Professional Documents

Culture Documents

MT1-A22 Blank CNC Lathe Process Sheet

Uploaded by

niroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT1-A22 Blank CNC Lathe Process Sheet

Uploaded by

niroCopyright:

Available Formats

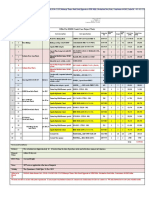

DEPARTMENT OF MACHINING TECHNIQUES

Process Sheet

DWG#: PART NAME: QTY: OPERATION: LATHE

REV: PROGRAMMER: MATERIAL:

PROGRAM#: O MACHINE/CONTROL: GOODWAY/ HAAS

SHEET OF ISSUE DATE: DUE DATE: ASAP

OPER OFFSET OPERATION TOOL HOLDER FEED D.O.C

SFM

# # NAME DESCRIPTION TYPE (ipr/ipm) a

( p)

T0404

MWLNR16-4D

N10 P3 Stopper WNMG432-A KTM10U

(3/4 SHANK OR 1’’)

---------- ---------- ----------

R.03125

T0505 800

.008

MWLNR16-4D (650-1600SFM)

N20 P3 Facing WNMG432-A KTM10U

(3/4 SHANK OR 1’’) P.49

(.008-.02 IPR)

P.48

R.03125

T0505 Roughing profile 800

.008

MWLNR16-4D (650-1600SFM)

N30 P3 G71 WNMG432-A KTM10U

(3/4 SHANK OR 1’’) P.49

(.008-.02 IPR)

P.48

R.03125 USED TNRC

T KEEP.006

Plain center drill#4

N40 P Center drilling (pointØ.125, shankØ5/16)

Collet or drill chuck (.005-.007ipr)

p.58

R

T Drilling with sub-

200-300 sfm

N50 P program HSS drill (Ø______’’) Collet or drill chuck p.56

R (#_____)

T

Tapping with Carbide ______ spiral-point KEEP 50 SFM

.0393ipr KEEP .75’’

N60 P tap OR spiral fluted

Collet (50-65 sfm)

p.98

G32 OR G84 p.98

R

T Finishing profile KEEP 900 SFM FINISH ALL

VCGT332-AP KT10U SVJCR16-3D

N70 P G7_ (PVD COATED) (3/4’’ OR 1’’ SHANK)

(700-1000SFM) AROUND

P.49

R USED G41/G42

T A2040N00CF02- KC5025

Part-off and KEEP 400SFM KEEP .0025

2X WIDTH=

N80 P (PVD COATED) A2BNSN26J04 HOLDER (150-1500 sfm (.002-.010.ipr

2X.1575=.314’’

back chamfer TOOL WIDTH=4mm=.1575’’ p.84) p.84)

R

NOTES: (***Safety 1ST**** FOLLOW INSTRCUTIONS***) SKETCH here:

1. Workshift Z=0 on center face

2. Use the stock: Aluminum bar Ø1 x 24’’ maximum

length

3. Stick-out bar 1.75’’ long from jaws face to setup

tools and work

4. Before starting N10 stick-out ensure that the bar is

2’’ minimum long INSIDE Jaws

5. Mount all tools for M03 rotation AT MAX. 3500 RPM

6. Calibrate all external tools on left-corner face &

center tools (e.g., DRILLS) on tip-center face

7. Simulate and edit program before machining

8. Setup, Operate Machine and measure all features

9. Clean machine and report the results

You might also like

- MT1-A22 Workpiece-L5 Mod18 - CNC Lathe Process SheetDocument2 pagesMT1-A22 Workpiece-L5 Mod18 - CNC Lathe Process SheetniroNo ratings yet

- VX-351_PMR446_SM_EC083U90FDocument20 pagesVX-351_PMR446_SM_EC083U90Fvjt.radioNo ratings yet

- 850c Catalogo Pc2832sDocument772 pages850c Catalogo Pc2832sestesgfe100% (4)

