Professional Documents

Culture Documents

Workshop M

Uploaded by

manhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop M

Uploaded by

manhCopyright:

Available Formats

Service Manual2005 Matiz UNIT REPAIR Page 1 of 69

Matiz

UNIT REPAIR

Cylinder Head and Valve Train Components

(Typical Type Shown, Euro III Similar)

Tools Required

09916-14510 Valve Spring Compressor.

09916-37320 Valve Guide Reamer (5 mm).

09916-38210 Valve Guide Reamer (11 mm).

09916-44910 Valve Guide Remover.

09916-48210 Valve Spring Compressor Attachment.

09916-58210 Valve Guide Installer.

09917-88220 Valve Guide Installer Attachment.

KM 412Engine Overhaul Stand.

Disassembly Procedure

1. Remove the cylinder head with the intake manifold and the exhaust manifold

attached. Refer to "Cylinder Head and Gasket", "Intake Manifld" and "Exhaust

Manifold" in this section.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 2 of 69

2. Remove the rocker arm shaft and rocker arm.

Remove the bolts (1).

Remove the rocker arm shaft (2).

Remove the rocker arm (3).

3. Remove the camshaft.

Remove the screw (1).

Remove the camshaft plate (2).

Remove the camshaft (3).

Notice : Removing the camshaft, take extreme care to prevent any scratch, nick

or damage.

Remove the camshaft front oil seal from housing hole (4).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 3 of 69

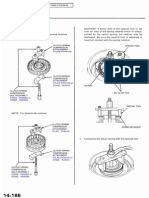

4. Remove the valve keepers.

Using the valve spring compressor 09916-14510 with the valve spring

compressor attachment 09916-48210, compress the valve springs (1).

Remove the valve keepers (2).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 4 of 69

5. Remove the valves.

Remove the valve spring retainer and valve springs (1).

Remove the valves (2).

6. Remove the valve stem oil seals.

Remove the valve stem oil seals (1).

Remove the valve spring seat (2).

Important : Do not reuse the removed oil seals. And the removed oil seals

should be replaced by new one.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 5 of 69

7. Remove the valve guide.

Position the valve guide remover 09916-44910 on the valve guide.

Hammer and remove the valve guide from the combustion chamber to the

direction of the installed valve spring using the valve guide remover 09916-

44910.

Important : The removed valve guide should be replaced by new one of

oversized. Do not reuse the removed valve guide.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 6 of 69

Inspection/Measurement/Adjustment Procedure

Abrasion of The Cam

1. Measure the height of the cam using a micrometer, and replace the camshaft when

the measured valve is less than the specified limit.

Unit : mm (in.)

Item Standard Limit

IN 35.156 (1.3841) 35.124 (1.3828)

Height of the cam

EX 34.814 (1.3706) 34.789 (1.3696)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 7 of 69

Measuring The Camshaft Bend

1. Measure the bending of the camshaft using a dial gauge, and replace it when the

measured value is over the specified limit.

Unit : mm (in.)

Item Limit

Bending Limit 0.03 (0.0012)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 8 of 69

Abrasion of The Camshaft Journal

1. Measure the outer diameter of each journal at the 4 different places (1).

2. Using a bore gauge, measure the inner diameter of the cylinder head journal at the 4

places (The clearance of journal is measured by the difference between the outer

diameter of camshaft journal and inner diameter of cylinder head journal part (2).

3. Replace the camshaft (or cylinder head, if necessary) of which limit is over the

specified limit.

Unit : mm (in.)

Item Standard Limit

Journal clearance 0.05-0.091 (0.0020-0.0036) 0.15 (0.0059)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 9 of 69

Unit : mm (in.)

Item Outer diameter, camshaft journal Inner diameter, cylinder head journal part

Standard 43.425-43.450 (1.7096-1.7106) 43.500-43.516 (1.7126-1.7132)

a

Limit 43.375 (1.7077) 43.525 (1.7136)

Standard 43.625-43.650 (1.7175-1.7185) 43.700-43.716 (1.7205-1.7211)

b

Limit 43.575 (1.7156) 43.725 (1.7215)

Standard 43.825-43.850 (1.7254-1.7264) 43.900-43.916 (1.7283-1.7290)

c

Limit 43.775 (1.7234) 43.925 (1.7293)

Standard 44.025-44.050 (1.7333-1.7343) 44.100-44.116 (1.7362-1.7369)

d

Limit 43.975 (1.7313) 44.125 (1.7372)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 10 of 69

Bending of The Rocker Arm Shaft

1. Measure the bending of the rocker arm shaft by using the V block and dial gauge.

2. Replace the rocker arm shaft of which bending is over the limit.

Unit : mm (in.)

Item Limit

Bending Limit 0.10 (0.0039)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 11 of 69

Clearance Between The Rocker Arm and The Rocker Arm Shaft

1. Measure the outer diameter of the rocker arm shaft using a micrometer (1).

2. Measure the inner diameter of the rocker arm using a bore gauge (2).

3. Replace the shaft or rocker arm (or both of them, if necessary) if the difference is

over the limit between the outer diameter and the inner diameter.

Unit : mm (in.)

Item Standard Limit

Clearance between the rocker arm and the 0.005-0.040 (0.0002-

0.06 (0.0024)

rocker arm shaft 0.0016)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 12 of 69

Clearance Between The Valve Stem and The Valve Guide

1. Measure the outer diameter of the valve stem using a micrometer (1).

2. Measure the inner diameter of the valve guide using a bore gauge (at least 1 place in

the direction to valve length) (2).

3. Measure the clearance between the valve stem and the valve guide.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 13 of 69

Unit : mm (in.)

