Professional Documents

Culture Documents

OEE Calculator Sylution2

OEE Calculator Sylution2

Uploaded by

amr mohamed0 ratings0% found this document useful (0 votes)

4 views1 pageCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageOEE Calculator Sylution2

OEE Calculator Sylution2

Uploaded by

amr mohamedCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

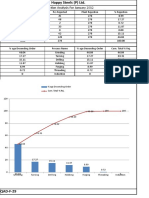

OEE Calculator

This is a chart showing how OEE metrics are calculated. The first two metrics, Lights Out Time and Lights On Time measure how well Planed Downtime

time is used. Planed Downtime time is the time that is used for maintenance, and cleaning when no sellable production is planned. The remaining metrics

measure how well the time during a shift is used towards sellable production. Use the calculator by filling in the light "Blue Fields" with your values.

Planned Downtime OEE Time Base (Planned Run Time)

Time Period (days): 7 (days) Total Time (24x7) Full Week

Weekly

Idle Time

Lights On Time

Weekly

Planned Downtime Shift Planned Shift Length (min): 480 Scheduled Shift Time

Downtime

( Lights Out Time )

On Time )

( Lights OEE Time Base Operators Present Shift Time

(hrs) (hrs) (min/shift)

Availability Loss Shift Up Time

ShutDown 24 Cleaning 0 Lunch 30

0 30

(Unplanned Downtime) Actual

ChangeOver Breaks Performance Loss

PMs 12 Meetings 0 Line Speed (units/min) After Speed Loss Production

Expected

Other 0 Other 0 Shift 70 Actual 95 Quality Loss

Total 12 Total 60 Downtime (min/shift) Design 100 Scrap % 3.00%

Lights Out Shift Planned

Lights On Time Availability Performance Quality

Time Downtime

( Shifts ) ( Shifts ) ( Minutes per Shift ) ( Minutes per Shift ) ( Minutes per Shift ) ( Minutes per Shift )

Available 21.0 Available 18.0 Available 480.0 Available 420.0 Available 350.0 Available 332.5

Used 3.0 Used 1.5 Used 60.0 Used 70.0 Used 17.5 Used 10.0

Left 18.0 Left 16.5 Left 420.0 Left 350.0 Left 332.5 Left 322.5

85.7% 91.7% 87.5% 83.3% 95.0% 97.0%

OEE ( Overall Equipment Effectiveness ) OEE

83.3% x 95.0% x 97.0% = 76.8%

Lights On OEE Lights ON

91.7% x 87.5% x 83.3% x 95.0% x 97.0% = 61.6%

TEEP (Total Effective Equipment Performance): 24/7 Utilization TEEP

85.7% x 91.7% x 87.5% x 83.3% x 95.0% x 97.0% = 52.8%

Sylution Incorporated ● www.sylution.com ● (800) 254-9140

You might also like

- OEE Template Version 01 PHDocument11 pagesOEE Template Version 01 PHAjitNo ratings yet

- Value Stream VSM TemplateDocument6 pagesValue Stream VSM TemplateAndrea Jesus Quenta VillarrealNo ratings yet

- Writing Good Multiple Choice Test QuestionsDocument10 pagesWriting Good Multiple Choice Test QuestionsAndi Ulfa Tenri PadaNo ratings yet

- Overall Equipment Efficiency: Sis - Tpm-AmDocument14 pagesOverall Equipment Efficiency: Sis - Tpm-AmShamasNo ratings yet

- OEE Calculation USDocument3 pagesOEE Calculation USBenjamin MossoNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- OEE Calculation USDocument1 pageOEE Calculation USankur panwarNo ratings yet

- OEE Calculation USDocument2 pagesOEE Calculation USFeroz GullNo ratings yet

- OEE Explained PDFDocument3 pagesOEE Explained PDFcarrot123456No ratings yet

- Lean CalculatorDocument28 pagesLean CalculatorFrank Rojas100% (1)

- Job Schedule Sheet: Machine Component Job Description Planned by Wo NoDocument8 pagesJob Schedule Sheet: Machine Component Job Description Planned by Wo NoYudha RafiNo ratings yet

- MTTR and MTBFDocument4 pagesMTTR and MTBFchandrashekharNo ratings yet

- Assembly Lean Assessmentv1Document19 pagesAssembly Lean Assessmentv1Leontin LeonNo ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- RELIABILITYDocument10 pagesRELIABILITYElle Cee EmmeNo ratings yet

- Transfer PricingDocument29 pagesTransfer PricinghezronNo ratings yet

- Root Cause Analysis FormDocument2 pagesRoot Cause Analysis Formgunnery02No ratings yet

- Adem Jashari SchwandnerDocument17 pagesAdem Jashari SchwandnerAlbanBoNo ratings yet

