Professional Documents

Culture Documents

Tugas Bahasa Inggris Kelompok

Uploaded by

pyudi51690 ratings0% found this document useful (0 votes)

2 views20 pagesCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views20 pagesTugas Bahasa Inggris Kelompok

Uploaded by

pyudi5169Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 20

Introduction to PLC

(Programmable Logic Controller)

Hendra Catur Satria B R (2040201012)

Fajar Maulana Ibrahim (2040201119)

Yudi Prayoga (2040201145)

Yusma Aprillia Novani (2040201039)

History

• Initially machines were controlled by gears,

levers and other basic mechanical equipment.

• Machines require more sophisticated equipment

involving relays and switch control elements→

control logic for certain types of machines.

• Electromechanical control systems that use

relays have many weaknesses.

Weaknesses of the relay system

• The contacts used are easily worn out due to

heat/burning or due to short

circuitsmembutuhkan biaya yang besar saat

instalasi.

• Maintenance and modification of the system that

has been created if modifications are needed in

the future.

• etc

PLC

• PLC pertama kali dikembangkan pada tahun akhir 1960 –

akhir 1970.

• PLC is the abbreviation of Programmable Logic Controller.

• By using a PLC, difficulties in relay systems can be

overcome, because the PLC system integrates various

independent component into an integrated control system

and can easily be renovated without having to replace all

existing instruments.

• Still experiencing difficulties at the beginning of its

development due to the impractical language and untrained

users.

Basically, a PLC is a microprocessor-based

electronic device that utilizes

programmable memory to store

instructions that implement functions such

as logic, sequencing, timing, counting and

arithmetic to control machines and

processes. process in a control (controller)

using a computer and programming

language.

PLC Concept

The concept of PLC as the name suggests is as follows:

• Programmable : shows its ability to be easily changed

according to the program created and its ability in

terms of program memory that has been created.

• Logic : show its ability to process input arithmetic

(ALU), namely carrying out operations of comparing,

adding, multiplying, dividing, subtracting and

negating.

• Controller : demonstrate the ability to control and

organize processes so as to produce the desired

output.

PLC Function

The functions and uses of PLC can be said to be

almost unlimited. But in practice it can be divided

into general and specific. In general, the function

of a PLC is as follows:

• Sequential Control

The PLC processes binary signal input into

output which is used for technical processing

purposes sequentially, here the PLC ensures that

all steps in the sequential process take place in

the right order.

• Monitoring Plant

The PLC continuously monitors a system (e.g.

temperature, pressure, altitude level) and takes

necessary action regarding the controlled

process (e.g. a value has exceeded a limit) or

displays the message to the operator.

PLC vs Conventional System

• PLC can perform complec mathematical

functions including numerical analysis of

integration and differentiation.

• PLC can work in heavy industrial conditions

(high pollution, temperature 0-60°

• Other PLC advantages:

- work reliably, safely and flexibly.

- saves on the amount of wiring.

- simple programming using language and

instructions that are easy to understand.

- easy installation or installation.

Blok Diagram of Main PLC Components

Work Principle PLC

Sumber : bahan kuliah PLC Programming Basic , 2006, MIT

• The CPU or processor unit is a unit that

contains a microprocessor that interprets

input signals and carries out control actions,

according to the program stored in memory,

then communicates the decisions it takes as

control signals to the output interface.

• Power Supply or power supply unit is needed

to convert the source AC voltage into low DC

voltage (5, 12 or 24 volts) needed by the

processor and circuits in the input and

output interface modules.

Programming Device or programming

device is a device used to edit, input,

modify and monitor programs in PLC

memory.

The parts of PD or PDT (Programming

Device Terminal) are the monitor and

keyboard.

In PLC there are 3 types of PD, namely:

- Special Purpose is a PD device similar

to a special computer used for PLC

programming.

- A keypad is equipment similar to a

calculator that is specifically used

for PLC programming.

- Personal Computer or PC is a

programming device used to control

a PLC using a personal computer.

The program created in the

Programming Device is then moved

into the PLC memory unit.

• Programming Memory or Memory Unit

is the part that functions to store

instructions, programs and data.

