Professional Documents

Culture Documents

Work Instruction 013

Uploaded by

Venkat RamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction 013

Uploaded by

Venkat RamanCopyright:

Available Formats

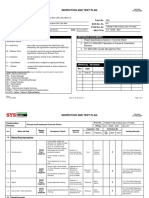

Done by Approved by DATE REV

WORK INSTRUCTION 013

QA MR 4-Sep-19 00

TITLE : FIRST ARTICLE INSPECTION PROCEDURE AND AS9102 FORM FILL-IN

1.0 PURPOSE

To establish First Article inspection procedures and guidance of fill-in AS9102 form.

2.0 SCOPE

For all FA inspection process as per AS9102B standard.

3.0 AUTHORITY / RESPONSIBILITY

Quality Engineer are to ensure the effective operation fo the procedure.

4.0 PROCEDURES

4.1. Sales receive PO from customer and will communicate within company that FA inspection shall be carried out.

4.2. Engineering issued drawing to Production by stamped on route card " FAI ” according to customer PO request.

4.3. Production will submit first piece/batch after machining to QC technician for buy-off accoring to requirement in

rout card.

4.4. QC check the first piece/batch and record the result into AS9102 form.

4.5. If QC found any non-conformance, will feedback to Production and request Production take actions to meet

customer spec.

customer spec.

4.6. QC will submit completed FAI report to customer after the first piece/batch finish all processes.

4.7 AS 9102 form fill-in:

Step1: Apply standard AS9102 form according to SAE International requirement.

Step 2: Inside Form1 - Part Number Accountability; Form 2 -Product Accountability - Material, Special Processes,

and Functional Testing; Form 3 - Characteristic Accountability, Verification, and Compatibility Evaluation

Each input field is identified as:

• Required (R) - This is mandatory information, these fields are depicted in bold font.

• Conditional Required (CR) - This field shall be completed when applicable to the product or when required by

the customer, these fields are depicted in bold italic font.

• Optional (O) - This fields are provided for conveniemce; the field may be left blank. All these fields are depicted in

standard font.

Step 3: Highlight several points:

Form 1 - Item 7 (CR) Drawing Revision Level associated with FAI part, if the drawing has not been revised,

then item 8 (CR) additional Changes shall be indicated as such (e.g. none, no change).

Form 1 - Item 19 Signatur & Form 2 - item 14 Prepared by & Form 3 - item 12 Prepared by shall be signed and

stamped by QC technician before submit the FAI from to customer.

Form 1 - item 21 Reviewed by, it has to indicate the printed name or unique identification, or QC stamp also can be

accepted if the person reviewing hold stamp.

You might also like

- AS9102 FAI GuidelinesDocument27 pagesAS9102 FAI Guidelinesjamilvora100% (1)

- As9102 BlankDocument4 pagesAs9102 Blankshoobi82No ratings yet

- First Article Inspection FAI AS9102 PresentationDocument28 pagesFirst Article Inspection FAI AS9102 PresentationaldiNo ratings yet

- Saudi Aramco Oil Company: SECTION 01400 Quality ControlDocument4 pagesSaudi Aramco Oil Company: SECTION 01400 Quality ControlphilipyapNo ratings yet

- DCL14NRN-002 Rev5Document3 pagesDCL14NRN-002 Rev5Lioreo DanielNo ratings yet

- Fai 1Document5 pagesFai 1AnbuNo ratings yet

- Tandard Perating Rocedure: SOP-Engg-01Document5 pagesTandard Perating Rocedure: SOP-Engg-01lokelooksNo ratings yet

- First Article Inspection (FAI) AS9102 PresentationDocument28 pagesFirst Article Inspection (FAI) AS9102 PresentationAlan Flores Rodriguez100% (3)

- NCAR 2023-027-03 Audits R0Document4 pagesNCAR 2023-027-03 Audits R0Nancy BorasoNo ratings yet

- First Article Inspection - Aerospace FormsDocument6 pagesFirst Article Inspection - Aerospace Formssqalopez100% (1)

- As9102 A 6 3 6Document4 pagesAs9102 A 6 3 6John R BeldenNo ratings yet

- Required Inspection Item Recurrent Training: Changes To NJA FAR 135 General Maintenance ManualDocument52 pagesRequired Inspection Item Recurrent Training: Changes To NJA FAR 135 General Maintenance ManualTrần Triệu PhongNo ratings yet

- Saudi Aramco Oil Company: SECTION 01720 Record DocumentsDocument4 pagesSaudi Aramco Oil Company: SECTION 01720 Record DocumentsPhilip YapNo ratings yet

- New Installations ATA and Activity Quality Check SOP V 4.2Document22 pagesNew Installations ATA and Activity Quality Check SOP V 4.2Malik Rizwan AhmedNo ratings yet

- QP9 Inspection & TestingDocument4 pagesQP9 Inspection & TestingMuhammad Shiraz KhalidNo ratings yet

