Professional Documents

Culture Documents

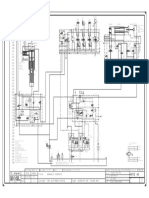

Hyd Schem SN 71184

Uploaded by

Francisco PestañoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hyd Schem SN 71184

Uploaded by

Francisco PestañoCopyright:

Available Formats

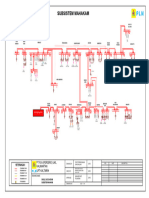

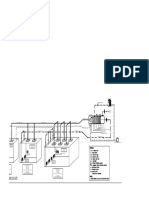

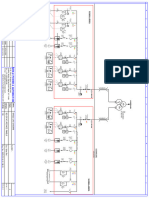

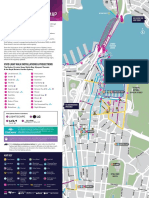

HYD.

MOTOR

TABLE

Test PT. ROTARY TABLE

G1/8" LIFTING

HYDRAULIC TABLE

B3

G1/4" G1/4" EJECTOR LOCKING A

U -BFC

P J2

B6 OPEN B5

(BFC) 2004.0314

G3/8" P A 2011.6042

-S2.1 2220.0219 T B CARRIAGE INJECTION SCREW DRIVE MOTOR

101 P T B

(S2.1)

NG6

Gauge 1 # 5 T

J

80cc & 200cc INJECTION

RA2 RB2 RB3 RA4 RB4 RAM RBM OMR-100

102

b 2004.0307

G3/8" G3/8" G3/8" G1/4" G3/8" G3/8" G3/8" G3/8" G3/8" G3/8" G1/2" G1/2"

330cc INJECTION

30mm,35mm screw OMR-160

103 X

HI PRESS

C2011.0134

2051.0331

VENT

-S2.2

2011.6010

-SC A B

A1 B1 A2 B2 A3 B3 A4 B4 AM BM

2004.0308

R10 40mm,45mm screw OMR-200

-S1.2 (SC) 2004.0338

104 a (S1.2)

NG6

(S2.2)

a

a

NG6 P T G3/8"

G G G Anpr Abh Dak Spr R9

MFD 6235.950.2946C

C2023.0054 A

105 G1/4"

P3

P

T

A

B

P A

Ø1

140 BAR

C2026.3060

-YC -S26 -S25

2026.2501

-SDTH -SDTL

2026.2501

-SDTVE

2026.2501

-SDTVV -SCC -SCW

G1/2"

CF

G1/2"

CB

G1/2"

TM

(YC) COVER (S26) (S25) (SDTH) (SDTL) (SDTVE) (SDTVV) (SCC) (SCW)

Ø1 A B A B A B A B A B G3/4"

106 RP4 RPX RX F

KCR

NG10 P T

2000.631.2307B

a

P T

2011.6024

b a

P T

2011.6024

b a

P T

2011.6024

b a

P T

b

G1/2"

T

SB

G3/4"

I RISER PLATE 4180.470.2907D TM

NG6 NG6 NG6 NG10 G1/2"

107 HI-PRESSURE

LOCK-UP

B B G3/8" T C2026.0113

100 BAR 100 BAR 40 BAR

MFD

6235.950.2945C

Gauge 1 # 4

G1/4"

M4

AB AA ZSA ZSB

YM - PROMIS

G1/2"

NG16 ZC PM

A Y3 - MEDUSA

108 C2023.0003 H H H VALVE -S4D A B

PLUGGED G3/8" (S4D)

1/8" NPT 2011.6025 G5 a C2026.3053

PA1

C2026.0113 C2026.0113 C2027.0200 P T INJECTION

C2027.0172 F NG10

109 G1/4"

G3/8"

-S6

(S6) A B

-S5

(S5)

REGEN

A B

-YM

(YM) -S3 A B

C2011.0300 SUCKBACK (S3)

110

P Ø1 RET a b FOR a

G1/4" G3/8" P T

C2011.0160 -S24 P1 P2 T P T

NG6 A B (S24) NG10 NG10

T

:

G3/8" G3/4" G1" G1" G3/8" G3/8" G1/4" 2029.4169 C2011.0124 C2011.0353

b

111 XR PC T PA Y

MFD. 6234.950.9823E

Ø1.0

-S6A A (S6A)

P T

NG6 SCREW

TURN

a

112 DRAIN ABOVE

OIL LEVEL

D1

D5 T

Test PT.

