Professional Documents

Culture Documents

MT-2 Univ QN Paper Jun 28, 2022

Uploaded by

MUTHUMANOJ K PCT- A2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT-2 Univ QN Paper Jun 28, 2022

Uploaded by

MUTHUMANOJ K PCT- A2Copyright:

Available Formats

Reg No.

:

8 o A2 B o 5

Question Paper Code: 20380|

B.E./B.Tech. DEGREE EXAMINATIONS, APRIL/MAY 2022.

Sixth Semester

Chemical Engineering

CH 8651- MASS TRANSFER - II

(Common to Petrochemical Engineering/Chemical and Electrochemical

Engineering/Petrochemical Technology)

(Regulations 2017)

Time Three hours Maximum 100 marks

Answer ALL questions.

PART A-(10 x 2 20 marks)

1. Define stripping factor.

2. Write the significance of absorption and stripping factor.

3. What is the difference between steam and flash distillation?

Define relative volatility.

5. When do you prefer liquid- liquid extraction?

6. Name some of the equipments used for liquid-liquid extraction.

7. Define leaching.

8. Write the advantages and disadvantages of leaching by percolation.

9 Write the uses of membrane separation process.

10. List the different types of adsorption isotherms.

08803

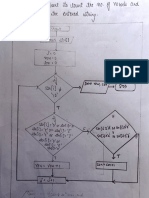

(OT) wBlsep uIsap pue

OSEYd 1eeu qitM ss20oId 3utyoe3 quaLIns isquno3 aäe]s-Inu E ut

saae]s JO 1qunu jo uoneujure1ap 1oJ arnpa00.id uatsap ayi uETdxa (

(E) suuoee paq auLAou jo suoreodde jetsnput oqi u3y3HI (1 () 7I

(EI)

yoea yitM a1qtosIuui are IsnEM pue ouenjoj ayj ounssy auen[o 3

/ epsyoprejaoe Sq =X pue eje MS/ apsyapreja0e 3 =A aoy X87=X

"uoenba aqn [q uaAta St dusuonejai unuq|Tmba ayL 108.12xa paxtu pu

81EueI [eug Jo ustam aui pue (poqiau [eotyde13 Sutsn) apíy»prej0E

JO uoOEIIxe aae]u3oad paay Jo 3x 009 IOJ 3e]S

aui a1enojeo

Ied pasn st zejBM JO S 00I JI atun juaLInD-sso1o a3v]s a3yi e ut iajEM

(1u3taM Aq) %9 V (9

yTA pajoe.ixa st auanjo1 ur epssaprej3oe Jo uotjnros

10

Ss3ooId

(9 a1e 1ey

uotgoexa ut qu3A[OS JO 3otoqo ayi

autouanut siojoeJ aqi

(8) ay eqiosaa (1 (E)

yLM IOgOeI]xa I3M01 pa]e]Lae JO auryiom pue aqdtOu;Id

[[ejap ut j e i a u n u g

UotIe[TIsTp a A I o e x a inoqe

(S)

Sutsn sajejd

poyieu LIEAES ueyoued

(8) aqiiosad ()

uojeunsa Jo poqjau ayi

BotjaIoaui Jo 1aqunu ayi Jo

a]E]d paaJ

Iaqunu aqi a]enoqe)

T

(ET) uunjos ayi ut

saIETd [EoTaioYi JO a n o d e a J[Es

aui a]eoo[ pue aYL F aq

01 st otEI xngai pue

AIIETOA aAIE[aI 9696 pue 6a[ou g26

ayi ui y

sI g 0 V JO pa18A03I St paaJ autjeuoyOEJ

aJEIIIISIp ayi ut

SI paaJ ayL YL uunjo3

JO uoE1juaIu0 ainixru ¥ ()

aui u o%3[ouu gE Jo

st a1e[[[ISIp g9 pue y

o SI a 6 [ O u

pajexBdas aq

ayi ui aAtuaa

a u u e r a d o JO UOIEnba

XOJ BuI[13]unos

quaino

uojdiosqe

()

