Professional Documents

Culture Documents

Calculating OEE Worksheet: Production Data

Uploaded by

Praveen GoswamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculating OEE Worksheet: Production Data

Uploaded by

Praveen GoswamiCopyright:

Available Formats

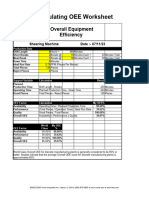

Calculating OEE Worksheet

MACHINE SPEED 45 MTR / MINUTE

Production Data Shift Length Short Breaks Meal Break Down Time Ideal Run Rate Total Pieces Reject Pieces

12 3 1 60 45

Hours = 720 Minutes Breaks @ 15 Minutes Each = Breaks @ 30 Minutes Each = Minutes PPM (Pieces Per Minute) Pieces Pieces

45 Minutes Total 30 Minutes Total

Support Variable Planned Production Time Operating Time Good Pieces

Calculation Shift Length - Breaks Planned Production Time - Down Time Total Pieces - Reject Pieces

Result 645 Minutes 585 Minutes 0 Pieces

OEE Factor Availability Performance Quality Overall OEE

Calculation Operating Time / Planned Production Time (Total Pieces / Operation Time) / Ideal Run Rate Good Pieces / Total Pieces Availability x Performance x Quality

My OEE% 90.70% 0.00%

OEE Factor Availability Performance Quality Overall OEE

World Class My OEE% 90.00% 90.70% 95.00% 0.00% 99.90% 85.00%

World Class Overall OEE for discrete manufacturing plants is generally considered to be 85% or better. Studies indicate that the average Overall OEE score for discrete manufacturing plants is approximately 60%.

2002-2005 Vorne Industries Inc., Itasca, IL USA (630) 875-3600 www.vorne.com www.oee.com

Calculating OEE Worksheet

Fill in the highlighted areas with your production data for a single shift. In some cases, you may have to convert units to simplify the calculation. For example, 3600 PPH (Pieces per Hour) is 60 PPM (Pieces per Minute).

Production Data Shift Length Short Breaks Meal Break Down Time Ideal Run Rate Total Pieces Reject Pieces

8 2 1 47 60 19,271 423

Hours = 480 Minutes Breaks @ 15 Minutes Each = Breaks @ 30 Minutes Each = Minutes PPM (Pieces Per Minute) Pieces Pieces

30 Minutes Total 30 Minutes Total

Support Variable Planned Production Time Operating Time Good Pieces

Calculation Shift Length - Breaks Planned Production Time - Down Time Total Pieces - Reject Pieces

Result 420 Minutes 373 Minutes 18,848 Pieces

OEE Factor Availability Performance Quality Overall OEE

Calculation Operating Time / Planned Production Time (Total Pieces / Operation Time) / Ideal Run Rate Good Pieces / Total Pieces Availability x Performance x Quality

My OEE% 88.81% 86.11% 97.80% 74.79%

OEE Factor Availability Performance Quality Overall OEE

World Class My OEE% 90.00% 88.81% 95.00% 86.11% 99.90% 97.80% 85.00% 74.79%

World Class Overall OEE for discrete manufacturing plants is generally considered to be 85% or better. Studies indicate that the average Overall OEE score for discrete manufacturing plants is approximately 60%.

2002-2005 Vorne Industries Inc., Itasca, IL USA (630) 875-3600 www.vorne.com www.oee.com

You might also like

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Simple Oee SpreadsheetDocument2 pagesSimple Oee SpreadsheetadeNo ratings yet

- Calculating OEE WorksheetDocument2 pagesCalculating OEE WorksheetPravin BabarNo ratings yet

- Calculating OEE Worksheet: Production DataDocument2 pagesCalculating OEE Worksheet: Production DataKhathutshelo KharivheNo ratings yet

- Oee SpreadsheetDocument2 pagesOee SpreadsheetMohammed ImranNo ratings yet

- Accounting Profit Formula Excel Template-1Document52 pagesAccounting Profit Formula Excel Template-1Marwan SaidNo ratings yet

- Oee Spreadsheet FabricationDocument7 pagesOee Spreadsheet FabricationVINAYNo ratings yet

- Availability: Example OEE CalculationDocument2 pagesAvailability: Example OEE CalculationVaibhav Sharma100% (1)

- Shift Length Short Breaks Meal Breaks Downtime Ideal Run Rate Total Pieces Reject Pieces Prodution DataDocument8 pagesShift Length Short Breaks Meal Breaks Downtime Ideal Run Rate Total Pieces Reject Pieces Prodution DataMustaffa FajraNo ratings yet

- Optimize OEE calculation with availability, performance, quality factorsDocument11 pagesOptimize OEE calculation with availability, performance, quality factorsosbertodiazNo ratings yet

- Calculating OEEDocument3 pagesCalculating OEETuấn Trần ĐứcNo ratings yet

- Calculating Oee WorksheetDocument2 pagesCalculating Oee WorksheetAdriano Tiago EinsfeldNo ratings yet

- Reduce Manufacturing DowntimeDocument7 pagesReduce Manufacturing DowntimeJigar DesaiNo ratings yet

- Overall Equipment EffectivenessDocument43 pagesOverall Equipment EffectivenessKailas Sree Chandran100% (4)