• An input/output module is an electronic

device or equipment that functions as an

intermediary or interface between the

CPU and external input or output

equipment. This module is installed

non-permanently or is easy to remove

and reinstall on the shelf.

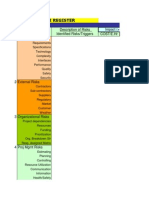

Types of Input/Output Devices

Based on the working voltage used, input/output devices

can be grouped into three, namely:

- Input/output module with a supply voltage of 200 V to

400 V AC.

- Input/output module with a supply voltage of 100 V to 120

V AC.

- Input/output module with supply voltage 12 V to 120 V

AC.

The input/output voltage from the input device or output

device module can be divided into 12 V DC or 24 V DC

according to the I/O module used.

Arsitektur Internal PLC

Various Types of PLC

The smallest size Mitsubishi PLC Direct DL 105 with 18

PLC with 14 I/O I/O and capacity of 6 A per

output channel

Giddings & Lewis PIC90 with

Allen Bradley PLC 5/15 (512

128 I/O capacity and

I/O)

movement control capability

Omron C200H PLC (1392 I/O) Allen Bradley PLC 5/80

(3072 I/O)

You might also like

- Programmable Logic Controllers (PLC) : Powerpoint Presentation OnDocument17 pagesProgrammable Logic Controllers (PLC) : Powerpoint Presentation OnSumanAgarwalNo ratings yet

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- Developers Guide For Tricon, TriStation v1.1Document442 pagesDevelopers Guide For Tricon, TriStation v1.1velusunilNo ratings yet

- SPE 2321 Lectures 8Document40 pagesSPE 2321 Lectures 8Martinez MutaiNo ratings yet

- Introduction to PLC Programming LanguagesDocument17 pagesIntroduction to PLC Programming LanguagesBandi vennelaNo ratings yet

- PLC Applications and Uses ExplainedDocument23 pagesPLC Applications and Uses ExplainedJyoti Prakash Naik100% (1)

- EJ501 T3 PLC IntroductionDocument44 pagesEJ501 T3 PLC IntroductionLoga HSNo ratings yet

- PLCDocument36 pagesPLCsonhack96No ratings yet

- What Is A PLC-introductionDocument18 pagesWhat Is A PLC-introductionUma100% (1)

- Programmable Logic Controllers (PLC) SyllabusDocument14 pagesProgrammable Logic Controllers (PLC) SyllabusDhananjay YelwandeNo ratings yet

- Programmable Logic Controllers (PLCS) : Basics, Types & ApplicationsDocument19 pagesProgrammable Logic Controllers (PLCS) : Basics, Types & ApplicationsAmol PatilNo ratings yet

- What Is A PLCDocument8 pagesWhat Is A PLChafizarslanmushtaq0No ratings yet

- PNEUMATICSDocument33 pagesPNEUMATICSAllysa Grace SobradoNo ratings yet

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- PLC Industrial AutoDocument17 pagesPLC Industrial Autoselar7347No ratings yet

- PLC Based Sequential Batch Process CONTROL System1Document27 pagesPLC Based Sequential Batch Process CONTROL System1Ritesh Vaishnav100% (1)

- PLC Programming for Mechatronics Control SystemsDocument63 pagesPLC Programming for Mechatronics Control SystemsSwapvaibNo ratings yet

- Basics of PLC Workshop - Day 1 AgendaDocument119 pagesBasics of PLC Workshop - Day 1 AgendaOwais Khan100% (2)

- 1.introduction To PLCDocument47 pages1.introduction To PLCEmmanuel MatutuNo ratings yet

- PLCPPTXDocument36 pagesPLCPPTXJohn Paul BruanNo ratings yet

- Bahan Ajar PLCDocument64 pagesBahan Ajar PLCsinsemila278070No ratings yet

- Programmable Logic Controller (PLC) and AutomationDocument24 pagesProgrammable Logic Controller (PLC) and AutomationJeeva RajNo ratings yet

- Basic PLC Hardware and Programming GuideDocument77 pagesBasic PLC Hardware and Programming Guideasfarooq029No ratings yet

- PLCDocument77 pagesPLCZakir Uddin Ahmad100% (1)