SAE 6

P

2011.5173

113 V

G1/4"

MFD.# C2051.0619 G1" G1/4"

G3/4" G1"

G3/8"

114 CLAMP CYL.DIMENSIONS

(ES55-85)

P M3

P

(PH3)

T1 T X

D1=240 (9.45") U

115 D2=230 (9.06")

D3= 65 (2.56") R5

-PH3

R6 R8

D4=220 (8.66")

116 D5= 45 (1.77")

STROKE: 300 (11.81") D3

FAST CLOSING

Gauge 1 # 3

117

LINE

T

118 D4

119

120

121

122

123

R85

Test Point Z36C

Gauge 1 # 6 C2023.0051

124 G3/8" G3/8" G3/8" G1/4" G3/8" G3/4" G3/4" G1/2"

2029.7015

MFD. C2051.0615

125 T4 P4 PX MC AB B2 R F G1" G1/4" F Ø0.8

Test PT. P1 M6

G1/4" G3/4" B B G1"

126 G7

C2027.0003 B 2027.5050

F

MO R14 FILTER

2041.1107

P2 Z36

NG16 A

C2023.0003

D

Ø1.0

K20 20 BAR

T1

ELEMENT C2021.0005

L 2021.2083

127 2011.6011

X

A

KP

-S11A

(S11A)

a

A B

-F2

2041.5079

C5100.0190

C2011.7001 -S11B P T

2011.5066

128 -S8.1

(S8.1)

A B

(E8)

A

P

B

T

(S11B)

b

205 BAR

NG6

C2011.0134

(F2) -S10

(S10)

a

A B

a NG6 NG06 P T

-E8

129 NG10 P T

D3 2011.5066

G3/8"

X3

Ø0.9 -S3A A B S

130 B

KCL

G1/4"

-Y

C5100.0191

D

Ø1.0

C5100.0190

(S3A)

a

NG06 P T

C5100.0193

FB SET FOR REMOVE COVER M (Y) A B

131 CLOSE A

(GB) MINIMUM MOLD

PROTECTION

C2051.0623

REPLACE WITH

NG10

P T

K18

230 BAR -K (K)

P

D4

Ø1.2

OPEN PRESSURE 3700.631.9538C 2021.2084 2021.2085

C2051.0018

132 -S2

(S2) A B

-S1

(S1)

C2027.0182 2026.3063

-S1.3 A F FT

250 BAR

2011.5153

NG06 T

G1/4"

M1

Gauge 1 # 1

a b (S1.3) G1"

133 NG10 P T

2011.6025

a

P

VALVE

C2023.0003

B B R1 2604.0104

0.5 BAR

T2

K19 K19

2021.2083

G3/8"

X

COVER NG16 A

Z

134 C2023.0071

G3/4"

P2

G3/4"

ZB

ø20

:

G3/8"

XR

G3/8" G3/8"

L FP

RISER 5890.638.1645C

G1"

135 G3/8" G1"

MFD. 5785.560.1624E : G3/4"

P

G3/4"

P3 T X TK

136 R56 P

Gauge 1 # 2

137 R33

SAE 1" SAE 1-1/4"

138

B B

R132

139 -M1 P=30HP

n=1800U/min

M1

140

SAE 4 SAE 4

P2 P1

FUNCTIONING OF VERTICAL CLAMP

141 CLAMP CLOSE

S1 : CLOSING

C2031.0300 P. COMP

100 BAR

P. COMP

240 BAR

MULTI-STATION PRESSURE GAUGE

FILTROIL "OPTION 132"

