Professional Documents

Culture Documents

Detailed de - Nitions and Guidance For Application of Technology Readiness Levels

Uploaded by

afhlmdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed de - Nitions and Guidance For Application of Technology Readiness Levels

Uploaded by

afhlmdCopyright:

Available Formats

190 J. AIRCRAFT, VOL. 39, NO.

1: ENGINEERING NOTES

Downloaded from arc.aiaa.org by UNIVERSITY OF MARYLAND on 10/18/14. For personal use only.

Detailed De nitions

and Guidance for Application

of Technology Readiness Levels

David J. Moorhouse¤

Air Force Research Laboratory,

Wright– Patterson Air Force Base, Ohio 45305

Introduction

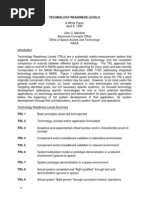

I T has been common to judge the relative “goodness” of some-

thing by using a numerical scale to assess gradations of that

goodness. The technology readiness level (TRL) scale does seem to

Fig. 1 Progression of system application risk vs TRL.

6) Risk is the judgment of probability and consequence to the

be universally accepted, but there is a need for detailed de nitions system applicationof failure of that technologyto match predictions

of each level to aid in the planning process. The detailed de nitions adequately.

given in this Note were developed as part of the National Fixed 7) Transition readiness is the judgment of how ready the tech-

Wing Vehicle program. The focus was on the TRLs applicable to nology is for incorporation into the development phase of a system

Science and Technology (S&T), i.e., the portion where the greatest application.

variability from interpretationis likely to be. It is suggested that the Now we can discuss the details of each of the levels that were

extreme values of the scale are not as ambiguous, although this is considered.

discussed later. A primary factor in this approach is the judgment

of how risk for system application reduces as technology maturity Technology Readiness Levels 1 and 2

increases. This is illustrated in Fig. 1, with consideration of risk for

These levels were not addressed in much detail in the aforemen-

technology application in the phases of system acquisition. S&T is

tioned process, but would need to be included if we are considering

typically considered to develop technology for input to the demon-

elements of basic research, i.e., basic principles or a technology

stration/validation phase with TRL 6 (acceptable risk) or 5 (high

concept. The typical case will be analytical or theoretical predic-

risk). These de nitions are intended to help program management

Journal of Aircraft 2002.39:190-192.

tions with no supporting test data. It would also be appropriate to

decisions.

assign these levels for cases of incomplete experimental data, e.g.,

TRL 1 for an experiment with incomplete documentation of con-

Technology Readiness Levels trol parameters, or TRL 2 for an experiment that was done with

Before discussing the individual levels, we de ne some of the no theoretical analysis. In either case models could be considered

terminology that will be used: order-of-magnitude approximations for performance. For system

1) Hardware is any piece of physical equipment that is part of application feasibility is unknown so that there is major risk be-

the technology under consideration. This should be construed in a cause of the uncertainties.

general sense so that it could be a structural component, or a wind-

tunnel model, etc. Technology Readiness Level 3

2) Model is the next term, which is the analytical model, i.e., the

complete descriptionof the performanceand cost of the technology. This level applies when analytical and experimental evidence is

This term can include empirical models based on wind-tunnel data, available to identify critical functions and/or characteristics so that

physics-based models, or simulation models that are a composite. the concept is considered to be proven. Testing of breadboard or

The engineer applying the TRL approach has to make a judgment generic hardware should have been accomplished. Examples could

about the delity of the model. be parametric wind-tunneltesting or partial testing of subscale com-

3) The test environment is the set of parameters of the demonstra- ponents. First-order analytical models should have been developed.

tion or test that provide the data to de ne the TRL. For example, the The contributionsof the technologytoward the goals of the planned

parameters of a wind-tunnel test would include scale, Reynolds and applicationshould have been predicted, but not correlated with data

