Professional Documents

Culture Documents

Quantitative Analysis of Solid Waste Generation From Tanneries in Kano State

Quantitative Analysis of Solid Waste Generation From Tanneries in Kano State

Uploaded by

Moti TadegeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quantitative Analysis of Solid Waste Generation From Tanneries in Kano State

Quantitative Analysis of Solid Waste Generation From Tanneries in Kano State

Uploaded by

Moti TadegeCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/360496459

Quantitative Analysis of Solid Waste Generation from Tanneries in Kano State

Article · May 2022

DOI: 10.46610/JoEES.2022.n07i01.004

CITATIONS READS

0 54

2 authors:

Ibrahim Haruna Umar Ahmad Muhammad

Kano University of Science & Technology Kano State Polytechnic

9 PUBLICATIONS 0 CITATIONS 12 PUBLICATIONS 9 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Geotechnical Engineering View project

Masters research project View project

All content following this page was uploaded by Ahmad Muhammad on 10 May 2022.

The user has requested enhancement of the downloaded file.

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

Quantitative Analysis of Solid Waste Generation from Tanneries in Kano

State

Haruna I. U.1*, Kabir M.2, Yalo S. G.1, Muhammad A.2, Ibrahim A. S.4

1

Department of Civil Engineering, Firat University, Elazig, Turkey/Department of Civil Engineering,

Kano University of Science and Technology Wudil, Kano State, Nigeria

2

Assistant Lecturers, Department of Agricultural and Bio-Environmental Engineering, Audu Bako

College of Agriculture Dambatta, Kano State, Nigeria

3

Department of Civil Engineering, Kano State Polytechnic, Nigeria

4

Assistant Lecturer, Department of Civil Engineering, Federal University Dutsin-Ma, Nigeria

*Corresponding E-mail: iharunaumar@kustwudil.edu.ng

ABSTRACT INTRODUCTION

Tanning industries have been so important

since ancient times because it helps to Tanning is simply the production of

produce essential goods such as garment and leather from raw hides and skins. The tanning

footwear. However, these industries have industry (also called tannery) has been one of the

been polluting the environment, so there was most important industrial processes (as in ) since

a need for investigations, observations, and ancient times, used to produce highly durable

analysis by researchers for better garments and footwear [1].

management and environmental

sustainability. In this study, solid wastes from In Nigeria, leather tanning is one of the

tanning industries in Kano State, Nigeria oldest industrial activities. According to a

were quantitatively analyzed. Both UNIDO report [2], it was already active before

questionnaires and physical measurements the colonial occupation, producing items for

were used in the Bompai, Sharada, and trans-Saharan trade for the Sudanese and

Challawa industrial areas. The average Maghreb markets. In the 1980s, Nigeria was the

weight of raw skin was 0.96 kg and the African hub for tanneries and leather processing,

generation rate was 27.5% of the total weight with over 40 functioning tanneries. Moreover,

of processed skin. It was found that 85% of 95 percent of these industries were concentrated

the generated waste was organic, while only in the northern city of Kano, where more than a

15% was inorganic. The peak season for a third of the local workforce was employed in the

solid waste generation was the holy season of sector at that time. The tanning industry

the Muslim-majority communities, known as continues to be an important contributor to the

"Eid al-Adha", (10th-13th Zulhajj of the Nigerian economy. According to a statement by

lunar calendar). While the off-peak the Nigerian Vice President, the leather industry

generation season was during the rainy is capable of generating up to US$1 billion by

season, generated solid wastes from the 2025 [3].

tanning industries could have the potential

for sustainable utilization in terms of Tanneries are classified as one of the

renewable energy generation and some most polluting industries and harm the

agricultural applications. It was therefore environment due to the generation of liquid,

recommended that future researches should solid, and gaseous wastes [4]. Although leather

analyze the potentiality of these industries for tanning primarily utilizes waste from the meat

the benefit of Kano State. industry, many chemicals are also used to

transform the raw material into a final product

Keywords-- Environment, Kano State, Solid (Fig. 1). Therefore, the leather industry

Waste Generation, Tanneries consumes resources and produces pollutants that

are toxic and hazardous to the environment [5].

23 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

Figure 1: Solid waste generation process from the tanning industry [6].