Item Standard Limit

IN 5.465 - 5.480 (0.2152-0.2157) -

Valve stem outer diameter

EX 5.440 - 5.455 (0.2142-0.2148) -

IN 5.500 - 5.512 (0.2165-0.2170) 5.53 (0.2177)

Valve guide inner diameter

EX 5.500 - 5.512 (0.2165-0.2170) 5.53 (0.2177)

IN 0.020 - 0.047 (0.0008-0.0019) 0.07 (0.0028)

Clearance between stem and guide

EX 0.045 - 0.072 (0.0018-0.0028) 0.09 (0.0035)

4. If a bore gauge is not available, measure the clearance using a dial gauge by moving

the edge of the stem to the directions of (a), (b) (3).

5. Replace the valve stem or valve guide, if the measured valve is over the limit.

Unit : mm (in.)

Item Limit

IN 0.14 (0.0055)

Edge of the valve (a)↔(b) Clearance limit

EX 0.18 (0.0071)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 14 of 69

Valve

1. Remove all carbon from the valve.

2. Check the valve or stem for abrasion, burn or bending, and replace as necessary.

3. Abrasion of the valve edge.

Check the edge of each valve for abrasion. Some uneven abrasion would be

made on the edge because the rocker arm gets contacted at this surface when

operating. Repair the section within 0.05 mm (0.002 in.) as required, or replace

the valve if some modification is required more than that (1).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 15 of 69

4. Deviation to the rotating direction (2).

Measure the deviation to the rotating direction using a dial gauge and the V

block by turning the valve slowly.

Replace valve, if the measured value exceeds the limit.

Unit : mm (in.)

Item Limit

Deviation limit of valve head to the rotating direction 0.08 (0.0031)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 16 of 69

5. Checking the contact width (3).

Clean the valve and the valve seat and apply red stamping ink thinly to the

contacting surface of the valve seat. Check the fitness after installing the valve

unit.

A good contact shows the equal contact width within the specified.

Unit : mm (in.)

Item Limit

IN 1.46 - 1.66 (0.0575 - 0.0654)

Contact width on the surface of the valve seat

EX 1.46 - 1.66 (0.0575 - 0.0654)

6. Valve seat repair (4).

Repair by grinding and cutting off the valve seat, and lap it if its contacting width

is not even or out of the specified.

Upon applying a seat cutter, use the one of smaller angle first and increase the

angle of the using cutter up to the light and final modification of the contact. And

finish contact surface and its location with the cutter of 45 degrees.

Important : Upon cutting, take care of the contact width. Finish the cutting with

gradually reduced power for no cutting mark on the surface.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 17 of 69

7. Valve lapping.

Make lapping in two stages, first with normal lap and second with fine one for

the both sides.

a. Intake side.

b. Exhaust side.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 18 of 69

Cylinder Head

1. Remove all carbon from the combustion chamber.

2. Be sure not to make scratch on the intake and exhaust ports of the cylinder head, the

combustion camber, and the head surface together with and the valve seats.

3. Flatness of the cylinder head (1).

Measure the flatness of the 6 different places using a straight ruler and the

thickness gauge. If the measurement is red over the limit of use, confirm the

deformed area by placing it on the flat plate and repair it with fine abrasives.

Replace the cylinder head of which repair is impossible.

Notice : The deformation of the cylinder head surface may cause the loss of

power due to the leakage of the compression.

Measure the flatness of the cylinder head surface in the location of each 4 side

and diagonal.

Unit : mm (in.)

Item Limit

Deformation limit of the cylinder head flatness 0.05 (0.0020)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 19 of 69

4. Deformation of the surface for manifold installation (2).

Inspect the surface for installing manifold of the cylinder head using a straight

ruler and the thickness gauge and repair the installing surface or replace the

cylinder head if necessary.

Unit : mm (in.)

Item Limit

Limit of the manifold deformation 0.10 (0.0039)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 20 of 69

Valve Springs

1. Weakened valve springs can be the cause of chatter, not be mentioned to possibility

of reducing the power output due to gas leakage caused by decreased seating

pressure.

2. Free length of the valve spring (1).

3. Replace the valve springs of which valve spring free length is less than than the limit.

Unit : mm (in.)

Item Standard Limit

Valve spring free length 54.45 (2.1437) 53.40 (2.1024)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 21 of 69

4. Spring preload (2).

Replace the valve springs of which valve spring preload is less than the limit.

Unit : mm (in.)

Item Standard Limit

Valve spring preload 23.4-27.0 (0.9213-1.0630) 22.0 (0.8661)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 22 of 69

5. Spring squareness (3).

Measure the squareness of each spring using a flat plate and the square.

Replace the valve spring of which clearance is over the limit.

Unit : mm (in.)

Item Limit

Valve spring squareness 2.4 (0.0945)

Installation Procedure

1. Make the valve guide hole using a valve guide reamer 09916-38210.

Before installing the new valve guide into the cylinder head, ream guide hole

with 11mm reamer to remove burrs. Make sure that the guide hole cones to a

complete roundness (1).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 23 of 69

2. Install the valve guide.

Heat the cylinder head uniformly at a temperature 80-100°C (176-212°F) not to

make the head deformed, and drive new valve guide completely into the hole

with the tools the valve guide installer 09916-58210 with the valve guide

installer attachment 09917-88220.

Peen and install new valve guide (1).

After installation, check the protruded part of the guide from the cylinder head

(2).

Important : Do not reuse the valve guide once disassembled, replace it with the

new oversized valve guide.

Unit : mm (in.)

Valve guide oversize 0.03 (0.0012)

Valve guide protrusion 14 (0.5512)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 24 of 69

3. Repair the valve guide bore.

Repair the valve guide bore with the valve guide reamer 09916-37320 (5 mm or

0.1969 in.) (1).

Make the hole free from foreign material.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 25 of 69

4. Install the new valve stem seals.

Install the valve spring seats (1).

Install new valve stem oil seal to the valve guide (2).

After applying engine oil to seal and installing seal to the valve guide and make

sure that seal is properly fixed to the valve guide.

Important : Do not reuse the disassembled oil seal and replace it with new one.