Mach numbers, etc., to assess the reliability vs the full-scale aircraft directly for the planned con guration. Examples could be detailed

conditions. Component tests would be judged based on scale, envi- computational uid dynamics predictions, or using extrapolations

ronmental conditions, etc. There will be a progression to integrated from test data. In addition,predictionsof bene ts would typicallybe

testing, where interactions will represent the actual operation more for a single technology so that system integration and interactions

closely. are unknown. The products would be technology models but with

4) Products are the data that are available from the activity de n- many uncertainties. At this TRL the technology characteristics are

ing the TRL. This will range from analytical calculations through being de ned. The concept has been justi ed as worth further de-

ground testing and ight demonstration results. The product can be velopment, and there is potential transition for system applications.

interpreted as deliverable from a technology program. The uncertainties are with system integration, and so there is still

5) Uncertainty is an assessment of the demonstration data prod- major risk.

ucts that relate any uncertainties in the technologymodel to the risk

of system integration. Technology Readiness Level 4

This level applies when there has been component and/or bread-

board validation of hardware that is representative of the technical

concept showing that the approach is suitable for ight articles. A

Received 4 July 2001; revision received 22 September 2001; accepted laboratory, in the general sense, is considered to be the relevant test

for publication 23 September 2001. This material is declared a work of the environment. This could include a wind-tunnel test of the chosen

U.S. Government and is not subject to copyright protection in the United con guration at the appropriate Reynolds and Mach numbers or a

States. Copies of this paper may be made for personal or internal use,

on condition that the copier pay the $10.00 per-copy fee to the Copyright simulation of moderate delity. Analytical models will have been

Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923; include de ned and correlationsmade with initial test data. Cost predictions

the code 0021-8669/02 $10.00 in correspondence with the CCC. will have been made, but that will be discussedlater in the paper.The

¤ Senior Research Engineer, Air Vehicles Directorate, VASD, 2210 Eighth products for this level are models that are credible for design and

Street. Associate Fellow AIAA. performance predictions. At this level the technology is de nitely

J. AIRCRAFT, VOL. 39, NO. 1: ENGINEERING NOTES 191

appropriate for use in design tradeoffs. Actual test data show that Table 1 Detailed de nitions of risk progression

the technology can probably be transitioned to system application,

TRL Risk Risk de nition

but the integration issues are still not well de ned.

9 Zero (0) Successfully demonstrated in UAV ops.

Technology Readiness Level 5 8 Low (1) Concept demonstrated in UAVs

Successfully demonstrated, not in UAVs

This level applies when there has been component and/or bread- 7 Acceptable (2) Problems identi ed and solutions

board validation in a relevant environment. In contrast with TRL 4, known based on UAV development

the testing must be of hardware of appropriate scale and function- Concept demonstrated, but not in UAVs

ally equivalent to ight articles. The hardware may not be ight 6 Medium (3) Current advanced development can probably

weight, representative material, etc., but judgment should be used be accomplished within cost/time schedule;

to assess risk depending on the criticality of those properties to the problems of application to UAVs are identi ed;

application. Also, at this level the relevant test environment is a negligible possibility of failure

high- delity ground demonstration or a simulation with system in- 5 Medium (4) Advanced development can incur cost/time

overruns, but very low possibility of failure

teractions identi ed. There should be analytical models of the tech- for near term (1 year)

nology integrated into the system, including test correlations made 4 Medium (5) Possibility of failure to meet near-term needs;

with good agreement. The products will be models with good esti- negligible possibility of failure for midterm

mates of performance (and cost impacts). The technology is ready (5– 10 years)

for detailed design studies, and uncertainties can be judged to be 3 High (6) Long-term development with estimated

medium. The integration issues have been de ned, and the technol- costs; very low possibility of failure

ogy potential for transition can be considered good, but still high for midterm application

risk for Engineering Management and Development (EMD). 2 High (7) Costs largely unknown; low possibility of failure

for midterm; parallel efforts desirable

1 V. high (8) Concepts indicating high potential payoff,

Technology Readiness Level 6 but technology may not be feasible now;

This level applies when there has been system/subsystem, model, possibility of failure through midterm;

or prototype demonstration in a relevant environment. The tested parallel efforts mandatory

hardware must be of full scale, and the hardware must be actual

ight articles or ight type to be above TRL 5. At this level the rele-

vant test environment is either a high- delity ground demonstration and midterm (5 – 10 year) developments. Table 1 provides detailed

or simulation with components that could y, or a low- delity ight guidance on how the risk would be assessed to augment the appli-

cation of the detailed de nitions of TRL in laying out a required

Journal of Aircraft 2002.39:190-192.

