Professional Documents

Culture Documents

Act 2 Tema3 Man

Uploaded by

Papeleria vatis0 ratings0% found this document useful (0 votes)

8 views4 pagesHeijunka is an important Lean technique that aims to level production according to real demand. It helps mitigate the impacts of fluctuating demand on inventory levels. Rather than dedicating lines to single products, heijunka uses flexible lines capable of producing various products. This cushions variations in demand for each product through production flexibility. Heijunka also allows mixing production orders to smooth line loads and facilitate standardized work. Implementing heijunka requires tools like work cells, continuous piece-by-piece flows, production adjusted to takt time, and leveling production quantities to obtain a constant, level flow system based on real demands.

Original Description:

Original Title

act 2 tema3 man

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHeijunka is an important Lean technique that aims to level production according to real demand. It helps mitigate the impacts of fluctuating demand on inventory levels. Rather than dedicating lines to single products, heijunka uses flexible lines capable of producing various products. This cushions variations in demand for each product through production flexibility. Heijunka also allows mixing production orders to smooth line loads and facilitate standardized work. Implementing heijunka requires tools like work cells, continuous piece-by-piece flows, production adjusted to takt time, and leveling production quantities to obtain a constant, level flow system based on real demands.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesAct 2 Tema3 Man

Uploaded by

Papeleria vatisHeijunka is an important Lean technique that aims to level production according to real demand. It helps mitigate the impacts of fluctuating demand on inventory levels. Rather than dedicating lines to single products, heijunka uses flexible lines capable of producing various products. This cushions variations in demand for each product through production flexibility. Heijunka also allows mixing production orders to smooth line loads and facilitate standardized work. Implementing heijunka requires tools like work cells, continuous piece-by-piece flows, production adjusted to takt time, and leveling production quantities to obtain a constant, level flow system based on real demands.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

INGENIERÍA INDUSTRIAL

Manufactura Esbelta

Heijunka

Profesor: Lorena De Jesús Silva

Alumno: José Guadalupe Tiscareño Vargas

Fecha: 23 /OCTUBRE/2022

DESCRIPTION:

Based on the heijunka file, prepare a reading report (Free) where you indicate the

most important parts of the Lean tool.

Report:

Heijunka is one of the most important techniques that exist within the

implementation of Lean Manufacturing, because it represents a maximum degree

of commitment to the Just In Time philosophy;

This is due to the idea of leveling the flow of the product according to the real

behavior of the demand.

The heijunka is a means used to be able to adapt production flows to the behavior

of demands.

This is how the impacts caused by fluctuations in demands and their effects on the

system's inventories are mitigated.

Something important about this topic is that it is done by moving from a line

dedicated to a single product, therefore, this being sensitive to variations in sales

towards flexible lines, capable of manufacturing various types of products;

These variations in the demands of each type of product are cushioned by the

flexibility of production tools with the idea that there will be less variation and

variability.

While the process requires strict compliance with the principles of standardization

and production balance.

In short, Heijunka allows us to smooth line loads by mixing product manufacturing

orders, thereby facilitating work stability and standardization.

The second objective of Heijunka is to be able to assemble the different models of

the same line while eliminating the Mudas with the normalization of the work.

This application will allow production in the orders of customer demands, this is

because the Heijunka practice helps distribute and balance production in the

available means instead of subjecting the dedicated means to variations in

demand.

In order to implement Heijunka, it is necessary to use a series of tools that are

integrated to allow a constant and level flow production system to be obtained

based on real demands.

- The use of work cells

- Continuous flows piece by piece

- Production adjusted to takt time

- Leveling production quantities

- Production leveling for your reference

With this, more is understood about what Lean Manufacturing encompasses and

the various issues that it has;

The principle of Lean is to produce the variety of a limited team to be able to

compete without the costs of mass production, this Lean system specifies how the

demand is as level as possible so that the products flow regularly in the processes

and that these require a minimum of the stock in the necessary points without

incurring the risks of breaking the flow.

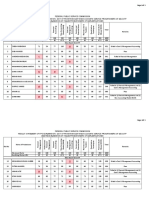

Production adjusted to takt time

The takt time is an indicator of the frequency of the customer's purchase in

measurements taken in a matter of seconds.

For Heijunka it is an objective time to which the production system must adapt and

meet customer expectations.

It is calculated as follows:

TIEMPO TAKT = Tiempo disponible/Demanda

The way to level the amount of production:

The objective of leveling the quantity of production is to minimize the differences

between the production in one period and that of the following period.