- C050203 - 0710 - 1110 - E - RGL - Specter Summit - FULL - 0Document34 pagesC050203 - 0710 - 1110 - E - RGL - Specter Summit - FULL - 0Dennis ArhinNo ratings yet

- Motor Test ReportDocument5 pagesMotor Test ReportMuhammad Kholis JaimonNo ratings yet

- Gambar Rencana ULP Tanjung TiramDocument9 pagesGambar Rencana ULP Tanjung Tiramtopik retigaNo ratings yet

- Suplemant PC SUPRA X DD 2Document17 pagesSuplemant PC SUPRA X DD 2M. Lutfi Zaeni FuadNo ratings yet

- AL-811 (Circa 2000) SchematicDocument2 pagesAL-811 (Circa 2000) SchematicSalvi AlonsoNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 pagesJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranNo ratings yet

- QTN-9394301 - Offer For M&M Crank Case Project ToolsDocument1 pageQTN-9394301 - Offer For M&M Crank Case Project ToolsNathan ChenNo ratings yet

- Rigrepecuasep06 2023Document6 pagesRigrepecuasep06 2023Fernando TorresNo ratings yet

- NASH ENGINEERING LIQUID RING PUMP SPECIFICATION SHEETDocument1 pageNASH ENGINEERING LIQUID RING PUMP SPECIFICATION SHEETGabriel VejarNo ratings yet

- Id Pump 420DDocument2 pagesId Pump 420DManuel MayeyaNo ratings yet

- Pantalla Anterior Bienvenido: r120pm2Document2 pagesPantalla Anterior Bienvenido: r120pm2Eliecer godoyNo ratings yet

- Feeder Breaker Hydraulic Unit TableDocument1 pageFeeder Breaker Hydraulic Unit TableAyman AlhalfawyNo ratings yet

- Product Information Packet: 7.5HP, 1125RPM, 3PH, 60HZ, 254T, 0932M, OPENDocument11 pagesProduct Information Packet: 7.5HP, 1125RPM, 3PH, 60HZ, 254T, 0932M, OPENFirulay FirulayNo ratings yet

- All New Soul GT 1p2sx460e1 PDFDocument53 pagesAll New Soul GT 1p2sx460e1 PDFdindin ylNo ratings yet

- Toyota Rack End Code GuideDocument3 pagesToyota Rack End Code GuideNarwan anwarNo ratings yet

- 250kW VDFDocument3 pages250kW VDFalex.burgosNo ratings yet

- 1LE1503-1DB43-4FK4_datasheet_enDocument1 page1LE1503-1DB43-4FK4_datasheet_enNicolas RossettoNo ratings yet

- 13KRP3D3 00062636 3Document13 pages13KRP3D3 00062636 3Sourabh TiwariNo ratings yet

- ARY90TLC3 Service Manual PDFDocument26 pagesARY90TLC3 Service Manual PDFRicardo Morán SilvaNo ratings yet

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- PB 001 - Innova VenturerDocument23 pagesPB 001 - Innova VenturerHary PrasetyoNo ratings yet

- 4689 - Clivet WRAT 322Document1 page4689 - Clivet WRAT 322Roko0% (1)

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- Pantalla Anterior Bienvenido: r120pm2Document2 pagesPantalla Anterior Bienvenido: r120pm2Eliecer godoyNo ratings yet

- Oo-08-Detail of Mooring & Anchoring Fitting PDFDocument61 pagesOo-08-Detail of Mooring & Anchoring Fitting PDFCelal BozdoganNo ratings yet

- Product Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCDocument9 pagesProduct Information Packet: 250HP, 3570RPM, 3PH, 60HZ, 449TS, 18104M, TEFCJosé Isaac Chávez HuamánNo ratings yet

- Bomba de InyeccionDocument3 pagesBomba de InyeccionMarvin Melendez VanegasNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- Poste PilotageDocument24 pagesPoste Pilotagelionel henriquesNo ratings yet