When installing it, never tap or hit tool with a hammer or else. Install seal to

guide only by pushing special tool with hand. Tapping or hitting tool may

cause damage on seal.

5. Install the valves.

Important : Before installing it, coat engine oil to the stem seals, valve guide

bore and valve stem.

Install the valve to the valve guide (1).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 26 of 69

6. Install the valve springs and the spring retainers.

Install the valve springs (1).

Each valve spring has top end (large-pitch end) (a) and bottom end (small-pitch

end) (b). Be sure to position spring in place with its bottom end down to valve

spring seat side (2).

Install the valve spring retainers (3).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 27 of 69

7. Install the valve keepers.

Using the valve spring compressor 09916-14510 with the valve spring

compressor attachment 09916-48210, compress the valve springs (1).

Install the valve keeper (2).

Important : Coat engine oil to the valve stem oil seals, the valve guide hole, and

the valve stem.

8. Install the camshaft.

Coat engine oil to the camshaft front oil seal, the cam, and the camshaft journal.

Install the camshaft front oil seal to the housing hole (1).

Install the camshaft to the cylinder head (2).

Notice : Installing the camshaft, take extreme care to prevent any scratch, nick

or damage.

Install the camshaft plate (3).

Tighten

Tighten the screw to 9-12 N•m (80-106 lb-in).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 28 of 69

9. Install the rocker arms and the rock arm shafts.

Coat engine oil to the rocker arms and the rocker arm shafts.

Install the rocker arms and the rocker arm shafts (1).

Install the bolt (2).

Tighten

Tighten the screw to 9-12 N•m (80-Tighten the bolts to 9-12 NSm (80-106 lb-in).

(Coat the Loctitte).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 29 of 69

Proceeding procedures when repairing the pistons and crankshaft unit :

- Remove the engine and the transaxle. Refer to "Engine Assembly" in this

section.

- Remove the transaxle from the engine. Refer to Section 5B1, Five-Speed

Manual Transaxle.

- Remove the fly wheel.

- Install the engine overhaul stand KM 412 to the engine assembly as the

figure.

- Drain engine oil from the engine.

- Remove the cylinder head. Refer to "Cylinder Head and Gasket" in this

section.

- Remove the oil pump from the cylinder block. Refer to "Oil Pump" in this

section (In case of repairing the crankshaft unit).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 30 of 69

Engine Block Components

Tools Required

09916-77310 Piston Compressor

Disassembly Procedure

1. Remove the components attached around the engine block.

Remove the power steering/air conditioning belt.

Remove the bolts and loosen one bolt (lower side) (1).

Turn the A/C compressor downward.

Remove the power steering rear bracket bolt/nut and the adjusting bolt (2).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 31 of 69

Remove the A/C compressor bracket bolts (3).

Remove the A/C compressor, the power steering, and the bracket.

Remove the bracket (5).

Loosen the generator bolt (6).

Loosen the generator lower bolts and the nut (7).

Remove the generator and belt (8).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 32 of 69

Loosen the engine mount upper bracket bolts (9).

Remove the generator shackle (10).

Remove the upper bracket (11).

Loosen the engine mount lower bracket bolts (12).

Remove the lower bracket (13).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 33 of 69

2. Remove the oil pan and the oil pump pickup tube.

Remove the bolts (1).

Remove the nuts (2).

Remove the oil pan (3).

Remove the bolts (4).

Remove the oil pump pickup tube and the oil seal (5).

Clean the surfaces of the oil pan and the engine block.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 34 of 69

3. Remove the connecting rod bearing caps.

Turn the crankshaft slowly to make the big end of the No.1 cylinder connecting

rod come on the top side.

Remove the nuts (1).

Remove the connecting rod bearing caps (2).

Insert guide hose in the screw side of connecting rod stud bolt to prevent any

damage on the crankshaft pin and cylinder wall (3).

Mark the order of the crankshaft bearing caps.

Remove the connecting rod lower bearing.

4. Remove the piston and the connecting rod.

Remove the piston and the connecting rod by pressing the connecting rod stud

bolt toward cylinder head.

Remove the upper connecting rod bearing.

Mark the order of cylinder on the piston and the connecting rod.

Arrange the piston and the connecting rod of No.2 and No.3 cylinders according

to the sequence as above 2 to 4 procedure.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 35 of 69

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 36 of 69

5. Remove the piston oil rings, and the compression rings, then remove the connecting

rod.

Using a piston ring expander tool to expand the piston rings, remove the piston

rings.

a. Top compression ring (No.1).

b. Second compression ring (No.2).

c. Piston oil rings (No.3).

Remove the circlip and pull out the piston pin to separate the piston and the

connecting rod.

d. Circlip.

e. Piston pin.

f. Piston.

g. Connecting rod.

h. Connecting rod bearing cap.

Inspection/Measurement/Adjustment Procedure

Cylinder

1. Wipe out the cylinder wall and check any scratch or excess abrasion on it. Apply

boring with oversize when such damage is over the limits.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 37 of 69

Measure the inner diameter of cylinder with bore gauge in longitudinal and

transverse directions (1).

There are 3 measuring locations (a, b, c). If beyond specifications, rebore to

next oversize (2).

Unit : mm (in.)

Item Limit

Bore diameter of cylinder Ø 8.570 (2.700)

Taper 0.10 (0.0039) and less

Out of Round 0.05 (0.002) and less

Important : Specification of oversize shall be varied as 0.25, 0.50, 0.75 and 1.00,

and the oversize should be same for cylinder, piston and rings upon boring

and installing. The same oversize on the 3 cylinders should be maintained.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 38 of 69

Piston

1. Clean piston with soft cloth and check any damage to determine whether to replace

it.

Use micrometer to measure the outer diameter of piston. Check the outer

diameter of the piston in the perpendicular direction of the piston pin at 15mm

(0.5906 in.) high from the skirt (1).

Unit : mm (in.)