- Oee (Referencia Rapida) PDFDocument2 pagesOee (Referencia Rapida) PDFVíctor Hugo Carvajal GaticaNo ratings yet

- OEE CalculationDocument2 pagesOEE CalculationSudhaNo ratings yet

- MODEL Moulding OEE Report WeekDocument194 pagesMODEL Moulding OEE Report WeekOctavian MitaNo ratings yet

- ICAS - Initial Capacity Assessment Sheet - 2010-12-09Document15 pagesICAS - Initial Capacity Assessment Sheet - 2010-12-09pchakkrapaniNo ratings yet

- OEE Calculation USDocument2 pagesOEE Calculation USchemist_tmaNo ratings yet

- Kobetsu Kaizen Activities: Chapter - 4Document11 pagesKobetsu Kaizen Activities: Chapter - 4Amalendu Sundar MandalNo ratings yet

- Calculate OEE - Definitions, Formulas, and ExamplesDocument4 pagesCalculate OEE - Definitions, Formulas, and ExamplescleitonmoyaNo ratings yet

- What Is The Purpose of The Tco Calculator?: Homepage - Procurement - Govt.NzDocument4 pagesWhat Is The Purpose of The Tco Calculator?: Homepage - Procurement - Govt.NzDeepak VeerNo ratings yet

- LEAN Execution OEEDocument11 pagesLEAN Execution OEEVergence Business Associates100% (7)

- Maintenance SWOTDocument1 pageMaintenance SWOTJohnNo ratings yet

- OEE Calculation Example: Factors Number of Shifts Hours Per Shift TimeDocument5 pagesOEE Calculation Example: Factors Number of Shifts Hours Per Shift Timetarunkumar6262100% (1)

- Cost Weighted OEE TemplateDocument10 pagesCost Weighted OEE TemplateSAMGPRONo ratings yet

- DashboardDocument6 pagesDashboardIndah RatuNo ratings yet

- Opr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableDocument3 pagesOpr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableSudhaNo ratings yet

- Rejection Analysis For January 2012: % Age Desending Order Cum. Total % RejDocument7 pagesRejection Analysis For January 2012: % Age Desending Order Cum. Total % RejazadNo ratings yet

- d3 Sec 1 Maintenance PrinciplesDocument64 pagesd3 Sec 1 Maintenance PrinciplesGérard PIERRE LOUISNo ratings yet

- Uganda Tourism PolicyDocument30 pagesUganda Tourism PolicyDerrick Patrick Waiswa100% (11)

- Quality Dashboard RKFL Dashboard Apr 2022Document4 pagesQuality Dashboard RKFL Dashboard Apr 2022ASHIM PAULNo ratings yet

- Simple Oee SpreadsheetDocument2 pagesSimple Oee SpreadsheetadeNo ratings yet

- Lead Time - 001Document18 pagesLead Time - 001Purushothama Nanje GowdaNo ratings yet

- Production KPI 22Document3 pagesProduction KPI 22Senthilmani MuthuswamyNo ratings yet

- Manufacturing KPI Review by CEO-Aug Final 10Document41 pagesManufacturing KPI Review by CEO-Aug Final 10ramapvk100% (1)

- GNM - Zicta Week 41 01102020 (F)Document270 pagesGNM - Zicta Week 41 01102020 (F)andrewnkhuwa17No ratings yet

- Oee 3Document2 pagesOee 3Lowell HarperNo ratings yet

- OEE Januari 2021Document292 pagesOEE Januari 2021bimaNo ratings yet

- 10 MovementDocument26 pages10 MovementjvanandhNo ratings yet

- DMAIC Process IllustrationDocument14 pagesDMAIC Process Illustrationsqaiba_gNo ratings yet

- Value Stream MapTemplateDocument6 pagesValue Stream MapTemplatebuddy-20087751No ratings yet

- 7146 01 World Data Dashboard For Powerpoint 16x9Document2 pages7146 01 World Data Dashboard For Powerpoint 16x9Elma PuspaningtyasNo ratings yet

- Impact of Defects-Measuring Defect LevelsDocument16 pagesImpact of Defects-Measuring Defect LevelsDiego FloresNo ratings yet

- OEE OPE CalculationDocument1 pageOEE OPE CalculationJuan PabloNo ratings yet

- Indicators Performances Lafiguie Mars 2023Document1 pageIndicators Performances Lafiguie Mars 2023Yves Crescent AdonNo ratings yet

- Programming Guide: VLT Automationdrive FC 360Document144 pagesProgramming Guide: VLT Automationdrive FC 360nitin hadkeNo ratings yet

- Dashboard & Data Visualization Course PresentationDocument77 pagesDashboard & Data Visualization Course PresentationMWANGI BRIAN KIRIGWINo ratings yet

