for control of these procedure lies with the DDE (Form-04 Holder)

whereas, CMA holders of wheel shop are equally responsible for managing and keeping

these procedures updated.

2. CMA holders of wheel shop is responsible to ensure no work shall be carried out outside

the capability unless approved.

3. Any unapproved procedure must not be adopted unless specified otherwise.

4. CMA holders of wheel shop is responsible to ensure no minor or major changes are

allowed unless brought in knowledge of the DDE and approved by CE &TQA.

2.4.3. SCOPE:

Wheel shop CMA holder shall be responsible for keeping updated the scope of approval of

the shop. Scope of the wheel shop as defined in MOE section 1.9.4 is under C14 component

maintenance rating i.a.w approved company capability list (CCL).

2.4.4. GENERAL PROCEDURE FOR WHEEL SHOP

Wheel shop CMA holder shall carryout following steps after arrival of components in shop as

defined in CCL under C14 component rating:

1. Ensure receiving of Work order (WO) from SSPC office or concerned shop/section after

checking the CCL scope.

2. Evaluate the task according to shop’s capability i.a.w maintenance data, personnel

authorization & CCL. If scope does not fall in shop scope, inform SSPC office for further

necessary action.

3. Ensure receipt of work order and un-serviceable tag with the wheel assembly.

4. Check the following incoming inspection of U/S wheel assembly before accepted for

shop maintenance work. If found anything found unsatisfactory, inform SSPC for further

action at customer end.

a) At the time of loading U/S wheel to the shop, customer make sure that no irrelevant

part fitted/installed on the wheel assembly.

b) Wheel & Bearing Protectors must be installed on the wheel assembly.

c) Wheel must be deflated to 40 psi before dispatch to shop.

Serene Engineering Services (Pvt.) Ltd. Page 2 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

5. If the task found within shop capability scope and incoming inspection found

satisfactory, then enter the task in shop incoming/outgoing register on latest.

6. Check availability of material, spares in store or customer and tools/equipment in shop

for the task received. If found anything unavailable inform SSPC for further action.

7. Check the wheel history cards (Form No: SES-SHOP-2402) if no history is available set up

the wheel for overhaul as per applicable CMMs or OEM instruction.

8. CMA holder shall record the details of work order on latest incoming & outgoing register

& record of history card on form no. SES-SHOP-2402.

9. Carry out inspection of wheel assembly for damaged, missing or defective parts as per

applicable CMMs or OEM instruction.

10. Deflate tire immediately prior to disassembly as per applicable CMMs or OEM

instruction.

11. Carry out dismantling and cleaning of wheel assembly and parts as per applicable

components maintenance manual (CMM) or OEM recommended procedures.

12. After dismantling & cleaning wheel assembly, if wheel is under overhaul process

dispatch wheel halves to paint facility for paint stripping.

13. Carry out thorough inspection of wheel halves, bearings, tie bolts, nuts, heat shields,

rotor drive keys and other spares, as per CMM or OEM recommended procedure. If found

beyond repair limit, reject the component as per procedure defined SPM 1.7 & MEP 19 and

handed over the component to customer.

14. If found within repair or acceptable limit as per CMM or OEM recommended procedure

but not in the shop capability scope defined in CCL, return the component to customer and

inform SSPC.

15. If wheel is under tire change process, then dispatch wheel halves to NDT shop for NDT

task as per CMM or OEM recommended procedure, by initiating fractional work order on

latest form SES-EBPO-005.

16. It is mandatory to have a reference of WO no. on fractional work order (FWO).

17. If wheel assembly found unsatisfactory in NDT task, then reject the component as per

procedure defined SPM 1.7 & MEP 19 and handed over the component to customer.

18. If non-destructive testing (NDT) task found satisfactory or within allowable limit as per

CMM or OEM recommended procedure, then proceed to assembly buildup of wheel halves.

19. After NDT wheel halves assembles together with tire & attachment hardware’s as per

CMM or OEM recommended procedure.

20. Carry out assembly of wheel halves in accordance with latest CMM or OEM

recommended procedure.

21. Carry out inflation of wheel assembly with dry nitrogen gas using recommended wheel

inflation procedure in CMM or OEM recommended procedure.

22. Hold wheel assembly in inflated condition for at least sixteen (16) hours and check for

drop of pressure limit.

23. Wheel assembly leak test shall be carried out for possible causes of leakage as per CMM

or OEM recommended procedure.

Serene Engineering Services (Pvt.) Ltd. Page 3 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

Note: Hardness check shall only be required on wheel assemblies removed due to fuse plug

blown or tire burst.

