Professional Documents

Culture Documents

RB26M10

Uploaded by

Mohamed Elsanee0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageRB26M10

Uploaded by

Mohamed ElsaneeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

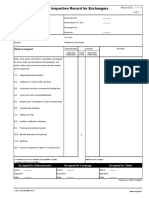

Inspection Record for Mixers Record No.

: –––––

Client: ––––– Subcontractor: –––––

Project No.: ––––– Subcontract P.O. No.: –––––

Project Name: ––––– Equipment No.:

Additional Information: P.O. No.:

Vendor: Reference Document:

Items to inspect Subcontractor Company Remarks

inspected Hold inspected*

initials/date Point initials/date

1.0 Mounting flange level (or plumb)

2.0 Driver direction of rotation

3.0 Shaft plumb (or level)

4.0 Shaft straightness

5.0 Alignment of drive shafts

End clearance .......................... mm.

6.0 Concentric parallel

1/4 turn

1/2 turn

3/4 turn

full turn

7.0 Mechanical seal or packing in coupling cleaned,

closed and lubed

8.0 Shaft turns freely by hand Important:

Do not start mixer with dry mechanical seal

9.0 Bearing house flushed and relubed

10.0 Seal fluid system operable

11.0 Lubricator operable

12.0 Driver dowelled in place

13.0 Coupling guard in place

14.0 Grounding strap installed

H - Company’s presence is mandatory for all activities in section. Attachments, No. of pages:

h - Company’s presence is mandatory.

Accepted for Subcontractor Accepted for Company Accepted for Client

Name: ––––– Name: ––––– Name: –––––

Signature: Signature: Signature:

Date: ––––– Date: ––––– Date: –––––

*Company only initials for holdpoint

C:\RB_Forms\RB26M10.DOT\ www.red-bag.com

You might also like

- RB26P01-Inspection and Test Record For PumpCompressorDocument2 pagesRB26P01-Inspection and Test Record For PumpCompressorMohamed ElsaneeNo ratings yet

- H Hole MesaurmentDocument2 pagesH Hole MesaurmentHamzaNoumanNo ratings yet

- Inspection Record For Instrument Installation and Mechanical Acceptance FormDocument2 pagesInspection Record For Instrument Installation and Mechanical Acceptance FormKyrie AbayaNo ratings yet

- Inspection Record For Site WeldingDocument1 pageInspection Record For Site WeldingCinek_cin100% (1)

- RB26J23-Inspection Record For Suspended Ceiling of BuildingsDocument1 pageRB26J23-Inspection Record For Suspended Ceiling of BuildingsMohamed ElsaneeNo ratings yet

- Inspection and Test Record For Piping CoDocument1 pageInspection and Test Record For Piping CoFouad EANo ratings yet

- Inspection Record For Instrument Impulse Hook-UpsDocument1 pageInspection Record For Instrument Impulse Hook-Upsganesan 0011No ratings yet

- Preliminary Mechanical Acceptance Report For InstrumentationDocument1 pagePreliminary Mechanical Acceptance Report For Instrumentationganesan 0011No ratings yet

- Inspection Record For Local Indicating Instruments Press., Temp.,Flow and Level GaugesDocument1 pageInspection Record For Local Indicating Instruments Press., Temp.,Flow and Level Gaugesganesan 0011No ratings yet

- Orifice Plate Installation RecordDocument1 pageOrifice Plate Installation Recordganesan 0011No ratings yet

- Inspection Record for Gates SEODocument1 pageInspection Record for Gates SEORoshin99No ratings yet

- IV. Non-Conformance Report FormDocument15 pagesIV. Non-Conformance Report FormAnduel SelamajNo ratings yet

- O o o o o o o O: Submittal FormDocument1 pageO o o o o o o O: Submittal FormAngelo Carlo MalabananNo ratings yet

- ANX Authorized Distributor CSIDCDocument9 pagesANX Authorized Distributor CSIDCanshukool26No ratings yet

- 1-M-C-CI09-ATC-AD-MS-0064 - Forms For Cylindrical Columns, Pedestals & Supports (AMA)Document1 page1-M-C-CI09-ATC-AD-MS-0064 - Forms For Cylindrical Columns, Pedestals & Supports (AMA)rthomsanNo ratings yet