In leather processing, for instance, only disposed of or recycled, these solid wastes

200 kg of usable leather product (comprising 3 generated from various tanning operations can

kg of chromium) is produced from one tonne of cause several serious environmental problems

raw material. The solid and liquid waste includes [9]. If salt dust or de-dusted salt removed from

about 250 kg of non-tanned solid waste, 200 kg preserved hides or skins is stored in heaps

of tanned waste (comprising 3 kg of chromium), outside tanneries or disposed of in open dumps,

and 50,000 kg of wastewater (comprising 5 kg of it is likely to be washed away by rain, causing

chromium). In total, only 20% of a tonne of raw pollution of groundwater. The discharge of hair

material is produced as a finished leather product waste and lime sludge along with sewage leads

and more than 60% as solid and liquid waste to clogging of sewage systems [10]. Raw and

containing the highly carcinogenic heavy metal green fleshing limed fleshing, splits (splitting

"chromium" [7- 8]. Solid wastes generated by waste), and cutting waste also decay easily and

tanneries contain various chemicals used in cause foul odors. Some biodegradable solid

leather production. These solid wastes from tannery wastes are sources of pathogenic

tanneries have different properties because bacteria and volatile organic compound

different chemicals and mechanical processes emissions [11-12].

are applied to the raw hides/skins. If not properly

24 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

Quantitative assessment of the nature of Sampling Technique

solid waste generated by tanneries in Kano State

is therefore very important for effective Based on random sampling, samples of

management and potential utilization of solid ten pieces of salt-preserved raw skin processed

waste as an important resource for renewable to produce finished leather were taken piece by

energy [13]. However, environmentally sound piece at each leather production operation likely

solid waste management requires the selection to produce solid waste (i.e. fleshing, splitting,

and application of appropriate techniques, chrome shaving, trimming off the crust, and

technologies, and management programs to trimming of the finished leather).

achieve certain waste management objectives.

Therefore, this study will be of great importance Data Collection

in collecting useful, accurate, and up-to-date

data on the amount and type of solid waste The type of solid waste generated in

generated in tanneries. Nevertheless, the study each stage of the operation was identified

does not include household solid wastes that through physical observation, and material

may be generated in the tanneries (e.g. paper balance analysis techniques were used (i.e.

wastes, nylons, metal wastes, etc.), liquid weighing samples before and after the operation

effluents, and solid wastes that are disposed of stages) to determine the solid waste generation

along with the effluents (e.g. sludge). rate.

MATERIALS AND METHODS Questionnaires were developed and

Study Area distributed to the various tanneries currently in

operation. From the responses to the

Kano is the largest city in the Sudan questionnaires, the average daily and average

region of Nigeria. It lays between latitude 120 25 annual weights of solid waste generated by the

to 120 40N and longitude 80 35N to 80 45E. Kano tanneries in Kano State were determined.

is the economic and commercial nerve center of

the north. Tanneries in Nigeria are also located RESULTS AND DISCUSSION

in Kano [14]. The first integrated tannery was Solid Waste Generation in the Tanneries

established in 1949 in the Bompai suburb of

Kano. Later, other tanneries were established in The Solid Waste Generation Rate of the

the Sharada and Challawa industrial areas of the Tanneries

Kano metropolis [2]. Therefore, the present

The material balance measurements

study was conducted in all the tannery sites in

showed that the average weight of the raw skins

Kano State (Bompai, Sharada, and Challawa). A

measured was 0.96 kg. The physical

comprehensive list of the subjects is presented in

composition of the solid waste generated in the

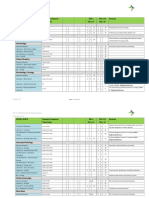

Appendix I. tannery is as follows (Fig. 2): deducted salt, raw

skin trimmings, hair waste, fleshing waste, split

Materials waste, chrome shavings, and finished leather

trimming waste. Hair waste was the largest

Raw skin samples preserved in salt, proportion of solid waste in these industries at

chemicals for leather processing, tanning 57%, while finished leather trimming waste was

machines for processing the raw skins, and the smallest at 2%. The tanning industry in Kano

laboratory equipment (digital scales, collection could therefore provide abundant resources for

containers for solid waste samples). the production of fertilizers and biomaterials.

Consequently, the burden of importing fertilizers

Methods for agriculture could be significantly reduced.

The solid waste generation rates of each The generation rate of each type of solid

tannery, the period of peak generation, and the waste in kg/tonne of salt-preserved raw skin is

total annual solid waste generated by all presented in Fig. 3. It was found that the

tanneries in Kano State were obtained. processing of one tonne of wet salted skin

25 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

generates a total of 275.10 kg of solid waste, the literature as estimates of solid waste

which is 27.5% of the total weight of skin generation in the tanning industries. Such

processed. This, however, exceeds the 8.33% variations could be due to the adaptation of these

estimated by [15] indicating a significant decline industries to environmental guidelines, the type

in solid waste generation in the Kano tanning of hiding/skin and the chemicals used in the

industries. However, much higher values such as tanning process.