Caution: Make sure that the wheel assembly is inflated to testing pressure in safety cage as

per components maintenance manual (CMM) by using calibrated pressure regulator.

24. Complete following documents on completion of work package.

a) Incoming & Outgoing register as per Form No.: SES-SHOP-2401

b) Wheel history cards as per Form No.: SES-SHOP-2402

c) Authorized release certificate (ARC) as per Form No.: PCAA Form 01

d) Component rejection certificate as per Form No.: SES-SHOP-1211 (if applicable)

25. Wheel Shop CMA holder shall ensure wheel protectors for safe transportation.

26. Dispatch the wheel assembly with relevant documents such as PCAA Form 01 to SES

store or customer.

27. Keep the record of the work package along with supporting documents in soft or hard

copy for 3 years.

28. Send complete work package along with respective documents to SSPC for further action

at their end.

Serene Engineering Services (Pvt.) Ltd. Page 4 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

2.4.4.2. WORK FLOW DIAGRAM OF GENERAL PROCEDURE FOR WHEEL SHOP

WORK ORDER

(From SSPC)

ASCERTAINING OF WORK

EVALUATE AS PER CMM

CHECK HISTORY RECORDS OF

INCOMING. RECORD IN INCOMING

& OUTGOING HISTORY CARD

YES

DEFLATE THE WHEEL & DISMANTLE

CARRY OUT WORK AS PER APPLICABLE CMM & FILL WORKSHEET

NDT

CARRIED OUT WORK AS PER APPLICABLE CMM AND DOCUMENTATION

UNSATISFACTORY

JOB FINDINGS REJECT VIA (SES

SHOP 1208)

SATISFACTORY

ASSEMBLY AS PER CMM

UPDATE INCOMING & OUTGOING REGISTER AND HISTORY CARD

COMPLETE WORK PACKAGE TO SENT TO SSPC OFFICE & COMPONENT

SEND TO RELAVENT STORE WITH RELAVENT DOCUMENTS

Serene Engineering Services (Pvt.) Ltd. Page 5 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.4

Issue: 05

WHEEL SHOP (C14) Revision: 00

Date: 22-Nov-2021

2.4.5. FORMS IN USE:

All list of controlled forms used in wheel shop shall be maintained by SSPC office on SES-

SSPC-1110.

2.4.6. RECORDS OF WORK ACCOMPLISHMENT

ALL procedure defined on SPM part 01 regarding filling of work sheet, WO, ARO, UWO and

FWO shall be applicable to complete the work package and keep in records for 3 years.

Serene Engineering Services (Pvt.) Ltd. Page 6 of 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- C-6.2 HSTDocument38 pagesC-6.2 HSTBILAL FAROOQUI100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

- Building - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoDocument128 pagesBuilding - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoBILAL FAROOQUINo ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- Cga C-8-2017 Last PageDocument2 pagesCga C-8-2017 Last PageBILAL FAROOQUINo ratings yet

- Cga C-6.1 First Page-2019Document2 pagesCga C-6.1 First Page-2019BILAL FAROOQUINo ratings yet

- Inv 0148 22 (Fly Baghdad)Document1 pageInv 0148 22 (Fly Baghdad)BILAL FAROOQUINo ratings yet

- Cga-6.3 - 2019 First PageDocument2 pagesCga-6.3 - 2019 First PageBILAL FAROOQUINo ratings yet

- Cga C-6.1 Last PageDocument1 pageCga C-6.1 Last PageBILAL FAROOQUINo ratings yet

- Inv 0145 22 (Assl)Document1 pageInv 0145 22 (Assl)BILAL FAROOQUINo ratings yet

- INV 0140 22 (Air Sial Limited)Document1 pageINV 0140 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0147 22 (Vision Air)Document1 pageInv 0147 22 (Vision Air)BILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- Inv 0135 22 (Pia)Document1 pageInv 0135 22 (Pia)BILAL FAROOQUINo ratings yet

- INV 0144 22 (Jordan Aviaition)Document1 pageINV 0144 22 (Jordan Aviaition)BILAL FAROOQUINo ratings yet

- Inv 0139 22 (Vision Air)Document1 pageInv 0139 22 (Vision Air)BILAL FAROOQUINo ratings yet

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- C-6.1 HSTDocument24 pagesC-6.1 HSTBILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- C 6 HSTDocument30 pagesC 6 HSTBILAL FAROOQUINo ratings yet

- C-8 HSTDocument10 pagesC-8 HSTBILAL FAROOQUINo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet