Professional Documents

Culture Documents

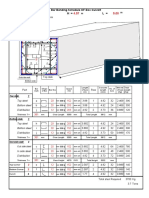

Attachemnt 686

Attachemnt 686

Uploaded by

ponyot aOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachemnt 686

Attachemnt 686

Uploaded by

ponyot aCopyright:

Available Formats

PIPING DESIGN LAYOUT TRAINING

LESSON 1

PIPE STRESS

Page 85 of 95

15/11/2002 Rev. 0

necessity and require an overhead structure. Hydraulic rubbers may be

required if the line is resonant with the heater pulse so line routing should

be in a manner which permits minimum shock absorber installation either

initially or later in the field if vibration develops. Predicting resonance on

these lines is practically impossible and controlling it after start-up, if and

when it develops, can be quite expansive if the line is not routed reasonably

close to structures or equipment which can be utilized.

3.3.2 Overhead line from vessel to condensers: This is usually one of the largest,

if not the largest, line attaching to a vessel. The trend has been for more

application of air coolers to perform the condensing operation, which can

create a major support problem. The vertical expansion of the vessel

frequently is large, exceeding the compensating growth of the line by more

than one inch. Routing the line down the side adjacent to the condenser

may not be the most economical if lengths and elbows have to be added for

flexibility reasons, then spring hangers have to be added for unbalanced

loads and line stability. To further complicate the problem, relief valves are

sometimes added on this line to a blowdown system, linking the flexibility of

both systems and adding a weight concentration with no visible means of

support, because the line is ten feet or more above the nearest available

structure. The route that appears shortest sometimes turns out the longest

unless temperature differential growths are evaluated.

3.3.3 Vessel reflux lines: These lines are normally the smallest line on the vessels

and consequently considered quite flexible. The problem here is created

when a control valve assembly is located directly below the nozzle and

adjacent to the vessel at grade. Due to the relatively low temperature of

these lines, the bottom of the Control Valve loop is pulled up over 1-1/2", so

that special guides and spring supports must be detailed if the C.V. manifold

is left in this location. Relocating the C.V. manifold below the pipeway run

avoids this problem, or as an alternate, locating the manifold on vessel

platform close to the reflux nozzle. The alternate location on the platform

may or may not be approved by the Instrument or Process engineer if he

thinks hand operation of the bypass valve makes it necessary to locate at

grade because of fluctuating operations. It is a matter of opinion and

operators' methods, however, and worth consideration, as automated

design is becoming more reliable.

You might also like

- Flexible Grouted ClampDocument14 pagesFlexible Grouted ClampMiroslav AleksicNo ratings yet

- Naima GuideDocument36 pagesNaima GuideJebús Eduardo MenesesNo ratings yet

- Piping Layout UDLDocument24 pagesPiping Layout UDLLegend Anbu100% (1)

- Graham - Proper Piping For Vacuum SystemDocument5 pagesGraham - Proper Piping For Vacuum SystemAnonymous DJrec2No ratings yet

- Cutting ListDocument17 pagesCutting ListeddieNo ratings yet

- Unit No: 09 Cable StructuresDocument34 pagesUnit No: 09 Cable StructuresRoman BaralNo ratings yet

- Pipeline Tow MethodDocument25 pagesPipeline Tow MethodctrlaltdestroyNo ratings yet

- Cement Concrete BlocksDocument21 pagesCement Concrete BlocksIndika Yapa0% (2)

- SAES-L-120 PDF Download - Piping Flexibility Analysis - PDFYARDocument6 pagesSAES-L-120 PDF Download - Piping Flexibility Analysis - PDFYARZahidRafiqueNo ratings yet

- HVAC Handbook Part 3 Piping DesignDocument122 pagesHVAC Handbook Part 3 Piping DesignTanveer100% (7)

- General Guidelines of Pump Piping LayoutDocument8 pagesGeneral Guidelines of Pump Piping LayoutbainNo ratings yet