Standard Ø68.465-Ø68.485 (2.6955 - 2.6963)

Outer diameter of

Oversize 0.25 Ø68.715 - Ø68.735 (2.7053 - 2.7061)

piston oversize

Oversize 0.50 Ø68.965 - Ø68.985 (2.7152 - 2.7160)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 39 of 69

Calculate the different value of the measurement between cylinder inner

diameter (50mm (1.9685 in.) below the head surface) and piston outer diameter

(15mm (0.5906 in.) above the piston skirt) (2).

Unit : mm (in.)

Piston clearance 0.025 - 0.045 (0.00098 - 0.00177)

Important : Upon measuring of cylinder bore diameter and piston outer

diameter, calculate the measured values both in the same directions of

crankshaft and piston pin.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 40 of 69

Piston Ring

1. Remove carbon and make the groove clean before inserting the ring, and measure

the clearance between ring and ring land with thickness gauge. If the measured

exceeds the limit, replace the piston (1).

Unit : mm (in.)

Piston ring Standard Limit

0.02-0.06 (0.00079-

Compression ring 0.10 (0.0039)

Ring clearance in 0.0024)

the groove 0.02-0.06 (0.00079-

Second compression ring 0.10 (0.0039)

0.0024)

Piston oil ring 0.06 - 0.15 (0.0024-0.006) -

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 41 of 69

2. To measure the end gap, insert the piston ring into the cylinder bore with the piston,

locating it at the lowest part of the bore, then use a filler gauge to measure the gap. If

the gap measured exceeds the limit, replace the ring (2).

Unit : mm (in.)

Piston ring Standard Limit

Ring clearance in Compression ring 0.15-0.30 (0.0059-0.0120) 0.70 (0.0280)

the groove Second compression ring 0.3-0.45 (0.012-0.018) 0.70 (0.0280)

Piston oil ring 0.20-0.70 (0.0079-0.0280) 1.80 (0.0709)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 42 of 69

Piston Pin

1. Measure the clearance between piston pin and piston boss part, and if the measured

exceeds the standard, replace the piston pin (1).

Unit : mm (in.)

Item Standard

15.995-16.000 (0.6297

Outer diameter of piston pin

0.6299)

16.006-16.014 (0.6302

Inner diameter of piston boss

0.6305)

0.006-0.019 (0.0002-

Piston pin clearance

0.0007)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 43 of 69

Connecting Rods

1. Check the big end of each connecting rod for thrust clearance, with the rod fitted and

connected to the crank pin in the normal manner. If the measured clearance is found

to exceed the limit or any damage is found on the thrust surface of both ends, the

responsible connecting rod or the crankshaft must be replaced (1).

Unit : mm (in.)

Connecting rod big end thrust Standard Limit

clearance 0.10-0.25 (0.0039-0.010) 0.35 (0.0138)

2. Check the bending and the twist of connecting rod with the connecting rod aligner,

and if the limit is exceeded, replace it.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 44 of 69

Unit : mm (in.)

Item Limit

Bending (a) 0.05 (0.0020) (in case of 100mm (3.937 in.))

Twist (b) 0.10 (0.0039) (in case of 100mm (3.937 in.))

3. Bearing clearance (3).

Inspect the bearing shell for signs of damage, fusion, burn, etc. and observe the

contact pattern. Bearings found in defective condition through this inspection

must be replaced.

Measure the oil clearance by using the plastigauge. Prepare, by cutting a length

of plastigauge equal to bearing width and place it axially on crank pin, avoiding

oil hole.

a. Plastigauge

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 45 of 69

Install connecting rod bearing and bearing cap and tighten to the specified

torque. At this time, never turn or rotate the crankshaft.

b. Connecting rod bearing.

c. Bearing cap.

Tighten

Tighten the connecting rod bearing cap nuts to 31-35 N•m (23-25 lb-ft).

Remove the cap, and measure the width of plastgauge with the scale marked

on the plastigauge case. The measurement must be taken at the widest part of

the compression and attention should be also paid to the different values

measured at the both ends of the plastigauge.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 46 of 69

Unit : mm (in.)

Standard Limit

Bearing oil clearance

0.020-0.040 (0.00079 - 0.00157) 0.065 (0.00256)

If the oil clearance exceeds the limit, replace the bearings.

Unit : mm (in.)

Size Standard

Bearing size 37.982-38.000

Outer diameter of crank pin

(1.4954-1.4961)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 47 of 69

Crankshaft

1. Remove the engine block.

2. Remove the crankshaft rear oil seal housing.

Remove the bolts and the nuts (1).

Remove the gasket and the oil seal housing (2).

3. Remove the crankshaft bearing cap.

Remove the bolts (3).

Remove the bearing and the bearing cap (4).

4. After removing the crankshaft, remove the upper bearing.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 48 of 69

5. Crankshaft runout.

Measure runout at center journal with block and dial gauge by turning

crankshaft slowly. If runout exceeds the limit, replace the crankshaft (1).

Unit : mm (in.)

Limit on runout 0.03 (0.0012)

Important : To measure runout, turn crankshaft once to be matched with dial

gauge on the journal part, and read and take 1/2 value of the maximum gauge.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 49 of 69

6. Crankshaft thrust play

Install crankshaft thrust bearings and journal bearings on the engine block, and

tighten bearing cap bolt to the specification, then measure the axial play of

crankshaft. If the measured exceeds the limit, replace the thrust bearing with

the new standard one or the one of the next oversize (2).

Unit : mm (in.)

Standard Limit

Crankshaft thrust play

0.11-0.31 (0.0043-0.0122) 0.4 (0.0157)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 50 of 69

7. Out of round and taper (uneven wear) of journal.

Measure the fluctuations of journal diameter in the axle and right angle direction

of crankshaft and confirm the condition of uneven wear. If some serious

damage is found, or the deviation and partial deviation exceeds the limit,

replace the crankshaft or repair it by polishing (3).