60% [16] and 85% [17] have been reported in

Figure 2: percentage proportion of the solid waste generation rate of tanneries in Kano State.

158

35.2

22.9 17.8 17.6 17.4

5.2

Figure 3: Solid waste generation rate in Kano Tanneries (kg/ton of raw skin).

Organic-Inorganic Solid Waste Ratio generated in the tanning industries was organic.

Accordingly, this could pave the way for

Organic waste includes trimmings, sustainable utilization of solid waste from the

flashings, and hair wastes. The ratio of organic tanning in Kano for bioenergy use in the tanning

to inorganic components of solid waste is shown industries and industrial areas of the state.

in Table 2. Most (85%) of the solid waste

Table 2: Organic-inorganic solid waste ratio.

Nature of Solid Weight Generated (kg/ton)

Percentage (%)

Waste From Raw Skin Processed From Solid Waste Generated

Organic 234.80 853.50 85.40

Inorganic 40.30 146.50 14.60

26 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

Moreover, the few inorganic wastes most functional tanneries, Challawa Industrial

could also have significant application in some Area generated the most solid wastes. With

other industries. Thus the need for investigation Bompai having the poorest performance, this is a

into the suitability of these wastes for proper result of its high number of non-functional

utilization and management. tanneries. This could be attributed to the old age

of the area amongst the other tanneries, and its

Total Annual Solid Waste Generation of proximity to some well classified governmental

Tanneries in Kano State layouts for residential purposes. Sharada

industrial area also possesses somewhat

The average total daily weight and similarities with Bompai in terms of proximity to

average total annual weight of skins processed classified residential settings. This could have an

by tanneries in Kano State are shown in Table 3. impact in reducing the number of tanneries, thus

A total of 112,428.00 tonnes was the estimated concentrating these tanneries at Challawa

solid waste generated annually. Since it has the

Table 3: Total Annual weight of Skins Processed by Tanneries in Kano State.

AVERAGE AVERAGE SOLID

WEIGHT OF WASTE

S. NO. OF SOLID SKINS GENERATION

INDUSTRIAL

N TANNERIE WASTE PROCESSED RATE

AREA

o. S TYPE Daily Annually

Daily Annually

(tons/day (tons/year

(tons) (tons)

) )

1 Bompai 4 - 44.16 13,248.00 12.14 3643.20

273.0

2 Challawa 11 - 81,900.00 75.08 22522.50

0

3 Sharada 7 - 57.60 17,280.00 15.84 4752.00

374.7 112,428.0

TOTAL 22 103.06 30917.70

6 0

318.5

Organic 95563.80 87.60 26280.05

5

Inorganic 56.21 16864.20 15.46 4637.66

Solid Waste Generation during Peak and Off-

Peak Periods

Sharad

From the responses in the a

questionnaires, it was found that the period of

peak production is the Muslim “Eid Al-Kabir”

period when the masses slaughter a lot of

Challaw

livestock by Islamic worship between the 10th

a

and 13th Zulhajj (the last month) of the Hijri

calendar (lunar date system). It has been found

that the rainy season (usually June-September) is

the off-peak period for production. Bompai

The daily amount of solid waste

generated during peak and off-peak production 0 500 1000

periods in the three tanning industrial areas (Fig.

4) shows that the tanning industries site that is Off-Peak Period Peak Period Normal

the most productive is the Challawa industrial

area as well. Figure 4: Average Solid Waste Generation per

period (tonnes/day).

27 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

CONCLUSION RECOMMENDATIONS

The following conclusions were drawn from the Based on the study conducted in

study on the assessment of solid waste tanneries in Kano State, the following

generation by tanneries in Kano State: recommendations are made:

The solid waste generation rate by tanneries There is the need to explore the

in Kano is 275.10 kg per tonne of salt- biochemical conversion of these solid

preserved raw skin. The nature of solid wastes, especially anaerobic digestion (bio

waste is 85% organic and 15% inorganic. methanation) to determine the potential for

The average annual amount of solid waste producing biogas from the solid tannery

generated by all tanneries in the Kano wastes in Kano State.

metropolis is 30,918 tonnes/year. The Based on the solid waste proclamation

organic and inorganic components of the number, further research should be carried

solid waste are 26280.3 tonnes and 4637.7 out on the utilization of solid tannery waste

tonnes respectively. for the production of valuable products and

The study revealed that the Eid Al-Kabir energy generation.

period is the peak period of production and

hence the peak period of solid waste The relevant agencies in the tanneries

generation. The average daily total weight need practical training on how to implement

of solid waste generated during the peak solid waste management strategies (waste source

production period, normal production reduction, recycling and composting, waste

period, and off-peak production period is conversion/energy generation, and landfilling) to

1199.3 tonnes/day, 359.8 tonnes/day, and manage the solid waste generated in their

63.8 tonnes/day respectively. tanneries.