- Holding Down Bolts Tightening Quality Control and Inspection Report Form PDFDocument2 pagesHolding Down Bolts Tightening Quality Control and Inspection Report Form PDFGanesh YadavNo ratings yet

- Air Coolers Run in TestDocument2 pagesAir Coolers Run in TestchambigmacNo ratings yet

- (Form GNQ 15C) FrickCompPrestartChecklist 1Document1 page(Form GNQ 15C) FrickCompPrestartChecklist 1eugene mejidanaNo ratings yet

- (Form GNQ 19) Pump Pre Commissioning Checklist 1Document2 pages(Form GNQ 19) Pump Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- Subconsultant Bid FormDocument2 pagesSubconsultant Bid FormIskandar HasibuanNo ratings yet

- Inspection Datasheet For Pumps Skids' Frame & Skid Assembly (EDR - 950-2-0151-000-VOG-InP-DTS-1590 - 001 - A) - 1Document8 pagesInspection Datasheet For Pumps Skids' Frame & Skid Assembly (EDR - 950-2-0151-000-VOG-InP-DTS-1590 - 001 - A) - 1naveen_86No ratings yet

- Duct House Company ProfileDocument67 pagesDuct House Company ProfileMahmoud ElsadatNo ratings yet

- Inspection Record For Airflow Control Devices: Record No.: - Page 1 of 2Document2 pagesInspection Record For Airflow Control Devices: Record No.: - Page 1 of 2Schwihdi ZakNo ratings yet

- F-PUR-09 Supplier Registration FormDocument2 pagesF-PUR-09 Supplier Registration FormRakesh ChauhanNo ratings yet

- (Form GNQ 15A) FrickCompPrestartChecklistDocument7 pages(Form GNQ 15A) FrickCompPrestartChecklisteugene mejidanaNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Project Quality Plan (PQP R 02) MMH BI 10 1409Document53 pagesProject Quality Plan (PQP R 02) MMH BI 10 1409SARANGMUMBAINo ratings yet

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- Check List For Installation of Cooling TowersDocument2 pagesCheck List For Installation of Cooling TowersGirithar M Sundaram67% (3)

- Nit FormDocument40 pagesNit FormLokesh ChandrakarNo ratings yet

- Earnest Money Deposit (EMD) and Security Deposit Exemption PDFDocument3 pagesEarnest Money Deposit (EMD) and Security Deposit Exemption PDFdasuyaNo ratings yet

- Change Order DetailsDocument16 pagesChange Order Detailsomoboriowo ayodejiNo ratings yet

- Technical & Commercial BidDocument46 pagesTechnical & Commercial BidnareshpaneruNo ratings yet

- RB26C05 PDFDocument1 pageRB26C05 PDFGerritNo ratings yet

- Process Site Visit Report 25.03.2019Document15 pagesProcess Site Visit Report 25.03.2019hatem jlolNo ratings yet

- 9 CSR VW Rev 13 - TRLDocument6 pages9 CSR VW Rev 13 - TRLandte costaNo ratings yet

- 1st-Final Bill FormDocument2 pages1st-Final Bill FormsinghNo ratings yet

- Approved Drawings To Be Re-Stamped (Building Permit Unit-DNDD)Document1 pageApproved Drawings To Be Re-Stamped (Building Permit Unit-DNDD)NiggaNo ratings yet

- Synthetics Rubber Indonesia Pile InspectionDocument2 pagesSynthetics Rubber Indonesia Pile InspectionDenny SyafwalufiNo ratings yet

- FOREMATbDocument95 pagesFOREMATbKedir ShiferawNo ratings yet

- Field Inspection ChecklistDocument1 pageField Inspection ChecklistHoang Xuan ChauNo ratings yet

- Inspection Record For Grouting: Items To InspectDocument1 pageInspection Record For Grouting: Items To InspectJoseph PeterNo ratings yet

- A. General Information: Department of Public Works and Highways Registry of Contractors For Civil Works ProjectsDocument10 pagesA. General Information: Department of Public Works and Highways Registry of Contractors For Civil Works ProjectsKing BangngayNo ratings yet

- Hrs-Frm-Ijin-1 (Rapat, Memo Dan Dokumen)Document44 pagesHrs-Frm-Ijin-1 (Rapat, Memo Dan Dokumen)dimas handikaNo ratings yet

- Form 02 Crane Inspection FormDocument2 pagesForm 02 Crane Inspection FormDenny SyafwalufiNo ratings yet

