Professional Documents

Culture Documents

Insitu Metallography R2

Uploaded by

hasansm farabipc0 ratings0% found this document useful (0 votes)

21 views4 pagesOriginal Title

Insitu_Metallography_R2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pagesInsitu Metallography R2

Uploaded by

hasansm farabipcCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

IN-SITU

METALLOGRAPHY

(Replica testing)

Early warnings: an effective tool for condition\life assessment of

process plant components.

TCR ADVANCED ENGINEERING P. LTD

250-252/9 GIDC Estate

Makarpura, Vadodara

+912652657233

www.tcradvanced.com www.tcreng.com

Early warnings through in-situ metallography

For safety and reliability of plants

In situ metallography is a knowledge based NDT technique which can

provide the early warnings of onset of many damages to the process

and engineering industries.

Damage mechanism like creep, fatigue, stress relaxation cracking, high

temperature corrosion including hydrogen attack, intergranular

corrosion, stress corrosion cracking, hydrogen induced cracking,

graphitization are possible to detect in the early stages and possible to

monitor them with time and provide the judgment to replace or repair

the component.

Microstructure examination done with experienced person and

judgment is given by an experienced metallurgist preferably involved

experienced with failure investigation and remaining life assessment.

Based on the creep cavities and classification of extent of damage the

next inspection intervals are decided based on the Number and charts.

Many life assessment calculations are proposed based on the cavitation

models of microstructure examination.

TCR’s metallurgists have backup of vast database of more than 30,000

in-situ microstructure interpretations on various components and

materials. These databases contain extensive information from various

plants that have been captured by providing this service. The databases

also include rare collections of varying microstructure damage levels for

various industries such as power, oil and gas, petrochemical, fertilizers,

and other process industries.

The In-Situ Metallography team is highly skilled in the art of replica

preparation. TCR has custom developed special purpose in-situ polishing

devices to produce high quality replication even on warm components

and unapproachable locations.

Our replication team of is capable of delivering throughput of about 20

metallography structures per shift

A service partner company of TCR Engineering P. Ltd.

Use of In-situ Metallography

Remaining life assessment.

Health assessment of critical components operating at high

Temperature And High Pressure in process plants

Damage assessment of fire affected equipment.

Quality check for metallurgical processes such as heat treatments.

Generate the data on imported components for indigenisation.

adapt to Middle-East (localization)

Failure Investigations.

Useful For Repair Welding Decisions.

Damages identified by Microstructures

Graphitization

Degradation Of Pearlite

Creep

Thermal Fatigue

Oxidation

Grain Growth

Hydrogen Attack

Stress Corrosion Cracking

Sigma phase

Benefits of In-Situ Metallography in industries

Monitor The Damages to the Plant Components.

Preventive Maintenance and Inventory Control.

Safe and Reliable Operation.

To Ensure the Use of Correct Metallurgical Status of

Components.

Useful for Indigenization.

Localization of Imported Components

Heat treatment certification.

Useful for Repairing Decisions for used Components.

A service partner company of TCR Engineering P. Ltd.

TCR Engineering Services

www.tcreng.com

TCR Engineering Services Pvt. Ltd

Plot No. EL-182, MIDC-TTC,

Electronic Zone, Mhape,

Navi Mumbai – 400 705.

Ph : (022) 67380900-02

Fax : 91-22-27612044.

E-mail : navimumbai@tcreng.com

Website : www. tcreng.com

TCR Advanced Engineering Pvt. Ltd

250-252/9,GIDC Estate, Makarpura,

Vadodara-390010.

Ph : (0265) 2657233, 2636329

Fax : (0265) 2643024

E-mail : tcradvanced@tcradvanced.com

Web-site : www.tcradvanced.com

TCR Engineering Consulting FZC

International HQ

PO Box 122453,

Dubai, UAE

Tel: +971-50-785-8901

E-Mail: uae@tcreng.com

TCR Arabia Company Limited.

P.O.Box 3422, # 3 & 4, next to Al Kifah Construction

besides Al-Kadi Tent Factory

near King Abdulaziz Sea Port

Dammam, Kingdom of Saudi Arabia

Tel: +966-3-8475785-84, 8475014

Fax: +966-3-8475768

E-Mail: sales@tcr-arabia.com

TCR Kuwait

PO Box 47928, Al-Anud complex, 4th floor

Fahaheel-64023, Kuwait

Tel: +965-23910315

Fax: +965-23910335

E-Mail:kuwait@tcreng.com

TCR Engineering Malaysia.