- Managing OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryDocument26 pagesManaging OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryMohammad QureshiNo ratings yet

- Oee - TPM: AvailabilityDocument4 pagesOee - TPM: Availabilityp ganeshNo ratings yet

- Overall Equipment EffectivenessDocument12 pagesOverall Equipment EffectivenessAbdul RashidNo ratings yet

- How To Calculate Overall Equipment Effectiveness: A Practical GuideDocument8 pagesHow To Calculate Overall Equipment Effectiveness: A Practical GuideKumarNo ratings yet

- World Class OEEDocument22 pagesWorld Class OEESinggihNo ratings yet

- Oee 2Document9 pagesOee 2fernandothekingNo ratings yet

- Ch7 PDFDocument40 pagesCh7 PDFAKARSH JAISWALNo ratings yet

- 1.lean - VSMDocument65 pages1.lean - VSMBangaru BharathNo ratings yet

- Calculate OEE Factors and Overall OEEDocument3 pagesCalculate OEE Factors and Overall OEEMuhammad Javed IqbalNo ratings yet

- The Basics of OEEDocument30 pagesThe Basics of OEEguillermina_galleg_2No ratings yet

- Improving Operations at a Tile ManufacturerDocument5 pagesImproving Operations at a Tile ManufacturerHai HaNo ratings yet

- Calculate OeeDocument24 pagesCalculate OeeAyman AliNo ratings yet

- OEE PrimerDocument4 pagesOEE PrimerjaydeepsinhNo ratings yet

- Overall Equipment EffectivenessDocument32 pagesOverall Equipment Effectivenesshasan_waqar2004No ratings yet

- Calculating Oee Worksheet: Line / Cell: Process: Machine: DateDocument4 pagesCalculating Oee Worksheet: Line / Cell: Process: Machine: DateArunCdmNo ratings yet

- Overall Equipment Effectiveness: Balakumar VDocument10 pagesOverall Equipment Effectiveness: Balakumar VBalakumar VNo ratings yet

- Calculating OEE for a Coca Cola Plant ShiftDocument4 pagesCalculating OEE for a Coca Cola Plant ShiftCommence NkomoNo ratings yet

- Overall Equipment Effectiveness Calculator SpreadsheetDocument34 pagesOverall Equipment Effectiveness Calculator SpreadsheetMathias WafawanakaNo ratings yet

- OEE What Is OEE?Document4 pagesOEE What Is OEE?Mamun IENo ratings yet

- OEE ExplainedDocument3 pagesOEE Explainedvvv5452100% (2)

- Calculate OEE from Production DataDocument3 pagesCalculate OEE from Production DataRidhwan Hibatullah100% (1)

- Simple Calculation: Three Loss-Related FactorsDocument8 pagesSimple Calculation: Three Loss-Related FactorsTHANH THAO DO THINo ratings yet

- Overall Equipment Effectiveness CalculationDocument1 pageOverall Equipment Effectiveness Calculationmedi38No ratings yet

- Lesson 3 Importance and Uses of Time Study StudentDocument16 pagesLesson 3 Importance and Uses of Time Study StudentAllona Jean Pacquiao DayapNo ratings yet

- CII - AVANTHA Centre For CompetitivenessDocument31 pagesCII - AVANTHA Centre For CompetitivenessRohit TripathiNo ratings yet

- What Is Oee?: Intro To LeanDocument3 pagesWhat Is Oee?: Intro To LeanNelson VianaNo ratings yet

- Calculating Oee Worksheet: Line / Cell: Process: Machine: DateDocument2 pagesCalculating Oee Worksheet: Line / Cell: Process: Machine: DateJose Luis AtaullucoNo ratings yet

- Oee CalculatedDocument1 pageOee Calculatedmortezasafir62No ratings yet

- Calculate TEEP - Measure Utilization and Capacity - OEEDocument4 pagesCalculate TEEP - Measure Utilization and Capacity - OEEahmed nawaz100% (1)

- Calculating Oee Worksheet: Line / Cell: Process: Machine: DateDocument2 pagesCalculating Oee Worksheet: Line / Cell: Process: Machine: Datehasan_waqar2004No ratings yet

- FinalDocument26 pagesFinalRitesh KumarNo ratings yet

- OEE Calculation USDocument2 pagesOEE Calculation USJose Luis AtaullucoNo ratings yet

- Improve manufacturing efficiency with OEEDocument3 pagesImprove manufacturing efficiency with OEEcarrot123456No ratings yet

- The Toyota Production SystemDocument21 pagesThe Toyota Production SystemfoofoolNo ratings yet

- TPM and OEEDocument46 pagesTPM and OEErajee101100% (1)

- Understanding OEE and TPM for Improved Machine EffectivenessDocument46 pagesUnderstanding OEE and TPM for Improved Machine EffectivenessJanan ArrosyadiNo ratings yet

- OEE and OLEDocument53 pagesOEE and OLESumit KumarNo ratings yet

- Oee Exercise Result: Please Perform This Analysis For All Key ProcessesDocument1 pageOee Exercise Result: Please Perform This Analysis For All Key ProcessesBalu RaviNo ratings yet

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsFrom EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (6)