Professional Documents

Culture Documents

3.PLC Hardware Components

Uploaded by

Emmanuel Matutu0 ratings0% found this document useful (0 votes)

4 views36 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views36 pages3.PLC Hardware Components

Uploaded by

Emmanuel MatutuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 36

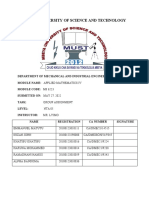

LECTURE 03

PLC Hardware Components

Learning objectives

• At the end of this lecture trainee should be

able to;

✓Define PLC Hardware

✓ Identify PLC Hardware Components

✓ Describe the PLC Hardware Components

✓ Illustrate the function of PLC Components

Introduction to PLC Hardware

• A PLC (Programmable Logic Controller) is

made up of both hardware and software

components. The PLC hardware refers to

the physical components that make up a

PLC system.

• Whereas the PLC software refers to the

PLC’s operating system and application

program that are stored in the PLC’s

memory

Introduction cont….

• PLC hardware is a term that describes the

physical components that make up the overall

PLC system.

• Each piece of PLC hardware is designed to

perform a specific task.

• Without all of its hardware components a PLC

system cannot operate effectively.

Introduction cont….

• Think of the main components that make up a

car. The engine, gearbox, wheels, electrics,

steering, body etc. Without all of its

components a car cannot function properly.

And most of the components that are used,

say in a Ford, cannot be used in a Honda. In

that sense, PLC Hardware is a similar concept.

Introduction cont….

• The majority of PLC manufacturers have

developed hardware and software

components to establish a proprietary PLC

system.

• That means PLC hardware components vary

for different manufacturers and in the

majority of cases are not interchangeable with

hardware components from other PLC brands

Basic Hardware Components

There are 6 basic hardware components that

make up a PLC;

– Processor (CPU)

– Mounting System

– Power Supply

– Input & Output Interface

– Communication Interface

– Programming Device

Basic Hardware components cont..

• These main PLC hardware components are

found in all PLC systems regardless of

manufacturer, type and size.

• They are the essential hardware elements

that make up every PLC system.

PLC Hardware Block diagram

Functions of PLC Block diagrams

1. PLC Processor (CPU)

At the heart of every PLC system is a processor.

It is perhaps the most crucial PLC hardware

component. Sometimes the PLC processor is

also referred as the PLC controller or PLC CPU

(Central Processing Unit).

Regardless of the name used, the PLC processor

is the workhorse of the PLC system responsible

for all the logic computation and number

operation

Function cont…

• The PLC processor can be embedded into the

PLC unit or come as a separate PLC module.

Generally fixed PLC types have their processor

embedded in the PLC itself.

• While modular and distributed PLC types have

their PLC processors as a separate module.

PLC samples

• Some examples of PLCs with embedded

processors are;

• Siemens Simatic S7-200 CPU 224, S7-200 CPU

226 and more recently the Siemens Simatic

S7-1200, CPU 1214C (6ES7 214).

• They are a fixed style PLC with embedded

processor, but have the ability to expand with

input and output modules. See below….

PLC samples

PLC processor module

• Some examples of PLC processor modules are

the Allen Bradley Control Logix 5580

controller, the Mitsubishi Melsec-Q Processor

CPU (Q03UDECPU), the Delta AHCPU560-EN2

processor and the Omron CJ2M-CPU1 and

CJ2M-CPU3 controllers.

PLC Processor

The PLC processor contains 3 fundamental

components:

• PLC CPU (Central Processing Unit)

• PLC Memory

• PLC Programming port

1. The PLC CPU

• The PLC CPU is a microprocessor that is

similar to a computer CPU. However, the

PLC CPU is not set up to multitask like a

computer CPU, but rather to perform

dedicated tasks such as program scan and

execution.

PLC CPU cont…

• In a PLC the CPU is responsible for control of

all PLC activity. This includes program scanning

(such as ladder logic), program executing,

handling data storage, directing data flow and

controlling communication among the various

interfaces.

The details of PLC processor

• The most common processor used in a

PLC is a single microprocessor. However,

the higher powered PLCs have multiple

microprocessors to divide up the various

tasks in order to improve overall operating

speed.

