Professional Documents

Culture Documents

Epbp - STP

Epbp - STP

Uploaded by

y.s.6saputro0 ratings0% found this document useful (0 votes)

4 views1 pageThis document outlines various standardized testing procedures for different bottle components including:

1. QT500-QT508 which test for things like oven tests, sink/float tests, and label/ink separation.

2. Sorting protocols to determine recyclability based on factors like colors and additives.

3. EPBP protocols that evaluate recyclability routes depending on material and whether colors/coverage are within recommendations.

4. It notes that innovative bottle designs challenging guidelines should undergo industrial scale or innovative testing to identify potential negative impacts.

Original Description:

Original Title

EPBP - STP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines various standardized testing procedures for different bottle components including:

1. QT500-QT508 which test for things like oven tests, sink/float tests, and label/ink separation.

2. Sorting protocols to determine recyclability based on factors like colors and additives.

3. EPBP protocols that evaluate recyclability routes depending on material and whether colors/coverage are within recommendations.

4. It notes that innovative bottle designs challenging guidelines should undergo industrial scale or innovative testing to identify potential negative impacts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageEpbp - STP

Epbp - STP

Uploaded by

y.s.6saputroThis document outlines various standardized testing procedures for different bottle components including:

1. QT500-QT508 which test for things like oven tests, sink/float tests, and label/ink separation.

2. Sorting protocols to determine recyclability based on factors like colors and additives.

3. EPBP protocols that evaluate recyclability routes depending on material and whether colors/coverage are within recommendations.

4. It notes that innovative bottle designs challenging guidelines should undergo industrial scale or innovative testing to identify potential negative impacts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

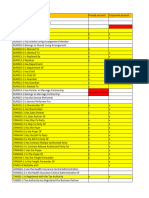

August 2022

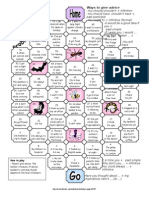

Standard Testing Table

QT500 QT502 QT504 QT507 QT508 Sorting RecyClability

Standardized Testing Procedures (oven (sink/float (glue (label lebels and (RecyClass EPBP

test) comments test) comments separation) comments inks) comments adhesives comments Protocol) comments Protocol comments

depending on

Route 2 (25, market

Material (PET grades, copolyesters, etc.) x evaluation per case 50%) penetration

in case of dark

Colours x colors

Route 1

Barrier x (25%)

when in resin

when in Route 1

Additives x label/sleeve (25%)

Closure x x when decorated

Liners, valves, seals x

in case coverage or

colors are outside

Labels x x x when printed x x

the

x reccomendations

Sleeves x x when printed x

Tamper Evidence Wrap x x x x when printed

when in the Route 1

Adhesives x label x x (25%) addition

Route 1

Inks x x (25%)

Route 1

Direct printing x x (25%)

Label should be tested transparent clear and white, without printing

Innovative bottle design challaging the guidelines should be tested at industrial scale or by applying innovative testing protocols, able to capture the potential negative impacts.

You might also like

- Esl Sample Progress ReportDocument2 pagesEsl Sample Progress ReportMisho Bata100% (1)

- Handout 3Document11 pagesHandout 3y.s.6saputroNo ratings yet

- Handout 2Document38 pagesHandout 2y.s.6saputroNo ratings yet

- Heidegger - Letter On HumanismDocument27 pagesHeidegger - Letter On HumanismDennis Schep67% (3)

- Third Quarter Item Analysis in Esp 6: Canlingga Elementary School (121292)Document10 pagesThird Quarter Item Analysis in Esp 6: Canlingga Elementary School (121292)Nelia goNo ratings yet

- Gantt Inspection - Common BaseDocument1 pageGantt Inspection - Common BaseCesar ArellanoNo ratings yet

- Nine Mile County Forest X-C Ski Trails: ChaletDocument1 pageNine Mile County Forest X-C Ski Trails: ChaletJohn Lee PettimoreNo ratings yet