AgaLug (1) (

InoqE [TE]ap

ut ueTdxa

(8) JO auyIOM

JaM01 paq payoed

qiim

aXE Å pue x

uojoE.Y [Ou

= EOY S]IUn

C9 1 a m o j ayi Jo

uje g u y [ouy u n L q ! [ t n b a auL

(EI) St uotjE[OI damoI,

å = Aq uaAt3 1E p o u E J U I E U st

'x 86'0 3inssald u j e I pue 0.sT payoed

a1aym 1 a A 0 3 a I 03 J3Mo1

nLN PuIH = D °HN %96 (E) II

y s t o s pue 3 N 0008 -JIE UY

ST u = a u r u r e u o s a n i x T U SHN

00ST

uu ySy paqqnios Butaq sI HN %g

18]eM qiLM

B Ut

=

*

( y E u g9 EI g)-& LYVd

caustic soda by the lime-soda process gives slurr

The production of per kg

(b)

water and 0.85 kg sodium hydroxide (NaOH)

containing 9 kg currently with

The slurry is washed counter

calcium carbonate particles. 3 kg

from each stage contains

in four stages. The solid discharged wash water

water Calculate the a m o u n t of

calcium carbonate.

kg contains a

water per calcium carbonate after drying

the discharged (13)

needed when calcium carbonate.

kg sodium hydroxide per kg

maximum of 0.0075

ion-exchange operation

demineralization process by (10)

15. (a) Explain the

with neat sketch.

process.

(3)

of ion-exchange

industrial application

Write the

(ii)

Or

atm and 303

K with a

a c e t o n e at 1

containing air and activated carbon is

(b) One liter flask acetone. 2 kg of fresh

relative humidity

of 35% of the final v a p o u r

composition

flask is sealed. Compute (13)

introduced and the of air.

neglecting adsorption

and final pressure

Equilibrium data: 0.35

0.1 0.2 0.3

O

acetone adsorbed/g carbon

g

0 2 12 42 92

mm Hg

Partial pressure of

acetone,

is 283 mm. Hg.

pressure of a c e t o n e at 30°C

Vapour

15 15 marks)

PARTC-(1 x

Toluene containing 30%

of binary mixture of Benzene and

(i) 1000 kg distilled at atmospheric

16. (a) is differentially

f Benzene by weight contain 18% Benzene by

pressure until

the residue in the still

of the distillate and

the composition and weight

weight. Determine data. (10)

the following equilibrium

weight of the residue using 1

0.659 0.823

0.256 0.376 0.508

X: 0 0.058 0.155

0.453 0.596 0.720 0.830 0.922 1

Y: 0 0.128 0.304

fractions of Benzene in liquid and vapour

Where x and y are mole

phase in equilibrium.

of packing used in packed bed towers. (5)

(i) Explain the different types

Or

diagram of leaching operation. (5)

Sketch the typical equilibrium

(b)

and working of reverse osmosis process with

(i) Explain the principle (10)

neat sketch.

20380

3

You might also like

- D 4442 - 15 Standard Test Methods For Direct Moisture Content Measurement of Wood and Wood-Based MaterialsDocument6 pagesD 4442 - 15 Standard Test Methods For Direct Moisture Content Measurement of Wood and Wood-Based MaterialsshgsuhermanNo ratings yet

- Chapter 1 Modern Separation ProcessDocument46 pagesChapter 1 Modern Separation ProcessVivek Sharma82% (11)

- Reficar, Cartagena, Colombia, Cdhydro Cdhds SomDocument408 pagesReficar, Cartagena, Colombia, Cdhydro Cdhds Som•It's Mari Cami•No ratings yet

- Axe Wolzer Stsojdode: "XtpuoddeDocument1 pageAxe Wolzer Stsojdode: "XtpuoddeGerard Dominic ArguellesNo ratings yet

- Phonetic ReduplicationDocument10 pagesPhonetic Reduplicationironman135064No ratings yet