PLC processor detail…

• A PLC with dual microprocessors could

have a control processor to carry out data

manipulation and complex computation

as well as a second logic processor to

execute the logic, timing, counting and

other functions of the application

program

2. The PLC Memory

• The PLC memory is made up of program

memory, data memory and firmware. The PLC

uses the memory to store the program for

processing by the CPU and to store data for

input and output processing and execution.

• The size of the PLC memory will vary

depending on the processing power of the

CPU.

• The higher powered PLC models will be

equipped with faster CPUs and will have more

onboard memory.

PLC memory cont…

So if you have a large PLC program then

you will require a PLC controller with a

large integrated memory capacity to

accommodate.

Therefore, some PLC controllers have

expandable memory which can get you out

of trouble if you run out of memory

unexpectadly.

2. PLC Programming Port

The programming port on the PLC processor is

used to connect to a programming device such

as a PC or laptop.

The communication protocol used for the PLC

programming port varies between PLC

manufacturers. Some examples of the

communication protocol used for the PLC

programming port includes RS232, RS485 and

Ethernet

PLC Hardware Mounting Systems

• The hardware mounting system of a PLC

provides the means to physically connect the

various hardware components of the PLC

system. PLC hardware mounting systems can

vary from one PLC manufacturer to another

and can also vary depending on the type of

PLC used.

PLC Hardware Mounting Systems…

The 3 main PLC mounting systems used in industrial

automation projects are:

• Rack mounted PLC

• Rail mounted PLC

• Panel mounted PLC

PLC Mounting systems detail

• Rack Mounted PLC

A rack mounted PLC uses a mechanical

mounting system in order to physically connect

the PLC processor and other PLC hardware

components together.

The most common rack mounted PLCs use an

arrangement whereby the hardware

components are slotted into the rack.

Mounting detail cont…

This allow the hardware components to be

secured in placed and at the same time

connected together, with plugs at the base of

the rack, via the PLC bus

• Rack Mounted PLCs are commonly used in

modular and distributed type PLC systems.

They are well suited to service higher end

and plant wide applications where multiple

PLC racks and large numbers of inputs and

outputs are required. They have a fixed

number of hardware module slots and

generally have an orderd hardware module

layout.

• Such as power supply module, PLC processor

module, communication modules then input

and output modules.

• An example of a rack mounted PLC is the

Siemens Simatic S7-400. The PLC mounting

rack, rack slots, PLC bus and PLC modules are

clearly labelled. This particular PLC mounting

rack has 9 slots, with some PLC hardware

modules taking up multiple slots. See below….

PLC Rack

• Some PLC manufacturer use different

terminology to describe their rack mounted

PLCs. Terms such

as chassis, backplane, base, base

rack and base module are all examples of

different terminology to describe rack

mounted PLCs. Siemens uses the term PLC

rack for their S7-400 PLC mounting system.

• An example of a Siemens PLC rack is shown

below…

• Allen Bradley uses the term PLC chassis for

their Control Logix PLC mounting system. An

example of an Allen Bradley Control Logix

chassis is shown below….

• The term PLC backplane is used by the the

Omron CS1, Schneider Modicon M340 and

Delta AH series PLCs to describe their PLC

mounting system.

• Examples of the Omron CS1 series PLC

backplane, Delta AH Series PLC back plane

and Modicon M340 backplane are shown

below…

PLC Backplane

PLC base

• Koyo, Toshiba and Yokogawa use the

term PLC base to describe their PLC

mounting systems.

• Examples of the Koyo DL205 series PLC

base, Koyo DL405 series PLC base,

Yokogawa FA-M3V PLC base and the

Toshiba Type 1 Light Series PLC base.

