Professional Documents

Culture Documents

Eng SS Tec-117-9 J

Uploaded by

Ahmad dérouicheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng SS Tec-117-9 J

Uploaded by

Ahmad dérouicheCopyright:

Available Formats

Calibration

TEC-117-9

30 APR 15 Rev J

Specification

All Paragraphs Revised

Dial, Vernier and Digital Calipers

1. SCOPE

This specification covers the calibration procedure for inch and metric dial, vernier, and digital calipers.

2. EQUIPMENT

Gage blocks, vernier caliper master, ring gage, or equivalent

3. PROCEDURE

NOTE

Recorded results are in accordance with Calibration Specification TEC-117-1 (Instrument and

Gage Calibration Service).

3.1. Verify that the identification markings on the caliper are distinct and conform to Production Machine

Drafting standard TEC-222-1 (Tooling and Gage Numbering System).

3.2. Clean the exterior surfaces of the caliper as required.

NOTE

The caliper should not be disassembled at this time.

3.3. Visually examine the caliper for obvious damage, abuse, or wear that would make calibration

impossible. If applicable, discontinue procedure, reject, and record results.

3.4. Slide the caliper over its full range to check for roughness. If present, check for burrs, nicks, scratches,

etc. on moving parts and remove if necessary.

3.5. Check for parallelism of the OD jaw faces by measuring at the outer and inner edges. The 2 readings

shall not differ by more than .001 in [0.02 mm].

3.6. On the OD jaws, zero the caliper and take readings at a minimum of 5 dimensions (including zero) over

the range of the caliper.

Full Scale Range Tolerance

Inch [mm] Inch [mm]

0 to 6 [0 to 150] ± .001 [± 0.02]

0 to 12 [0 to 300] ± .002 [± 0.05]

0 to 24 [0 to 600] ± .002 [± 0.05]

0 to 40 [0 to 100] ± .003 [± 0.08]

Figure 1 – Tolerance Requriements

© 2015 TE Connectivity family of companies

All Rights Reserved

1 of 2

| Indicates Change

*Trademark. TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

TEC-117-9

3.7. Check the ID jaws by taking 2 or more measurements along the length of the ID jaws. This will verify the

linear accuracy and parallelism of the ID jaws. All measurements shall be within the specified tolerance

limit. For parallelism, the readings shall not differ by more than .001 inch [0.02 mm].

3.8. If the caliper is equipped with a depth rod, take 1 or more measurements.

3.9. If the caliper is equipped with ‘step measuring faces’, take 1 or more measurements.

3.10. If the caliper meets specifications, no further work is required. Record results, label the caliper, and

place back in service.

3.11. If measurement error, tightness, or other performance abnormalities reveal the caliper is not adjustable

or repairable, reject, and record results.

NOTE

Other international, regional, national, or manufacturer’s standards may be referenced as

necessary. The following documents represent some of those available that pertain to the same

subject matter as this specification.

ANSI B89.1.14 - Still in committee, not yet released

NAVAIR 17-20MD-07 (01SEP1987) - (from GIDEP)

T.O. 33K6-4-552-1 (30OCT1999) - (from GIDEP)

Rev J 2 of 2

You might also like

- JS215 ManualDocument629 pagesJS215 Manualsunil dhaugoda83% (6)

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Saab 9000 Wiring DiagramsDocument45 pagesSaab 9000 Wiring DiagramsLeer Sobie100% (1)

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Toyota7FBEU15 207FBEHU18 PDFDocument564 pagesToyota7FBEU15 207FBEHU18 PDFTrung NguyễnNo ratings yet

- Cursor SeriesDocument274 pagesCursor SeriesDaniel AyalaNo ratings yet

- 1986 Isuzu Trooper II KB83 Workshop Manual Section 00 General InformationDocument70 pages1986 Isuzu Trooper II KB83 Workshop Manual Section 00 General InformationHenry Carrillo100% (1)

- MS For Roof Sheeting and Wall Cladding WorkDocument16 pagesMS For Roof Sheeting and Wall Cladding Workkienking80100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- g100 g102 Chassis ManualDocument538 pagesg100 g102 Chassis Manualtoscana1234575% (12)

- Bangladesh National Building Code 2020Document2,464 pagesBangladesh National Building Code 2020Pranoy Barua100% (2)

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- FT 70 - 80 DT Dual Transmission PDFDocument78 pagesFT 70 - 80 DT Dual Transmission PDFAntnhe BayuNo ratings yet