142 S2.1: PREFILL VALVE OPEN GAUGE # 1

S1.2: HI-PRESSURE LOCK-UP AA10VSO45 AA10VSO71

PUMP # 1

C2004.0011 C2004.0054

S1.3: ROD-END UNLOADING (SKO) RG1

143 COUNTER PRESSURE MOLD PROTECTION

S11A: ACTIVE COUNTER PRESSURE PUMP 2

-SKO C2032.0041 SAE 10 SAE 1-1/2"

FLOW COMP.-20BAR

SAE 12 SAE 2"

FLOW COMP.-20BAR

RG2

PUMP # 2

INJECTION

144

L S L S

S11B: ROD END OPEN TO COUNTER LOAD RELIEF C2004.0035 RG3

3010.0411 1 2 3

CLAMP OPEN Q1.2 P1+P2 COMBO

-OEN -OL

S2 : OPENING

145 S2.2: UNLOADING CLOSING END

S2.1: PREFILL VALVE OPEN

2041.0011

D (OEN) (OL)

R3 Q1

-F1

R2 R77

R133

C2041.2111 6 5 4

146 MECHANICAL-HYDRAULIC SAFETY

X26 : HYDRAULIC INTERLOCK ACTUATED BY MECHANICAL

t

(F1)

2031.0021

RG4

CARRIAGE

DEVICE ON SAFETY GATE

147 E8.1 : MONITORING LIGHT CURTAIN TO ACTIVATE S8.1

HYDRAULIC INTERRUPT

RG5

EJECTOR

MOLD PROTECTION

PUMP CASE SHOULD BE FILLED BEFORE STARTUP. RG6

148 ALL HYD.COMPONENTS LISTED ABOVE LOCATED BY CLAMP CYL.

RECOMMENDED TEMPERATURE OF 120F(49C) WITH ISO VG46 VISCOSITY GRADE OIL.

MAINTAIN OIL FILTRATION LEVEL TO ISO CLASS 16/13.

LAST PAGE REV#: V0 REV. DATE: 6/28/2002 ECO#: D.T. REVISION NOTE: Machine Shipped HIGHEST REVISION COUNT FOR DEPARTMENTS E,H,P V0 V0 V0

El. diagram Date Name Ser.No. 71184.055.02

dr'n. 05/01/02 D.T.

Title HYDRAULIC SCHEMATIC

O r d e r N o .1 0 5 5 8 1 . 7

=H Y D +0

Origin. C0-000 PG# Total

CANADA

chkd. M.H. Customer TYCO ELECTRONICS Type ES200\55 VH: CC100 A03 D.No. H184-040-0000 1 11

You might also like

- Hyd Schem. SN 71102Document1 pageHyd Schem. SN 71102Francisco PestañoNo ratings yet

- Hyd Schem SN 71185Document1 pageHyd Schem SN 71185Francisco PestañoNo ratings yet

- 2018 Henty Machinery Field 2018 MapDocument1 page2018 Henty Machinery Field 2018 MapNeenNo ratings yet

- Cek Struktur EL 18.5 MeterDocument1 pageCek Struktur EL 18.5 Meterrhp1989No ratings yet

- 4.4 Id Drawings For Lv75eDocument43 pages4.4 Id Drawings For Lv75erollyNo ratings yet

- Corlu VFR ChartDocument1 pageCorlu VFR Chartcod modernwarfareNo ratings yet

- A C D 25300 150 8400 8500 150 B: Roof Framing Plan ADocument1 pageA C D 25300 150 8400 8500 150 B: Roof Framing Plan AAhmed Ayman AhmedNo ratings yet

- Air 1Document1 pageAir 1saipNo ratings yet

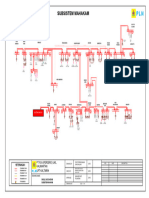

- SLD Mahakam Update September 2020Document1 pageSLD Mahakam Update September 2020Sela MartasiaNo ratings yet