With this it is understood that it is best to produce the same amount of products in

each period (usually in each day).

Although the demand for it can change considerably depending on the factors of

seasonal variations, for example, the leveling of production quantities allows the

daily production volume to remain constant.

With this we understand the advantages of implementing Heijunka:

- Helps minimize overproduction

- Fully implements the pull system

- Minimizes inventories of products in process and finished

- Helps minimize opportunity costs

- Synchronizes the use of working capital and billing rates.

You might also like

- Production Planning and ControlDocument29 pagesProduction Planning and ControlShivam BansalNo ratings yet

- Applied Economics11 - q1 - m2 - Applied Economics - v3Document57 pagesApplied Economics11 - q1 - m2 - Applied Economics - v3Analiza Pascua100% (1)

- Labor Repair (Office Equipment) Labor Repair (Office Equipment)Document7 pagesLabor Repair (Office Equipment) Labor Repair (Office Equipment)MaricrisNo ratings yet

- Hunter & Bard's Account-Based Marketing Playbook: For Enterprise MarketersDocument20 pagesHunter & Bard's Account-Based Marketing Playbook: For Enterprise MarketersPatricia Ezell100% (2)

- CH 3 JITDocument68 pagesCH 3 JITmaheshgNo ratings yet

- Fin 425 Final NIKEDocument11 pagesFin 425 Final NIKEcuterahaNo ratings yet

- Om0017 Solved AssignmentDocument13 pagesOm0017 Solved AssignmentAnant KumarNo ratings yet

- 20220106-Production Planning and ControlDocument216 pages20220106-Production Planning and ControlRavi KumarNo ratings yet

- Introduction To Lean Manufacturing: Achieving World-Class Organizational ResultsDocument75 pagesIntroduction To Lean Manufacturing: Achieving World-Class Organizational ResultsAshokNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Korytkowski Grimaud Dolgui Exponential 2 2014Document7 pagesKorytkowski Grimaud Dolgui Exponential 2 2014Juby JoyNo ratings yet

- Lesson 8 (Process Design/Advanced Operations Technologies)Document6 pagesLesson 8 (Process Design/Advanced Operations Technologies)Marica ShaneNo ratings yet

- Iarjset-Agni-Pankh 52Document5 pagesIarjset-Agni-Pankh 52My HanhNo ratings yet

- Must ReadDocument10 pagesMust ReadJuby JoyNo ratings yet

- My Project Chapter1$2Document24 pagesMy Project Chapter1$2Omoniyi Ezekiel BNo ratings yet

- FALLSEM2023-24 MEE2013 ETH VL2023240101818 2023-07-26 Reference-Material-IDocument21 pagesFALLSEM2023-24 MEE2013 ETH VL2023240101818 2023-07-26 Reference-Material-Ijayfulewar23No ratings yet

- C. Productivity Production ConceptDocument7 pagesC. Productivity Production ConceptPradyuman VermaNo ratings yet

- Product Development PrinciplesDocument3 pagesProduct Development PrinciplesCollins OtienoNo ratings yet

- 00 Lean ManufacturingDocument12 pages00 Lean ManufacturingErnesto Rascon Basaldua0% (1)

- The Five Manufacturing ProcessesDocument3 pagesThe Five Manufacturing ProcessesDante CalambaNo ratings yet

- Continuous Flow Manufacturing: EdifymindsDocument2 pagesContinuous Flow Manufacturing: EdifymindsKomal TagraNo ratings yet

- Yasir Hussain: Subject Quality and Reliability Engineering TopicDocument15 pagesYasir Hussain: Subject Quality and Reliability Engineering TopicYasir HussainNo ratings yet

- Acttivity ADocument4 pagesActtivity AManuel PlandañoNo ratings yet

- Assignment Ujjawal-1Document8 pagesAssignment Ujjawal-1Ujjawal PandeyNo ratings yet

- Just in Time TQMDocument43 pagesJust in Time TQMpareek9590No ratings yet

- Lean Case Study - LeatherDocument9 pagesLean Case Study - LeatherSk Mosaib AhamedNo ratings yet

- Manufacturing & Delivery OperationsDocument12 pagesManufacturing & Delivery OperationsFadekemi AdelabuNo ratings yet

- Production and Operation ManagementDocument41 pagesProduction and Operation ManagementJessamine Romano AplodNo ratings yet