You might also like

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- 1.introduction To PLCDocument47 pages1.introduction To PLCEmmanuel MatutuNo ratings yet

- Unit-I Introduction To PLC: What Is The Programmable Logic Controller (PLC) ?Document17 pagesUnit-I Introduction To PLC: What Is The Programmable Logic Controller (PLC) ?Bandi vennelaNo ratings yet

- 2.classification of PLCsDocument51 pages2.classification of PLCsEmmanuel MatutuNo ratings yet

- SPE 2321 Lectures 8Document40 pagesSPE 2321 Lectures 8Martinez MutaiNo ratings yet

- PLC 1Document30 pagesPLC 1dayyan hashimNo ratings yet

- Lecture 2 - PLC Components PDFDocument6 pagesLecture 2 - PLC Components PDFhozar abbasNo ratings yet

- Programmable Logic Controller OperationDocument4 pagesProgrammable Logic Controller OperationJacob MallariNo ratings yet

- In The Name of Allah The Most Benificet and The Most MercifulDocument24 pagesIn The Name of Allah The Most Benificet and The Most MercifulAsad RazaNo ratings yet

- PLC 30 PDFDocument272 pagesPLC 30 PDFnithinNo ratings yet

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- PLC1 BDocument91 pagesPLC1 BSymon Justine SañoNo ratings yet

- Programmable Logic ControllersDocument35 pagesProgrammable Logic ControllersBin MassoudNo ratings yet

- Nns Notes Ie PLCDocument13 pagesNns Notes Ie PLCNarendra SinhaNo ratings yet

- Programmable Logic Controller: Engr - Jama Adam SalahDocument158 pagesProgrammable Logic Controller: Engr - Jama Adam Salahjustus KamenyeNo ratings yet

- PLC Industrial AutoDocument17 pagesPLC Industrial Autoselar7347No ratings yet

- Control System Training - Session 07: PLC ArchitectureDocument25 pagesControl System Training - Session 07: PLC ArchitecturelinkskilNo ratings yet

- PLC 1703025724Document14 pagesPLC 1703025724Yeyen RoyhanNo ratings yet

- PLC Workshop 1-2 DayDocument120 pagesPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- Unit-II: Programmable Logic ControllersDocument74 pagesUnit-II: Programmable Logic ControllersNaga RajanNo ratings yet

- Programmable Logic Controllers: Introduction To PlcsDocument10 pagesProgrammable Logic Controllers: Introduction To PlcsSteveNo ratings yet

- Applications of PLCDocument23 pagesApplications of PLCJyoti Prakash Naik100% (1)

- Air Polution Control - Project (Rockwell)Document16 pagesAir Polution Control - Project (Rockwell)Chandan MandalNo ratings yet

- Fundamentals of PLCs ReviewDocument65 pagesFundamentals of PLCs ReviewPatrickSchardt100% (2)

- PLC Workshop 1-2 DayDocument119 pagesPLC Workshop 1-2 DayOwais Khan100% (2)

- PLC Based Sequential Batch Process CONTROL System1Document27 pagesPLC Based Sequential Batch Process CONTROL System1Ritesh Vaishnav100% (1)

- PLCPPTXDocument36 pagesPLCPPTXJohn Paul BruanNo ratings yet

- Tugas Bahasa Inggris KelompokDocument20 pagesTugas Bahasa Inggris Kelompokpyudi5169No ratings yet

- PLC - The Basics: Programmable Logic ControllersDocument69 pagesPLC - The Basics: Programmable Logic Controllersvinnu162No ratings yet

- Programmable Logic Controllers (PLCS)Document24 pagesProgrammable Logic Controllers (PLCS)MiguelNo ratings yet

- PLC 2Document26 pagesPLC 2UM ZaidNo ratings yet

- PLCDocument36 pagesPLCsonhack96No ratings yet

- PLCDocument34 pagesPLCManisha Sudeep Kaintura100% (2)

- Chapter 3 Introduction To PLC SystemDocument26 pagesChapter 3 Introduction To PLC SystemMuhammad AniqNo ratings yet

- Lect 001Document18 pagesLect 001lana_salahadinNo ratings yet

- Unit IV - MechatronicsDocument46 pagesUnit IV - Mechatronicsvivekananthan.mechNo ratings yet

- Programmable Logic Controller: Shankar JothyrajDocument39 pagesProgrammable Logic Controller: Shankar Jothyrajtt_aljobory3911No ratings yet

