Professional Documents

Culture Documents

Jockey Pump

Uploaded by

Presidh Kp0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

Jockey pump

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesJockey Pump

Uploaded by

Presidh KpCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

GAMA INFRAPROP PRIVATE LIMITED,

KASHIPUR

225 MW Combined Cycle Power Plant

INSPECTION REPORT

Doc. No: SESI /GIPL/Mech/DOC/

Revision No.:1 Review Date: Page 1 of 4

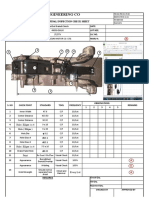

FIRE JOCKEY PUMP - 2:

Observations:

1. Initial free float (without bearings) readings recorded as 0.50 mm.

2. Visual condition of bearing appears normal.

3. Lantern ring (MOC: Brass) was not found/missing while

dismantling.

4. The condition of o-rings positioned at all diffuser stages were

found to be completely distorted.

5. Pump shaft both DE & NDE side sleeve groove O-rings were also

found damage.

6. Pump shaft suction (Drive end) side sleeve locking circlip was

found in deformed condition.

7. Pump suction side (DE side) first & second stage impeller rubbing

marks observed.

8. Pump shaft run out was recorded at the local workshop and found

above tolerance limit. i.e., 0.13 mm.

GAMA INFRAPROP PRIVATE LIMITED,

KASHIPUR

225 MW Combined Cycle Power Plant

INSPECTION REPORT

Doc. No: SESI /GIPL/Mech/DOC/

Revision No.:1 Review Date: Page 2 of 4

Dismantling photographs:

Marking on impeller Marking on impeller

Diffuser stage o-ring Sleeve locking circlip

GAMA INFRAPROP PRIVATE LIMITED,

KASHIPUR

225 MW Combined Cycle Power Plant

INSPECTION REPORT

Doc. No: SESI /GIPL/Mech/DOC/

Revision No.:1 Review Date: Page 3 of 4

O-ring between spacer & suction O-ring between spacer & delivery

sleeve sleeve

Pump Dismantling records:

(1) Pump float with antifriction bearing was 0.04 mm.

(2) Pump free float was recorded to be 0.50 mm.

Pump internal clearance records:

DIFFUSER IMPELLER

DIFFUSER STAGE SLEEVE

STAGE NECK NECK

(ID mm) (OD mm)

(ID in mm) (OD in mm)

1 79.90 79.77 39.35 38.95

2 80.03 79.83 36.10 35.95

3 80.02 79.83 36.18 35.90

4 80.03 79.80 36.13 35.92

5 80.00 79.79 36.13 35.90

DELIVERY

STAGE

39.33 38.98

GAMA INFRAPROP PRIVATE LIMITED,

KASHIPUR

225 MW Combined Cycle Power Plant

INSPECTION REPORT

Doc. No: SESI /GIPL/Mech/DOC/

Revision No.:1 Review Date: Page 4 of 4

Pump shaft run out record:

S NO LOCATION RUN OUT READING

1 Coupling position 0.05 mm

2 DE bearing seat 0.06 mm

3 Between 1st & 2nd impeller 0.13 mm

4 Between 2nd t & 3rd impeller 0.13 mm

5 Between 3rd & 4th impeller 0.08 mm

6 Between 4th & 5th impeller 0.10 mm

7 NDE bearing seat 0.08 mm

Maintenance Requirement :

(1) Pump shaft replacement/straightening is required considering the

over run out readings.

(2) O-rings for all stages need to be replaced.

(3) Sleeve locking circlips both DE & NDE side need to be replaced.

(4) O-ring between spacer & suction sleeve need to be replaced.

(5) O-ring between spacer & delivery sleeve need to be replaced.

(6) Graphite Gland rope of size 8 mm is required.

(7) Both DE & NDE side bearing need to be replaced (6306)

.