test, e.g., ight in a restricted ight envelope. There is now an ana-

lytical model of the technology as integrated into the ight system, technology program for the project. Then, it is straightforward to

well correlated with test data and showing acceptable uncertainties. use the TRL de nitions for exit criteria on a roadmap. A phase or

The products are substantiated performance and design data, with task that includeda restrictedwind-tunneltest, e.g., parametric tech-

cost predictions supported by some actual data. Actual test data nology variations or only low speed, etc., would support raising the

showing minor risk for transition and integration of the technology TRL to 3. In principle, those results could feed into the next task on

into the ight system are well de ned. At this level technology has the roadmap. That next task could be a high- delity wind-tunneltest

an acceptable risk for incorporation in a demonstration/validation (TRL 4) or testing of functionallyequivalent ight articles (TRL 5).

phase, but input into the EMD phase would be judged medium to The process would put rigorous criteria into what had to be accom-

high risk. plished by the various tasks on the roadmap and ensure consistency.

Cost Aspects

Technology Readiness Level 7

There is a cost implication in all of the de nitions just given, but

This level applies when there has been system prototype demon- any discussion is speculativebecause it is not possible frequently to

stration in an operational environment. At this level the hardware separateout the cost of an individualtechnology.There are examples

being tested must be full-scale actual ight articles. The relevant of system cost overrun in Ref. 1, but it is pointed out that technology

environment is ight in the appropriate envelope, i.e., the planned immaturity is only one factor. We can assume that cost predictions

system operational envelope for safety-critical technologies. Alter- are not made until TRL 3 and that costs are known at TRL 9. In a

natively, a ground demonstration of ight hardware might be con- form that is consistent with the preceding technical de nitions, we

sidered appropriate for noncritical technologies provided the test can de ne tasks to predict the incremental effects of the technology

replicated governing ight conditions such as loads, temperatures, on cost that are applicable for each level:

etc. Analytical and simulation models will have high- delity, fully 1) TRL 3: Initialestimateshave been made to assessthe direct cost

validated with test data at operational conditions. Uncertainty is of developingand maturing the individual technology.For example,

low, and system integration has been demonstrated. The products the cost of required wind-tunnel tests or structural coupon tests can

will be design criteria with validated performance, validated to the be estimated with reasonable con dence. Return on investment has

point that it could be used with some con dence on a different ap- been calculated.

plication (but downgraded to maybe TRL 6). Cost predictions will 2) TRL 4: Estimates have been made to assess the cost impacts

be supported by data from manufacture and operation of the test of the technology integrated into a system. These estimates can be

articles. The technology is well substantiated with realistic test data based on statistical data.

and validated as being ready for low-risk transition to EMD. 3) TRL 5: Initial cost estimates have been made for development,

production, and ownership. Departures from database validity have

Project Application of TRLs been identi ed, so that there may be some prediction of variability

TRLs have been used on some projects, but they are not yet about the likely cost.

widespread. Reference 1 represents recommendationsthat their use 4) TRL 6: Some actual hardware will have been built for this TRL

be standard for development of technology. That reference also so that some data are available. Also, relative to the planned system

presents examples of the use in a variety of different applications, application, there will have been planning of all tasks and activities

although some of the examples are “after-the-fact”analyses.In con- in EMD, production, operation, and support.

sideringthe use of new technologyfor a potentialsystemacquisition, 5) TRL 7: Actual fabrication of major components has to be

the risk that can be expectedis the major factor as alluded to in Fig. 1. accomplishedto support this TRL. Also, detailed planningwill have

It is possible to provide an analogous detailed progression of risk been accomplished.

from the precedingTRL de nitions. For illustration,consideran un- Even the preceding de nition of the tasks is very subjective and

manned air vehicle (UAV) applicationwith a judgment of near-term only provides the most general guidance. First, we need to consider

192 J. AIRCRAFT, VOL. 39, NO. 1: ENGINEERING NOTES

cost is the 50% probability value. Along with an assumption that

costs are higher than predicted in the majority of cases, this empir-

ical assessment of cost yields Fig. 2. There are no data to support

numerical scales that could be a required aspect of future cost mod-

eling activities. The discussion in this Note is to suggest a process

for program managers to recognize the probable effects of maturity

on the costs of technology.