- Programmable Logic Controllers: May 19 Presentation TitleDocument27 pagesProgrammable Logic Controllers: May 19 Presentation Titlechafic WEISSNo ratings yet

- PLC Interview Questions With Answers Part 1Document54 pagesPLC Interview Questions With Answers Part 1Hagos AlemNo ratings yet

- Introduction To PLCsDocument42 pagesIntroduction To PLCsArun Kumar YadavNo ratings yet

- LECT01 - Introduction To PLCsDocument9 pagesLECT01 - Introduction To PLCsElisha MbiseNo ratings yet

- Manufacturing Automation Lecture 3Document55 pagesManufacturing Automation Lecture 3Kashan Aamir Aamir IshaqNo ratings yet

- PLCDocument111 pagesPLCNikhil Srivastava67% (3)

- Iii B.Tech Ii Sem Eie (R18)Document96 pagesIii B.Tech Ii Sem Eie (R18)Srinivas PapaniNo ratings yet

- Automation Project ReportDocument32 pagesAutomation Project ReportVicky Chaudhary100% (1)

- Programmable Logic Controller Lecture 6Document43 pagesProgrammable Logic Controller Lecture 6rowlandmollNo ratings yet

- PLCDocument26 pagesPLCSamNo ratings yet

- Module4 Programmable Logic ControllerDocument105 pagesModule4 Programmable Logic ControllerHemadri SubramanyaNo ratings yet

- A127474955 - 23429 - 4 - 2019 - PLC ProgrammingDocument37 pagesA127474955 - 23429 - 4 - 2019 - PLC Programmingbalakondaiah pNo ratings yet

- PLC Orientation 2.0Document27 pagesPLC Orientation 2.0HarisumiranNo ratings yet

- Programmable Logic ControllersDocument14 pagesProgrammable Logic ControllersStefan BotaNo ratings yet

- Programmable Logic Controllers (PLC) : Industrial Automation Unit 3Document14 pagesProgrammable Logic Controllers (PLC) : Industrial Automation Unit 3Dhananjay YelwandeNo ratings yet

- What Is PLC?Document3 pagesWhat Is PLC?AnirbanSenNo ratings yet

- What Is Programmable Logic Controllers (PLCS) ?Document6 pagesWhat Is Programmable Logic Controllers (PLCS) ?Md Omar FaruqueNo ratings yet

- Introduction To Robotics (Lab) : K. Menaka ThathsaranaDocument27 pagesIntroduction To Robotics (Lab) : K. Menaka ThathsaranaUditha MuthumalaNo ratings yet

- Mechatronics (302050) Lecture Notes / PPT Unit IvDocument63 pagesMechatronics (302050) Lecture Notes / PPT Unit IvSwapvaibNo ratings yet

- Unit 2Document96 pagesUnit 2eie.vgnt2023No ratings yet

- PLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLCDocument12 pagesPLC Ladder Logic: Nano PLC Micro PLC Mini PLC Compact PLC Small PLC Brick PLC Medium PLC Large PLC Modular PLCmanisha daundNo ratings yet

- Program Logic ControllerDocument49 pagesProgram Logic ControllerMuhammad Mukhlish HudaNo ratings yet

- Lecture 5 Keys and SplinesDocument6 pagesLecture 5 Keys and SplinesEmmanuel MatutuNo ratings yet

- Automation PLC ScadaDocument14 pagesAutomation PLC ScadaEmmanuel MatutuNo ratings yet

- Cover PageDocument1 pageCover PageEmmanuel MatutuNo ratings yet

- Final Timetable For Semester Ii Examinations of The Academic Year 2022/2023 TO Students Under Certificate and Diploma ProgrammesDocument45 pagesFinal Timetable For Semester Ii Examinations of The Academic Year 2022/2023 TO Students Under Certificate and Diploma ProgrammesEmmanuel MatutuNo ratings yet

- Machine Element and Design IDocument34 pagesMachine Element and Design IEmmanuel MatutuNo ratings yet

- Class Schedule: Schedule Start Time IntervalDocument2 pagesClass Schedule: Schedule Start Time IntervalAlexandra AlexievaNo ratings yet