You might also like

- Specification: Model: Hyd. Crawler Drill (JD-800) CustomerDocument12 pagesSpecification: Model: Hyd. Crawler Drill (JD-800) CustomerAsad Aijaz100% (2)

- Manual de Mtto Md-200 3.74Document142 pagesManual de Mtto Md-200 3.74Jonathan Martinez100% (2)

- My Lesson Plan in Computer HardwareDocument6 pagesMy Lesson Plan in Computer HardwareSeiji Posa100% (1)

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Ariel Compressor DatasheetDocument8 pagesAriel Compressor Datasheetadewunmi olufemiNo ratings yet

- SEBF 8059 Procedure Clean PistonDocument33 pagesSEBF 8059 Procedure Clean Pistonprayogi_905701429No ratings yet

- Generator Bearing ServiceDocument10 pagesGenerator Bearing ServiceMustafa A.W100% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFDavid Fino Y. Seguro100% (1)

- GER3620L Nov 3 09b RevDocument60 pagesGER3620L Nov 3 09b RevGTENG CPINo ratings yet

- Technical Manual Operation and Maintenance 5.56mm Low Maintenance Rifle (LMR)Document24 pagesTechnical Manual Operation and Maintenance 5.56mm Low Maintenance Rifle (LMR)C.A. Monroe100% (1)

- Stihl MS361 Service ManualDocument110 pagesStihl MS361 Service ManualScott Kramer92% (12)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (2)

- Everything You Need to Know About Your Yanmar Diesel EngineDocument56 pagesEverything You Need to Know About Your Yanmar Diesel EngineScott Erik Chisling100% (1)

- The PG1 Gearbox - Demystifying The Codes and RatiosDocument8 pagesThe PG1 Gearbox - Demystifying The Codes and Ratioshagleyr5638No ratings yet

- High Step-up DC-DC Converter: 3-Winding Coupled Inductor DesignDocument44 pagesHigh Step-up DC-DC Converter: 3-Winding Coupled Inductor DesignSriramNo ratings yet

- GP050402 - Free Water Knockout Drum PDFDocument11 pagesGP050402 - Free Water Knockout Drum PDFJosefina Carmona100% (1)

- Hydraulic Crawler Drill Specification SheetDocument14 pagesHydraulic Crawler Drill Specification Sheetedgar cabrera100% (2)

- 928G Especifiaciones TransmisionDocument3 pages928G Especifiaciones TransmisionPlstina RamsNo ratings yet

- Anti-Heeling Pump ManualDocument13 pagesAnti-Heeling Pump ManualAndrey BogorodskiyNo ratings yet

- Ariel JGK4 F11982 PartsDocument19 pagesAriel JGK4 F11982 PartsAnonymous TXOkcdy100% (3)

- 6 Turbocharger OverhaulDocument22 pages6 Turbocharger OverhaulTuan Linh Vo100% (2)

- Pumping Solutions Slurry Pump CatalogueDocument39 pagesPumping Solutions Slurry Pump CatalogueCardoso MalacaoNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- Specification: Model: Hyd. Crawler Drill (JD-1400E) CustomerDocument10 pagesSpecification: Model: Hyd. Crawler Drill (JD-1400E) CustomerSerkanAlNo ratings yet

- Especifications Junjin SD 1300 eDocument14 pagesEspecifications Junjin SD 1300 eignacio helo varela50% (2)

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdNo ratings yet

- Renegade Ii 125 Efi Motor Rep Handbuch Und Mikuni Efi DiagnoseDocument110 pagesRenegade Ii 125 Efi Motor Rep Handbuch Und Mikuni Efi DiagnoseGines SanchezNo ratings yet

- Transfer Pump GBSDocument2 pagesTransfer Pump GBSsiddik.s2582100% (1)

- Project Report On "Pedal Operated Washing Machine"Document62 pagesProject Report On "Pedal Operated Washing Machine"Prajwal Kamble76% (54)

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- Manual ZB400II Catalogo de Repuestos PDFDocument31 pagesManual ZB400II Catalogo de Repuestos PDFDAVID GUTIERREZ POLONo ratings yet

- Manual de ZB400Document35 pagesManual de ZB400marthos ericson muñoz castilloNo ratings yet

- General: Instruction Manual For Zb-400Ii Plunger PumpDocument2 pagesGeneral: Instruction Manual For Zb-400Ii Plunger PumpEnrrique Vega MecatronicNo ratings yet