More than 80% of the tanneries dispose of Conflict of Interests

their solid waste at the open landfill on the

Challawa River. The authors declare no conflict of interests.

APPENDIX 1

List of the Available Tanneries in Kano State

S.No. Name of Tannery Location Status

1 Gashash Tannery Bompai Functional

2 Gods Little Tannery Bompai Functional

3 Afrimpex Ent. Ltd Bompai Functional

4 Mahaza Company limited Challawa Functional

5 Kano Tan Tannery Limited Challawa Functional

6 Gb Tannery limited Challawa Functional

7 West Africa Tannery Limited Challawa Functional

8 Mario Jose Tannery Limited Challawa Functional

9 Fine Leather Processing Company Ltd Challawa Functional

10 Mamuda Industries Limited Challawa Functional

11 Fata Tanning Limited Challawa Functional

12 Nakudu Tannery Limited Challawa Functional

13 Loquat Classies Nigeria Limited Sharada Functional

14 Unique Leather Processing Co. Ltd Sharada Functional

15 Globus Tannery Limited Sharada Functional

16 B&B Leather Limited Sharada Functional

17 Hufawa Limited Sharada Functional

28 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

18 Tannorth Tannery Sharada Functional

19 Multitan Company Limited Challawa Functioning

20 Great Northen Tanning Company Bompai Not functioning

21 International Tanners Bompai Not functioning

22 Sule Galadima Tanneries Bompai Not functioning

23 Tanarewa Nig. Ltd Challawa Not Functioning

24 First Tanneries limited Challawa Not Functioning

25 Arewa Tannery Challawa Not Functioning

26 Darum Enterprises Challawa Not functioning

27 Nabegu Tanning Challawa Not functioning

28 Daras Nigeria Challawa Not functioning

29 Kano Pickling and Tanning Company Challawa Not functioning

30 Harmattan Tannery Challawa Not functioning

31 Challawa Tannery Challawa Not functioning

32 Kapitan Tannery Challawa Not functioning

33 Darum tannery Challawa Not functioning

34 KTL Tanneries Challawa Not functioning

35 Akkad Tannery Challawa Not functioning

REFERENCES Series in Energy, 55-67, Available at:

https://doi.org/10.1016/B978-0-08-102528-

1. Azom M. R., Mahmud K., Yahya S. M. 4.00005-5

(2012). Environmental Impact Assessment 6. United Nations Industrial Development

of Tanneries, International Journal of Organization-UNIDO (2011), Introduction

Environmental Science and Development, to Treatment of Tannery Effluents,

3(2), 152-156, Available at:

DOI:10.7763/IJESD.2012.V3.206 https://www.unido.org/resources/publicatio

2. Felsner, G. (2003). Improving Tannery ns/creating-shared-prosperity/agribusiness-

pollution control in Kano, Technical Report and-rural-entrepreneurship/introduction-

Prepared for the Government of Nigeria by treatment-tannery-effluents

UNIDO, YA/NIR/03/440/11-52. 7. International Trade Centre (2022). Leather,

3. State House Media. (2021). Generating Available at:

$1bn by 2025, Leather Industry is a Game- http://www.intracen.org/itc/sectors/leather/.

Changer Waiting to Happen in Nigeria, 8. Hüffer S.& Taeger T. (2004). Sustainable

Osinbajo, Available at: leather manufacturing: a topic with growing

https://statehouse.gov.ng/news/generating- importance, J Am Leather Chem Assoc.,

1bn-by-2025-leather-industry-is-a-game- 99(10), 424–8, Available at:

changer-waiting-to-happen-in-nigeria- https://www.semanticscholar.org/paper/Sust

osinbajo/ ainable-leather-manufacturing%3A-A-

4. Manjushree C., Mostafa M. G., Tapan K.B topic-with-Huffer-

et al. (2015). Characterization of the Taeger/40538b40cbb141867d83768f71040

Effluents from Leather Processing e174eecd2b4

Industries, Environ. Process, 173-187, 9. Baba A, Garba ST, Bello H. S. (2020).

Available at: Bioremediation Potential of Immobilized

https://link.springer.com/article/10.1007/s4 Corynebacterium kutsceri in the Treatment

0710-015-0065-7 of Tannery Industry Effluent from

5. Sivaram N. K & Barik D. (2019). Toxic Challawa Industrial Estate, Kano State,

Waste from Leather Industries. In: Energy Nigeria, JOTCSA, 7(2), 335-350,

from Toxic Organic Waste for Heat and DOI:10.18596/jotcsa.643771.