- SCMH 3.2.2 FAI 9102 Rev B FAQs 8FEB2021 Noted 7AUG2023Document9 pagesSCMH 3.2.2 FAI 9102 Rev B FAQs 8FEB2021 Noted 7AUG2023GÜRHAN EMİNNo ratings yet

- R-As0010-Qa-proc-7036 Cfu Factory Acceptance Test Procedurer - 1Document19 pagesR-As0010-Qa-proc-7036 Cfu Factory Acceptance Test Procedurer - 1ngoailong_0609No ratings yet

- Visit Report - 312Document4 pagesVisit Report - 312Vinay YadavNo ratings yet

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- PATOQ Folder ChecklistDocument1 pagePATOQ Folder Checklistjames alfarasNo ratings yet

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocument9 pages017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- SHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Document334 pagesSHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Akhtar JavedNo ratings yet

- Amf-P-02 Procedure For NC ProductDocument4 pagesAmf-P-02 Procedure For NC Productgangadhar.patilNo ratings yet

- Emergent Repairs To Riding Surace KM 3.6 - 4.8Document6 pagesEmergent Repairs To Riding Surace KM 3.6 - 4.8venugopalchintaNo ratings yet

- AS9102 FormsDocument4 pagesAS9102 Formstongai100% (1)

- Shop Drawing, Sample and SubmittalsDocument6 pagesShop Drawing, Sample and SubmittalsPhilip Yap100% (2)

- Guide For Successful Completion of First Article Inspection (Fai) ReportsDocument34 pagesGuide For Successful Completion of First Article Inspection (Fai) ReportsJohn OlayNo ratings yet

- NCR Procedure Rev. 0Document8 pagesNCR Procedure Rev. 0Ganjar Dreadlocks NugrahaNo ratings yet

- Amf-P-10 Procedure For Engineering SpecificationDocument2 pagesAmf-P-10 Procedure For Engineering Specificationgangadhar.patilNo ratings yet

- Works Instruction For Piping Welding InspectionDocument5 pagesWorks Instruction For Piping Welding InspectionAbg SepulNo ratings yet

- GYPSUMDocument1 pageGYPSUMgerardo b. manuelNo ratings yet

- 00-10-001 - F - Nov.2000Document0 pages00-10-001 - F - Nov.2000Levi MurdokNo ratings yet

- Mechanical WIP ChecklistsDocument20 pagesMechanical WIP ChecklistsJovani G. BallonNo ratings yet

- Alb Ir ST 005Document2 pagesAlb Ir ST 005civil_ramNo ratings yet

- Gallery 7 & 7XDocument2 pagesGallery 7 & 7XMAHENDRANo ratings yet

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- Control of NC ComponentDocument3 pagesControl of NC Componentdanaka007No ratings yet

- Fai 1Document5 pagesFai 1pawoe3064No ratings yet

- RDM SpecDocument56 pagesRDM Specanon_103239931No ratings yet

- MTD - SOP.18-Masterlog v0Document5 pagesMTD - SOP.18-Masterlog v0vinothNo ratings yet

- Cofmow Specification SWL With AmcDocument78 pagesCofmow Specification SWL With Amcsanjib palNo ratings yet

- Alm-Ims-Prc-Si-012 Piping Site Fabrication & Installation Inspection FDocument12 pagesAlm-Ims-Prc-Si-012 Piping Site Fabrication & Installation Inspection F123netflix542No ratings yet

- QC SUPERVISOR InterviewDocument7 pagesQC SUPERVISOR InterviewMohamed S. Elrapat100% (5)

- Ppap User GuideDocument60 pagesPpap User GuideTuyen Deple100% (1)

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- AS9102B GuthCAD TemplateDocument6 pagesAS9102B GuthCAD TemplatelpplnigNo ratings yet

- AC7126-1 Rev B 23-AUG-2016Document26 pagesAC7126-1 Rev B 23-AUG-2016unknown1711No ratings yet

- SCMH 3.2.2 FAI 9102 FAQs Rev C Dated 8FEB2021Document9 pagesSCMH 3.2.2 FAI 9102 FAQs Rev C Dated 8FEB2021John OlayNo ratings yet

- Bored Piling Method StatementDocument8 pagesBored Piling Method StatementTAHER AMMAR100% (1)

- Ssem 564 C27 SKM 01Document6 pagesSsem 564 C27 SKM 01Ahmed Mostafa Fadly MadyNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Basheer VadakkethilNo ratings yet

- Checklist DocumentDocument46 pagesChecklist DocumentGaurav Vishwakarma100% (2)

- Product/ Service RealizationDocument5 pagesProduct/ Service RealizationMai HiềnNo ratings yet

- Supplier Evaluation Process BHELDocument63 pagesSupplier Evaluation Process BHELBaalu KathirveluNo ratings yet

- Sample Witness Hold Inspection Procedure PDFDocument107 pagesSample Witness Hold Inspection Procedure PDFdep_vinNo ratings yet

- AS9102 Blank PaperworkDocument3 pagesAS9102 Blank PaperworkjNo ratings yet

- CTR 8500-8300 3.6.0 TACACS+ CLI Commands - July2018Document16 pagesCTR 8500-8300 3.6.0 TACACS+ CLI Commands - July2018Bryan Delfín Aguirre OrtegaNo ratings yet