- CehDocument561 pagesCehAlexander Torres0% (1)

- Varian Chap1 Partie 1 - RotatedDocument11 pagesVarian Chap1 Partie 1 - RotatedBintou RassoulNo ratings yet

- Employer Cert308Document3 pagesEmployer Cert308taramaNo ratings yet

- Img015 PDFDocument1 pageImg015 PDFefrataNo ratings yet

- EconometrixDocument5 pagesEconometrixAvinandan DuttaNo ratings yet

- 2017 H2 Maths Prelim SA2 Victoria Junior CollegeDocument32 pages2017 H2 Maths Prelim SA2 Victoria Junior CollegeAmelia WongNo ratings yet

- 2017 VJCDocument31 pages2017 VJCAnson LimNo ratings yet

- Aitta ObservationDocument7 pagesAitta ObservationjomejiNo ratings yet

- Wood 1995Document15 pagesWood 1995Stacy WilsonNo ratings yet

- Cotizacion Camioneta 4x4Document14 pagesCotizacion Camioneta 4x4LUIS MIGUEL RAMOS MARCANo ratings yet

- 1 - Uu Die®: Olnhiindvn Ha Oc (VolhiihmDocument5 pages1 - Uu Die®: Olnhiindvn Ha Oc (VolhiihmMauricio SanchezNo ratings yet

- Η Λαβύρινθος της Μεσαράς - Καλούστ Παραγκαμιάν & Αντώνης ΒασιλάκηςDocument156 pagesΗ Λαβύρινθος της Μεσαράς - Καλούστ Παραγκαμιάν & Αντώνης ΒασιλάκηςGiorgosTzathasNo ratings yet

- Zozl On Noiovziioo) A Aniioiios: G# Ol AesDocument2 pagesZozl On Noiovziioo) A Aniioiios: G# Ol AesWilson Juan Flores MamaniNo ratings yet

- ALSS 101 2021-2022 ExamDocument5 pagesALSS 101 2021-2022 ExamMatty MontshoNo ratings yet

- K-TET Category - 1 - MathsDocument1 pageK-TET Category - 1 - MathsDevine AquaticNo ratings yet

- Depreciation and Inventory Class NotesDocument8 pagesDepreciation and Inventory Class Notesakshitapaul19No ratings yet

- Accounts Depreciation and Imventory Valuation Class NotesDocument8 pagesAccounts Depreciation and Imventory Valuation Class Notesakshitapaul19No ratings yet

- PERDEP No. 14 - Juknis Evkin BUMD Aneka Usaha PDFDocument63 pagesPERDEP No. 14 - Juknis Evkin BUMD Aneka Usaha PDFSinar HendrawanNo ratings yet

- Adobe Scan 07 Agu 2022Document1 pageAdobe Scan 07 Agu 2022ulefirmansyah874No ratings yet

- 08ni3tcwm Uam1cwoi: 3 DW 1 2019 3th4r02Document4 pages08ni3tcwm Uam1cwoi: 3 DW 1 2019 3th4r02Paulson RaphelNo ratings yet

- SURAWIDocument1 pageSURAWINur Eka FaniaNo ratings yet

- Certificado de ExtintorDocument2 pagesCertificado de ExtintorRosario Ramos MedinaNo ratings yet

- Estadistica - SkoogDocument6 pagesEstadistica - SkoogCARLANo ratings yet

- LeveragesDocument9 pagesLeveragesShrayan SarkarNo ratings yet

- PDF Analisis Kesenjangan Antara Ketercapaian Target - CompressDocument1 pagePDF Analisis Kesenjangan Antara Ketercapaian Target - CompressPerawaty PerawatyNo ratings yet

- Contrato de Ejecución PuenteDocument16 pagesContrato de Ejecución PuenteRAMON ASCENCIONo ratings yet

- Pram A: Tamdmy DhhamicDocument7 pagesPram A: Tamdmy DhhamicRiniNo ratings yet

- Steel MCQ MergedDocument44 pagesSteel MCQ MergedNischal thapaliyaNo ratings yet