- Instrument Calibration ProcedureDocument10 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- Shaft AlignmentDocument44 pagesShaft Alignmentrodolfosti100% (1)

- Press Tool Components Die MakingDocument29 pagesPress Tool Components Die Makingmayank123100% (1)

- SKF BearingsDocument19 pagesSKF BearingssordelaflorNo ratings yet

- Mazda RX8 Transmission ManualDocument49 pagesMazda RX8 Transmission ManualSpyros Stasinos50% (2)

- Metric and Inch (Sae) Fasteners: All ModelsDocument22 pagesMetric and Inch (Sae) Fasteners: All ModelsLenin100% (1)

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Product Specification Dimensioning and TolerancingDocument64 pagesProduct Specification Dimensioning and TolerancingilroscioNo ratings yet

- Amec SpecDocument32 pagesAmec Specshinojbaby4148No ratings yet

- Manual ToyotaDocument37 pagesManual ToyotaBastian Tapia LopezNo ratings yet

- 5g Matlab PDFDocument31 pages5g Matlab PDFArunNo ratings yet

- Apache Solr Search Patterns - Sample ChapterDocument33 pagesApache Solr Search Patterns - Sample ChapterPackt PublishingNo ratings yet

- Repair Procedure Slug CatcherDocument4 pagesRepair Procedure Slug Catchershabbir626100% (1)

- GR00000700 00Document36 pagesGR00000700 00Van GAPNo ratings yet

- Metric and Inch (Sae) Fasteners: MaintenanceDocument36 pagesMetric and Inch (Sae) Fasteners: MaintenanceDaniel Alejandro García PérezNo ratings yet

- ATRT-01D SCE User's ManualDocument16 pagesATRT-01D SCE User's ManualSultan Uddin KhanNo ratings yet

- File PDFDocument43 pagesFile PDFKamrul Islam JashimNo ratings yet

- Report SI-08010025 - SPRO1Document42 pagesReport SI-08010025 - SPRO1Rashyd RidhaNo ratings yet

- 3.20 On-Off - 27000Document13 pages3.20 On-Off - 27000Cuong TranNo ratings yet

- Oiml R035-1-E07Document6 pagesOiml R035-1-E07Juan Sebastián Martinez NunciNo ratings yet

- Typical Sources of Uncertainty in Materials TestingDocument3 pagesTypical Sources of Uncertainty in Materials TestingSonja KostićNo ratings yet

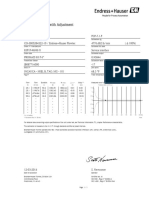

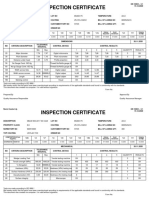

- Flow Calibration With AdjustmentDocument1 pageFlow Calibration With AdjustmentLuis Meza ArevaloNo ratings yet

- Dial Indicator: General ClassificationDocument4 pagesDial Indicator: General ClassificationOladimeji TaiwoNo ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- J1037 - 201504-Windshield Washer TubingDocument5 pagesJ1037 - 201504-Windshield Washer TubingJicheng PiaoNo ratings yet

- Promass 80 - Flow Calibration StandardDocument1 pagePromass 80 - Flow Calibration StandardMiguel Angel Diaz GuzmanNo ratings yet

- A2LA 1101 01 Valid To February 28 2017Document4 pagesA2LA 1101 01 Valid To February 28 2017QA LAB ISMNo ratings yet

- Metric and Inch (Sae) Fasteners: All ModelsDocument22 pagesMetric and Inch (Sae) Fasteners: All ModelsMONTACARGAS AVSNo ratings yet

- Kenr8577 00 01 AllDocument20 pagesKenr8577 00 01 AlldavidNo ratings yet

- Tns Dw2 ManualDocument6 pagesTns Dw2 Manualyeison11No ratings yet

- TM 215461 SRTDocument3 pagesTM 215461 SRTömer cılızNo ratings yet

- 01.RPM Meter 4to20Document1 page01.RPM Meter 4to20Sathish KarunNo ratings yet

- TB 9-5210-207-24 - Micrometer ISDocument16 pagesTB 9-5210-207-24 - Micrometer ISJose Hernandez DiazNo ratings yet

- Oil Pressure Transmitter: Part NumberDocument8 pagesOil Pressure Transmitter: Part NumberMassimo GiachettaNo ratings yet

- DM-27 Part2Document14 pagesDM-27 Part2Adrian CantaragiuNo ratings yet

- MP 2585Document6 pagesMP 2585JohnNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument32 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNo ratings yet