- Narora atomic power station Calandria Vault pump maintenance reportDocument4 pagesNarora atomic power station Calandria Vault pump maintenance reportRuchi Ragvendra BistNo ratings yet

- DS 5RB-CCDocument2 pagesDS 5RB-CCJOSE INESNo ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- High Performance Applications: Marine Propulsion EngineDocument2 pagesHigh Performance Applications: Marine Propulsion EngineRocco SilfieddiNo ratings yet

- Repair SD 100 5Document16 pagesRepair SD 100 5aytepeNo ratings yet

- K Brine and Submersible Pump DataDocument5 pagesK Brine and Submersible Pump Datajacs127No ratings yet

- Universal Shipbuilding Corporation: Single Loop Electro-Hydraulic Steering Gear S.No.038 TYPEDocument125 pagesUniversal Shipbuilding Corporation: Single Loop Electro-Hydraulic Steering Gear S.No.038 TYPEisabella bibkoNo ratings yet

- Raup Iom 0705 PDFDocument35 pagesRaup Iom 0705 PDFritoNo ratings yet

- Speck Pompa & Motor Area TurbineDocument46 pagesSpeck Pompa & Motor Area TurbineRelianus TandiNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- Section 4 Brake SystemDocument5 pagesSection 4 Brake SystemAndré TarginoNo ratings yet

- Blow Room and Card Process Parameter SettingsDocument6 pagesBlow Room and Card Process Parameter SettingsDeepakNo ratings yet

- 1384 3942 00 en General Arrangement Drawing Omega 50 HzDocument32 pages1384 3942 00 en General Arrangement Drawing Omega 50 Hzmohamed ghareebNo ratings yet

- Specification: Model: Hyd. Crawler (JD - 1300E) CustomerDocument14 pagesSpecification: Model: Hyd. Crawler (JD - 1300E) CustomerAsad Aijaz100% (1)

- Product InformationDocument56 pagesProduct InformationJose Enrique Mendoza RodriguezNo ratings yet

- QSM11 Sea Water PumpDocument2 pagesQSM11 Sea Water Pumpzubrs77No ratings yet

- LIT Sullair Air Tools Brochure PAPTOOLS202012-5 enDocument8 pagesLIT Sullair Air Tools Brochure PAPTOOLS202012-5 enJonathan Campos SanchezNo ratings yet

- FRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7Document2 pagesFRAME RIVETS REPLACEMENT WITH BOLTS SERVICE TIPS - Article No. 97-4-7FlogamagNo ratings yet

- Workshop MDocument69 pagesWorkshop MmanhNo ratings yet

- Especificaciones Bomba Levante y Enfriamiento CAT789CDocument3 pagesEspecificaciones Bomba Levante y Enfriamiento CAT789CRafael RodriguezNo ratings yet

- Bomba de Aceite MotorDocument8 pagesBomba de Aceite MotorFredy ReyesNo ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- Triveni Turbine Limited: Customer Care Cell Site ReportDocument6 pagesTriveni Turbine Limited: Customer Care Cell Site ReportRahulChaturvediNo ratings yet

- Aic TG0 18029Document24 pagesAic TG0 18029joseNo ratings yet

- Propeller Shaft: Click On The Applicable Bookmark To Selected The Required Model YearDocument11 pagesPropeller Shaft: Click On The Applicable Bookmark To Selected The Required Model YearCao LanNo ratings yet

- UL Test Report FM200 RPT 17th Aug 01 Updated Nov 07Document51 pagesUL Test Report FM200 RPT 17th Aug 01 Updated Nov 07Canberk KarahanNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- 224722-HAMMER 6IN RH510R;32-5165-RMA-04C 山特钻头Document1 page224722-HAMMER 6IN RH510R;32-5165-RMA-04C 山特钻头Jimmy ZhaoNo ratings yet

- 9802/6220 E4-8-1 Ram, StabiliserDocument2 pages9802/6220 E4-8-1 Ram, StabiliserGarcia CruzNo ratings yet

- UVPL-CAT-Dia Act-UA-11 & 12 - 04 - 2018Document12 pagesUVPL-CAT-Dia Act-UA-11 & 12 - 04 - 2018Subhash NarayananNo ratings yet