Unit : mm (in.)

Limit on out of round and taper 0.01 (0.00039)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 51 of 69

8. Crankshaft bearing oil clearance (4).

Check the surface in contact for wear, burn, scratch, etc. and if necessary,

replace it.

Cut the plastigauge to the length equal to the width of the bearing and place it

axially on the journal, avoiding the oil hole.

a. Plastigauge.

Install the crankshaft bearing and bearing cap and tighten it to the

specifications. Do not rotate the crankshaft at this moment.

b. Crankshaft bearing.

c. Bearing cap.

Tighten

Tighten the crankshaft bearing cap bolt to 55-60 N•m (41-44 lb-ft).

Remove the caps and measure the width of plastigauge with the scale marked

on the plastigauge case. This measurement must be taken at the widest part of

the compression and attention should be also paid to the different values

measured at the both ends of the piastigauge. If the oil clearance exceeds the

limit, replace the bearing.

Unit : mm (in.)

Oil clearance for Standard Limit

crankshaft bearings 0.020-0.040 (0.00079-0.00157) 0.065 (0.00256)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 52 of 69

Unit : mm (in.)

Item Standard

43.982-44.000 (1.7316

Outer diameter of crankshaft journal

1.7323)

Inspect the oil seal lips for wear, damage and mixture of foreign material.

Repalce the deteriorated (5).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 53 of 69

Flywheel

1. Inspect it for damage, crack and abnormal wear at the ring gear part, or at the

contacting surface to the clutch plate. Replace the flywheel if necessary.

2. Measure runout of the flywheel using block and dial gauge, and replace it if runout

exceeds the limit (1).

Unit : mm (in.)

Limit on runout 0.2 (0.0079)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 54 of 69

Engine Block

1. Measure 6 different places using thickness gauge and straight scale in the same

method as for the cylinder head (1).

2. Polish and repair it, if the distortion, bent or twist exceeds the limit. If polishing needs

more than 0.15mm (0.0059 in.), replace it with new one.

Important : Pay attention to the flatness on the surface between combustion

chambers.

Unit : mm (in.)

Limit of cylinder distortion 0.05 (0.0020)

Standard flatness 0.03 (0.0012)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 55 of 69

Notice : The deformation of the cylinder head surface may cause the loss of

power due to the leakage of the compression.

Important : Measure the flatness of the cylinder head surface in the location of

each 4 side and diagonal.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 56 of 69

Installation Procedure

1. Install the crankshaft thrust bearing and upper main bearing, then install the

crankshaft to the crankshaft journal.

Coat engine oil in the oil groove and install the crankshaft thrust bearings to

place the oil groove in the outer part of the journal portion (1).

a. Oil groove.

Install the upper crankshaft main bearings to the crankshaft journal with the

bearing oil port to direction of the oil filter (2). (Install the lower crankshaft

bearings identically when installing bearing cap).

b. Bearing oil port.

Important : Coat engine oil to the inner surface of bearing, or journal surface of

crankshaft (crank pin side) when installing bearing.

Position the crankshaft on the engine block journal.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 57 of 69

2. Install the crankshaft bearing cap with the lower crankshaft main bearing installed to

the crankshaft journal.

On the bearing cap of the crankshaft journal part, Numbers 1 to 4 are marked in

sequence.

Install the lower crankshaft main bearing to the crankshaft journal part (1).

Install the bearing cap to the crankshaft journal part with the bolts according to

the sequence (2).

Tighten

Tighten the bearing cap bolts to 55-60 N•m (40-44 lb-ft).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 58 of 69

3. Install the gasket and the crankshaft rear oil seal housing.

Important : Do not reuse the removed gasket and replace it with new one.

Install the oil seal housing gasket (1).

Install the crankshaft rear oil seal housing after coating engine oil to the oil seal

lip (2).

Cut them with scraper, if the gasket edges are bulged.

Tighten

Tighten the bolts to 9-12 N•m (80-106 lb-in).

Tighten the screws to 9-12 N•m (80-106 lb-in). (Coat the Loctitte)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 59 of 69

4. Install the oil pump with the gasket. (In case of the crankshaft unit repair)

Important : Do not reuse the removed gasket and replace it with new one.

Install the oil pump gasket (1).

Insert the hose in the crankshaft to prevent and damage on the oil pump seal

when installing the oil pump (2).

Install the oil pump housing with the bolts (3).

Tighten

Tighten the bolts to 9-12 N•m (80-106 lb-in).

Cut them with scraper, if the gasket edges are bulged.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 60 of 69

5. Assemble the piston and the connecting rod.

Important : There are assembling directions for the piston and the connecting

rod. Direct the piston front mark (→) (a) on the piston head toward the

crankshaft pulley and toward the inlet manifold (b) on the connecting rod

toward the exhaust manifold to assemble the piston and the connecting rod.

Install the piston pin (1).

Retain the piston pin with the circlips (2).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 61 of 69

6. Install the compression ring and the oil ring to the piston.

When installing oil ring, insert the spacer first and two rails later (1).

Install the second compression ring to direct the marked R side upward (2).

Install the compression ring (3).

Install three rings and position their openings as shown in Fig K5B11BS4.

a. Opening of compression ring (No.1).

b. Opening of compression ring (No.2)

c. Opening of oil ring rail (upper rail)

d. Opening of oil ring spacer

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 62 of 69

e. Opening of oil ring rail (lower rail)

f. Mark

g. Piston head

7. Install the piston and the connecting rod assembly.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 63 of 69

Coat engine oil to piston, ring, cylinder wall and bearing crank pin of connecting

rod.

Position piston into cylinder to make the arrow point direct toward the

crankshaft pulley (1).

Confirm the hose inserted in connecting rod stud bolt to prevent the damage of

the cylinder wall and the crankshaft bearing crank pin before installing the

piston and connecting rod assembly.