- Extracted Pages From CAT FINAL BOOK MODULE 1Document9 pagesExtracted Pages From CAT FINAL BOOK MODULE 1yashvichetanranaNo ratings yet

- Las PalmasDocument1 pageLas PalmasAlberto AnguloNo ratings yet

- Cash Flow Statement Practice TestDocument3 pagesCash Flow Statement Practice Testmr IndiaNo ratings yet

- (T) Q) Utacl (7) G) (L) (D L, Lruaol (L) (Z) 4 7Document1 page(T) Q) Utacl (7) G) (L) (D L, Lruaol (L) (Z) 4 7abin sNo ratings yet

- Img 001Document1 pageImg 001Robertino Crispin AlvinagortaNo ratings yet

- Admn Report 2009 10 To 2014 15Document174 pagesAdmn Report 2009 10 To 2014 15cscthayyur680584No ratings yet

- Otanalyis: Actoym AlsfondsDocument10 pagesOtanalyis: Actoym AlsfondsCH Lalu NayakNo ratings yet

- SXPQ - 0 Se!8Epej) S Supexpur 9ap - T 9A9I Oi SL Estzsst3D Eqtjo Esodrnd Eq - , 8Document1 pageSXPQ - 0 Se!8Epej) S Supexpur 9ap - T 9A9I Oi SL Estzsst3D Eqtjo Esodrnd Eq - , 8Mystique CarreraNo ratings yet

- Proses 8A-1Document15 pagesProses 8A-1Devin Boris Setiadi ÃrtNo ratings yet

- String, String PointerDocument12 pagesString, String Pointerasha.py81No ratings yet

- Cesaire A TempestDocument45 pagesCesaire A TempestStephen WittekNo ratings yet

- Set TheoryDocument9 pagesSet TheoryTanima DeyNo ratings yet

- Jornais CEETEPS1989Document110 pagesJornais CEETEPS1989CELINA SILVANo ratings yet

- Acid, Bases and Salt NoteDocument8 pagesAcid, Bases and Salt NoteSalja SameerNo ratings yet

- Maths ActivityDocument12 pagesMaths ActivityShairiaNo ratings yet

- Sertifikat ProfesiDocument1 pageSertifikat ProfesiMuhammad RasyidNo ratings yet

- Balance 2021Document5 pagesBalance 2021Bernal Vargas Hugo BernalNo ratings yet

- Baemo :CJ: D D D DDocument10 pagesBaemo :CJ: D D D DThalia IoannouNo ratings yet

- Lecturas Extras de PricingDocument49 pagesLecturas Extras de PricingGloria barrueta natividadNo ratings yet

- 0 - Ud"8Oao - Ouotlvnleetiodsapeid: Seieqoi6 So) Ueiiu! Oili Sol SgiuDocument1 page0 - Ud"8Oao - Ouotlvnleetiodsapeid: Seieqoi6 So) Ueiiu! Oili Sol SgiudianaNo ratings yet

- CSE051 TOC - AssgnDocument6 pagesCSE051 TOC - AssgnAishwarya RajeshNo ratings yet

- Img 008Document1 pageImg 008Isabela BragançaNo ratings yet

- D2EA2EC3-C82C-4980-91AB-3DFB194E4AB7Document2 pagesD2EA2EC3-C82C-4980-91AB-3DFB194E4AB7shuaiea9No ratings yet

- JC2 Maths H2 2017 ST AndrewsDocument43 pagesJC2 Maths H2 2017 ST AndrewsliusihanNo ratings yet

- Repaso La Fabula 7° Periodo 2Document1 pageRepaso La Fabula 7° Periodo 2Heidy RomeroNo ratings yet

- Unit - 3Document12 pagesUnit - 3Chavalla DeekshithaNo ratings yet

- Img20240312 09410601Document1 pageImg20240312 09410601cristovive.riosNo ratings yet

