Professional Documents

Culture Documents

C-8 HST

C-8 HST

Uploaded by

BILAL FAROOQUI0 ratings0% found this document useful (0 votes)

14 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views10 pagesC-8 HST

C-8 HST

Uploaded by

BILAL FAROOQUICopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

CGA

Compressed Gas Association

The Standard For Safty Since 191

CGA C-8—2017

SUA rey

REQUALIFICATION OF

DOT-3HT, CTC-3HT, AND

TC-3HTM SEAMLESS STEEL

fon (BIS) SS)

EIGHTH EDITION

Pace i COMPRESSED Gas ASSOCIATION, INC. CGAC-8—2017

PLEASE NOTE:

‘The information contained in this document was obtained from sources believed to be reliable and is based on

technical information and experience currently available from members of the Compressed Gas Association, Inc.

land others. However, the Association or its members, jointly or severally, make no guarantee of the results and

‘assume no liability or responsibilty in connection with the information or suggestions herein contained, Moreover,

it should not be assumed that every acceptable commodity grade, test or safety procedure or method, precaution,

‘equipment or device is contained within, or that abnormal or unusual circumstances may not warrant or suggest

further requirements or additional procedure.

This document is subject to periodic review, and users are cautioned to obtain the latest edition. The Association

invites comments and suggestions for consideration. In connection with such review, any such comments or

suggestions willbe fully reviewed by the Association after giving the party, upon request, a reasonable oppor-

tunity to be heard, Proposed changes may be submitted via the Internet at our web site, www caanet com,

‘This document should not be confused with federal, state, provincial, or municipal specifications or regulations:

insurance requirements; or national safety codes. While the Association recommends reference to or use of this

document by government agencies and others, this document is purely voluntary and not binding unless adopted

by reference in regulations.

A listing of all publications, audiovisual programs, safety and technical bulletins, and safety posters is available

Via the Intemet at our website at vnww caanet.com. For more information contact CGA at Phone: 703-788-2700,

ext. 799. E-mail: customerservice@caanet com.

Work item 16-019

inser ions Comms

NOTE—Technical changes from the previous edition are underlined,

NOTE—Appendix A (Normative) is @ requirement.

NOTE—Appendix B (Informative) is for information only.

EIGHTH EDITION: 2017

REAFFIRMED: 2010

SEVENTH EDITION: 2005

‘SIXTH EDITION: 1997

©2017 The Compressed Gas Association nc. Alright reserved

‘All materials contained in tis work are protected by United States and international copyright laws. No part of this work may be

‘reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording. or any information

storage and retrieval system without permission in wring ftom The Compressed Gas Association, Inc. All requests for

permission to reproduce material from this work should be directed to The Compressed Gas Association, Inc. 8484 Westpark Drive,

Suite 220, McLean, VA 22102. You may not alter or remove any trademark, copyright or ather natioe from this work.

CGAC-8-2017. CoMPRESseD Gas ASSOCIATION, INC, Pace il

Contents

11 Introduction

2 Scope:

3. Definitions.

4 U.S. Department of Transportation and Transport Canada regulations

5 Shipping

6 Semvice life

7 Visual inspection

7.4 Preparation for inspection

7.2. Design minimum wall thickness calculations

8 Reaualification

8 Disposition

8.1 Accept

82 Reject

93° Condemn

10 Recorakeeping

11 References

‘Appendices

‘Appendix A—Visual examination disposition criteria (Normative)

‘Appendix B—Background information on 3HT series cylinders (Informative)

Page

1

1

CGAC-8—2017, COMPRESSED GAS ASSOCIATION, INC, Pace 1

1 Introduction

This publication provides information on the requalification of DOT-3HT, CTC-3HT, and TC-3HTM seamless stee!

cylinders.

2 Scope

This publication has been prepared to advise cylinder users and requalifcation facilties regarding the require-

ments for establishing their own cylinder inspection procedures and standards. This publication is general in

nature, although specfc limits are given. Rejection or acceptance for continued use, in accordance with these

limits, represent accepted practice that has proven satisfactory for the continuance of these oylinders in service

3 Definitions

For the purpose of this publication, the following definitions apply.

3.1 Publication terminology

3.4.4 Shall

Indicates that the procedure is mandatory. It is used wherever the criterion for conformance to specific recom-

mendations allows no deviation.

3.4.2 Should

Indicates that a procedure is recommended,

34.3 May

Indicates that the procedure is optional

3.4.4 Will

|s used only to indicate the future, not a degree of requirement.