- Piping Slide Chart DetailsDocument36 pagesPiping Slide Chart Detailstandk1989100% (2)

- DQR Pj. - Motor Operated Valves (Gate)Document2 pagesDQR Pj. - Motor Operated Valves (Gate)Usman ArifNo ratings yet

- HAIL SURFACE FACILITIES WELD REQUESTDocument1 pageHAIL SURFACE FACILITIES WELD REQUESTAnonymous AdofXEYAgENo ratings yet

- 1le5533 3ab63 4ab3Document2 pages1le5533 3ab63 4ab3Whipman ArduinoNo ratings yet

- Equipment ListDocument11 pagesEquipment ListTunaNo ratings yet

- Schneider Electric Price List Feb 2020 V2Document478 pagesSchneider Electric Price List Feb 2020 V2Amr SohilNo ratings yet

- CIW TIREADS JRD ANGLE PROJECTI ON DIMENSIONSTHODTINDIVAL TOLERAKCDocument2 pagesCIW TIREADS JRD ANGLE PROJECTI ON DIMENSIONSTHODTINDIVAL TOLERAKCAnkit GeorgeNo ratings yet

- DX 300 Panel DetailDocument4 pagesDX 300 Panel DetailKarthick BalakrishnanNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- Parts Catalogue News: New Model Afx110Mcs - Mcsma and Afx110S - Sma Types Component Parts-MarketedDocument23 pagesParts Catalogue News: New Model Afx110Mcs - Mcsma and Afx110S - Sma Types Component Parts-MarketedjetionNo ratings yet

- Swaraj operation sheet for rear cover machiningDocument7 pagesSwaraj operation sheet for rear cover machiningAjaySinghNo ratings yet

- 4650 and 4850 Section 50Document22 pages4650 and 4850 Section 50josephmw0308No ratings yet

- 1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enDocument2 pages1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enTien NguyenNo ratings yet

- QCOC 2762M88P01 Rev A, Int0Document1 pageQCOC 2762M88P01 Rev A, Int0nidhal kotorsiNo ratings yet

- Wps 225Document29 pagesWps 225Muhammad firdaus rusliNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument2 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Serial Unit Parts ListingDocument2 pagesSerial Unit Parts ListingjacksonNo ratings yet

- HeikerDocument6 pagesHeikerSatriyo WijayaNo ratings yet

- National Board NumberiDocument3 pagesNational Board NumberiAmrut ChalkeNo ratings yet

- PENTACUT - MMDocument4 pagesPENTACUT - MMphạm minh hùngNo ratings yet

- Atb BRG de 6306zzcnDocument2 pagesAtb BRG de 6306zzcnTeguh JayaNo ratings yet

- Boss BF-3 Service NotesDocument12 pagesBoss BF-3 Service NotesgirouxlpNo ratings yet

- DATASHEETDocument3 pagesDATASHEETToko DownloadNo ratings yet

- Pump Specification Weights and MeasurementsDocument5 pagesPump Specification Weights and MeasurementsjaimeNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Earn 5 Unlocks For Every 10 Resources You UploadDocument1 pageEarn 5 Unlocks For Every 10 Resources You UploadHuber Emiro Riascos GomezNo ratings yet

- SAFC Biosciences - Technical Bulletin - The Science of LONG®R3IGF-I: Features and BenefitsDocument4 pagesSAFC Biosciences - Technical Bulletin - The Science of LONG®R3IGF-I: Features and BenefitsSAFC-GlobalNo ratings yet

- MCQDocument6 pagesMCQArup Kumar DasNo ratings yet

- Insurance Licenses Required for Foreign Insurer and Local AgentDocument2 pagesInsurance Licenses Required for Foreign Insurer and Local AgentAbilene Joy Dela CruzNo ratings yet

- Oh DarlingDocument4 pagesOh DarlingLaurent BotzNo ratings yet

- Sample Motion To Dismiss Petition For Facial InsufficiencyDocument5 pagesSample Motion To Dismiss Petition For Facial InsufficiencybrandonNo ratings yet