- SLD Mahakam Update Juli 2020Document1 pageSLD Mahakam Update Juli 2020Sela MartasiaNo ratings yet

- Asurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023Document8 pagesAsurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023JohnNo ratings yet

- AC Cleanroom - ModelDocument1 pageAC Cleanroom - ModelMahardika Yusuf SesotyaNo ratings yet

- Schema Hydraulique HTL14-17Document4 pagesSchema Hydraulique HTL14-17Jaime Perez FuenzalidaNo ratings yet

- 5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Document1 page5-2-4 LOGIQ E9 Overall Block Diagram (Cont'd)Nguyen TanNo ratings yet

- Air Bersih GFDocument1 pageAir Bersih GFMuhammad AfifuddinNo ratings yet

- Wiring Diagram 78 fj40 PDFDocument1 pageWiring Diagram 78 fj40 PDFnenadNo ratings yet

- 3 Bid Document Vol III 02Document10 pages3 Bid Document Vol III 02Dhabalia AshvinNo ratings yet

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Document1 pageGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNo ratings yet

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Document1 pageGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNo ratings yet

- Sanchore MapsDocument4 pagesSanchore Mapsvillage tachNo ratings yet

- Key Plan, Location Plan, Plumbing Layout, Sanitary LayoutDocument1 pageKey Plan, Location Plan, Plumbing Layout, Sanitary LayoutF1030 Iman FaizNo ratings yet

- Map SnowDocument1 pageMap SnowFreehold InJerseyNo ratings yet

- SRP Mastr PlanDocument1 pageSRP Mastr PlanSudarshan DujariNo ratings yet

- Cat 3412Document4 pagesCat 3412hoseinNo ratings yet

- Hwi Apo6br Ge LLD 0002Document1 pageHwi Apo6br Ge LLD 0002Nideesh RobertNo ratings yet

- 90 X 60 Warehouse - Floor Plan Layout-Layout1Document1 page90 X 60 Warehouse - Floor Plan Layout-Layout1Rathna KumarNo ratings yet

- 62MGH000 25 CWMR80Document2 pages62MGH000 25 CWMR80Kiss JózsefNo ratings yet

- DNSW Vivid Sydney Lightwalk Map FinalDocument2 pagesDNSW Vivid Sydney Lightwalk Map FinalShuba SundaramNo ratings yet

- A042J126Document6 pagesA042J126peninggal jejakNo ratings yet

- HVAC Schematic Drawing - WMO Rev ADocument2 pagesHVAC Schematic Drawing - WMO Rev Aarief bahtiarNo ratings yet

- Air Kotor GFDocument1 pageAir Kotor GFMuhammad AfifuddinNo ratings yet

- WAYFINDINGDocument1 pageWAYFINDINGDennise PandianNo ratings yet

- Battery: Exhaust Gas Sensor (RH)Document3 pagesBattery: Exhaust Gas Sensor (RH)Joakin BcNo ratings yet

- Anand Kasaudhan Assignment 1Document1 pageAnand Kasaudhan Assignment 1Anand KasaudhanNo ratings yet

- Siddharth AdminDocument1 pageSiddharth AdminFan FollowingNo ratings yet

- 854 Iahe WW MJB Gad 001 R2 594X2000Document1 page854 Iahe WW MJB Gad 001 R2 594X2000KA25 ConsultantNo ratings yet

- R3 - Hdc-Bbs-Ix-Xx-Dr-M-1201 (Schmatic Sistem T3 Ix - Sheet 2)Document1 pageR3 - Hdc-Bbs-Ix-Xx-Dr-M-1201 (Schmatic Sistem T3 Ix - Sheet 2)Fitria Purnama SariNo ratings yet

- GIV Panel - ArtDocument6 pagesGIV Panel - ArtJdawg JdawgNo ratings yet

- Building Line Building Line: Nh-Row Nh-RowDocument1 pageBuilding Line Building Line: Nh-Row Nh-RowNhai VijayawadaNo ratings yet