- APDevFundamentals4.3 StudentManual 29apr2021Document562 pagesAPDevFundamentals4.3 StudentManual 29apr2021yaswanth velagapudiNo ratings yet

- Oracle® Transportation Management: Data Management Guide Release 6.3 Part No. E38426-04Document128 pagesOracle® Transportation Management: Data Management Guide Release 6.3 Part No. E38426-04Nirav PanchalNo ratings yet

- Modbus RTU Slave 302 - PCPDocument46 pagesModbus RTU Slave 302 - PCPsilvanna alvarez castroNo ratings yet

- Analysis of Blast Fragmentation Using WipFragDocument7 pagesAnalysis of Blast Fragmentation Using WipFragrakoNo ratings yet

- RJFK (Ils Z or Loc Z Rwy34)Document1 pageRJFK (Ils Z or Loc Z Rwy34)tommyNo ratings yet

- Lab #5 - Assessment Worksheet Elements of a Security Awareness & Training Policy Student Name: Vũ Tuấn Anh Student ID: SE130255Document5 pagesLab #5 - Assessment Worksheet Elements of a Security Awareness & Training Policy Student Name: Vũ Tuấn Anh Student ID: SE130255U MinhNo ratings yet

- Finite State Machines: Ref:, Rosen BookDocument22 pagesFinite State Machines: Ref:, Rosen BookSomaiah SulaimanNo ratings yet

- 04 U2000 ATAE IntroductionDocument16 pages04 U2000 ATAE IntroductionHung NguyenNo ratings yet

- Invoice EUINTR21 32330Document1 pageInvoice EUINTR21 32330Emre OralNo ratings yet

- Respuestas Oracle PL-SQL Practica 5Document3 pagesRespuestas Oracle PL-SQL Practica 5Ezequiel Hernán VillanuevaNo ratings yet

- Individual Essay Eldymar.Document20 pagesIndividual Essay Eldymar.Eldymar Zyrin Alejo (Utoy)No ratings yet

- Infrastructure Administrator LinuxDocument3 pagesInfrastructure Administrator Linuxbiru kumarNo ratings yet

- GCSE CS (2210) / IGCSE CS (0478) P1 NOTES Chapter 1.3: Hardware and Software 1.3.3 Input DevicesDocument15 pagesGCSE CS (2210) / IGCSE CS (0478) P1 NOTES Chapter 1.3: Hardware and Software 1.3.3 Input DevicescollenNo ratings yet

- Dip Computer Science 2023Document8 pagesDip Computer Science 2023DripNo ratings yet

- Applicable To BPL/EWS/SC/ST/OBC-NCL/DA: Reply ?Document4 pagesApplicable To BPL/EWS/SC/ST/OBC-NCL/DA: Reply ?sambhudharmadevanNo ratings yet

- Composition and AggregationDocument2 pagesComposition and AggregationFaraz AmjadNo ratings yet

- Romantis UHP 1000 TerminalDocument2 pagesRomantis UHP 1000 TerminalPravesh Kumar ThakurNo ratings yet

- Operacion Modulo y Codigos de FallaDocument21 pagesOperacion Modulo y Codigos de FallaJimmyJavierTorresSalas100% (1)

- 06Document11 pages06junaid_ishaqueNo ratings yet

- Simone's ResumeDocument4 pagesSimone's ResumeMorrisa AlexanderNo ratings yet

- Introduction To Boolean LogicDocument5 pagesIntroduction To Boolean LogicTapaswiniNo ratings yet

- Logiq P6 Quickstarts: Beginning An ExamDocument5 pagesLogiq P6 Quickstarts: Beginning An ExamjamesNo ratings yet

- KIEN7009: 9 Port Layer 2 Simple Managed DIN-Rail SwitchesDocument7 pagesKIEN7009: 9 Port Layer 2 Simple Managed DIN-Rail SwitchesHaider-e-KararNo ratings yet

- Examen, 03 ED, 2020A - ECUACIONES DIFERENCIALES (2020A), Spring 2020 - WebAssign PDFDocument4 pagesExamen, 03 ED, 2020A - ECUACIONES DIFERENCIALES (2020A), Spring 2020 - WebAssign PDFMarcos ArtolaNo ratings yet

- List of Virtual Labs For Various Engineering DisciplinesDocument7 pagesList of Virtual Labs For Various Engineering DisciplinesMAHESH V100% (1)

- ABSTRACT Virus and AntivirusDocument1 pageABSTRACT Virus and AntivirusSoumen GhoseNo ratings yet

- A Practical Approach To Software Quality PDFDocument297 pagesA Practical Approach To Software Quality PDFTrendkill Trendkill TrendkillNo ratings yet

- Golf Project ReportDocument12 pagesGolf Project ReportRaja Sekhar PNo ratings yet

- VTU Contact DetailsDocument6 pagesVTU Contact DetailsSathish YANo ratings yet