Pucker the piston ring with the piston compressor 09916-77310 and insert the

connecting rod and the piston to the cylinder properly. In this time, push the

piston compressor 09916-77310 against the engine block and insert the piston

lightly (2).

Install the connecting rod according to the sequence.

Install the upper connecting rod bearing to the connecting rod bearing journal.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 64 of 69

8. Install the bearing cap with the lower bearing installed to crankshaft crank pin part.

Install the lower crankshaft main bearing to the crank pin part (1).

Position the bearing cap on the crankshaft crank pin part to make the arrow

point direct toward the crank pulley according to the sequence after positioning

the piston on BDC (Bottom Dead Center) (2).

Tighten

Tighten the bearing cap nuts to 31-35 N•m (23-25 lb-ft).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 65 of 69

9. Install the oil pump pickup tube and the oil pan.

Install the oil pump pickup tube with the bolts (1).

Tighten

Tighten the oil pump pickup tube bolts to 9-12 N•m (80-106 lb-in).

Coat the liquefied gasket on the engine block.

Install the oil pan with the bolts and the nuts (2).

Tighten

Tighten the nuts and bolts to 9-12 N•m (80-106 lb-in). (Coat the Loctitte)

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 66 of 69

10. Install the components removed.

Install the lower alternator bracket and the generator with the bolts (1).

Tighten

Tighten the bolts to 35-41 N•m (25-30 lb-ft) (a).

Install the upper engine mount bracket and the generator shackle with the bolts

(2).

Tighten

Tighten the bolts to 35-41 N•m (25-30 lb-ft) (b).

Install the generator with the bolts and the nut (3).

Install the generator belt.

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 67 of 69

Tighten

Tighten the generator lower bolts and the nut loosely to 18-28 N•m (13-21 lb-ft)

(c).

Tighten the generator belt tension adjusting bolt to 18-28 N•m (13-21 lb-ft) (d).

Install the engine mount bracket (4).

Install the A/C compressor/power steering pump and the bracket with the bolts

(5).

Tighten

Tighten the bracket bolt to 18-22 N•m (13-16 lb-ft) (e).

Tighten the bracket bolts to 35-41 N•m (25-30 lb-ft) (f).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 68 of 69

Install the power steering pump bracket with the bracket bolt/nut and the

adjusting bolt (6).

Tighten

Tighten the power steering rear bracket bolt to 18-22 N•m (13-16 lb-ft) (g).

Tighten the adjusting bolt and the power steering rear bracket nut to 20-24 N•m

(15-18 lb-ft) (h).

Position the A/C compressor into the normal location.

Tighten

Tighten the bolts to 18-22 N•m (13-16 lb-ft) (i).

Tighten the bolt to 20-24 N•m (15-18 lb-ft) (j).

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

Service Manual2005 Matiz UNIT REPAIR Page 69 of 69

Install the power steering/air conditioning belt.

Install the cylinder head with the intake manifold, the exhaust manifold, and

distributor/adaptor attached. Refer to "Cylinder Head and Gasket" in this

section.

Install the timing belt and components. Refer to "Timing Belt" in this section.

Install the clutch and the transaxle to the engine, then engine assembly to the

engine compartment. Refer to "Engine Assembly" in this section.

Refill the engine crankcase with engine oil.

Refill the engine coolant system. Refer to Section 1D, Engine Cooling.

Bleed the power steering system as necessary. Refer to Section 6A, Power

Steering System.

Refill the A/C refrigerant system as necessary. Refer to Section 7B, Manual

Control Heating, Ventilation, and Air Conditioning System.

Refill the transaxle oil as necessary.

Connect the negative battery cable.

Start the engine and operate all systems.

Operate the idle air control valve reset procedure as necessary.

© Copyright Chevrolet Europe. All rights reserved

file://G:\AUTOCAR\GM-DEAWOO-CHEVROLET\CHEVROLET\DATA\Workshop ... 24/01/2024

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- Daewo Matiz2Document54 pagesDaewo Matiz2hipo84575% (4)

- Rover 100 TUD5 Overhaul ManualDocument59 pagesRover 100 TUD5 Overhaul ManualAndy Moe63% (8)

- Eee-1Document9 pagesEee-1Luigi Russo TorresNo ratings yet

- d348 - M.serviceDocument1,704 pagesd348 - M.serviceMarcos Vinicius BinottoNo ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- Cat312dlrhl00001andup Service ManuelDocument28 pagesCat312dlrhl00001andup Service Manuelfernando feitosaNo ratings yet

- Cylinder Block: Cerrar SIS Pantalla AnteriorDocument6 pagesCylinder Block: Cerrar SIS Pantalla AnteriorJefferson HuamanNo ratings yet

- C7.1 Generator Set Vibration Damper CheckDocument2 pagesC7.1 Generator Set Vibration Damper CheckbejoythomasNo ratings yet

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicNo ratings yet

- Einstelldaten Kubota 03-M-Serie (EU Stage IIIA, EPA Int - Tier 4)Document24 pagesEinstelldaten Kubota 03-M-Serie (EU Stage IIIA, EPA Int - Tier 4)Alex AyalaNo ratings yet

- 216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFDocument3 pages216B 226B 232B 242B Skid Steer Loader BXM00001-04224 (MACHINE) POWERED BY 3024C Engine (SEBP3770 - 65) - Systems & Components 6 UBA PDFubaldo caraballoNo ratings yet

- Engine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyDocument23 pagesEngine: 303-01C Engine - 3.2L Duratorq-Tdci (148Kw/200Ps) - Puma 2011 - 2014 Ranger AssemblyCamille Fajardo Danganan100% (1)

- Specifications and Repair Procedures For C4.4 Cylinder BlocksDocument8 pagesSpecifications and Repair Procedures For C4.4 Cylinder BlocksMarielis ContrerasNo ratings yet