- Modules SteelDocument42 pagesModules SteelSergio Herrera CelisNo ratings yet

- 148 DC SLD FinalDocument1 page148 DC SLD Finalprakashumesh529No ratings yet

- 上柴DSE7320 12GTAA27 9A221117TH SC563E5ADocument1 page上柴DSE7320 12GTAA27 9A221117TH SC563E5ABradNo ratings yet

- Tech ss40t Wiring PDFDocument1 pageTech ss40t Wiring PDFmuhammad nazirNo ratings yet

- Working Drawing: Primary Health CentreDocument1 pageWorking Drawing: Primary Health CentreRupali KhatriNo ratings yet

- Bishop'S Cap: Heron Lake 3,303'Document1 pageBishop'S Cap: Heron Lake 3,303'Shamela McmeansNo ratings yet

- Seven9 Sky Brochure-2Document1 pageSeven9 Sky Brochure-2Thakor MistryNo ratings yet

- Typ 1Document1 pageTyp 1husseinqahtan09No ratings yet

- Fire Parmit Drawing (Final Floors Plans)Document15 pagesFire Parmit Drawing (Final Floors Plans)Moe Oo HtunNo ratings yet

- Chamber Detail Drill Site B-Reva-6Document1 pageChamber Detail Drill Site B-Reva-6ahmed saadNo ratings yet

- Vs23 Access Map v12 Final WebDocument2 pagesVs23 Access Map v12 Final WebalanNo ratings yet

- 0282 - 001 - Ga For Sump-Ph-Ap Channel - 09 - 04 - 2024-2Document1 page0282 - 001 - Ga For Sump-Ph-Ap Channel - 09 - 04 - 2024-2HRP InfraNo ratings yet

- 3 Exhibit A 02-Aerial and Land Use-500-ScaleDocument1 page3 Exhibit A 02-Aerial and Land Use-500-ScaleBradley JacquesNo ratings yet

- SCR 004934Document1 pageSCR 004934jeplgpbmcNo ratings yet

- 62.Ms e 8 External Water Metter Valve Box Ms e 8Document1 page62.Ms e 8 External Water Metter Valve Box Ms e 8Phúc Đinh TấnNo ratings yet

- GFPlanTrafficSignals PDFDocument1 pageGFPlanTrafficSignals PDFKASHISH RAJESH BHARDWAJNo ratings yet

- GFPlanPedestrian+ Subway PDFDocument1 pageGFPlanPedestrian+ Subway PDFKASHISH RAJESH BHARDWAJNo ratings yet

- 750 DWT GA-ModelDocument1 page750 DWT GA-ModelHanzalah NaufalNo ratings yet

- GFPlanParking PDFDocument1 pageGFPlanParking PDFKASHISH RAJESH BHARDWAJNo ratings yet

- GFPlanPublicTransport PDFDocument1 pageGFPlanPublicTransport PDFKASHISH RAJESH BHARDWAJNo ratings yet

- TR20EH3 Appendix DiagramsDocument64 pagesTR20EH3 Appendix DiagramsFrancisco PestañoNo ratings yet

- E-Multi 4PG Brochure 2015 FinalDocument2 pagesE-Multi 4PG Brochure 2015 FinalFrancisco PestañoNo ratings yet

- SR1013 Service Manual 10-20Document40 pagesSR1013 Service Manual 10-20Francisco PestañoNo ratings yet

- Infineon IRFB260N DataSheet v01 - 01 ENDocument10 pagesInfineon IRFB260N DataSheet v01 - 01 ENFrancisco PestañoNo ratings yet

- Dsa 0055371Document2 pagesDsa 0055371Francisco PestañoNo ratings yet

- Test Frame User GuideF0435F24EC43Document26 pagesTest Frame User GuideF0435F24EC43Francisco PestañoNo ratings yet

- Equipo de Dart VisionDocument51 pagesEquipo de Dart VisionFrancisco PestañoNo ratings yet