C/o Approved Group International

No 6 Jalan DBP 3, Dolomite Business Park

68100 Batu Caves, Selangor, Malaysia

24-hour hotline: +603-6188 6311

E-Mail: malaysia@tcreng.com

Printed in India

© 2012-16

All rights are reserved.

A service partner company of TCR Engineering P. Ltd.

You might also like

- Position Applied: Rope Access Tec NDT Curriculam VitaeDocument5 pagesPosition Applied: Rope Access Tec NDT Curriculam VitaeKABILAMBIGAI VNo ratings yet

- Murad - NDT TechnicianDocument3 pagesMurad - NDT TechnicianrifanNo ratings yet

- Metalex Oil & Gas Corporate ProfileDocument240 pagesMetalex Oil & Gas Corporate ProfileYaromirNo ratings yet

- Ttd. %wwwwruk: Consortium ForDocument1 pageTtd. %wwwwruk: Consortium ForFahimNo ratings yet

- Induction Melting Furnace Quotation 010720Document4 pagesInduction Melting Furnace Quotation 010720ranamzeeshanNo ratings yet

- List of Venders DOI 11062019Document112 pagesList of Venders DOI 11062019Shyam SundarNo ratings yet

- Shining3D EPlus - M150 20210203Document6 pagesShining3D EPlus - M150 20210203Shakeeb JabsNo ratings yet

- GD KT PRO-CT-Schwerzerspanung SEN ABS V1Document130 pagesGD KT PRO-CT-Schwerzerspanung SEN ABS V1massimocalviNo ratings yet

- PQ Spray ContectDocument57 pagesPQ Spray ContectUnited Construction Est. TechnicalNo ratings yet

- SSM - Work - Order - TNPSC - 10th June 2022Document1 pageSSM - Work - Order - TNPSC - 10th June 2022IshaNo ratings yet

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- How To Set Up A Fabrication WorkshopDocument63 pagesHow To Set Up A Fabrication WorkshopBurhaan Taskeen100% (1)

- DyesDocument12 pagesDyesRohan SinglaNo ratings yet

- Welding Superintendent: Curriculm VitaeDocument5 pagesWelding Superintendent: Curriculm VitaeMuhammad WarisNo ratings yet

- CV Al Deqaa Al Mutanahea Co.Document37 pagesCV Al Deqaa Al Mutanahea Co.Sarah KPP2No ratings yet

- Brosur MMJDocument80 pagesBrosur MMJBAMBANG IRAWANNo ratings yet

- HydroDocument3 pagesHydroAbubakar lawan moduNo ratings yet

- National Epcm Company: No EPC Company Services Contact PT ResindoDocument2 pagesNational Epcm Company: No EPC Company Services Contact PT ResindoalirahmaniwanNo ratings yet

- Material Submittal For Wiring Accessories - Rev.00Document167 pagesMaterial Submittal For Wiring Accessories - Rev.00721917114 47No ratings yet

- Strat3D ConferenceDocument4 pagesStrat3D ConferencemanatNo ratings yet

- Brochure Design Sample 1Document4 pagesBrochure Design Sample 1Gomathi SelvarajNo ratings yet

- Approved List of Contractros of CEEC Renewed Upto 31 Dec 2025Document111 pagesApproved List of Contractros of CEEC Renewed Upto 31 Dec 2025barmansourav1979No ratings yet

- Approved Supplier of IFR For IOCL Vijayawada Tender.Document2 pagesApproved Supplier of IFR For IOCL Vijayawada Tender.rohitNo ratings yet

- Email From Berger Regarding Final PaintingDocument4 pagesEmail From Berger Regarding Final PaintingRajeev KumarNo ratings yet

- Certificat ISO 14001Document3 pagesCertificat ISO 14001CARMEN DIMITRIUNo ratings yet

- New Profile LASTDocument187 pagesNew Profile LASTKadry Nabil HegazyNo ratings yet

- PQ PDFDocument74 pagesPQ PDFShahzad Nasir SayyedNo ratings yet

- MTT08 Exhibiting CompaniesDocument42 pagesMTT08 Exhibiting CompaniesShAi_MyStERiOuS86% (7)

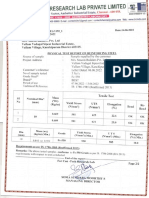

- 6 Con - Tech Research Lab Privaie Limited: - EndofthereportDocument2 pages6 Con - Tech Research Lab Privaie Limited: - EndofthereportCon TechNo ratings yet

- In-Situ Metallography Mett-Bio PDFDocument3 pagesIn-Situ Metallography Mett-Bio PDFMettBioNo ratings yet