- Digital Marketing Dashboard Template: Paid Media Organic MediaDocument5 pagesDigital Marketing Dashboard Template: Paid Media Organic MediaAwais ZafarNo ratings yet

- Maintenance Pyramid NewDocument13 pagesMaintenance Pyramid NewYen NguyenNo ratings yet

- Assembly-Line Balancing: A Valuable Tool For Increasing EfficiencyDocument20 pagesAssembly-Line Balancing: A Valuable Tool For Increasing Efficiencyaqsa imranNo ratings yet

- Types of ReliabilityDocument39 pagesTypes of ReliabilityAydila SaputriNo ratings yet

- Plant Loss Tree DataDocument1 pagePlant Loss Tree DataJoseph OrjiNo ratings yet

- REYES. Evidence-2021-Activity-1-1Document7 pagesREYES. Evidence-2021-Activity-1-1Diana Rose DalitNo ratings yet

- Material Holding Cost TempDocument5 pagesMaterial Holding Cost TempPeracha EngineeringNo ratings yet

- Reliability PPT Day3 SampleDocument12 pagesReliability PPT Day3 SampleFarash Muhamed100% (2)

- COPQ TrackerDocument2 pagesCOPQ Trackergopalranjan_2000939No ratings yet

- Oee in PracticeDocument30 pagesOee in PracticeAlois AmaldNo ratings yet

- Line Balancing SheetDocument2 pagesLine Balancing SheetWaqar DarNo ratings yet

- Key Concepts of Supply Chain ManagementDocument28 pagesKey Concepts of Supply Chain ManagementMASROOR ALI SOOMRONo ratings yet

- OEE TempletDocument2 pagesOEE Templetashutoshpal21No ratings yet

- Calculating Oee Worksheet: Line / Cell: Process: Machine: DateDocument2 pagesCalculating Oee Worksheet: Line / Cell: Process: Machine: DateKabul AbdullahNo ratings yet

- Word Files Expression of InterestDocument4 pagesWord Files Expression of Interestapi-3700469100% (2)

- English 2b Assignment 2 Jessica Campbell 18352955Document5 pagesEnglish 2b Assignment 2 Jessica Campbell 18352955api-408361297No ratings yet

- DocDocument550 pagesDocMD MABUDNo ratings yet

- Evaluation ToolsDocument11 pagesEvaluation Toolssuchismita panda100% (1)

- Criteria For BroadcastingDocument2 pagesCriteria For BroadcastingAmihan GrandeNo ratings yet

- Job Description For ReceptionDocument2 pagesJob Description For Receptionadriana1cmNo ratings yet

- Module 6 FinalDocument31 pagesModule 6 FinalElaine Felipe MarquezNo ratings yet

- Assignment No. 1Document2 pagesAssignment No. 1jnk ratedNo ratings yet

- Cikal Application Form Excel 2018Document3 pagesCikal Application Form Excel 2018Ranger BiruNo ratings yet

- Industrial RevolutionDocument11 pagesIndustrial RevolutionLisa BangsNo ratings yet

- Divisional Women'S Sports Complex: in ChattogramDocument6 pagesDivisional Women'S Sports Complex: in ChattogramTareq NehalNo ratings yet

- CASE STUDY by Dexian Consulting - Smart Factory Creation - EnglishDocument2 pagesCASE STUDY by Dexian Consulting - Smart Factory Creation - EnglishNitika SharmaNo ratings yet

- Case Study - Agvs - ProcurementDocument17 pagesCase Study - Agvs - ProcurementSrividhyaNo ratings yet

- Scope of Engineering EthicsDocument3 pagesScope of Engineering EthicsanissfarhanaaNo ratings yet

- 1 Brief History of NTSPDocument3 pages1 Brief History of NTSPVincent Knight Y. SaliganNo ratings yet

- Kaduna Soil PlainsDocument18 pagesKaduna Soil PlainsZINART MUSANo ratings yet

- Total Quality ManagementDocument25 pagesTotal Quality ManagementDark LordNo ratings yet

- Suzich Jaqueline Resume July 2017Document2 pagesSuzich Jaqueline Resume July 2017api-316774688No ratings yet

- PUB100373Document12 pagesPUB100373saba0707No ratings yet

- The Inca Masters of The CloudsDocument1 pageThe Inca Masters of The CloudsJavi EdNo ratings yet

- Introduction To ComputingDocument21 pagesIntroduction To ComputingNauman Abbas GondalNo ratings yet

- Student Literacy Discipline ReflectionDocument4 pagesStudent Literacy Discipline Reflectionapi-451215422No ratings yet

- Prof Arup Barman 2020-21Document4 pagesProf Arup Barman 2020-21Arup BarmanNo ratings yet

- RDJ ResumeDocument2 pagesRDJ ResumeRaymond Mapusao AndesNo ratings yet