34.5 Can

Indicates a possibilty or ability,

4 U.S. Department of Transportation and Transport Canada regulations

‘The Hazardous Materials Regulations of the U.S. Department of Transportation (DOT) (Title 49 of the

USS. Code of Federal Regulations [49 CFR] Part 180 Subpart C) and Transport Canada (TC) (Clause 24 of

CSA 8339, Cylinders, spheres, and tubes for the transportation of dangerous goods) require that cylinders be

Periodically requalified to ensure their suitability for continued service [1, 2].' These regulations and this publica.

tion require that a cylinder is condemned when it leaks; when internal or external corrosion, denting, bulging, or

evidence of rough usage exists to the extent that the cylinder integrity is likely to have been compromised: or

when the cylinder fails to pass the hydrostatic requalification

‘Seamless stee! cylinder requalification requirements in these regulations or this publication vary depending on

design and the type of service (pressure, commodity, etc.) for which the cylinder is authorized. All seamless steel

cylinders require a periodic visual examination and most require a periodic hydrostatic reaualifcation, The requal-

ification criteria for acceptance or rejection also vary. For the majority of steel cylinders, including specifications

DOT-3HT and CTC-3HT cylinders, the permanent expansion limit shall not exceed 10% ofthe total expansion

For cylinders manufactured to TC-3HTM., the permanent expansion shall not exceed 5% (see CSA B339, clause

24.2.1.3(b)) [2]. Additional requirements for all 3HT series cylinders are that the elastic expansion (total expan-

sion less permanent expansion) at tequalification shall not exceed the elastic expansion at manufacture by more

than 5%

Requalification of cylinders shall be performed only by an authorized DOT or TC facility,

* References are shown by bracketed numbers and are ised in order of appearance inthe reference section,

CGAC-8—2017. ComPRESSED GAS ASSOCIATION, INC. Pace 3

7.22 TC-3HTM series

For TC-3HTM series cylinders, the minimum design wall thickness can be obtained from the cylinder manufac-

turer or by using the following formula derived from sections 4.2 and 10.3 of CSA B339 [2]

NOTE—P is 15 times service pressure for TC-3HTM,

dD d(1-p)

te 5- py $(54)

2. 8

3

oes gar

‘Where:

£15 encase eis i

8 = Smtmam design wal sos; shal ot exoud 67.5% of fhe rnin ica strength o 652 MPa

wien ase

P= 1. teste serve prestrain MPa (tw mart ere posers uti bx

D = _uildedameer mm

= Ina cretr or

‘When metric equivalents are used, they shall be used consistently throughout the formula

894757 x 10° MPa; 1 MPa = 10 bar

NOTE—+t in = 25.4 mm; 1 pe

8 Requalification

Atleast once every 3 years, a SHT series cylinder shall be subjected to a requaliication by hydrostatic pressure

in a water jacket for the determination of the expansion of the cylinder in accordance with the requirements of

CGA C-1, Methods for Pressure Testing Compressed Gas Cylinders [5]. A cylinder shall be condemned i

‘+ Permanent volumetric expansion exceeds 10% of the total expansion for DOT-3HT and CTC-3HT:

‘+ permanent volumetric expansion exceeds 5% of the total expansion for TC-3HTM: or

‘+ _ elastic expansion exceeds the original elastic expansion (EE) by more than 5% or the elastic expansion (EE)

exceeds the marked rejection elastic expansion (REE) stamped on the cylinder by the manufacturer.

9 Disposition

A cylinder shall be identified as accepted, rejected, or condemned

91 Accept

‘Accylinder that passes the inspection and tests required in this publication shall be accepted and shall be marked

in accordance with 49 CFR 180.213 and clause 24.6 of CSA 8339 [1. 2].

Requalification dates and inspector symbols shall be applied by low-stress type steel stamping using round-faced

‘stamps to. depth no greater than that of the original marking at the time of manufacture Stamping on the

sidewall is prohibited,

9.2 — Reject

When a cylinder is rejected, the requalifier shall notify the cylinder owner in writing that the cylinder has been

fejected and may not be filled with a hazardous material for transportation in commerce. However, a rejected

cylinder may be repaired in accordance with the criteria in Appendix A where repair actions are applicable.

CGA C-8-2017. COMPRESSED GAS ASSOCIATION, INC, Pace 5

Appent

(Normative)

A—Visual examination disposition criteria

Defect

Description

Action

Corrosion involving wall loss or producing piting

Condemn cylinder

Internal superficial corrosion

Discoloration of surface without wall loss or piting

‘Accept as is or clean

Internal coating (if applied)

Cracks, flaking lifting, oF discoloration of the coating

Reject cylinder

Internal physical

Cuts, digs, gouges, etc.