Power Generation, Woodhead Publishing 10. Yorgancioglu A., Başaran B., Sancakli A.

29 Page 23-30 © MAT Journals 2022. All Rights Reserved

Journal of e-ISSN: 2582-3132

Environmental Engineering and Studies Volume-7, Issue-1 (January-April, 2022)

www.matjournals.com https://doi.org/10.46610/JoEES.2022.v07i01.004

(2020). Value Addition to Leather Industry in Kano Metropolis, Techno Science

Wastes and By-Products: Hydrolyzed Africana Journal, Available at:

Collagen and Collagen Peptides Waste in https://catalog.ihsn.org/index.php/citations/

Textile and Leather Sectors, Ayşegül Körlü, 60990

IntechOpen, Available at: 15. Teklay A, Gebeyehu G, Getachew T, et al.

https://www.intechopen.com/chapters/7236 (2008). Quantification of Solid Waste

5 Leather Generation Rate from the Ethiopian

11. Yadav A., Mishra S., Kaithwas G., Raj A. Leather Sector-A Contributing Perspective

& Bharagava R. N. (2016). Organic to Waste Management Approach, Innov

Pollutants and Pathogenic Bacteria in Ener Res., Available at:

Tannery Wastewater and their Removal https://www.omicsonline.org/open-

Strategies, In “Microbes and access/quantification-of-solid-waste-

Environmental Management, 1st Edition, leather-generation-rate-from-the-ethiopian-

104-130, Available at: leather-sector--a-contributing-perspective-

https://www.researchgate.net/publication/29 to-waste-manag-2576-1463-1000208-

0709995_Organic_Pollutants_and_Pathoge 102312.html

nic_Bacteria_in_Tannery_Wastewater_and 16. Clare A. (2021). Waste Reduction in the

_their_Removal_Strategies Leather Industry 2/3 – Utilising Leather

12. Urase T., Okumura H., Panyosaranya S., Solid Wastes in Other Industries, Available

Inamura A. (2008). Emission of volatile at:

organic compounds from solid waste https://www.authenticae.co.uk/post/waste-

disposal sites and importance of heat reduction-in-the-leather-industry-2-3-

management, Waste Manag Res., 26(6), utilising-leather-solid-wastes-in-other-

534-8, DOI: 10.1177/0734242X07084321 industries

13. Onukak I. E., Mohammed-Dabo I. A., 17. Kanagaraj J, Valappan K C, Babu NKC, et

Ameh O. A., et al. (2017). Production and al. (2006). Solid Waste Generation from

Characterization of Biomass Briquettes Leather Industry and Its Utilization for

from Tannery Solid Waste, Recycling, 2(4), Cleaner Environment- A Review, Journal

17 of Scientific and Industrial Research, 541-

https://doi.org/10.3390/recycling2040017 548, DOI:10.1002/chin.200649273.

14. Nabegu, A. B. (2008). An Assessment of

Refuse Management and Sanitation Board

(REMASAB)’s Solid Waste Management

30 Page 23-30 © MAT Journals 2022. All Rights Reserved

View publication stats

You might also like

- Method Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01Document13 pagesMethod Statement For Painting System KAFD-RY-RIA2-CP04-SAB-ARF-MES-05001 Rev.01khalid khanNo ratings yet

- By Michael Hailu Advisor: Bahran Asrat (PHD)Document88 pagesBy Michael Hailu Advisor: Bahran Asrat (PHD)Micheale HailuNo ratings yet

- Environmental Impact Assessment - ReportDocument22 pagesEnvironmental Impact Assessment - ReportSiddharth SinghNo ratings yet

- Australian Animals SimpleDocument2 pagesAustralian Animals SimpleDubravka CrnicNo ratings yet

- Sari Sari Store KSDDocument2 pagesSari Sari Store KSDPatrick Dg100% (1)

- Adsorption of Methylene Blue From Textile Industrial Wastewater Onto Activated Carbon of Parthenium HysterophorusDocument15 pagesAdsorption of Methylene Blue From Textile Industrial Wastewater Onto Activated Carbon of Parthenium HysterophorusShurooq TaibNo ratings yet

- Adsorption of Methylene Blue From Textile Industrial Wastewater Onto Activated Carbon of Parthenium HysterophorusDocument15 pagesAdsorption of Methylene Blue From Textile Industrial Wastewater Onto Activated Carbon of Parthenium HysterophorusShirley ramosNo ratings yet