Conclusions

Detailed de nitionshave been suggestedfor technologyreadiness

levels from 1 through 7, the typical range for technology develop-

ment. These de nitions provide guidance on how to progress from

Fig. 2 Heuristic variation of technology cost with TRL.

one level to higher levels. It is suggested that the TRLs can provide

formal exit criteria for tasks or phases in a technology development

program. Risk is discussed as the inverse of the TRL progression.

the prediction of costs without “management reserve” or a factor Last, the cost implications are discussed, but only in a qualitative

to cover “unknown unknowns.” Following the preceding technical manner.

de nitions for each TRL, then there is obviously more uncertainty

on this predicted cost at the lower TRLs. We know absolutely, how-

ever, that there is a 100% probability that costs will be less than Reference

an upper bound and also 0% probability that costs will be less than 1 “Best

Practices—Better Management of Technology Development Can

a lower bound (neither of which will be known, in practice). Only ImproveWeapon System Outcomes,” Rept. GAO/NSIAD-99-162,U.S. Gen-

if the uncertainties are random can we assume that the most likely eral Accounting Of ce, Washington, DC, July 1999.

Journal of Aircraft 2002.39:190-192.

Errata

Strength of Stiffened 2024-T3 Aluminum Panels with Multiple Site Damage

B. L. Smith, A. L. Hijazi, A. K. M. Haque, and R. Y. Myose

[J. Aircraft, 38(4), pp. 764– 768 (2001)]

T he eighth column in Table 1 should be labeled 2ts rather than

ts .

You might also like

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- TRL Paper ESD Valerdi KohlDocument8 pagesTRL Paper ESD Valerdi KohlAhmed Abdalla100% (1)

- Systems Engineering - 2020 - Olechowski - Technology Readiness Levels Shortcomings and Improvement OpportunitiesDocument14 pagesSystems Engineering - 2020 - Olechowski - Technology Readiness Levels Shortcomings and Improvement OpportunitiesArzu CetinturkNo ratings yet

- What Is A Technical Readiness Level and How Is It Used?: L. WaganerDocument15 pagesWhat Is A Technical Readiness Level and How Is It Used?: L. WaganerkarunakaranNo ratings yet

- SES Unit 2Document24 pagesSES Unit 2K.Ramesh SanjuNo ratings yet

- Calibrating The Technology Readiness Level (TRL) Scale Using NASA Mission DataDocument9 pagesCalibrating The Technology Readiness Level (TRL) Scale Using NASA Mission DataafhlmdNo ratings yet

- Integration Readiness Levels: Abstract-Virtually All Successful Systems ExperienceDocument9 pagesIntegration Readiness Levels: Abstract-Virtually All Successful Systems Experienceelienai1No ratings yet

- TRL GuideDocument4 pagesTRL Guidepeteratisae_28214052No ratings yet

- Safety Analysis Using Petr NetsDocument12 pagesSafety Analysis Using Petr NetsBinglin YoungNo ratings yet

- MEC241 Engineering Sustainable Develeopment: Technology Development andDocument34 pagesMEC241 Engineering Sustainable Develeopment: Technology Development andMahesh MNo ratings yet

- Subseasystemreadinesslevelassessment PDFDocument17 pagesSubseasystemreadinesslevelassessment PDFHanoum Eva HayatiNo ratings yet

- Availability of Systems With Self-Diagnostic Components-ApplyingDocument9 pagesAvailability of Systems With Self-Diagnostic Components-ApplyingRicardo Javier PlasenciaNo ratings yet

- Technology V1.0Document30 pagesTechnology V1.0Ahmed MustafaNo ratings yet

- Technology Readyness LeveleDocument12 pagesTechnology Readyness LeveleSri SaiNo ratings yet