- Government Structure in CanadaDocument4 pagesGovernment Structure in CanadaMichelleLawNo ratings yet

- SOP For Machine Maintenance - For UpdateDocument3 pagesSOP For Machine Maintenance - For UpdatePeracha Engineering60% (5)

- Coca ColaDocument31 pagesCoca ColaAnmol JainNo ratings yet

- Burden of Proof ConceptDocument2 pagesBurden of Proof ConceptnikhilNo ratings yet

- Input Data Sheet For SHS E-Class Record: Learners' NamesDocument4 pagesInput Data Sheet For SHS E-Class Record: Learners' NamesJetro EspinasNo ratings yet

- FAA Issues AD for Certain Airbus Aircraft to Address Fire Extinguishing System IssueDocument6 pagesFAA Issues AD for Certain Airbus Aircraft to Address Fire Extinguishing System IssueJacob MillerNo ratings yet

- G.R. No. 171146Document9 pagesG.R. No. 171146Atty McdNo ratings yet

- Assignment 21 - EXERCISE 4.0Document2 pagesAssignment 21 - EXERCISE 4.0Ravi TNo ratings yet

- 2013 Legal and Ethical Issues in Nursing 6th Edition Test BankDocument14 pages2013 Legal and Ethical Issues in Nursing 6th Edition Test BankEricaPhillipsaszpc100% (29)

- Chapter 2 Energy and Energy TransferDocument35 pagesChapter 2 Energy and Energy TransferNik Hafiy Hafizi0% (1)

- Bdu-Jl Vol 7 No 1Document156 pagesBdu-Jl Vol 7 No 1Auto squadNo ratings yet

- Ebook Corporate Financial Management 5Th Edition Glen Arnold Test Bank Full Chapter PDFDocument28 pagesEbook Corporate Financial Management 5Th Edition Glen Arnold Test Bank Full Chapter PDFdextrermachete4amgqg100% (9)

- Volume 42, Issue 5 - February 4, 2011Document48 pagesVolume 42, Issue 5 - February 4, 2011BladeNo ratings yet

- Corporate Counsel in Omaha NE Resume Jeff AndersonDocument3 pagesCorporate Counsel in Omaha NE Resume Jeff AndersonJeffAndersonNo ratings yet

- USA V Kevin Seefried Sentencing Memo by USADocument42 pagesUSA V Kevin Seefried Sentencing Memo by USAFile 411No ratings yet

- Special Power of AttorneyDocument2 pagesSpecial Power of AttorneyBJ JavierNo ratings yet

- Starbucks Corporation: Form 10-KDocument139 pagesStarbucks Corporation: Form 10-KShady Mohsen MikhealNo ratings yet

- Dao 1992-25 (Nipas Irr)Document28 pagesDao 1992-25 (Nipas Irr)Martin L T. SantosNo ratings yet

- Top 50 Banking Interview Questions & Answers: 1) What Is Bank? What Are The Types of Banks?Document10 pagesTop 50 Banking Interview Questions & Answers: 1) What Is Bank? What Are The Types of Banks?FaizNo ratings yet

- 2022 Purples Notes in Criminal LawDocument136 pages2022 Purples Notes in Criminal LawChristine Gel100% (2)

- Zicta Annual Report 2019 PDFDocument172 pagesZicta Annual Report 2019 PDFCurter Lance LusansoNo ratings yet

- Ugrd-Ncm6308 Bioethics Prelim To Final QuizDocument39 pagesUgrd-Ncm6308 Bioethics Prelim To Final QuizMarckyJmzer033 OgabangNo ratings yet

- ITP PaintingDocument1 pageITP PaintingYash Sharma100% (3)

- Shri Mataji Nirmala Devi Short Biography and Awards PDFDocument4 pagesShri Mataji Nirmala Devi Short Biography and Awards PDFJai N TaldaNo ratings yet