- Capitulo 5 ToyotaDocument2 pagesCapitulo 5 ToyotaJorge OrtizNo ratings yet

- Module 4Document13 pagesModule 4isabel payupayNo ratings yet

- Module 4-1Document13 pagesModule 4-1saskiaNo ratings yet

- Process Design: Learning OutcomesDocument12 pagesProcess Design: Learning OutcomesMejidana, Rica Mae N.No ratings yet

- Product Design ProcessDocument7 pagesProduct Design ProcessMau BautistaNo ratings yet

- 10 - Lean Production - JaguarDocument15 pages10 - Lean Production - Jaguarchiuwuching260No ratings yet

- Managing The Transformation ProcessDocument6 pagesManaging The Transformation ProcessDwi SetiawatiNo ratings yet

- Foro de Manufactura EsbeltaDocument5 pagesForo de Manufactura EsbeltaDiego A. Sosa GonzalesNo ratings yet

- Just-In-Time: Study Unit Six Operational Efficiency and Business Process PerformanceDocument21 pagesJust-In-Time: Study Unit Six Operational Efficiency and Business Process PerformanceAhmed Mostafa ElmowafyNo ratings yet

- JIT Manufacturing and Lean ProductionDocument7 pagesJIT Manufacturing and Lean ProductionAhon BatangueñoNo ratings yet

- Ahmed Taha Paper1Document9 pagesAhmed Taha Paper1Mohamed KhalilNo ratings yet

- Dop IeDocument12 pagesDop IeshashujatinNo ratings yet

- Unit-V Contemporary Management End-User Computing: AnalysisDocument12 pagesUnit-V Contemporary Management End-User Computing: Analysisprudhvi saiNo ratings yet

- Om Unit IDocument20 pagesOm Unit IMiyonNo ratings yet

- The Concept of WasteDocument4 pagesThe Concept of Wasteshruthi01No ratings yet

- Chapter 1Document7 pagesChapter 1John Paul Palomino AndradeNo ratings yet

- Om Chapter 6Document20 pagesOm Chapter 6John Paul Palomino AndradeNo ratings yet

- GTFMS PPT1-1 (1) - 1Document15 pagesGTFMS PPT1-1 (1) - 1Anandu S KrishnaNo ratings yet

- Inventory Management-Nishi KantrDocument53 pagesInventory Management-Nishi KantrNishi KantNo ratings yet

- Production Capacity 62584Document16 pagesProduction Capacity 62584temesgen bimrawNo ratings yet

- Chapter 1Document64 pagesChapter 1Mominul MominNo ratings yet

- Proses StrategiDocument39 pagesProses StrategiMaz IfikNo ratings yet

- PPC 3122018Document52 pagesPPC 3122018arunNo ratings yet

- Midterm NotesDocument5 pagesMidterm NotesGupta KiraNo ratings yet

- Improvement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityDocument16 pagesImprovement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityNawshad HasanNo ratings yet

- Sciencedirect: Manufacturing System Flexibility: Product Flexibility AssessmentDocument6 pagesSciencedirect: Manufacturing System Flexibility: Product Flexibility AssessmentitzgayaNo ratings yet

- Chapter 6: Just-in-Time (Lean) Purchasing: Group 6: Holanda, Olleras and SabantoDocument10 pagesChapter 6: Just-in-Time (Lean) Purchasing: Group 6: Holanda, Olleras and SabantoMarie Antoinette HolandaNo ratings yet

- Lean Manufacturing in Apparel IndustryDocument10 pagesLean Manufacturing in Apparel IndustrynagaaintNo ratings yet

- EMC 4512 Production SystemsDocument8 pagesEMC 4512 Production Systemsstephen mwendwaNo ratings yet

- Unit-1 Introduction The Main Objectives of Production PlanningDocument68 pagesUnit-1 Introduction The Main Objectives of Production Planning19-4094 S Surya tejaNo ratings yet

- What Production System Do You HaveDocument6 pagesWhat Production System Do You HaveLourdes Marianne MenesesNo ratings yet

- Unit-3 Iem NotesDocument10 pagesUnit-3 Iem NotesAmar KoliNo ratings yet

- Lean Manufacturing: Just in Time (JIT)Document11 pagesLean Manufacturing: Just in Time (JIT)Vijay SinghNo ratings yet

- Assignment On JIT (Just-in-Time)Document12 pagesAssignment On JIT (Just-in-Time)Roop50% (4)