- 10 PDFDocument1 page10 PDFabin sNo ratings yet

- Feasibility Study On The Production of Bioethanol FromDocument12 pagesFeasibility Study On The Production of Bioethanol FromGeovanni masyhur billahNo ratings yet

- Residuo Por Evaporacion - D6934.6936Document2 pagesResiduo Por Evaporacion - D6934.6936Luis RamirezNo ratings yet

- Separation of MixturesDocument32 pagesSeparation of MixturesRajdev BraraNo ratings yet

- Boiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataDocument17 pagesBoiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataFAH MANNo ratings yet

- Teacher Packs in Experimental Science: CHE Pack 2Document8 pagesTeacher Packs in Experimental Science: CHE Pack 2Tol AdoNo ratings yet

- L1 Chemical Engineering FundamentalsDocument21 pagesL1 Chemical Engineering FundamentalsAnuar StyloNo ratings yet

- P&IDDocument34 pagesP&IDAz Zahra Assyifa UshwahNo ratings yet

- Chemistry ClassDocument13 pagesChemistry ClassbabuNo ratings yet

- Design and Analysis of Nonequilibrium Separation Processes: L. N. Sridhar, Carlos Maldonado, and Ana Maria GarciaDocument13 pagesDesign and Analysis of Nonequilibrium Separation Processes: L. N. Sridhar, Carlos Maldonado, and Ana Maria GarciaThaligari Sandeep KumarNo ratings yet

- ACTIVITY 3 Organic ChemDocument6 pagesACTIVITY 3 Organic ChemJasmin Sagun MacaraegNo ratings yet

- Sea Der 1977 WesterbergDocument4 pagesSea Der 1977 WesterbergValeria OchoaNo ratings yet

- Amie Syllabus Sec B ChemicalDocument6 pagesAmie Syllabus Sec B ChemicalArunkumarNo ratings yet

- Pharmaceutical Steam Generators and Water Distillation SystemsDocument12 pagesPharmaceutical Steam Generators and Water Distillation Systemssoajanii100% (2)

- Composition of Crude Oils: 1.1 Petroleum Versus Source Rock BitumenDocument40 pagesComposition of Crude Oils: 1.1 Petroleum Versus Source Rock BitumenTaha Lemdjed BelahçeneNo ratings yet

- Processes 10 01535Document24 pagesProcesses 10 01535Xezer HaciyevNo ratings yet

- Aspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedDocument7 pagesAspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedFernadez Ramos CarolayNo ratings yet

- WO2014188453A2Document43 pagesWO2014188453A2Dr-Nilesh SalunkheNo ratings yet

- Separation Techniques of Mixtures: General Chemistry 1Document19 pagesSeparation Techniques of Mixtures: General Chemistry 1Janine CarigNo ratings yet

- Column Internals For Distillation and AbsorptionDocument30 pagesColumn Internals For Distillation and AbsorptionNidhi SahuNo ratings yet

- Run Your Diesel Vehicle On Biofuels PDFDocument250 pagesRun Your Diesel Vehicle On Biofuels PDFedalzurcNo ratings yet

- Revised Report On Laboratory Soap MakingDocument34 pagesRevised Report On Laboratory Soap Makingpraise anuoluwapoNo ratings yet

- Wissington FactoryDocument3 pagesWissington Factoryjgascoine011No ratings yet

- Brandy by Yutik and Mohit, Batch - 2018 To 2121Document13 pagesBrandy by Yutik and Mohit, Batch - 2018 To 2121shouvik ghatakNo ratings yet

- Aspects of Analysis PDFDocument61 pagesAspects of Analysis PDFKowla100% (1)

- Essential Oils in Foods Extraction, Stabilization, and ToxicityDocument7 pagesEssential Oils in Foods Extraction, Stabilization, and ToxicityNajihah RamliNo ratings yet

- Task 2 Sem 2 LATEST PDFDocument149 pagesTask 2 Sem 2 LATEST PDFMuthu KumarNo ratings yet

- Engeniero Methanol Task 1&2Document61 pagesEngeniero Methanol Task 1&2sasi100% (1)