- Surge Pressure Formula PDFDocument3 pagesSurge Pressure Formula PDFnirmal_subudhiNo ratings yet

- Slickline and Coiled Tubing ProblemsDocument35 pagesSlickline and Coiled Tubing ProblemsMahmoud Eid0% (1)

- c4r - d111 - Design Requirements and Improved Guidelines v1.1 - Public-2 PDFDocument93 pagesc4r - d111 - Design Requirements and Improved Guidelines v1.1 - Public-2 PDFGonzaloNo ratings yet

- Doka Calculation GuideDocument70 pagesDoka Calculation GuideNuno Geirinhas67% (9)

- Failure Mechanisms For Hoses PDFDocument10 pagesFailure Mechanisms For Hoses PDFMahmoud Al HomranNo ratings yet

- 1.10 Vendor List-Architectural ProductsDocument9 pages1.10 Vendor List-Architectural Productsgopvij1No ratings yet

- Some Notes About Corrosion Coupons InstallationDocument23 pagesSome Notes About Corrosion Coupons InstallationHadi VeyseNo ratings yet

- Practical Fabrication Tips For Steam PipingDocument7 pagesPractical Fabrication Tips For Steam Pipingmahendra493100% (1)

- Pipeline Tie - inDocument2 pagesPipeline Tie - inanishsr75% (4)

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637No ratings yet

- Overboard Dump ValveDocument3 pagesOverboard Dump ValveekabudiartiNo ratings yet

- The Application of The Reelwell Drilling MethodDocument7 pagesThe Application of The Reelwell Drilling Methodraj kumarNo ratings yet

- Condensate Drain DesignDocument3 pagesCondensate Drain Designjdietz4606No ratings yet

- Pipe Expansion and SupportDocument11 pagesPipe Expansion and SupportLorenzoNo ratings yet

- Piping Layout PDFDocument24 pagesPiping Layout PDFEjaz Ahmed Rana100% (1)

- ST104 FinalforPosting2018Document5 pagesST104 FinalforPosting2018imtinanNo ratings yet

- This Document Was Downloaded From The Penspen Integrity Virtual LibraryDocument20 pagesThis Document Was Downloaded From The Penspen Integrity Virtual LibraryGRANRICKYNo ratings yet

- Factors Influencing Well Completion DesignDocument6 pagesFactors Influencing Well Completion DesignMahesh sinhaNo ratings yet

- Back Pressure While Pigging PDFDocument8 pagesBack Pressure While Pigging PDFinstsureshNo ratings yet

- Design and Optimization of Top Tension Risers For Ultra Deep WaterDocument19 pagesDesign and Optimization of Top Tension Risers For Ultra Deep WaterleelawrenceNo ratings yet

- Application of Moment Restraining Supports in Process Plant Critical Piping-Full Paper-2019 PDFDocument5 pagesApplication of Moment Restraining Supports in Process Plant Critical Piping-Full Paper-2019 PDFPratip BhattacharyaNo ratings yet

- Regulating ValveDocument18 pagesRegulating ValveMohammed Hassan B KorainaNo ratings yet

- Cavitation in Restriction Orifices and Valves - NeutriumDocument5 pagesCavitation in Restriction Orifices and Valves - Neutriumمنير أحمدNo ratings yet

- Parte 3.-Piping Design Carrier HandBookDocument122 pagesParte 3.-Piping Design Carrier HandBookNestor Sanchez Villasmil100% (8)

- Proper Piping For Vacuum SystemsDocument5 pagesProper Piping For Vacuum SystemsDowni Oader100% (1)

- Fluid Mechanics & Machinery: Topic: Water Hammer in PipesDocument12 pagesFluid Mechanics & Machinery: Topic: Water Hammer in PipesLoga MadishNo ratings yet

- Deck SealDocument7 pagesDeck SealAlamin Siddique100% (1)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Offshore Subsea Structures and Subsea Systems AssignmentDocument16 pagesOffshore Subsea Structures and Subsea Systems AssignmentGeorge Baby100% (2)

- Method Statement of Hydraulic Pressure Test For Transmission Pipe Line-1Document10 pagesMethod Statement of Hydraulic Pressure Test For Transmission Pipe Line-1gawtomNo ratings yet

- Surge DamageDocument12 pagesSurge DamageRajat WadhwaniNo ratings yet

- AA - SPEC - 114002 - Construction of Structural SteelworkDocument9 pagesAA - SPEC - 114002 - Construction of Structural SteelworkJakesNo ratings yet

- Attachemnt 685Document1 pageAttachemnt 685ponyot aNo ratings yet

- Offshore Orifice-Plate Impulse Line ArrangementDocument5 pagesOffshore Orifice-Plate Impulse Line ArrangementTimothy LeonardNo ratings yet

- Attachemnt 684Document1 pageAttachemnt 684ponyot aNo ratings yet

- Attachemnt 687Document1 pageAttachemnt 687ponyot aNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFSaidFerdjallahNo ratings yet

- Get More LifeDocument4 pagesGet More LifeSalim YilmazNo ratings yet

- Miscellaneous Safety Volumes Fist Volumes 5-3 Through 5-11: Internet Version of This Manual Created August 2000Document27 pagesMiscellaneous Safety Volumes Fist Volumes 5-3 Through 5-11: Internet Version of This Manual Created August 2000GennaroNo ratings yet

- Mechanism of Selective Oil ProducerDocument7 pagesMechanism of Selective Oil ProducerAlbert ChongNo ratings yet

- Ibp1236 12Document8 pagesIbp1236 12Marcelo Varejão CasarinNo ratings yet

- Corrosion Coupon 1689022630Document23 pagesCorrosion Coupon 1689022630gzan antonyNo ratings yet

- Attachemnt 689Document1 pageAttachemnt 689ponyot aNo ratings yet

- Vessel Clips For Pipe Supports: - Vessel Clips Are Structural Attachments Welded To EquipmentDocument10 pagesVessel Clips For Pipe Supports: - Vessel Clips Are Structural Attachments Welded To EquipmentshaliniNo ratings yet

- 16 PR Paper158175Document5 pages16 PR Paper158175Jomer J SimpsonNo ratings yet

- Tie Back Liner Casing-1Document18 pagesTie Back Liner Casing-1حسين الفيتوريNo ratings yet

- Jets Piping GuideDocument24 pagesJets Piping GuideCesar Muñoz OssesNo ratings yet

- Steam Mains and DrainageDocument12 pagesSteam Mains and DrainageGeovannyNo ratings yet

- Piping Design Group Technical Training Flexibility in Piping Design Doc. No. IND-TM-L-008 Rev.0 Date: Aug. 25, 2008Document22 pagesPiping Design Group Technical Training Flexibility in Piping Design Doc. No. IND-TM-L-008 Rev.0 Date: Aug. 25, 2008Christopher BrownNo ratings yet

- Nitrogen Handling PurgingDocument9 pagesNitrogen Handling PurgingJeet Singh100% (1)

- 5th Week ReportDocument13 pages5th Week ReportMuhammad AwaisNo ratings yet

- Large Diameter Risers From Tanker Fpsos: Stephen A. HattonDocument13 pagesLarge Diameter Risers From Tanker Fpsos: Stephen A. HattonRavikumar mahadevNo ratings yet

- Pipe Rack and Rack Piping Considerations With Online Course With PDFDocument5 pagesPipe Rack and Rack Piping Considerations With Online Course With PDFAmjadali ChoudhariNo ratings yet

- Ton Miles 1Document8 pagesTon Miles 1aowsNo ratings yet

- Anti-Fluttering DeviceDocument3 pagesAnti-Fluttering DeviceBilel MahjoubNo ratings yet

- Advance Pipeline Crossing AnalysisDocument7 pagesAdvance Pipeline Crossing AnalysisAmmarul NafikNo ratings yet