- Term Paper - Id-1053 - Md. Raisul Islam ShamratDocument12 pagesTerm Paper - Id-1053 - Md. Raisul Islam ShamratNature Solution LimitedNo ratings yet

- An AHP-ELECTRE Framework To Evaluate Barriers To Green Supply Chain Management in The Leather IndustryDocument21 pagesAn AHP-ELECTRE Framework To Evaluate Barriers To Green Supply Chain Management in The Leather Industryjaved iqbalNo ratings yet

- Green Chemistry Module IDocument27 pagesGreen Chemistry Module IRahul Mathur100% (1)

- Environmental Tech.Document31 pagesEnvironmental Tech.csyena28225No ratings yet

- TLR 2023 116 MottalibDocument31 pagesTLR 2023 116 Mottalibbarewolf0805No ratings yet

- Syabila Alia Binti Sairuzi - 2021840902 - Assignment 2 PDFDocument12 pagesSyabila Alia Binti Sairuzi - 2021840902 - Assignment 2 PDFSYABILA ALIA SAIRUZINo ratings yet

- Assessment of Environmental Impact For TanneryDocument4 pagesAssessment of Environmental Impact For Tanneryসাবিহা মাহমুদ মমিNo ratings yet

- Assessment of Environmental Impact For Tannery Industries in BangladeshDocument5 pagesAssessment of Environmental Impact For Tannery Industries in BangladeshAsif Bin ZamanNo ratings yet

- Saira Review PaperDocument11 pagesSaira Review Paperamala josephNo ratings yet

- 2 MptfinalpaperDocument14 pages2 MptfinalpaperYesmin LlachoNo ratings yet

- Leather Industry and Environment: Pakistan Scenario: June 2017Document7 pagesLeather Industry and Environment: Pakistan Scenario: June 2017Muhammad Moiz HasanNo ratings yet

- Environmental Impact Assessment of Tanneries: A Case Study of Hazaribag in BangladeshDocument6 pagesEnvironmental Impact Assessment of Tanneries: A Case Study of Hazaribag in Bangladeshসাবিহা মাহমুদ মমিNo ratings yet

- 1 s2.0 S0959652608002916 MainDocument7 pages1 s2.0 S0959652608002916 MainMeenakshi SamiduraiNo ratings yet

- Circular Economy and Sustainability of The Clothing and Textile IndustryDocument9 pagesCircular Economy and Sustainability of The Clothing and Textile IndustryAnanda DermawanNo ratings yet

- Circular Economy and Sustainability of The Clothing and Textile IndustryDocument9 pagesCircular Economy and Sustainability of The Clothing and Textile IndustryLOPIGA, HERSHA MHELE A.No ratings yet

- Effectiveness of Wastewater Purification With Watermelon Seed ChaffDocument11 pagesEffectiveness of Wastewater Purification With Watermelon Seed ChaffM Abul Hassan AliNo ratings yet

- A Review On Adsorption ofDocument17 pagesA Review On Adsorption ofkekeNo ratings yet

- Growth of Textile Industry and Their Issues On Environment WithDocument18 pagesGrowth of Textile Industry and Their Issues On Environment WithUtsho ParvezNo ratings yet

- 41 - MD Shamim Hosen - Acce 4204Document13 pages41 - MD Shamim Hosen - Acce 4204MD: Shamim HossainNo ratings yet

- Business Plan Project ReportDocument40 pagesBusiness Plan Project Reportrathodjaydeep989No ratings yet

- Publication 21Document12 pagesPublication 21Iheoma Chukwujike NwuzorNo ratings yet

- JBES Vol7No1 p501 525Document26 pagesJBES Vol7No1 p501 525Kirti KachhapNo ratings yet

- Environmental Impact Assessment of Tanneries A Case Study of Hazaribag in BangladeshDocument5 pagesEnvironmental Impact Assessment of Tanneries A Case Study of Hazaribag in BangladeshRed RudhyatmojoNo ratings yet

- 4R of Rubber Waste Management: Current and OutlookDocument15 pages4R of Rubber Waste Management: Current and OutlookYogesh DewangNo ratings yet

- JK 1Document49 pagesJK 1sachinNo ratings yet

- TFG Cristina Piera Final3Document92 pagesTFG Cristina Piera Final3ViShal SiNghNo ratings yet

- Green Textile Production: A Chemical Minimization and Substitution Study in A Woolen Fabric ProductionDocument16 pagesGreen Textile Production: A Chemical Minimization and Substitution Study in A Woolen Fabric ProductionDiana RoseroNo ratings yet

- 11.article FlowSegregationOptionsofETP withoutEndNoteDocument8 pages11.article FlowSegregationOptionsofETP withoutEndNoteEngineer WaleedNo ratings yet