- Ch1 Overview 4502734Document51 pagesCh1 Overview 4502734khaled99No ratings yet

- Programmable Logic Controller (PLC) GuideDocument13 pagesProgrammable Logic Controller (PLC) GuideNarendra SinhaNo ratings yet

- Air Polution Control - Project (Rockwell)Document16 pagesAir Polution Control - Project (Rockwell)Chandan MandalNo ratings yet

- Mechatronics CHAPTER 5Document61 pagesMechatronics CHAPTER 5NahomNo ratings yet

- Assignment A PCIDocument20 pagesAssignment A PCISanjay SundaralingamNo ratings yet

- Learning Objectives Upon Completion of This Chapter, Student Should Be Able ToDocument31 pagesLearning Objectives Upon Completion of This Chapter, Student Should Be Able Tormfaisalarafat1108No ratings yet

- Unit-II: Programmable Logic ControllersDocument74 pagesUnit-II: Programmable Logic ControllersNaga RajanNo ratings yet

- Basic PLC (Compatibility Mode)Document39 pagesBasic PLC (Compatibility Mode)Royal Ritesh SharmaNo ratings yet

- Introduction to PLC Programming & ComponentsDocument77 pagesIntroduction to PLC Programming & ComponentsAsgher KhattakNo ratings yet

- Auto and ControlDocument54 pagesAuto and Controlsupriya kharageNo ratings yet

- PLC m1Document11 pagesPLC m1Goutham KNo ratings yet

- Chapter 3 Introduction To PLC SystemDocument26 pagesChapter 3 Introduction To PLC SystemMuhammad AniqNo ratings yet

- PLC and PLC TechnologiesDocument28 pagesPLC and PLC Technologieskatjinomasa kavetuNo ratings yet

- Programmable Logic Controller: Shankar JothyrajDocument39 pagesProgrammable Logic Controller: Shankar Jothyrajtt_aljobory3911No ratings yet

- Control System Training - Session 07: PLC ArchitectureDocument25 pagesControl System Training - Session 07: PLC ArchitecturelinkskilNo ratings yet

- Industrial Control System IDocument28 pagesIndustrial Control System IIsaac KimaruNo ratings yet

- Programmable Logic Controller OperationDocument4 pagesProgrammable Logic Controller OperationJacob MallariNo ratings yet

- Programmable Logic Controller Applications and UsesDocument5 pagesProgrammable Logic Controller Applications and Usessumit100% (1)

- PLC Notes-3Document32 pagesPLC Notes-3PravinNo ratings yet

- In The Name of Allah The Most Benificet and The Most MercifulDocument24 pagesIn The Name of Allah The Most Benificet and The Most MercifulAsad RazaNo ratings yet

- Programmable Logic ControllersDocument35 pagesProgrammable Logic ControllersBin MassoudNo ratings yet

- PLCDocument87 pagesPLCAnoop RaviNo ratings yet

- PLC Basics Tutorial: What Is A PLC?Document6 pagesPLC Basics Tutorial: What Is A PLC?nov17muraliNo ratings yet

- PLC Workshop 1-2 DayDocument120 pagesPLC Workshop 1-2 DayHamza Khan Khattak100% (1)

- PLCDocument111 pagesPLCNikhil Srivastava67% (3)

- Programmable Logic Controller (PLC) DocumentationDocument225 pagesProgrammable Logic Controller (PLC) Documentation447 KusumanjaliNo ratings yet

- Report On PLCDocument17 pagesReport On PLCRahul SaxenaNo ratings yet

- CHP 2Document9 pagesCHP 2BRIAN CLIFFNo ratings yet

- Components of PLCDocument52 pagesComponents of PLCStella Pink0% (1)

- Industrial AutomationDocument16 pagesIndustrial Automationvivek6681No ratings yet

- PLC QuestionsDocument17 pagesPLC QuestionsbahyNo ratings yet

- PLC 1703025724Document14 pagesPLC 1703025724Yeyen RoyhanNo ratings yet

- IA Lab Manual.1pdf-1Document64 pagesIA Lab Manual.1pdf-1Harsh GajjarNo ratings yet