- Data Sources For Reliability Design Analysis: Technical NoteDocument7 pagesData Sources For Reliability Design Analysis: Technical NoteAdelmo FilhoNo ratings yet

- TechnologyReadinessLevels AWhitePaper 1995-Edited 2004Document6 pagesTechnologyReadinessLevels AWhitePaper 1995-Edited 2004peteratisae_28214052No ratings yet

- 0 - Markov Paper ExampleDocument4 pages0 - Markov Paper ExampleNishantAbrahamNo ratings yet

- Ada Programs: UsingDocument12 pagesAda Programs: UsingAlankrit PatnaikNo ratings yet

- Criticality Analysis of Process SystemsDocument8 pagesCriticality Analysis of Process SystemschevroletNo ratings yet

- Reliability Analysis of Digital Systems in A Probabilistic Risk Analysis For Nuclear Power PlantsDocument12 pagesReliability Analysis of Digital Systems in A Probabilistic Risk Analysis For Nuclear Power Plantsdo3llahNo ratings yet

- TRL eDocument5 pagesTRL eAden EirlNo ratings yet

- Meantime To FailureDocument10 pagesMeantime To FailureSatsangat KhalsaNo ratings yet

- Validation of Object Oriented Software Design With Fault Tree AnalysisDocument7 pagesValidation of Object Oriented Software Design With Fault Tree AnalysisHerareallychuckyshit WhatthevuckbloodyfreakNo ratings yet

- A Systematic Approach To Planning For A Designed Industrial Experiment - Coleman and Montgomery (1993)Document13 pagesA Systematic Approach To Planning For A Designed Industrial Experiment - Coleman and Montgomery (1993)Tony AlvessNo ratings yet

- Faa Research Project On System Complexity Effects On Aircraft Safety: Candidate Complexity MetricsDocument40 pagesFaa Research Project On System Complexity Effects On Aircraft Safety: Candidate Complexity MetricsMarzieh TavasoliNo ratings yet

- TechnologyReadinessLevels AWhitePaper 1995-Edited 2004Document6 pagesTechnologyReadinessLevels AWhitePaper 1995-Edited 2004bluedeathcontactoNo ratings yet

- A Method For Barrier-Based Incident InvestigationDocument7 pagesA Method For Barrier-Based Incident InvestigationEzatollah SalaryNo ratings yet

- Article in Press: An Extension To Fuzzy Fault Tree Analysis (FFTA) Application in Petrochemical Process IndustryDocument14 pagesArticle in Press: An Extension To Fuzzy Fault Tree Analysis (FFTA) Application in Petrochemical Process IndustryHebron GirsangNo ratings yet

- How To Design, Verify and Validate Emergency Shutdown SystemsDocument12 pagesHow To Design, Verify and Validate Emergency Shutdown SystemsJacekNo ratings yet

- R1-Thies Philipp-Reliability Assessment and Criticality Analysis For Wave Energy ConvertersDocument10 pagesR1-Thies Philipp-Reliability Assessment and Criticality Analysis For Wave Energy ConvertersThamer KhatibNo ratings yet

- Technology Readiness LevelsDocument5 pagesTechnology Readiness LevelsSânzia Almeida CostaNo ratings yet

- Practical Considerations in Developing AnDocument12 pagesPractical Considerations in Developing AnislandengineerNo ratings yet

- Fullpaper EMCHIE2015Document6 pagesFullpaper EMCHIE2015bfuentes.segulaNo ratings yet

- Tripod-BETA Incident Investigation and AnalysisDocument10 pagesTripod-BETA Incident Investigation and AnalysisAbdou BencheikhNo ratings yet

- RiskAnal Perspective-Jun04Document7 pagesRiskAnal Perspective-Jun04Panchdev KumarNo ratings yet

- Software Safety: Why, What, and How: Nancy G. LevesonDocument39 pagesSoftware Safety: Why, What, and How: Nancy G. LevesonJeremia AdiNo ratings yet

- J Sysarc 2018 04 001Document33 pagesJ Sysarc 2018 04 001Yusup SiswoharjonoNo ratings yet