- TA Training Program 2008Document1 pageTA Training Program 2008Mahyudin MohamadNo ratings yet

- Ahmc Thinking TabDocument12 pagesAhmc Thinking Tab孛儿只斤阿斯根夫100% (1)

- Ahmc Thinking2 TabDocument12 pagesAhmc Thinking2 Tab孛儿只斤阿斯根夫No ratings yet

- Tool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreDocument1 pageTool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreAnthonyNo ratings yet

- 1.2 Limits and Their PropertiesDocument2 pages1.2 Limits and Their PropertiesSithara A.PNo ratings yet

- Análise de TendenciaDocument6 pagesAnálise de TendenciaFernando SoaresNo ratings yet

- FLEXIBLE PAVEMENT DESIGN-student RevDocument74 pagesFLEXIBLE PAVEMENT DESIGN-student RevJosz LeaNo ratings yet

- TXP D17Document2 pagesTXP D17Md. Amir HossainNo ratings yet

- 10bet Affiliate Guidelines 03.2Document8 pages10bet Affiliate Guidelines 03.2masherifb1No ratings yet

- Tên chủ đề Câu Nội dung kiến thức Mức độDocument2 pagesTên chủ đề Câu Nội dung kiến thức Mức độnghiabuiaceNo ratings yet

- Software License 05Document17 pagesSoftware License 05Brian Jan AdelaNo ratings yet

- Capstone Week 4Document2 pagesCapstone Week 4Keshav SinghNo ratings yet

- Sawing Plan PDFDocument1 pageSawing Plan PDFuq2No ratings yet

- Sawing Plan PDFDocument1 pageSawing Plan PDFuq2No ratings yet

- 03-10-2019 Poligonal Somente Com Informacoes CTs Remocoes UrbelDocument1 page03-10-2019 Poligonal Somente Com Informacoes CTs Remocoes UrbelJair SantosNo ratings yet

- Chemical Compactability ChartDocument3 pagesChemical Compactability ChartSenthilkumar NatarajanNo ratings yet

- Senarai Semak Raptai (Merged)Document1 pageSenarai Semak Raptai (Merged)Yeoj NeskireNo ratings yet

- AsbestosPERIODICFORMHS10 11 2010Document1 pageAsbestosPERIODICFORMHS10 11 2010idahssNo ratings yet

- New BWT Log Book Aux. Boiler No1 May 2022Document2 pagesNew BWT Log Book Aux. Boiler No1 May 2022Денис ГанинNo ratings yet

- TutorialDocument8 pagesTutorialLordoc DoctorsaabNo ratings yet

- FM-GAHRD-01 Training Matrix FinalDocument12 pagesFM-GAHRD-01 Training Matrix FinalimamNo ratings yet

- Smartvacs CatalogeDocument1 pageSmartvacs CatalogeJUANSOLUSINDONo ratings yet

- Integral Çıktı ALINACAK SORULARDocument12 pagesIntegral Çıktı ALINACAK SORULARalisahanavci1No ratings yet

- Answer Scheme & Tos Paper 013 English Pra Upsr Year 6 2016 (SK)Document8 pagesAnswer Scheme & Tos Paper 013 English Pra Upsr Year 6 2016 (SK)Mar OmarNo ratings yet

- Fill Product InformationDocument1 pageFill Product InformationJuanes CantanteNo ratings yet

- Small Lab DesignDocument1 pageSmall Lab Designhernandezboyc6403No ratings yet

- Status of Conventions: File:///conversion/tmp/scratch/415396461.xlsx D DenunciationDocument10 pagesStatus of Conventions: File:///conversion/tmp/scratch/415396461.xlsx D Denunciationbehzad parsiNo ratings yet

- CertainTeed Ceilings Acoustic Ceiling Fire AssembliesDocument2 pagesCertainTeed Ceilings Acoustic Ceiling Fire AssembliesEmanuel Ciprian CiucurNo ratings yet