- Nurhilal 2018 J. Phys. Conf. Ser. 1080 012024Document7 pagesNurhilal 2018 J. Phys. Conf. Ser. 1080 012024Emmanuel MatutuNo ratings yet

- Machine Element and Design IDocument54 pagesMachine Element and Design IEmmanuel MatutuNo ratings yet

- Diploma AssignmentDocument2 pagesDiploma AssignmentEmmanuel MatutuNo ratings yet

- Diploma AssignmentDocument2 pagesDiploma AssignmentEmmanuel MatutuNo ratings yet

- Basics of AutomationDocument142 pagesBasics of AutomationEmmanuel MatutuNo ratings yet

- Machine Element and Design IDocument54 pagesMachine Element and Design IEmmanuel MatutuNo ratings yet

- 5Document1 page5Emmanuel MatutuNo ratings yet

- Transcript - Chadwick BosemanDocument5 pagesTranscript - Chadwick BosemanEmmanuel MatutuNo ratings yet

- RefrigerationDocument7 pagesRefrigerationEmmanuel MatutuNo ratings yet

- An Engineering Education Project Using A Robot and Thermal Imaging To Automate and Analyze Ultrasonic Welding of PlasticsDocument12 pagesAn Engineering Education Project Using A Robot and Thermal Imaging To Automate and Analyze Ultrasonic Welding of PlasticsEmmanuel MatutuNo ratings yet

- Engineering Encyclopedia: Piping Maintenance and RepairDocument46 pagesEngineering Encyclopedia: Piping Maintenance and RepairEmmanuel MatutuNo ratings yet

- Unesco - Eolss Sample Chapters: Mechanical EngineeringDocument8 pagesUnesco - Eolss Sample Chapters: Mechanical EngineeringEmmanuel MatutuNo ratings yet

- MbeyaregDocument206 pagesMbeyaregEmmanuel MatutuNo ratings yet

- Constantinople in The QuranDocument144 pagesConstantinople in The Quranwaqar2010No ratings yet

- Transcript - Wentworth MillerDocument3 pagesTranscript - Wentworth MillerEmmanuel Matutu100% (1)

- Transcript - Denzel WashingtonDocument4 pagesTranscript - Denzel WashingtonEmmanuel MatutuNo ratings yet

- Robotic Welding TechnologyDocument43 pagesRobotic Welding TechnologyMuhammad Bilal100% (1)

- 1888ConstantinopleConventionon PDFDocument4 pages1888ConstantinopleConventionon PDFEmmanuel MatutuNo ratings yet

- MonalisaDocument1 pageMonalisaEmmanuel MatutuNo ratings yet

- CSET 06201 Computer Programming and Data Structure - Semester IIDocument70 pagesCSET 06201 Computer Programming and Data Structure - Semester IIEmmanuel MatutuNo ratings yet

- The Last SupperDocument2 pagesThe Last SupperEmmanuel MatutuNo ratings yet

- Hiram Abiff 2Document3 pagesHiram Abiff 2Emmanuel MatutuNo ratings yet

- Sandro Botticelli: MasterworksDocument1 pageSandro Botticelli: MasterworksEmmanuel MatutuNo ratings yet

- 31027718-HUAWEI BSC6000 System DescriptionDocument84 pages31027718-HUAWEI BSC6000 System Descriptionabkarimtc100% (1)

- OscillatorsDocument14 pagesOscillatorsSoundararajan RajagopalanNo ratings yet

- Examples E Solara Type1 and 2 01Document15 pagesExamples E Solara Type1 and 2 01kaibouNo ratings yet

- Customization Manual BV Fam R2.3 (Software Release 2.5.1)Document51 pagesCustomization Manual BV Fam R2.3 (Software Release 2.5.1)Bassam GhaziNo ratings yet

- Service Oriented Architecture Reference Model: An Informal SOA OntologyDocument22 pagesService Oriented Architecture Reference Model: An Informal SOA OntologySudhir BiswalNo ratings yet

- Certified Labview Developer Examination: InstructionsDocument8 pagesCertified Labview Developer Examination: InstructionsAugustineEsperonParondaNo ratings yet