- R II Gear Mar09Document7 pagesR II Gear Mar09sujit5584No ratings yet

- Metric and Inch (Sae) Fasteners: MaintenanceDocument20 pagesMetric and Inch (Sae) Fasteners: MaintenanceДмитрийNo ratings yet

- Calibracion Flujo DM 101Document1 pageCalibracion Flujo DM 101Diego Fernando Ortiz EscobarNo ratings yet

- Check 3 Điểm MatchingDocument61 pagesCheck 3 Điểm MatchingNgọc Thiện BùiNo ratings yet

- 00Document36 pages00Catherine NansambaNo ratings yet

- TM 210728 SRTDocument3 pagesTM 210728 SRTömer cılızNo ratings yet

- Yale 524150797 03 03 Yrm0231Document16 pagesYale 524150797 03 03 Yrm0231jonathanrioscNo ratings yet

- 00 GะัเะะENERALDocument92 pages00 GะัเะะENERALBank 1991No ratings yet

- General Information: To IndexDocument9 pagesGeneral Information: To IndexandriNo ratings yet

- Metric and Inch (Sae) Fasteners: MaintenanceDocument22 pagesMetric and Inch (Sae) Fasteners: Maintenancegerod25No ratings yet

- Dokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478Document22 pagesDokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478npNo ratings yet

- 603B1 Calibration Interval DetailsDocument8 pages603B1 Calibration Interval Detailssunny sohaniNo ratings yet

- Group 00 GeneralDocument28 pagesGroup 00 GeneralGPRNo ratings yet

- Murata Magnetic SwitchDocument3 pagesMurata Magnetic Switchkn65238859No ratings yet

- Sae J175-2018Document10 pagesSae J175-2018nelliNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- QA QC BookDocument347 pagesQA QC BookTienNo ratings yet

- Starting and Stopping Apache ServerDocument4 pagesStarting and Stopping Apache Serverrenegade78No ratings yet

- Hyspan Span Guide 28pp Oct12 PDFDocument28 pagesHyspan Span Guide 28pp Oct12 PDF_Asylum_No ratings yet

- Comparison Between IOS & TCPDocument8 pagesComparison Between IOS & TCPMayada GamalNo ratings yet

- Senzations2014 Doukas Course1Document63 pagesSenzations2014 Doukas Course1vinayNo ratings yet

- 750 627Document1 page750 627Erasmo ColonaNo ratings yet

- Adventurer Pro BalanceDocument56 pagesAdventurer Pro BalancenascalesNo ratings yet

- STATISTICS FOR BUSINESS - CHAP07 - Hypothesis Testing PDFDocument13 pagesSTATISTICS FOR BUSINESS - CHAP07 - Hypothesis Testing PDFHoang NguyenNo ratings yet

- Index TermDocument23 pagesIndex TermWAGUDELONo ratings yet

- 0208Document41 pages0208jivasumanaNo ratings yet

- FLIR B250 (9 HZ, 2010 Model)Document6 pagesFLIR B250 (9 HZ, 2010 Model)tfemilianNo ratings yet

- Pistola CashDocument12 pagesPistola CashSEBASTIAN PEREZNo ratings yet

- Qs 4002 Bted AssignmentDocument7 pagesQs 4002 Bted AssignmentweerasinghekNo ratings yet

- Iecex Certificate of ConformityDocument4 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- Cabinet PDFDocument6 pagesCabinet PDFAnonymous 1xDxbkTz2No ratings yet

- Gensets Full EN-GM1606.1 LR PDFDocument44 pagesGensets Full EN-GM1606.1 LR PDFAldo Marcelo Soliz AngolaNo ratings yet

- Open Systems Interconnection Model (OSI) PDFDocument20 pagesOpen Systems Interconnection Model (OSI) PDFLink NguyenNo ratings yet

- WCDMA Mobile Mobile Test ApplicationDocument24 pagesWCDMA Mobile Mobile Test ApplicationsamwisegameeNo ratings yet

- C Program To Concatenate Two Strings Using Strcat FunctionDocument6 pagesC Program To Concatenate Two Strings Using Strcat FunctionprogrammingsimplysolvedNo ratings yet

- Atoll 3.1.0 Model Calibration GuideDocument96 pagesAtoll 3.1.0 Model Calibration Guidekamkamtoy67% (3)

- Chap04 Review 1Document3 pagesChap04 Review 1Rawle Ezra Sue-HoNo ratings yet