- Pallet Tie-Sheets - Layer Pad PDFDocument1 pagePallet Tie-Sheets - Layer Pad PDFDewiNo ratings yet

- Los Puritos Huesos - La ArrolladoraDocument11 pagesLos Puritos Huesos - La ArrolladoramarcogcbedollacervantesNo ratings yet

- Estación de Bomberos Zarzal - Arq - P1Document1 pageEstación de Bomberos Zarzal - Arq - P1Sebastian CartagenaNo ratings yet

- Stationery Requirements - 2023Document2 pagesStationery Requirements - 2023Tasneem DocratNo ratings yet

- Checklist DailyDocument1 pageChecklist DailySubistia IrwanNo ratings yet

- 2431 Dozvoljene Formule - Mat2 Za UsmeniDocument1 page2431 Dozvoljene Formule - Mat2 Za UsmeniMislav FranicNo ratings yet

- NDRC 1Document1 pageNDRC 1Archana SoorajNo ratings yet

- Engineering Project: TK-4094 Prarancangan Pabrik Kimia Semester 2 - 2015/2016Document9 pagesEngineering Project: TK-4094 Prarancangan Pabrik Kimia Semester 2 - 2015/2016Wilson LiangNo ratings yet

- Thin Lizzy - Risn Dubh Black RoseDocument29 pagesThin Lizzy - Risn Dubh Black RoseToni Ahola100% (1)

- To Do List For HACCPDocument2 pagesTo Do List For HACCPChâu TrầnNo ratings yet

- Examguru Mathematics Class 12 Question Bank 2023Document443 pagesExamguru Mathematics Class 12 Question Bank 2023Steve Rodgers100% (1)

- Checklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Document1 pageChecklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Subistia IrwanNo ratings yet

- Decanter Cake SiteDocument1 pageDecanter Cake SiteSteve Stephianus LausNo ratings yet

- HK Instruments - Catálogo ProductosDocument19 pagesHK Instruments - Catálogo ProductosRodrigoBracaNo ratings yet

- IND RA: Key PlanDocument1 pageIND RA: Key PlanLUUVANDONG48XFNo ratings yet

- Back in BlackDocument9 pagesBack in BlackLeandro PortelaNo ratings yet

- Perimeter Protection FunctionalitiesDocument1 pagePerimeter Protection FunctionalitiesRomiNo ratings yet

- Numerical Analysis I Chapter III - VIDocument38 pagesNumerical Analysis I Chapter III - VIKidist TaluNo ratings yet

- AwdadDocument1 pageAwdadtuyenbsrNo ratings yet

- GC397 452 Id 01 Est PL 001 - 0Document1 pageGC397 452 Id 01 Est PL 001 - 0APP Compañia 7RNo ratings yet

- César Cabarcas Angulo: Manga L 179.06Mts 1 2Document1 pageCésar Cabarcas Angulo: Manga L 179.06Mts 1 2Oscar Fernando Garcia GuardoNo ratings yet

- Graphs of Rational FunctionsDocument4 pagesGraphs of Rational FunctionsRomel DingilNo ratings yet

- Lean Six Sigma Skills AssessmentDocument4 pagesLean Six Sigma Skills Assessmentnaacha457No ratings yet

- Code For BP and ACDocument2 pagesCode For BP and ACAnti VitaNo ratings yet

- HSWR-TW-6-PP8-M00010-02 General Layout, (1 of 1) - ReviewedDocument1 pageHSWR-TW-6-PP8-M00010-02 General Layout, (1 of 1) - Reviewedjackkie7417No ratings yet

- Diagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995Document2 pagesDiagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995GualadrakeNo ratings yet

- Functional Properties of Brewer's Spent Grain Protein IsolateDocument18 pagesFunctional Properties of Brewer's Spent Grain Protein Isolatey.s.6saputroNo ratings yet