- DESCON Internship ReportDocument53 pagesDESCON Internship ReportTanzeel Ur Rehman100% (1)

- Mah Sing Plastics Industries SDN BHD: Line of Business: Service Product LineDocument30 pagesMah Sing Plastics Industries SDN BHD: Line of Business: Service Product LinemattNo ratings yet

- Sedar Perkasa SDN BHD - Company Profile 2023Document48 pagesSedar Perkasa SDN BHD - Company Profile 2023choong chloeNo ratings yet

- Mitra Roof Treatment CentreDocument4 pagesMitra Roof Treatment CentreSudip MitraNo ratings yet

- PowermechDocument4 pagesPowermechSunil BhaarathNo ratings yet

- Quotation For Power Quality Analysis With Fault Identification of Power System of Renaissance Apparels Ltd. - Dyeing Unit - 03 - 09 - 2022Document4 pagesQuotation For Power Quality Analysis With Fault Identification of Power System of Renaissance Apparels Ltd. - Dyeing Unit - 03 - 09 - 2022YousufNo ratings yet

- 2016CompositeList Web 159Document1 page2016CompositeList Web 159AnuranjanNo ratings yet

- Mitsubishi Met Turbochargers, Global Service Network Tz-E002-5362Document1 pageMitsubishi Met Turbochargers, Global Service Network Tz-E002-5362Сергей ГолощаповNo ratings yet

- Portable Microscope 2014 PDFDocument2 pagesPortable Microscope 2014 PDFhcmcrlhoNo ratings yet

- Mcomp CatalogueDocument8 pagesMcomp CatalogueChaifa AbdoNo ratings yet

- ras tanura informatin-مهدیDocument9 pagesras tanura informatin-مهدیxtrooz abiNo ratings yet

- AddressDocument2 pagesAddressSajad PkNo ratings yet

- Material TC - Enplas Antistatic UhmwDocument1 pageMaterial TC - Enplas Antistatic Uhmwjhax90No ratings yet

- Yasir AL-Taie: Piping Engineer - MechanicsDocument4 pagesYasir AL-Taie: Piping Engineer - MechanicsAnonymous 5yXwNCNo ratings yet

- Murad - NDT TechnicianDocument3 pagesMurad - NDT TechnicianrifanNo ratings yet

- Ras Tanura Informatin-مهدیDocument9 pagesRas Tanura Informatin-مهدیxtrooz abiNo ratings yet

- Curriculum Vitae: Personal DetailsDocument4 pagesCurriculum Vitae: Personal DetailsHariyanto oknesNo ratings yet

- CTCI Is A Global Provider of Reliable Engineering ServicesDocument6 pagesCTCI Is A Global Provider of Reliable Engineering ServicesKhurram Shadab IqbalNo ratings yet

- 02 Tanks Dia 12M Each at Kunnar Field, OGDCL PDFDocument14 pages02 Tanks Dia 12M Each at Kunnar Field, OGDCL PDFmc160403810 Usman AliNo ratings yet

- Azar Mukhtiar Abbasi: Arkad Engineering & ConstructionDocument4 pagesAzar Mukhtiar Abbasi: Arkad Engineering & ConstructionAnonymous T4xDd4No ratings yet

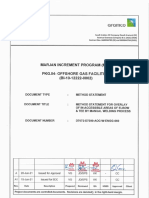

- D7072-D7390-AOC-W-ENGG-060 - A-Method Statement For Overlay of In-Accessible Areas of Elbow-Tee by Manual WeldingDocument10 pagesD7072-D7390-AOC-W-ENGG-060 - A-Method Statement For Overlay of In-Accessible Areas of Elbow-Tee by Manual WeldingpranshumishraNo ratings yet

- Ies-Industrial Engineering ServicesDocument2 pagesIes-Industrial Engineering ServicesAmit HasanNo ratings yet

- Certificate of Conformity (CT597-CoC-001 Rev.0)Document1 pageCertificate of Conformity (CT597-CoC-001 Rev.0)Romaida HutabaratNo ratings yet

- Life Sciences Consortium Poster Cum Front Page Brochure R1Document2 pagesLife Sciences Consortium Poster Cum Front Page Brochure R1ravichandran0506No ratings yet

- M 35Document11 pagesM 35Ssainaggdeep DeepNo ratings yet

- 2016CompositeList Web 64Document1 page2016CompositeList Web 64AnuranjanNo ratings yet

- التقريرDocument5 pagesالتقريرahmedinaNo ratings yet

- QIS UnderwarterInspectionRobotDocument34 pagesQIS UnderwarterInspectionRobotPeterNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Rapid Thermal Processing: Science and TechnologyFrom EverandRapid Thermal Processing: Science and TechnologyRichard B. FairNo ratings yet