- Sage ERP X3: Development Part 1 Exercises Level 1Document24 pagesSage ERP X3: Development Part 1 Exercises Level 1Yahya ChiguerNo ratings yet

- Excel Tips 2013 (Javed Iqbal Awan We Creat PDF Chemistry 03078162003)Document7 pagesExcel Tips 2013 (Javed Iqbal Awan We Creat PDF Chemistry 03078162003)waqarNo ratings yet

- DDO TipsDocument9 pagesDDO TipsRich Vincent100% (1)

- Success Is in Our Own HandsDocument12 pagesSuccess Is in Our Own HandsEnp Gus AgostoNo ratings yet

- IkeGPS 2 Page BrochureDocument2 pagesIkeGPS 2 Page BrochureShawn FausNo ratings yet

- Fortune - Tafadzwa - Madzivo - Infrastructure & Cyber Security OfficerDocument4 pagesFortune - Tafadzwa - Madzivo - Infrastructure & Cyber Security OfficerFortune Tafadzwa MadzivoNo ratings yet

- Hong Kong Shanghai Maitrox Services Limited: Packing List/Weight MemoDocument4 pagesHong Kong Shanghai Maitrox Services Limited: Packing List/Weight MemoEndang KusnadiNo ratings yet

- Broadband Policy-Draft - EnglishDocument16 pagesBroadband Policy-Draft - EnglishReg BhandariNo ratings yet

- Thesis ProposalDocument2 pagesThesis ProposalbadarkhanlodhiNo ratings yet

- IEEE 24748-5 - 2017 - SW Development PlanningDocument48 pagesIEEE 24748-5 - 2017 - SW Development Planningangel tomas guerrero de la rubiaNo ratings yet

- Instant Download Macroeconomics 12th Edition Arnold Test Bank PDF Full ChapterDocument21 pagesInstant Download Macroeconomics 12th Edition Arnold Test Bank PDF Full Chapterdrusilladaisyvlz9a100% (6)

- Cybercrime Tactics and Techniques: Q3 2018: Provided byDocument27 pagesCybercrime Tactics and Techniques: Q3 2018: Provided byAndres Felipe CameroNo ratings yet

- Thar MN04-20CE - ABPR-20 Operator Manual PDFDocument53 pagesThar MN04-20CE - ABPR-20 Operator Manual PDFSerge LapointeNo ratings yet

- Firmware Functional Description MPH-04, MPB-04, MPD-04 R911315485 - 02 PDFDocument914 pagesFirmware Functional Description MPH-04, MPB-04, MPD-04 R911315485 - 02 PDFCristopher EntenaNo ratings yet

- Class 2Document56 pagesClass 2Fizza MunirNo ratings yet

- Durbin LevinsonDocument7 pagesDurbin LevinsonNguyễn Thành AnNo ratings yet

- Itt320 Quiz (Question)Document9 pagesItt320 Quiz (Question)tesqNo ratings yet

- Kodak DirectView CR-825,850 - Diagrams PDFDocument12 pagesKodak DirectView CR-825,850 - Diagrams PDFAgustín CarranzaNo ratings yet

- NTA UGC NET Electronic Science SyllabusDocument3 pagesNTA UGC NET Electronic Science Syllabusgrk.elrNo ratings yet

- ChatLog - K21Academy - AWS Solutions Architect - SAA - C02 - Training Day 1 Meeting Invite 2020 - 12 - 19 08 - 41Document2 pagesChatLog - K21Academy - AWS Solutions Architect - SAA - C02 - Training Day 1 Meeting Invite 2020 - 12 - 19 08 - 41Fanof AbhijeetNo ratings yet

- Empowerment Technologies: 4th Quarter Week 1Document11 pagesEmpowerment Technologies: 4th Quarter Week 1Kay Tracey Aspillaga UrbiztondoNo ratings yet

- Google File System (GFS)Document18 pagesGoogle File System (GFS)Mohit GautamNo ratings yet

- Information & Communication Technology IN District JudiciaryDocument74 pagesInformation & Communication Technology IN District JudiciaryDontknowNo ratings yet

- Kyo 32Document28 pagesKyo 32Kulik AndreiNo ratings yet