- Kentang 2Document2 pagesKentang 2y.s.6saputroNo ratings yet

- Product Safety Declaration - Finolene Blue GSE-3610 - Version 1.0 - 8 Oct 2022Document5 pagesProduct Safety Declaration - Finolene Blue GSE-3610 - Version 1.0 - 8 Oct 2022y.s.6saputroNo ratings yet

- Packaging Report - Estimasi Loading 2Document5 pagesPackaging Report - Estimasi Loading 2y.s.6saputroNo ratings yet

- TDS - Oct 2022Document1 pageTDS - Oct 2022y.s.6saputroNo ratings yet

- Packaging Report - Estimasi LoadingDocument10 pagesPackaging Report - Estimasi Loadingy.s.6saputroNo ratings yet

- Kentang 1Document6 pagesKentang 1y.s.6saputroNo ratings yet

- Kentang 4Document4 pagesKentang 4y.s.6saputroNo ratings yet

- Packaging Report - Estimasi Loading 3Document1 pagePackaging Report - Estimasi Loading 3y.s.6saputroNo ratings yet

- Kentang 3Document2 pagesKentang 3y.s.6saputroNo ratings yet

- TDS SCGC PP P303S Rev Mar2022Document3 pagesTDS SCGC PP P303S Rev Mar2022y.s.6saputroNo ratings yet

- Peler Si JackDocument9 pagesPeler Si Jacky.s.6saputroNo ratings yet

- Journal - The Solid State Postcondensation of PET, 3a - Study of Dispersed Phase PrepolymerisationDocument6 pagesJournal - The Solid State Postcondensation of PET, 3a - Study of Dispersed Phase Prepolymerisationy.s.6saputroNo ratings yet

- TDS SCGC PP P348S Rev Mar2022Document3 pagesTDS SCGC PP P348S Rev Mar2022y.s.6saputroNo ratings yet

- Journal - The Solid State Postcondensation of PET, 2a - Toward The Development of A New Dispersed Phase Solid State ProcessDocument7 pagesJournal - The Solid State Postcondensation of PET, 2a - Toward The Development of A New Dispersed Phase Solid State Processy.s.6saputroNo ratings yet

- Journal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. II.Document6 pagesJournal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. II.y.s.6saputroNo ratings yet

- Journal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. I.Document8 pagesJournal - Solid-State Polycondensation of Poly (Ethylene Terephthalate) Recycled From Postconsumer Soft-Drink Bottles. I.y.s.6saputroNo ratings yet

- Journal - PET Recycling Evaluation of The Solid State Polymerization ProcessDocument7 pagesJournal - PET Recycling Evaluation of The Solid State Polymerization Processy.s.6saputroNo ratings yet

- Selecting A Waste Management O P T I o N Using A Life-Cycle Analysis Approach"Document14 pagesSelecting A Waste Management O P T I o N Using A Life-Cycle Analysis Approach"y.s.6saputroNo ratings yet

- Handout 1Document25 pagesHandout 1y.s.6saputroNo ratings yet

- PET - RPET Moisture ContentDocument6 pagesPET - RPET Moisture Contenty.s.6saputroNo ratings yet

- Recycling Plastic Packaging in The United States: Packaging Technology and Science VOLDocument6 pagesRecycling Plastic Packaging in The United States: Packaging Technology and Science VOLy.s.6saputroNo ratings yet

- Standard TestsDocument1 pageStandard Testsy.s.6saputroNo ratings yet

- Specification TLE 101Document1 pageSpecification TLE 101y.s.6saputroNo ratings yet

- Identification of Biodegradable and Oxo-Biodegradable Plastic Bags Samples CompositionDocument9 pagesIdentification of Biodegradable and Oxo-Biodegradable Plastic Bags Samples Compositiony.s.6saputroNo ratings yet

- The Structure of The European Packaging Industry": Carl H. WendtDocument5 pagesThe Structure of The European Packaging Industry": Carl H. Wendty.s.6saputroNo ratings yet

- Payment Details Customer Details: P.O. Number: Method: Name: Email: Contact NumberDocument1 pagePayment Details Customer Details: P.O. Number: Method: Name: Email: Contact Numbery.s.6saputroNo ratings yet