- PLC (Programmable Logic Control)Document57 pagesPLC (Programmable Logic Control)sunilNo ratings yet

- PLCDocument13 pagesPLCChalez ZengeretsiNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Java NotesDocument95 pagesJava NotesJanhviNo ratings yet

- C program examplesDocument13 pagesC program examplesS.m. MonimNo ratings yet

- Basic ComputerDocument3 pagesBasic ComputerDreime Estandarte-DecretoNo ratings yet

- IS621 CHAPTER ONE INTRODUCTIONDocument39 pagesIS621 CHAPTER ONE INTRODUCTIONChivaal PersothamNo ratings yet

- PythonDocument5 pagesPythonksravanpaniNo ratings yet

- Project works for Class XI subjectsDocument8 pagesProject works for Class XI subjectsAliyash khanNo ratings yet

- PLC vs DCS: Key Differences Between Programmable Logic Controllers and Distributed Control SystemsDocument4 pagesPLC vs DCS: Key Differences Between Programmable Logic Controllers and Distributed Control SystemsBhavik ShahNo ratings yet

- Risk RegisterDocument34 pagesRisk RegisterMohamedMoideenNagoorMeeran33% (3)

- Notes On Engineering ComputingDocument215 pagesNotes On Engineering ComputingShayan RazaNo ratings yet

- Electricity Bill Project ReportDocument77 pagesElectricity Bill Project ReportRavi KumarNo ratings yet

- Limit Switch (Throttle Lock Deactivation) (Electronic Technician) - AdjustDocument7 pagesLimit Switch (Throttle Lock Deactivation) (Electronic Technician) - AdjustRAMON CALDERONNo ratings yet

- Program Execution: Operating System System Operating Systems SystemsDocument3 pagesProgram Execution: Operating System System Operating Systems SystemsMUHAMMAD ATTIQUENo ratings yet

- Modules-1 Problem Solving Using Java (CSE 1004)Document64 pagesModules-1 Problem Solving Using Java (CSE 1004)Arghadeep GhoshNo ratings yet

- NI - VISA TutorialDocument25 pagesNI - VISA TutorialpbackeriNo ratings yet

- Computer Networks: EEC 484 Instructor: Sanchita Mal-SarkarDocument23 pagesComputer Networks: EEC 484 Instructor: Sanchita Mal-SarkarHamdi BenNo ratings yet

- Computer 3prep Scond Term EnglishDocument66 pagesComputer 3prep Scond Term EnglishMahmoud MuhammadNo ratings yet

- PLC Teaching BookDocument167 pagesPLC Teaching BookMitchell Daniels100% (2)

- Tasking C196 ManualDocument389 pagesTasking C196 Manualusmancheema81No ratings yet

- 'Employability Skills-PART-A Unit-3 Class 10Document5 pages'Employability Skills-PART-A Unit-3 Class 10Manasa NutiNo ratings yet

- CSO Gaddis Java Chapter01Document60 pagesCSO Gaddis Java Chapter01ẂalaMohammadNo ratings yet

- COMPUTER ORGANIZATION AND ARCHITECTURE Notes & Ebook PDFDocument138 pagesCOMPUTER ORGANIZATION AND ARCHITECTURE Notes & Ebook PDFSulekha100% (1)

- Java ProgramsDocument94 pagesJava ProgramsIndu AppleNo ratings yet

- S7-PLCSIM - Testing Your S7-CPU Programs - ManualDocument82 pagesS7-PLCSIM - Testing Your S7-CPU Programs - Manualsouza13021986No ratings yet

- Question Bank MCQ Questions: Shivaji University, KolhapurDocument9 pagesQuestion Bank MCQ Questions: Shivaji University, KolhapurSakshi KoliNo ratings yet

- The RFC GeneratorDocument47 pagesThe RFC GeneratoraniczoranNo ratings yet

- Smart Note TakerDocument24 pagesSmart Note Takerveparashar07No ratings yet

- Computer Teaching BookDocument84 pagesComputer Teaching Bookaditya kumarNo ratings yet

- Viva Questions Class 12Document28 pagesViva Questions Class 12aryabhumika946No ratings yet