- Reviewing Textile Wastewater Produced by Industries: Characteristics, Environmental Impacts, and Treatment StrategiesDocument21 pagesReviewing Textile Wastewater Produced by Industries: Characteristics, Environmental Impacts, and Treatment StrategiesSoro FrancisNo ratings yet

- Ijciet 08 12 063Document11 pagesIjciet 08 12 063dareymayree56No ratings yet

- Irjet V7i4334Document8 pagesIrjet V7i4334Arole JesuNo ratings yet

- GloveDocument9 pagesGloveturkmen.atilgan.burcinNo ratings yet

- Characteristicsand Treatmentof Pulpand Paper Mill Effluents AReviewDocument9 pagesCharacteristicsand Treatmentof Pulpand Paper Mill Effluents AReviewJaderson CarvalhoNo ratings yet

- Review On Various Types of Pollution Problem in Textile Dyeing & Printing Industries of Bangladesh and Recommandation For MitigationDocument8 pagesReview On Various Types of Pollution Problem in Textile Dyeing & Printing Industries of Bangladesh and Recommandation For Mitigationnimra navairaNo ratings yet

- Polymers 13 00429 v2Document23 pagesPolymers 13 00429 v2samiNo ratings yet

- 1 s2.0 S2214785321012943 MainDocument6 pages1 s2.0 S2214785321012943 MainCHLORINE SHAKENo ratings yet

- G03 - INVESTIGACION - RESIDUOS SOLIDOS TECNOLOGIA ECOLOGICA SOSTENIBLE - Krishna - 2020Document7 pagesG03 - INVESTIGACION - RESIDUOS SOLIDOS TECNOLOGIA ECOLOGICA SOSTENIBLE - Krishna - 2020Luis ToroNo ratings yet

- Textile Sludge Management by Incineration TechniquDocument6 pagesTextile Sludge Management by Incineration TechniquDebashish RoyNo ratings yet

- Ullah Hasan Ahmad Ahmed2020 JMCWMDocument12 pagesUllah Hasan Ahmad Ahmed2020 JMCWMKarishma NazimiNo ratings yet

- Bche Fa17 027Document6 pagesBche Fa17 027Hamza MughalNo ratings yet

- Utilization of Waste Wool Fibers For Fabrication oDocument15 pagesUtilization of Waste Wool Fibers For Fabrication oAbel TayeNo ratings yet

- Journal B3Document10 pagesJournal B3Putry1No ratings yet

- Art Cieti 2021Document15 pagesArt Cieti 2021NIGUSNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument17 pagesJournal of Environmental Chemical Engineering: SciencedirectNicholas YeohNo ratings yet

- Removal of Heavy Metals From Chemical Industrial Wastewater Using Agro Based Bio-SorbentsDocument6 pagesRemoval of Heavy Metals From Chemical Industrial Wastewater Using Agro Based Bio-Sorbentsmadiha javedNo ratings yet

- Challenges and Opportunities Linked With Waste Management Under Global Perspective: A Mini ReviewDocument6 pagesChallenges and Opportunities Linked With Waste Management Under Global Perspective: A Mini Reviewshambelabebe75No ratings yet

- Elhafez 2016Document19 pagesElhafez 2016Martial Art FaridNo ratings yet

- Journal of Cleaner Production: Emrah Alkaya, Göksel N. DemirerDocument9 pagesJournal of Cleaner Production: Emrah Alkaya, Göksel N. DemirerahtashamNo ratings yet

- Journal Pre-Proofs: Bioresource TechnologyDocument51 pagesJournal Pre-Proofs: Bioresource TechnologyPaoozzzNo ratings yet

- Effective Industrial Waste Utilization Technologies Towards Cleaner EnvironmentDocument5 pagesEffective Industrial Waste Utilization Technologies Towards Cleaner EnvironmentMumu ImayoshiNo ratings yet

- Leather Waste Management PDFDocument20 pagesLeather Waste Management PDFSrijon MalikNo ratings yet

- Measuring The Environmental Footprint of Leather Processing TechnologiesDocument9 pagesMeasuring The Environmental Footprint of Leather Processing TechnologiesKarel DhooreNo ratings yet

- Rice Straw RecyclingDocument15 pagesRice Straw Recyclingahmed.sakran92No ratings yet

- Journal of Water Process Engineering: Syahida Farhan Azha, Suzylawati IsmailDocument12 pagesJournal of Water Process Engineering: Syahida Farhan Azha, Suzylawati IsmailnovianaNo ratings yet

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- Recycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationFrom EverandRecycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationNo ratings yet