- Histopathologic TechniquesDocument9 pagesHistopathologic TechniquesLUZVIMINDA GORDONo ratings yet

- Typing NotesDocument6 pagesTyping NotesMuhammad Ali SaqibNo ratings yet

- Cinética Química UDocument16 pagesCinética Química UJesus Manuel Yallerco VenegasNo ratings yet

- The Greatness of Ravana - Forgotten AstrologerDocument5 pagesThe Greatness of Ravana - Forgotten AstrologerMarilou1963No ratings yet

- Wood AnatomyDocument16 pagesWood AnatomyDennis GilberoNo ratings yet

- Iii Research Group 4Document27 pagesIii Research Group 4enteng831No ratings yet

- Protective Tile & Stone SealerDocument2 pagesProtective Tile & Stone SealerParashuram ChauhanNo ratings yet

- Book PDFDocument19 pagesBook PDFAnjali KumarNo ratings yet

- Term Paper: FIN 101 Basic FinanceDocument3 pagesTerm Paper: FIN 101 Basic FinanceErfan TanhaeiNo ratings yet

- The Dialects of EnglishDocument28 pagesThe Dialects of EnglishChristopher IsNo ratings yet

- The Artifi Cial Intelligence IssueDocument92 pagesThe Artifi Cial Intelligence IssueVladimir IvkovicNo ratings yet

- Auditing Chp. 3 Flashcards - QuizletDocument9 pagesAuditing Chp. 3 Flashcards - Quizletglt0No ratings yet

- Cost II FInal ExamDocument4 pagesCost II FInal ExamAbaas AhmedNo ratings yet

- XML, COBOL and ApplicationDocument51 pagesXML, COBOL and ApplicationpsavazNo ratings yet

- Demonstration Teaching Plan DiassDocument5 pagesDemonstration Teaching Plan DiassRisel OliverosNo ratings yet

- Answers Drawing A: BS EN 22553 Course Reference WIS 10Document9 pagesAnswers Drawing A: BS EN 22553 Course Reference WIS 10JithuJohnNo ratings yet

- Haemnatopoiesis and CMLDocument8 pagesHaemnatopoiesis and CMLKe XuNo ratings yet

- Operation of The Classical CMOS SchmittDocument5 pagesOperation of The Classical CMOS SchmittAakash ChandraNo ratings yet

- ESL Board Game Advice NeededDocument3 pagesESL Board Game Advice NeededTrill_Mo0% (1)

- Asking and Giving PermissionDocument3 pagesAsking and Giving PermissionerwinNo ratings yet

- Relationship Between Emotional Intelligence and Students Academic Performance - Role of Ethnic FactorDocument13 pagesRelationship Between Emotional Intelligence and Students Academic Performance - Role of Ethnic Factorمعن الفاعوريNo ratings yet

- Fundamentals of Pipeline Engineering, Construction & OperationsDocument4 pagesFundamentals of Pipeline Engineering, Construction & OperationsMehedi HasanNo ratings yet

- Strategic Management Pgp1Document26 pagesStrategic Management Pgp1Guru PrasadNo ratings yet

- Relative SpeedDocument2 pagesRelative SpeedSahil VermaNo ratings yet

- Block-4 Others American Fiction Old IGNOU DelDocument38 pagesBlock-4 Others American Fiction Old IGNOU Delr kumarNo ratings yet

- Week 3: Technology of Mouldmaking and Core Making, Moulding ProcessesDocument4 pagesWeek 3: Technology of Mouldmaking and Core Making, Moulding ProcesseshenokzewduNo ratings yet

- Wool FolkDocument3 pagesWool FolkHendra Septian DalimuntheNo ratings yet

- Organic Kiwifruit ProductionDocument2 pagesOrganic Kiwifruit Productionaryan jainNo ratings yet

- 00.0 DKFG 1-2Document113 pages00.0 DKFG 1-2wisdom seeker100% (3)