- Citroenpeugeot 1820 Timing Belt Installation GuideDocument8 pagesCitroenpeugeot 1820 Timing Belt Installation GuideWawan SatiawanNo ratings yet

- 324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsDocument5 pages324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsjhonNo ratings yet

- Bearing Clearance - ChecksDocument3 pagesBearing Clearance - ChecksPutra JawaNo ratings yet

- SEBF8155 цил.головка 3500Document30 pagesSEBF8155 цил.головка 3500Евгений Абрамов100% (1)

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Volvo V70 Engine SpecsDocument17 pagesVolvo V70 Engine Specsapek1No ratings yet

- Remove Oil Pump and Relief ValveDocument5 pagesRemove Oil Pump and Relief ValveAnonymous cS9UMvhBqNo ratings yet

- Konica C451 Fuser Unit Noise SolutionsDocument21 pagesKonica C451 Fuser Unit Noise Solutionsroosterman4ever100% (1)

- 325 329 General Duty Intro PELJ1792 - V01Document6 pages325 329 General Duty Intro PELJ1792 - V01robert0126No ratings yet

- Specifications For Crankshafts in Caterpillar Engines (1202) : Cerrar SISDocument82 pagesSpecifications For Crankshafts in Caterpillar Engines (1202) : Cerrar SISLuis TepezanoNo ratings yet

- Alignment PDFDocument12 pagesAlignment PDFVictor Nunez100% (1)

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpDocument22 pages303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADANo ratings yet

- Virabrequim C32Document3 pagesVirabrequim C32PauloNo ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Document200 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- Reglaje de ValvulasDocument15 pagesReglaje de ValvulasJuan Antonio Ochoa PadronNo ratings yet

- Caterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)Document23 pagesCaterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)kfmuseddkNo ratings yet

- 190fe-ManualDocument21 pages190fe-Manualmochamady755No ratings yet

- 1.8L DuratorqTDCi (Lynx) DieselDocument15 pages1.8L DuratorqTDCi (Lynx) DieseltestNo ratings yet

- Generator Bearing ServiceDocument10 pagesGenerator Bearing ServiceMustafa A.W100% (1)

- Volvo D12D EspecificacionDocument42 pagesVolvo D12D EspecificacionSilas F Pimenta92% (72)

- Caterpillar Cat 305C CR Mini Hydraulic Excavator (Prefix HWJ) Service Repair Manual (HWJ00001 and Up)Document23 pagesCaterpillar Cat 305C CR Mini Hydraulic Excavator (Prefix HWJ) Service Repair Manual (HWJ00001 and Up)kfmuseddk50% (4)

- Daystar Service ManualDocument214 pagesDaystar Service ManualArture FratalisNo ratings yet

- YD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsDocument19 pagesYD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsMoaed Kanbar91% (105)

- d8k Motor D342Document4 pagesd8k Motor D342Omar Suazo100% (1)

- SB 10059770 2280Document7 pagesSB 10059770 2280zinou serraiNo ratings yet

- Deere - trs22 UserManualDocument23 pagesDeere - trs22 UserManualcimbom1979No ratings yet

- 315 SJ Rear Axle AssembleDocument25 pages315 SJ Rear Axle Assemblesphiri600No ratings yet

- 305 Con Rod 2Document3 pages305 Con Rod 2qwuLzNo ratings yet

- Turbocharger Maintenance StandardsDocument17 pagesTurbocharger Maintenance StandardsanggieNo ratings yet

- TP31201-1 700 Multi-Link Rear SuspensionDocument42 pagesTP31201-1 700 Multi-Link Rear Suspensionvanapeer100% (1)

- Engine Mechanical - 1.2LDocument86 pagesEngine Mechanical - 1.2Linterlo100% (1)

- Assembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Document20 pagesAssembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Bartłomiej StępieńNo ratings yet

- 194-210 CSG649Document107 pages194-210 CSG649IV FVNo ratings yet

- 24H Engine Valve SetDocument7 pages24H Engine Valve SetJohn GrayNo ratings yet

- Amboid Rear Differential Carrier: Rear/Rear Carrier On MT-40-143MA-N Tandem Drive AxlesDocument55 pagesAmboid Rear Differential Carrier: Rear/Rear Carrier On MT-40-143MA-N Tandem Drive AxlesCosmicdancer RudraNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 31 Wheel and TyreDocument2 pages31 Wheel and TyremanhNo ratings yet

- 54A Chassis ElectricalDocument17 pages54A Chassis ElectricalmanhNo ratings yet

- 42 BodyDocument20 pages42 BodymanhNo ratings yet

- 37A Power SteeringDocument12 pages37A Power SteeringasyrafjpkNo ratings yet

- 51 ExteriorDocument10 pages51 ExteriormanhNo ratings yet

- 52B Suplemental Restraint System (SRS)Document15 pages52B Suplemental Restraint System (SRS)manhNo ratings yet

- 35 Service BrakesDocument1 page35 Service BrakesGoran NikolicNo ratings yet

- Preface For WMDocument2 pagesPreface For WMMirek K.No ratings yet

- Howo A7 Cam Nang Sua Chua Dien00034Document1 pageHowo A7 Cam Nang Sua Chua Dien00034manhNo ratings yet

- Engine - Electrical Colt 2008Document3 pagesEngine - Electrical Colt 2008Mirek K.No ratings yet

- Howo A7 Cam Nang Sua Chua Dien00016Document1 pageHowo A7 Cam Nang Sua Chua Dien00016manhNo ratings yet

- 11B Engine MechanicalDocument17 pages11B Engine Mechanicalcrysttina100% (1)

- 35C Traction Control, Active Stability Control SystemDocument23 pages35C Traction Control, Active Stability Control Systemmanh100% (1)

- 35B Four-Wheel Anti-Skid Brake System (4ABS)Document11 pages35B Four-Wheel Anti-Skid Brake System (4ABS)manh100% (1)