- Production System in Operations ManagementDocument18 pagesProduction System in Operations ManagementMark Angelo NioscoNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Act 1 Tema 3 MANDocument7 pagesAct 1 Tema 3 MANPapeleria vatisNo ratings yet

- Visual AdministrationDocument5 pagesVisual AdministrationPapeleria vatisNo ratings yet

- Standardized WorkDocument5 pagesStandardized WorkPapeleria vatisNo ratings yet

- HeijunkaDocument6 pagesHeijunkaPapeleria vatisNo ratings yet

- Distribution Channels in International Marketing: ContentsDocument8 pagesDistribution Channels in International Marketing: ContentsHildaNo ratings yet

- Bba - Sem Vi Advertising and Salesman ShipDocument15 pagesBba - Sem Vi Advertising and Salesman Shipdeepshah8486No ratings yet

- All Slides PricingDocument15 pagesAll Slides Pricingb23010No ratings yet

- BBA IV Sen Advertising & Sales PromotionDocument2 pagesBBA IV Sen Advertising & Sales PromotionAmit SinghNo ratings yet

- Summary of Ifrs 4Document4 pagesSummary of Ifrs 4Divine Epie Ngol'esuehNo ratings yet

- Chapter 13 - Property, Plant, and Equipment Depreciation and DepletionDocument32 pagesChapter 13 - Property, Plant, and Equipment Depreciation and DepletionHamda AbdinasirNo ratings yet

- Cold Storage V/s Knitwear Case WACDocument6 pagesCold Storage V/s Knitwear Case WACHamza AmanullahNo ratings yet

- SM - 3Document13 pagesSM - 3Uday GowdaNo ratings yet

- Exam2008 07A KeyDocument15 pagesExam2008 07A KeyRajaaeajasd Gausdj100% (2)

- Nguyen Kim Rebranding - Agency BriefDocument2 pagesNguyen Kim Rebranding - Agency BriefAnNo ratings yet

- Customers' Attitude Towards Mobile Messaging Technology in Promoting CRM: A StudyDocument12 pagesCustomers' Attitude Towards Mobile Messaging Technology in Promoting CRM: A StudyCva KumarNo ratings yet

- 7-Global Marketing Communication DecisionDocument40 pages7-Global Marketing Communication DecisionAnja GuerfalaNo ratings yet

- Bidding Document ReportDocument78 pagesBidding Document ReportEngr Nissar KakarNo ratings yet

- Fpo 2017 43rd CTP - PaasDocument3 pagesFpo 2017 43rd CTP - Paaswaleedrana786No ratings yet

- Types of Incentive SchemesDocument27 pagesTypes of Incentive SchemesAnika KumarNo ratings yet

- Salesforce Control and EvaluationDocument11 pagesSalesforce Control and EvaluationRadHika GaNdotra100% (1)

- Cartel Theory of OligopolyDocument2 pagesCartel Theory of OligopolyUtkarshaNo ratings yet

- Frecy Catadman Delivery Service (Journal)Document2 pagesFrecy Catadman Delivery Service (Journal)Charlotte AdoptanteNo ratings yet

- 02 - Assignment - AmazonDocument4 pages02 - Assignment - AmazonsalmapratyushNo ratings yet

- Managerial Economics Project (Term 1, 2020-21) : Prof. Tanushree HaldarDocument3 pagesManagerial Economics Project (Term 1, 2020-21) : Prof. Tanushree HaldarAnkit SanodiyaNo ratings yet

- Sample Auditing Problems Proof of Cash Sample Auditing Problems Proof of CashDocument17 pagesSample Auditing Problems Proof of Cash Sample Auditing Problems Proof of Cashmariyha PalangganaNo ratings yet

- Questionnaire On Changing Importance of Media Vehicle in Advertising1Document6 pagesQuestionnaire On Changing Importance of Media Vehicle in Advertising1subbu2raj3372No ratings yet

- TASK PERFORMANCE-Strategic Cost Acctg-PrelimDocument5 pagesTASK PERFORMANCE-Strategic Cost Acctg-PrelimAnonymouslyNo ratings yet

- Project On Consumer Behaviour of Surf ExcelDocument14 pagesProject On Consumer Behaviour of Surf ExcelSoudip Ghosh0% (1)

- IKEA Case Study AnsDocument1 pageIKEA Case Study AnsVinayak JoshiNo ratings yet

- Assign 1 Solution PDFDocument18 pagesAssign 1 Solution PDFManmeet SinghNo ratings yet