- ExtractDocument7 pagesExtractMoti TadegeNo ratings yet

- WasteBiomass2017 1219 1224Document7 pagesWasteBiomass2017 1219 1224Moti TadegeNo ratings yet

- Simulation-Based Sustainable Manufacturing SystemDocument10 pagesSimulation-Based Sustainable Manufacturing SystemMoti TadegeNo ratings yet

- Work Environment DesignDocument30 pagesWork Environment DesignMoti TadegeNo ratings yet

- Dechroming of Chromium-Containing Leather Waste With Low Hydrolysis Degree of CollagenDocument6 pagesDechroming of Chromium-Containing Leather Waste With Low Hydrolysis Degree of CollagenMoti TadegeNo ratings yet

- Bakery Review Feb-March 2019 Issue. Reach 9810315463 To Advertise or Subscribe ! PDFDocument52 pagesBakery Review Feb-March 2019 Issue. Reach 9810315463 To Advertise or Subscribe ! PDFAmreesh MisraNo ratings yet

- DHA Lab Guidlines 2019-717-720Document4 pagesDHA Lab Guidlines 2019-717-720abinradhNo ratings yet

- 3X V65a 3XRDocument4 pages3X V65a 3XRDavid Angulo Esguerra100% (1)

- HP Pavillion dv2401 TUDocument3 pagesHP Pavillion dv2401 TUapi-3772095No ratings yet

- Basic Electronics Chap # 2 Diode: Engr. Farwa BatoolDocument10 pagesBasic Electronics Chap # 2 Diode: Engr. Farwa BatoolFarwa JaffriNo ratings yet

- K38 BrochureDocument2 pagesK38 BrochureMuhammad rizkiNo ratings yet

- Camlift Hydraulic Pumping Unit PsDocument4 pagesCamlift Hydraulic Pumping Unit PsJorge Resendez100% (1)

- BurnerDocument2 pagesBurnerVishnu PatidarNo ratings yet

- MQDocument7 pagesMQalaa icesNo ratings yet

- Chapter 1 Oil Seal IntroductionDocument6 pagesChapter 1 Oil Seal IntroductionNCvetarskyNo ratings yet

- Hydro Meteorological HazardsDocument1 pageHydro Meteorological HazardsKylie Zhane Uy0% (1)

- Location and Design For Traffic SignalsDocument7 pagesLocation and Design For Traffic SignalsGauri JagtapNo ratings yet

- Tor For Academic Building IIDocument19 pagesTor For Academic Building IILaurie Carr LandichoNo ratings yet

- Boettcher ThermodynamicsDocument78 pagesBoettcher ThermodynamicsCHE.ENG1734No ratings yet

- Notes On Static and Dynamic FrictionDocument2 pagesNotes On Static and Dynamic FrictiondrhillNo ratings yet

- Understand The Application Details. 2. Development of Logic For Specific ApplicationDocument2 pagesUnderstand The Application Details. 2. Development of Logic For Specific ApplicationAdarsh SriwastvaNo ratings yet

- SpectraLayers One 8 Operation ManualDocument74 pagesSpectraLayers One 8 Operation Manual릴황No ratings yet

- Prayer To Effect Change 28-06-2022-1 (C)Document2 pagesPrayer To Effect Change 28-06-2022-1 (C)Dolido EnterprisesNo ratings yet

- Restricted Earth Fault Technical ReportDocument5 pagesRestricted Earth Fault Technical ReportVijai PrasathNo ratings yet

- Cacho, Kathleen Joy C. (Digital Communication SFE Portfolio)Document14 pagesCacho, Kathleen Joy C. (Digital Communication SFE Portfolio)KATHLEEN JOY CACHONo ratings yet

- Indigenous - Machinery - document-DAIRY PLANT PDFDocument197 pagesIndigenous - Machinery - document-DAIRY PLANT PDFkunal shahNo ratings yet

- Bomhard (Translator) - Dhammapada (English and Pali) (2022)Document124 pagesBomhard (Translator) - Dhammapada (English and Pali) (2022)Allan BomhardNo ratings yet

- Dog Behaviour Problems: Why Do They Do It and What Can You Do?Document12 pagesDog Behaviour Problems: Why Do They Do It and What Can You Do?Mittu KurianNo ratings yet

- Correlation Does Not Imply CausationDocument9 pagesCorrelation Does Not Imply CausationeduliborioNo ratings yet

- Nia Up32gn 1236Document4 pagesNia Up32gn 1236Dheeraj PandeyNo ratings yet

- The Accurate Measurement of Contact Angle, Phase ContactDocument8 pagesThe Accurate Measurement of Contact Angle, Phase ContactaleiviNo ratings yet