- Analysis of TLCharts For Weapon Systems PDFDocument107 pagesAnalysis of TLCharts For Weapon Systems PDFSarma Jrc100% (1)

- Safety-Control SystemsDocument48 pagesSafety-Control SystemsRaja RamNo ratings yet

- Fault Tolerant DesignDocument4 pagesFault Tolerant DesignSandeep CharyNo ratings yet

- AP-1038 Technology Readiness Assessment: Common Aerospace ProcedureDocument29 pagesAP-1038 Technology Readiness Assessment: Common Aerospace ProcedureNitish SharmaNo ratings yet

- Average Probability Calculation Methods For System Safety AnalysisDocument15 pagesAverage Probability Calculation Methods For System Safety AnalysisJANGJAE LEENo ratings yet

- Techonology Readiness LevelDocument1 pageTechonology Readiness LevelairolhairrieNo ratings yet

- Modelado y Seguridad (Casos) Raoni2018Document11 pagesModelado y Seguridad (Casos) Raoni2018Ivan CisnerosNo ratings yet

- Automatic Sprinkler System ReliabilityDocument5 pagesAutomatic Sprinkler System ReliabilityNicoletta GalluzziNo ratings yet

- System Theory Based Hazard Analysis For Construction Site SafetyDocument12 pagesSystem Theory Based Hazard Analysis For Construction Site SafetymusniraNo ratings yet

- Mutation Testing NuclearDocument16 pagesMutation Testing NuclearMaham AwaisNo ratings yet

- FMR-TRL MapDocument1 pageFMR-TRL MapJames SnodgrassNo ratings yet

- Apostolakis 2004Document6 pagesApostolakis 2004Lorena CCNo ratings yet

- Reliability Analysis of The SPARC V8 Architecture Via Fault Trees and UPPAL-SMCDocument4 pagesReliability Analysis of The SPARC V8 Architecture Via Fault Trees and UPPAL-SMCcvsetfNo ratings yet

- Calculadora TRL ManualDocument16 pagesCalculadora TRL Manualmarchesini.engNo ratings yet

- Fault Tree AnalysisDocument18 pagesFault Tree AnalysisKyle Kelly100% (1)

- The ARTEMIS Air-to-Air Combat ModelDocument7 pagesThe ARTEMIS Air-to-Air Combat ModelSallu BhaiNo ratings yet

- IHA TechniqueDocument151 pagesIHA TechniquePaul LeungNo ratings yet

- It Security Testing, A Practical Guide MDocument5 pagesIt Security Testing, A Practical Guide MMeron SolomonNo ratings yet

- Reliability Engineering and System Safety: Steven Verlinden, Geert Deconinck, Bernard CoupeDocument13 pagesReliability Engineering and System Safety: Steven Verlinden, Geert Deconinck, Bernard CoupeGeorgeGeorgiadisNo ratings yet

- Optimization of Test and Maintenance Intervals Based On Risk and CostDocument14 pagesOptimization of Test and Maintenance Intervals Based On Risk and CostOntime BestwritersNo ratings yet

- Lec12 GaDocument33 pagesLec12 Galux0008No ratings yet

- Robust Design Optimization in Aeronautics UsingDocument21 pagesRobust Design Optimization in Aeronautics UsingReyMysterioNo ratings yet

- Eugene Hecht - Physics - Calculus 1996Document1,336 pagesEugene Hecht - Physics - Calculus 1996Ivana Stojanova100% (1)

- Home Automation Using Hand GestureDocument19 pagesHome Automation Using Hand GestureChandrashekhar KatagiNo ratings yet

- BSSPAR1: Chapter 10 Multi-BCF and Common BCCH: RN2010AEN14GLN0Document22 pagesBSSPAR1: Chapter 10 Multi-BCF and Common BCCH: RN2010AEN14GLN0sabagh_55No ratings yet

- Numerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueDocument27 pagesNumerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueIbsonhNo ratings yet

- CYBERBLOC FP - BrochureDocument7 pagesCYBERBLOC FP - BrochureMaisoun MohamedNo ratings yet