- Dect Metal1Document56 pagesDect Metal1Francisco PestañoNo ratings yet

- Hotplate Stirrer PDFDocument1 pageHotplate Stirrer PDFKuljinder VirdiNo ratings yet

- Nurse Education Today: Natalie M. Agius, Ann WilkinsonDocument8 pagesNurse Education Today: Natalie M. Agius, Ann WilkinsonSobiaNo ratings yet

- Reconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaDocument7 pagesReconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaJose ValdiviesoNo ratings yet

- Mrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265Document28 pagesMrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265amitNo ratings yet

- The London SchoolDocument3 pagesThe London SchoolKhawla Adnan100% (5)

- Ponce vs. Court of AppealsDocument7 pagesPonce vs. Court of AppealsMp CasNo ratings yet

- Cpa Review School of The Philippines: Related Psas: Psa 700, 710, 720, 560, 570, 600 and 620Document49 pagesCpa Review School of The Philippines: Related Psas: Psa 700, 710, 720, 560, 570, 600 and 620Jasmine LimNo ratings yet

- Microtech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryDocument1 pageMicrotech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryKumar AbhishekNo ratings yet

- Quantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.DvDocument6 pagesQuantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.Dvohenri100No ratings yet

- Edoc - Pub Grade 10 Science DLL q3 Week 3Document5 pagesEdoc - Pub Grade 10 Science DLL q3 Week 3Geraldine Pascua CardenasNo ratings yet

- BIO SCI OsmosisDocument10 pagesBIO SCI OsmosisJoy FernandezNo ratings yet

- Autonomic Nervous SystemDocument21 pagesAutonomic Nervous SystemDung Nguyễn Thị MỹNo ratings yet

- Nanoimprint Lithography: Presented by Group 7Document27 pagesNanoimprint Lithography: Presented by Group 7Samia SafaNo ratings yet

- 4148-Article Text-14752-1-10-20211029Document7 pages4148-Article Text-14752-1-10-20211029Daffa AzkaNo ratings yet

- Activities For Learner-Centered TeachingDocument56 pagesActivities For Learner-Centered TeachingAmiga Mi100% (1)

- Chapter-Communication & NetworkingDocument70 pagesChapter-Communication & NetworkingAfsar AhmedNo ratings yet

- Augusta Issue 1145 - The Jail ReportDocument24 pagesAugusta Issue 1145 - The Jail ReportGreg RickabaughNo ratings yet

- Assignment 1 SolutionDocument11 pagesAssignment 1 SolutionKash TorabiNo ratings yet

- Reducing Motor Vehicle Crashes in B.C.Document260 pagesReducing Motor Vehicle Crashes in B.C.Jeff NagelNo ratings yet

- Lesson PlansDocument12 pagesLesson Plansapi-282722668No ratings yet

- Block 7Document62 pagesBlock 7Poco ChanNo ratings yet

- Air Defence Systems: Export CatalogueDocument105 pagesAir Defence Systems: Export CatalogueserrorysNo ratings yet

- Explicit Lesson PlanDocument10 pagesExplicit Lesson PlanBanjo De Los SantosNo ratings yet

- Character AnalysisDocument3 pagesCharacter AnalysisjefncomoraNo ratings yet

- 30 This Is The Tower That Frank BuiltDocument26 pages30 This Is The Tower That Frank BuiltAlex BearishNo ratings yet

- Fall 2015 The Language of Anatomy PDFDocument14 pagesFall 2015 The Language of Anatomy PDFpikminixNo ratings yet

- PURL Questions and AnswersDocument3 pagesPURL Questions and AnswersSHAHAN VS100% (5)

- Creating A Pathway For Every Student: Holyoke High School Redesign Strategic PlanDocument29 pagesCreating A Pathway For Every Student: Holyoke High School Redesign Strategic PlanMike PlaisanceNo ratings yet

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDocument720 pagesCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyNo ratings yet

- Mrr2 Why The Future Doesnt Need UsDocument3 pagesMrr2 Why The Future Doesnt Need UsSunshine Glory EgoniaNo ratings yet