Condemn cylinder

Extemal corrosion

Corrosion involving wall loss or producing piting loss

than minimum design wall thickness,

‘Condemn cylinder

Extemal pitting

Corrosion that can be removed and

‘minimum design wall thickness maintained

Polish or sand before

hydrostatic test

Extemal physical

Cuts, digs. gouges, etc, involving loss of wall thick

Ness less than minimum design

Condemn cylinder

External physical

Cuts, digs, gouges, etc, rejected and repaired but re-

tain minimum design wall thickness

Polish or sand before

hydrostatic test

External steel surface

Uncoated surface finish exceeding

250 micro-inch root mean square

‘Condemn cylinder

External steel surface

Minor surface variations due to cosmetic imperfections

Accent as is

External dents Rounded deformations without wall thickness less | Condemn cylinder

Bulges Deformation Condemn cylinder

Fire damage Charing or burning of coating, buming or sintering of | Condemn cylinder

= ‘metal, distortion of cylinder, pressure relief device

(PRO) functioning, or melted valve parts

Refurbishment ‘Any operation where material can be removed from | Verify design minimum

the surface

wall thickness.

Pace 2. ComPRESSED GAS ASSOCIATION, INC. CGAC-8—2017

5 Shipping

Filled 3H1T series cylinders shall be shipped in individual suitable outer packaging such as a box. crate_or cra-

dle. This outer packaging shall be of sufficient strength to protect all parts of the cylinders from deformation

breakage. Cylinders shall be cushioned or braced inside the outer packaging, as necessary. fo prevent damage

It is recommended that empty 3HT series cylinders also be stored and transported in the same type of outer

packaging to prevent damage to the cylinder.

6 Service life

3HT series cylinders shall be removed from service and condemned at the end of a 24-year period following the

date of the original test marked on the cylinder or after 4380 pressurizations, whichever occurs first. Ifa cylinder

is recharged more than once every other day, a record of the number of such rechargings shall be maintained

by the cylinder owner or the owner's agent.

7 Visual inspection

Cylinders shall be visually inspected in accordance with the criteria in Appendix A. The visual inspection shall be

performed at the same time as the requalification (see Section 8), CGA C-6, Standard for Visual Inspection of

‘Stee! Compressed Gas Cylinders may be used as a reference for visual inspection [3].

7.4 Preparation for inspection

Cylinders shall be cleaned for inspection to permit the interior and exterior surfaces to be clearly observed. This

shall include the removal of excessive paint buildup from the exterior.

‘The number and variety of internal coatings are too numerous to list inthis publication, s0 itis impractical to detail

rework procedures. Therefore, analysis and repair shall be done by individuals or repair facilities that have ex-

Perience with the particular coating in question. This is most likely the original manufacturer or another cylinder

manufacturer.

7.2 Design minimum wall thickness calculations

7.24 DOT-3HT and CTC-3HT series

For DOT-3HT and CTC-3HT series cylinders, the minimum design wall thickness (t) can be obtained from the

cylinder manufacturer or by calculation using the following formula derived from DOT Specification 3HT in

49 CFR 178.44(f) [1]

NOTE—Piis 5/3 times service pressure for DOT-SHT and CTC-3HT

D S-13P

i 2) =]

Where:

SS = Maximum design wall stress; shall not exceed 75% of the minimum tensile strength or 105 090 psi

(723.975 kPa)*

P= 513 times service pressure in psi (kPa)

D- = Outside diameter in inches (mm)

{= Minimum design wall thickness in inches (mm)

2 kPa shall indicate gauge pressure unless otherwise noted as (kPa, abs) for absolute pressure or (kPa, diferential for difer-

ential pressure. AllkPa values are rounded off per CGA P-11, Mainc Practice Guide forthe Compressed Gas Indust 4]

Pace 4 COMPRESSED GAS ASSOCIATION, INC CGAC-8—2017

9.3 Condemn

When a cylindor is roquired to be condemnod, the requalifor chail oithor stamp a sorios of Xe over tho DOT,

CTC, or TC specification and the marked service pressure or stamp CONDEMNED on the shoulder, top head,

or neck using a steel stamp.

demned and may not be fled with a hazardous material for tansporiaion in commerce

‘As an alternative to stamping, with the consent of the owner, the requalifier may render the cylinder incapable of

holding pressure. Examples of these methods are described in CGA P-22, The Responsible Management and