- 05000Document4 pages05000José O TelloNo ratings yet

- ch2200 ch2300 mt3 Osprey Pro-Trim Single S Twin S sl-3: Installation InstructionsDocument12 pagesch2200 ch2300 mt3 Osprey Pro-Trim Single S Twin S sl-3: Installation InstructionsPedro GuerraNo ratings yet

- Omml 7 201 300 B enDocument7 pagesOmml 7 201 300 B enEngr Mohammed UsmaniaNo ratings yet

- 01 Equipments IndexDocument2 pages01 Equipments IndexPresidh KpNo ratings yet

- Ad For Trainee BatchDocument3 pagesAd For Trainee BatchPresidh KpNo ratings yet

- Wte Waste To Energy 2019Document10 pagesWte Waste To Energy 2019Presidh KpNo ratings yet

- Pump PPT GsDocument3 pagesPump PPT GsPresidh KpNo ratings yet

- Offer H 2019 138 PDFDocument3 pagesOffer H 2019 138 PDFPresidh KpNo ratings yet

- Convenience Store Alfamart Philippines: (As-Built)Document1 pageConvenience Store Alfamart Philippines: (As-Built)arnold san joseNo ratings yet

- Projects List and ReferencesDocument5 pagesProjects List and Referencesjhon mathewsNo ratings yet

- Nte 7201Document3 pagesNte 7201CRAFTNo ratings yet

- Rfs Series: Materials HandlingDocument4 pagesRfs Series: Materials Handlingaloknayak123No ratings yet

- Two-Color Small Offset Press: WarningDocument568 pagesTwo-Color Small Offset Press: WarningSachin NerkarNo ratings yet

- Philips LCD Monitor 220VW8FB Service ManualDocument71 pagesPhilips LCD Monitor 220VW8FB Service Manualpagy snv67% (3)

- Power Bass s124Document16 pagesPower Bass s124andrejko2No ratings yet

- Brain DRV 40Document1 pageBrain DRV 40imadz853No ratings yet

- Smart Car Parking System ReportDocument4 pagesSmart Car Parking System ReportMekonen GoshuNo ratings yet

- Menumaster RCS511TSDocument17 pagesMenumaster RCS511TSdhitoafidNo ratings yet

- HRPL Asset Details ReportDocument10 pagesHRPL Asset Details ReportSunil PatelNo ratings yet

- PROJECT NI myRIO - ISLEM1Document33 pagesPROJECT NI myRIO - ISLEM1Eslem DriraNo ratings yet

- Ev VRF MMC Ap 0157 0187 0247 0277 0367 0487 0567 HP e enDocument9 pagesEv VRF MMC Ap 0157 0187 0247 0277 0367 0487 0567 HP e endenis almeidaNo ratings yet

- FINAL INSPECTION CHECK SHEET Maru A 01-02-2021Document6 pagesFINAL INSPECTION CHECK SHEET Maru A 01-02-2021Ulfsaar KhanNo ratings yet

- 100 Most Important 3-Phase Induction Motor MCQ With Explanation 2Document13 pages100 Most Important 3-Phase Induction Motor MCQ With Explanation 2NaveedNo ratings yet

- Oeluem EkipmanlarDocument144 pagesOeluem EkipmanlarTaha BodurNo ratings yet

- DC MachineDocument33 pagesDC MachineAnu PrakashNo ratings yet

- CFS 504 100 57 60D SL GL NSG - CLF500173 A2Document3 pagesCFS 504 100 57 60D SL GL NSG - CLF500173 A2ganesangNo ratings yet

- Electrical Instrument PDFDocument6 pagesElectrical Instrument PDFLonghuynh LêNo ratings yet

- AVR sps-101Document1 pageAVR sps-101Sunil SangaNo ratings yet

- Shop-4-Cross Peen Hammer HeadDocument8 pagesShop-4-Cross Peen Hammer HeadJag MasterNo ratings yet

- Parking Radar: Parking Aid, or As Eye S' For Robo T Projec TsDocument0 pagesParking Radar: Parking Aid, or As Eye S' For Robo T Projec TsBalvendra SinghNo ratings yet