- Conti Corp Adm-Conti-056!17!18amend - RedactedDocument12 pagesConti Corp Adm-Conti-056!17!18amend - RedactedL. A. PatersonNo ratings yet

- Synthetics Rubber Indonesia – Soil Handling Equipment InspectionDocument2 pagesSynthetics Rubber Indonesia – Soil Handling Equipment InspectionDenny SyafwalufiNo ratings yet

- ESH26 - Generator Inspection ChecklistDocument1 pageESH26 - Generator Inspection Checklistmohd addin100% (1)

- Platform Inspection-General Report Template R001Document44 pagesPlatform Inspection-General Report Template R001St3fandragos4306100% (2)

- Rodelta - Elbow Pump - ProposalDocument18 pagesRodelta - Elbow Pump - ProposalgunociptoNo ratings yet

- WI 0000 FIC 002 Air Compressor InstallationDocument2 pagesWI 0000 FIC 002 Air Compressor InstallationBiju_PottayilNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Iw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFDocument115 pagesIw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFlinga2014No ratings yet

- Technical Specifications For Fabrication of Process EquipmentDocument152 pagesTechnical Specifications For Fabrication of Process EquipmentAgni DuttaNo ratings yet

- Inspection Test PlanDocument4 pagesInspection Test PlanJay Gaspar Jr.No ratings yet

- Standard Inspection Report of A Gas Distribution OperatorDocument21 pagesStandard Inspection Report of A Gas Distribution OperatorSaumitra Shankar GuptaNo ratings yet

- Weekly Report TemplateDocument14 pagesWeekly Report TemplateOmar DhiebNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumpKailash PandeyNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumphrimklimNo ratings yet

- Sharjah Municipaliyt - FOOTINGS - 6Document9 pagesSharjah Municipaliyt - FOOTINGS - 6Suhail AhamedNo ratings yet

- Semi-Circle DomeDocument4 pagesSemi-Circle DomeMohamed ElsaneeNo ratings yet

- Lecture 27Document103 pagesLecture 27Mohamed ElsaneeNo ratings yet

- LayoutDocument18 pagesLayoutMohamed ElsaneeNo ratings yet

- Lecture 25Document63 pagesLecture 25Mohamed ElsaneeNo ratings yet

- Lecture of FootingDocument195 pagesLecture of FootingMonirul IslamNo ratings yet

- Assignment 2Document2 pagesAssignment 2Mohamed ElsaneeNo ratings yet

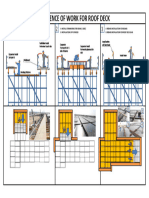

- Sequence of Work For Roof DeckDocument1 pageSequence of Work For Roof DeckMohamed ElsaneeNo ratings yet

- Risk Management 28012015Document26 pagesRisk Management 28012015Mohamed ElsaneeNo ratings yet

- Previous Exams Combined DM G+4Document10 pagesPrevious Exams Combined DM G+4Mohamed ElsaneeNo ratings yet

- How To Read Primavera Professionally - Maged Elhawary-AaceiDocument15 pagesHow To Read Primavera Professionally - Maged Elhawary-AaceiMohamed ElsaneeNo ratings yet

- Tucson - A4 Leaflet - Aug26 - LowResDocument2 pagesTucson - A4 Leaflet - Aug26 - LowResMohamed ElsaneeNo ratings yet

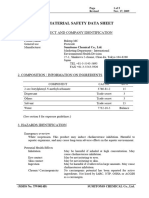

- Baktop MC MSDSDocument5 pagesBaktop MC MSDSMohamed ElsaneeNo ratings yet

- Work Permit ProcedureDocument13 pagesWork Permit ProcedureMohamed ElsaneeNo ratings yet

- RBY010B-Nonconformance Log and Status ReportDocument1 pageRBY010B-Nonconformance Log and Status ReportMohamed ElsaneeNo ratings yet

- 1100.36 Excavation and Pile DrivingDocument28 pages1100.36 Excavation and Pile DrivingMohamed ElsaneeNo ratings yet

- Mind MappingDocument1 pageMind MappingMohamed ElsaneeNo ratings yet

- Site Quality Responsibilities Matrix: CompanyDocument2 pagesSite Quality Responsibilities Matrix: CompanyMark D VillanuevaNo ratings yet