- Howo A7 Cam Nang Sua Chua Dien00022Document1 pageHowo A7 Cam Nang Sua Chua Dien00022manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00027Document1 pageHowo A7 Cam Nang Sua Chua Dien00027manhNo ratings yet

- Colt Technical Information Manual: ForewordDocument1 pageColt Technical Information Manual: ForewordDaniel Rosario0% (1)

- Howo A7 Cam Nang Sua Chua Dien00030Document1 pageHowo A7 Cam Nang Sua Chua Dien00030manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00023Document1 pageHowo A7 Cam Nang Sua Chua Dien00023manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00024Document1 pageHowo A7 Cam Nang Sua Chua Dien00024manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00001Document1 pageHowo A7 Cam Nang Sua Chua Dien00001manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00021Document1 pageHowo A7 Cam Nang Sua Chua Dien00021manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00020Document1 pageHowo A7 Cam Nang Sua Chua Dien00020manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00025Document1 pageHowo A7 Cam Nang Sua Chua Dien00025manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00004Document1 pageHowo A7 Cam Nang Sua Chua Dien00004manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00015Document1 pageHowo A7 Cam Nang Sua Chua Dien00015manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00006Document1 pageHowo A7 Cam Nang Sua Chua Dien00006manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00026Document1 pageHowo A7 Cam Nang Sua Chua Dien00026manhNo ratings yet

- Bao Gia Gach 3D Bs 2019Document7 pagesBao Gia Gach 3D Bs 2019manhNo ratings yet

- Howo A7 Cam Nang Sua Chua Dien00011Document1 pageHowo A7 Cam Nang Sua Chua Dien00011manhNo ratings yet

- 04c MS45 DME Part 4Document10 pages04c MS45 DME Part 4CristianNo ratings yet

- 92 trx350+d SpecsDocument17 pages92 trx350+d SpecsJason ConerlyNo ratings yet

- FORD Puma 2Document18 pagesFORD Puma 2Uriel MF100% (1)

- MIO Sporty Catalog PartsDocument52 pagesMIO Sporty Catalog PartsAngga Chumie Bernadi81% (16)

- 2014 690 SMC R EuDocument248 pages2014 690 SMC R EuJacopo Lo ConteNo ratings yet

- Chrysler Neon 2,0 L (Motor Sohc)Document3 pagesChrysler Neon 2,0 L (Motor Sohc)DavidNo ratings yet

- Desing Calculation of Engine Parts For 110-Kenbo Motorcycle (Piston, Crankshaft, Cam Shaft and Valve Gear Mechanism)Document5 pagesDesing Calculation of Engine Parts For 110-Kenbo Motorcycle (Piston, Crankshaft, Cam Shaft and Valve Gear Mechanism)Dr. Aung Ko Latt100% (1)

- 250cc (LT-F250 AJ47A 1988-1996) Suzuki ATV Parts ListDocument70 pages250cc (LT-F250 AJ47A 1988-1996) Suzuki ATV Parts ListMarkNo ratings yet

- wgp4205 Turbine PDFDocument46 pageswgp4205 Turbine PDFM Tri WinarkoNo ratings yet

- E60 CCC ErrorsDocument17 pagesE60 CCC ErrorsBenjamin Scharein100% (1)

- The Federation of Motor Sports Clubs of India: No - TDF070005 Valid From: 07 Sep 2007 Valid ToDocument11 pagesThe Federation of Motor Sports Clubs of India: No - TDF070005 Valid From: 07 Sep 2007 Valid Torudey1867% (3)

- 2RZ 3RZ SCDocument21 pages2RZ 3RZ SCDiego Pillco0% (1)

- Chevrolet Pinout PCM 8Document5 pagesChevrolet Pinout PCM 8Javier Inzaurgarat100% (1)

- Ly Coming Service Pubs IndexDocument65 pagesLy Coming Service Pubs IndexBobby ChippingNo ratings yet

- Ade 236 Workshop Manual v2Document94 pagesAde 236 Workshop Manual v2Orlando Mondlane100% (3)

- DNEPR M72 Manual EnglishDocument76 pagesDNEPR M72 Manual Englishdaemonium666100% (2)

- Workshop Manual - TDI Engine Fuel Ingection AMFDocument64 pagesWorkshop Manual - TDI Engine Fuel Ingection AMFantonioforteseNo ratings yet

- Description of Parameters, Engine Control Module (ECM)Document19 pagesDescription of Parameters, Engine Control Module (ECM)rahmat sanusiNo ratings yet

- U480 PDFDocument28 pagesU480 PDFLaura Rozmus67% (3)

- Bosch MotorSport Catalog F3 - Katalog - 2013Document78 pagesBosch MotorSport Catalog F3 - Katalog - 2013openjavier5208No ratings yet

- Report On PHBPL HaldiaDocument37 pagesReport On PHBPL HaldiaINCREDIBLE ADIONUNo ratings yet

- MC 10165111 9999Document15 pagesMC 10165111 9999ZuskerNo ratings yet

- Module 1 - A.E KtuDocument97 pagesModule 1 - A.E Ktujohnygeorge802No ratings yet

- AutomotiveDocument26 pagesAutomotiveskyliner53877% (13)

- Catalogo Kohller 18HP SV540 HUSI2009 - AAaa - SV540-0024Document11 pagesCatalogo Kohller 18HP SV540 HUSI2009 - AAaa - SV540-0024Jhonatan ComakNo ratings yet

- FORD CamsDocument10 pagesFORD CamsMystic BikerNo ratings yet

- Manual de MontacargasDocument12 pagesManual de MontacargasPako Xavier K100% (1)

- MF 200-Series Workshop Sec WatDocument0 pagesMF 200-Series Workshop Sec WatSelmirije2No ratings yet

- Specifications Manual l10 Series Engines External Damper ModelsDocument69 pagesSpecifications Manual l10 Series Engines External Damper ModelsHector Alejandro Mosqueda Torres84% (32)

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)