- Philippine Board of Nursing Course SyllabusDocument11 pagesPhilippine Board of Nursing Course SyllabusChin Chan100% (1)

- YR7 Revision Sheet - Working ScietificallyDocument6 pagesYR7 Revision Sheet - Working ScietificallyNisha zehra100% (1)

- The Hornbook Method and The Conflict of LawsDocument16 pagesThe Hornbook Method and The Conflict of LawslanglangNo ratings yet

- Employee Engagement - Korn - Ferry InternationalDocument2 pagesEmployee Engagement - Korn - Ferry InternationalЯрослава ЛояничNo ratings yet

- Calibration Tools ListDocument5 pagesCalibration Tools ListdianNo ratings yet

- DIRECTION: Read Each Question Carefully. Encircle The Letter That Corresponds To The Letter of Your AnswerDocument2 pagesDIRECTION: Read Each Question Carefully. Encircle The Letter That Corresponds To The Letter of Your AnswerMea-Ann OscianasNo ratings yet

- HG - Grade 12 - Module 3 - October 14Document19 pagesHG - Grade 12 - Module 3 - October 14RhasmineKyle BeltranNo ratings yet

- AaaaaDocument3 pagesAaaaaAnonymous C3BD7OdNo ratings yet

- Email Etiquettes: Click To Add TextDocument25 pagesEmail Etiquettes: Click To Add Textmanveen kaurNo ratings yet

- CAPE Unit 2 Pure Maths NotesDocument103 pagesCAPE Unit 2 Pure Maths NotesAltrupassionate girlNo ratings yet

- Filtergehà Use - Beutel Und - Kerzen - enDocument5 pagesFiltergehà Use - Beutel Und - Kerzen - ennabila OktavianiNo ratings yet

- Guidelines For Research ProjectsDocument10 pagesGuidelines For Research Projectspriyanshu shrivastavaNo ratings yet

- R.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickDocument1 pageR.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickPeter McGoldrickNo ratings yet

- Answers 2Document4 pagesAnswers 2Vika BodokiaNo ratings yet

- Heat Transfer in Internal Combustion Engines: 85-WA/HT-23Document7 pagesHeat Transfer in Internal Combustion Engines: 85-WA/HT-23muhammad basitNo ratings yet

- 302 Decision Science Question - PaperDocument3 pages302 Decision Science Question - Paperajay taleNo ratings yet

- WWW - Smccnasipit.edu - PH: Saint Michael College of CaragaDocument5 pagesWWW - Smccnasipit.edu - PH: Saint Michael College of CaragaDivine CompendioNo ratings yet

- Radiation Protection in Dental RadiologyDocument52 pagesRadiation Protection in Dental Radiologyivan dario ardila martinezNo ratings yet

- Effect of Childhood Adversity On Brain Dopamine Function in Adulthood !Document2 pagesEffect of Childhood Adversity On Brain Dopamine Function in Adulthood !Aaron AdamsNo ratings yet

- ECC Strategic Plan BookletDocument20 pagesECC Strategic Plan BookletAida MohammedNo ratings yet

- An Exploration of The Concept of Identity Crisis in Salman Rushdie's GrimusDocument3 pagesAn Exploration of The Concept of Identity Crisis in Salman Rushdie's GrimusIJELS Research JournalNo ratings yet

- Alexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Document404 pagesAlexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Barbara Kubiec75% (4)

- Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pagesDensity (Unit Weight), Yield, and Air Content (Gravimetric) of ConcretemickyfelixNo ratings yet

- EKJERP IPPF Document Eng v1.2 250819Document63 pagesEKJERP IPPF Document Eng v1.2 250819ahmad yaniNo ratings yet

- Admission Notification 2024-2025Document12 pagesAdmission Notification 2024-2025jsbska88No ratings yet

- CTS Company Profile Rev0Document11 pagesCTS Company Profile Rev0khalesnabilNo ratings yet

- Design Manual Is-800 Chapter 5Document92 pagesDesign Manual Is-800 Chapter 5Vivek Kumar GopeNo ratings yet

- Simulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine DesignDocument24 pagesSimulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine Designjeevan scplNo ratings yet

- Practice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Document2 pagesPractice For Group Work Week 2 Case 2.1 - Assigning Plants To Products (Better Products Company)Thu TrangNo ratings yet

- Abstract On Face Recognition TechnologyDocument1 pageAbstract On Face Recognition TechnologyParas Pareek60% (5)