- ICH3800 Class 7: 1st Semester 2022Document92 pagesICH3800 Class 7: 1st Semester 2022catalinaNo ratings yet

- Reverse WaterhammerDocument10 pagesReverse WaterhammerjygomezNo ratings yet

- Acoustic-Induced-Vibration Case Study For WDDM Onshore FacilitiesDocument5 pagesAcoustic-Induced-Vibration Case Study For WDDM Onshore FacilitiesMaría José JapaNo ratings yet

- Attachemnt 690Document1 pageAttachemnt 690ponyot aNo ratings yet

- Attachemnt 692Document1 pageAttachemnt 692ponyot aNo ratings yet

- Attachemnt 674Document1 pageAttachemnt 674ponyot aNo ratings yet

- Attachemnt 680Document1 pageAttachemnt 680ponyot aNo ratings yet

- Attachemnt 663Document1 pageAttachemnt 663ponyot aNo ratings yet

- Export Demo History 23654024 1632225497Document4 pagesExport Demo History 23654024 1632225497ponyot aNo ratings yet

- Final Exam (Take Home) Spring - 2020 Subject: Submission Day: Saturday Instructor: Submission Date: May 30, 2020 Program: Max. Marks: 40Document5 pagesFinal Exam (Take Home) Spring - 2020 Subject: Submission Day: Saturday Instructor: Submission Date: May 30, 2020 Program: Max. Marks: 40Sid SshrNo ratings yet

- ITP For Cable Tray Installation PDFDocument4 pagesITP For Cable Tray Installation PDFMochammad Waris SNo ratings yet

- Tablas KTDocument7 pagesTablas KTLorena ReyesNo ratings yet

- Commercial Kitchen Hood WorksheetDocument5 pagesCommercial Kitchen Hood Worksheetdavilla apizzasaNo ratings yet

- Engineering Department-Core Infra - Transportation EngineeringDocument28 pagesEngineering Department-Core Infra - Transportation EngineeringEswara PrasadNo ratings yet

- Project ReportDocument116 pagesProject ReportAnupam KumarNo ratings yet

- Water-Resistant Gypsum Backing Board: Standard Specification ForDocument3 pagesWater-Resistant Gypsum Backing Board: Standard Specification ForChester SmithNo ratings yet

- Construction Site Safety Manual Update 2000Document61 pagesConstruction Site Safety Manual Update 2000msc920138No ratings yet

- SSR 2012 PDFDocument550 pagesSSR 2012 PDFArshad Hussain100% (1)

- 1.study of R.C.C. T-Beam Bridge With SkewDocument6 pages1.study of R.C.C. T-Beam Bridge With SkewsujupsNo ratings yet

- Special TabelloutDocument56 pagesSpecial TabelloutWachama j SwanaNo ratings yet

- Well History ReportDocument3 pagesWell History Reportsoheilvb6No ratings yet

- Saudi Electricity Company: Revision 01 Aug 16, 2015Document10 pagesSaudi Electricity Company: Revision 01 Aug 16, 2015Prabhakar SvNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- MPDPMDocument181 pagesMPDPMvenkateshbitraNo ratings yet

- Loose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJDocument5 pagesLoose Tube, Outdoor Aerial (Fig8) FO Cable 4-12-24 SM Tech Spec MLT Dry Core Dry Core SJPetyo GeorgievNo ratings yet

- Bar Bending Schedule OF Box Culvert: Top Steel Bottom Steel DistributionDocument1 pageBar Bending Schedule OF Box Culvert: Top Steel Bottom Steel DistributionKyaw Zin HeinNo ratings yet

- Centrifugal in Line Pump Fix PDFDocument1 pageCentrifugal in Line Pump Fix PDFSafira KhairinaNo ratings yet

- Bike Rider in DubaiDocument19 pagesBike Rider in DubaiPACIFIC HUMAN RESOURCE P.LTD.No ratings yet

- SAMTAC - Overview - LinkedInDocument4 pagesSAMTAC - Overview - LinkedInLarry StanfordNo ratings yet