- APC Back-UPS 400 CLII-9FCLHR - R0 - ENDocument2 pagesAPC Back-UPS 400 CLII-9FCLHR - R0 - ENPatrizia CudinaNo ratings yet

- Skempton Pore Pressure Coefficients A and B PDFDocument5 pagesSkempton Pore Pressure Coefficients A and B PDFRoda Cadiz100% (1)

- Diatron Calcium Reagent: Application Procedure Catalog No. Size Diatron Pictus 400 Dtrca 5 X 40mL Reagent PreparationDocument1 pageDiatron Calcium Reagent: Application Procedure Catalog No. Size Diatron Pictus 400 Dtrca 5 X 40mL Reagent PreparationPhong DoNo ratings yet

- Energy Monitoring With Ultrasonic Flow MetersDocument35 pagesEnergy Monitoring With Ultrasonic Flow MetersViswa NathanNo ratings yet

- Automata Theory TutorialDocument82 pagesAutomata Theory TutorialHeena JainNo ratings yet

- Conditions, Switch, While Loop, and For LoopDocument22 pagesConditions, Switch, While Loop, and For LoopM MNo ratings yet

- Designing of Square Pad FootingDocument6 pagesDesigning of Square Pad FootingShamitha KanchanaNo ratings yet

- S4 HW Ans Sheet (CH - 18 Salts and Neutralization) - SDocument3 pagesS4 HW Ans Sheet (CH - 18 Salts and Neutralization) - STSZ HIN CHANNo ratings yet

- DHT - Latch-Les Wireline Coring SystemDocument33 pagesDHT - Latch-Les Wireline Coring SystemesandovalaNo ratings yet

- Gek 28075Document20 pagesGek 28075leaw81No ratings yet

- Space Time (ST) and Space Velocity (SV)Document2 pagesSpace Time (ST) and Space Velocity (SV)Marco A. Castillo LudeñaNo ratings yet

- M80 Motor Data Sheet - Rizel AutomotiveDocument1 pageM80 Motor Data Sheet - Rizel AutomotiveVarun Thana shekarNo ratings yet

- Elix® Essential 3, 5, 10, 15 Water Purification SystemDocument8 pagesElix® Essential 3, 5, 10, 15 Water Purification SystemMerck IndiaNo ratings yet

- Dehumidifier Technical ManualDocument17 pagesDehumidifier Technical ManualReynaldo FloresNo ratings yet

- (Rothe) Topic From Relativity (2010)Document107 pages(Rothe) Topic From Relativity (2010)Vbsa BsaNo ratings yet

- Introduction To Oracle SQL and PL - SyllabusDocument9 pagesIntroduction To Oracle SQL and PL - SyllabusmonikadograNo ratings yet

- Process of PhotosynthesisDocument3 pagesProcess of Photosynthesisapi-3731257No ratings yet

- MTRP 2016 - 9Document3 pagesMTRP 2016 - 9Nimai Roy100% (1)

- QueuingTheory Matlab AssignmentDocument3 pagesQueuingTheory Matlab AssignmentShyam ShankarNo ratings yet

- Smart BracketsDocument6 pagesSmart BracketslahyouhNo ratings yet

- High Commitment HR SystemsDocument50 pagesHigh Commitment HR Systemsshwetauttam0056296No ratings yet

- Plate Tectonics Web-Quest: Part I: Earth's Structure. Use The Following Link To Find These AnswersDocument8 pagesPlate Tectonics Web-Quest: Part I: Earth's Structure. Use The Following Link To Find These AnswersAshley jarren Lorenzo100% (1)

- Demister Beam Calculation - Final PDFDocument4 pagesDemister Beam Calculation - Final PDFGauravNo ratings yet

- Powell, J. David - Workman, Michael L. - Franklin, Gene F. - Solutions Manual For Digital Control of Dynamic Systems-Addison-Wesley (1998)Document454 pagesPowell, J. David - Workman, Michael L. - Franklin, Gene F. - Solutions Manual For Digital Control of Dynamic Systems-Addison-Wesley (1998)Francisco GarciaNo ratings yet