Disposition of Compressed Gases and their Cylinders (6

10 Recordkeeping

In accordance with 49 CFR 180.215, a record of the requalifcation results shall be maintained by the requali-

cation facility until either expiration of the requalification period or the cylinder is again requalified, whichever

occurs first [1]. Records shall be maintained by both the requalification facility and the cylinder owner for no less

than 10 years in accordance with section 6.10 of TC's Transportation of Dangerous Goods Regulations {7}

11 References

Unless otherwise specified, the latest edition shall apply

[1] Code of Federal Regulations, Title 49 (Transportation) Parts 100-180, U.S. Government Printing Office.

wow Ww

[2] CSA 8339, Cylinders, spheres, and tubes for the transportation of dangerous goods, Canadian Standards

Association. www csa.c

[3] CGA C-6, Standard for Visual Inspection of Stee! Compressed Gas Cylinders, Compressed Gas Associa

tion, Inc. weww.caanet.com

[4] CGA P-11, Metric Practice Guide for the Compressed Gas Industry, Compressed Gas Association, Inc.

[5] CGA C-1, Methods for Pressure Testing Compressed Gas Cylinders, Compressed Gas Association, Inc.

www.cganet

{61 CGA P22, The Responsible Management and Disposition of Compressed Gases and their Cylinders, Com-

pressed Gas Association, Inc. vnww.caanet.com

[7] Transportation of Dangerous Goods Regulations, Canadian Government Publishing. www tc oa ca

Pace 6. Compressed Gas ASSOCIATION, INC CGAC-8—2017

Appendix B—Background information on 3HT series cylinders

(Informative)

Cylinders made in accordance with 3HT specifications are similar to those made under 3AA specifications in

function and methods of fabrication. The major difference is that 3HT series cylinders are containers that are

authorized for inside aircraft use only and are made to a higher allowable design stress and therefore have a

‘thinner wall thickness and a lower weight.

Because SHT series cylinders are more highly stressed than 3A or 3AA series cylinders, the quality level and

inspection standards for them are higher. Additional tests and added quality features are imposed along with a

24-year maximum service life to ensure that the higher quality of 3HT series cylinders is maintained.

‘At the time of manufacture, the surface condition of a 3HT series cylinder is inspected, both visually and by the

magnetic particle method, to ensure a high-quality surface and uniformly distributed stress when pressurized,

Users, shippers, and testers of these cylinders should exercise care to maintain the surface quality by avoiding

local stress-raising effects of cuts, gouges, and digs, which can have a detrimental effect on the cycle life of the

cylinder

Compressed Gas Association

www.cganet.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- C-6.2 HSTDocument38 pagesC-6.2 HSTBILAL FAROOQUI100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- Building - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoDocument128 pagesBuilding - Your - Own - PC - Complete - Manual - Sep - 2023 Ijaba - InfoBILAL FAROOQUINo ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- Cga C-6.1 First Page-2019Document2 pagesCga C-6.1 First Page-2019BILAL FAROOQUINo ratings yet

- Cga C-8-2017 Last PageDocument2 pagesCga C-8-2017 Last PageBILAL FAROOQUINo ratings yet

- Cga C-6.1 Last PageDocument1 pageCga C-6.1 Last PageBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

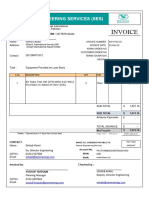

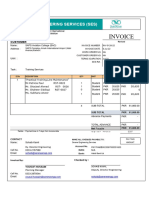

- Inv 0147 22 (Vision Air)Document1 pageInv 0147 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Cga-6.3 - 2019 First PageDocument2 pagesCga-6.3 - 2019 First PageBILAL FAROOQUINo ratings yet

- Inv 0148 22 (Fly Baghdad)Document1 pageInv 0148 22 (Fly Baghdad)BILAL FAROOQUINo ratings yet

- Inv 0145 22 (Assl)Document1 pageInv 0145 22 (Assl)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- INV 0140 22 (Air Sial Limited)Document1 pageINV 0140 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- C-6.1 HSTDocument24 pagesC-6.1 HSTBILAL FAROOQUINo ratings yet

- Inv 0139 22 (Vision Air)Document1 pageInv 0139 22 (Vision Air)BILAL FAROOQUINo ratings yet

- Inv 0135 22 (Pia)Document1 pageInv 0135 22 (Pia)BILAL FAROOQUINo ratings yet

- INV 0144 22 (Jordan Aviaition)Document1 pageINV 0144 22 (Jordan Aviaition)BILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- C 6 HSTDocument30 pagesC 6 HSTBILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- 2.4 Wheel ShopDocument6 pages2.4 Wheel ShopBILAL FAROOQUINo ratings yet