- D12 1Document8 pagesD12 1jamesabowdenNo ratings yet

- 2G 3G Interview QuestionsDocument10 pages2G 3G Interview Questionsmohnish1999No ratings yet

- Husqvarna R322 Owners ManualDocument40 pagesHusqvarna R322 Owners Manualsheba1023No ratings yet

- Heat Transfer Characteristics of Thermal Energy Storage System Using PCM Capsules - A Review - 2008Document21 pagesHeat Transfer Characteristics of Thermal Energy Storage System Using PCM Capsules - A Review - 2008navidelecNo ratings yet

- AMI Pen TestingDocument10 pagesAMI Pen TestingcutenemesisNo ratings yet

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- Engg Drawing QuestionsDocument30 pagesEngg Drawing QuestionsVarun Shastry50% (2)

- Engineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerDocument17 pagesEngineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerShubhom PaulNo ratings yet

- Procedure System of Plant & Equipment ManagementDocument19 pagesProcedure System of Plant & Equipment ManagementImtiyaz Akhtar100% (1)

- Security Analytics For Dummies Securonix Special Edition PDFDocument53 pagesSecurity Analytics For Dummies Securonix Special Edition PDFAgteNo ratings yet

- India Geological India: GovernmentDocument7 pagesIndia Geological India: GovernmentAshish KumarNo ratings yet

- Double Disc Gate ValveDocument12 pagesDouble Disc Gate Valveshafeeqm3086No ratings yet

- Renovate Galvanized SteelDocument1 pageRenovate Galvanized SteelSam SamuelsonNo ratings yet

- HX2-100 2V AGM battery specsDocument2 pagesHX2-100 2V AGM battery specsdarwin gualotoNo ratings yet

- Safety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDocument2 pagesSafety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDale JohnsonNo ratings yet

- Experiment #8 - Slender MemberDocument4 pagesExperiment #8 - Slender MemberLuís Alberto Tang YorisNo ratings yet

- Eee342 hw2 Solution PDFDocument7 pagesEee342 hw2 Solution PDFRedion XhepaNo ratings yet

- Impedance, Angular Velocities & Frequencies of Oscillating CurrentsDocument32 pagesImpedance, Angular Velocities & Frequencies of Oscillating CurrentselectrosciNo ratings yet

- Reduction of Non-Value Added ActivitiesDocument3 pagesReduction of Non-Value Added ActivitiesRenganathan IyengarNo ratings yet

- Enerflex Rocsole Presentation 051220 - 1033 - v.2Document28 pagesEnerflex Rocsole Presentation 051220 - 1033 - v.2Monsivais AntonioNo ratings yet

- Pneumatic Can Crusher SystemDocument21 pagesPneumatic Can Crusher Systemkamleshm2No ratings yet

- SLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsDocument3 pagesSLM in TOPdesk 5.4: A Straigtforward Way To Set Up Your SLAsTOPdeskNo ratings yet

- SJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443Document31 pagesSJ-20100630164932-027-ZXSS10 SS1b (V2.0.1.07) SoftSwitch Control Equipment Data Configuration Guide Subscriber Allocation - 280443منصورالمغربيNo ratings yet

- Top Sources and Solutions for Indoor Air PollutionDocument30 pagesTop Sources and Solutions for Indoor Air PollutionM.Sohail100% (1)

- CHEM 1315 Exam 3 Practice BDocument6 pagesCHEM 1315 Exam 3 Practice BmikamundkurNo ratings yet

- NM ENMR TeleCoop Fact Sheet 02-24-2010Document1 pageNM ENMR TeleCoop Fact Sheet 02-24-2010StimulatingBroadband.comNo ratings yet

- Compressor Tech May 2013Document89 pagesCompressor Tech May 2013H.a. UlicesNo ratings yet

- Transformer Test Report AnalysisDocument39 pagesTransformer Test Report AnalysisNguyễn Hoàng SơnNo ratings yet

- Daily production report for 17-JUN-19 highlights units, targets, actualsDocument1 pageDaily production report for 17-JUN-19 highlights units, targets, actualsSergio Quisbert P.100% (1)

- Tuticorin Thermal Power Project Structural Steel Rate ScheduleDocument13 pagesTuticorin Thermal Power Project Structural Steel Rate ScheduleVinod Kumar Verma100% (1)