Professional Documents

Culture Documents

Acrylic

Uploaded by

Asistencia Técnica JLFCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acrylic

Uploaded by

Asistencia Técnica JLFCopyright:

Available Formats

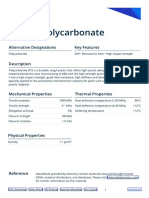

Data Sheet

Acrylic

Alternative Designations Key Features

PMMA Hard • Resistant to weather and chemicals •

Transparent • Durable

Description

This material is the most common form of clear, moldable thermoplastic, often used in place of glass

due to its higher resistance. It has good weather and chemical resistance with adequate surface

hardness. Acrylic has easy moldability and can be formed into various shapes and sizes. It is used for

transparent applications such as windows, frames etc.

Mechanical Properties Thermal Properties

Tensile modulus 2413 – 3447 MPa Heat deflection temperature (1.80 MPa) 65 – 100°C

Tensile strength 55.1 – 75.8 MPa Softening temperature 105 – 118°C

Elongation at break 2%

F lexural strength 82.7 – 117.2 MPa

F lexural modulus 5.51 – 7.58 GPa

Hardness (Shore D) 98

Physical Properties

Density 1.18 – 1.19 g/cm³

Reference Datasheets provided by Xometry contain materials sourced through trusted

OEMs, material distributors, and databases. Please visit Materialdatacenter.com

for further information on this material.

CNC Machining • Sheet Metal • 3D Printing • Injection Moulding • Die Casting | xometry.eu

You might also like

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationsAsistencia Técnica JLFNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationsAsistencia Técnica JLFNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationssribachaNo ratings yet

- DELRINDocument1 pageDELRINluuiissNo ratings yet

- AON3D Brochure Fixed 2 PDFDocument4 pagesAON3D Brochure Fixed 2 PDFSajalNo ratings yet

- Plastic Product DesignDocument256 pagesPlastic Product DesignManohar BNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationsAsistencia Técnica JLFNo ratings yet

- PC AbsDocument1 pagePC AbsJosue OrtizNo ratings yet

- Acetal Copolymer (POM)Document5 pagesAcetal Copolymer (POM)DiegoTierradentroNo ratings yet

- Product Design With PlasticsDocument256 pagesProduct Design With PlasticsPrachi LoharNo ratings yet

- TECAPEEK CF30 Black 7 PDFDocument1 pageTECAPEEK CF30 Black 7 PDFHARSHANo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- Metallic Additive ManufacturingDocument61 pagesMetallic Additive Manufacturingashok gadewalNo ratings yet

- Boedeker Plastics Polyurethane - Technical GuideDocument26 pagesBoedeker Plastics Polyurethane - Technical GuideJagdish PatelNo ratings yet

- TDS - TR144 - Astm (Eng)Document2 pagesTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- TECAPEEK GF30 Natural - Stock ShapesDocument1 pageTECAPEEK GF30 Natural - Stock ShapesHARSHANo ratings yet

- Tds Imix 93 PolymerDocument2 pagesTds Imix 93 PolymerMukul SareenNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Tds Imix 73 PolymerDocument2 pagesTds Imix 73 PolymerMukul SareenNo ratings yet

- Materials SLADocument30 pagesMaterials SLAR RAJESWARINo ratings yet

- PolycarbonateDocument1 pagePolycarbonateAsistencia Técnica JLFNo ratings yet

- Product Design With PlasticsDocument256 pagesProduct Design With PlasticsBhuban Limbu100% (3)

- Ficha Técnica Film Koro-Form 65 (20-45) - PapeDocument1 pageFicha Técnica Film Koro-Form 65 (20-45) - PapeJonathan Elvira VeraNo ratings yet

- Ficha Técnica Film KORO-ForM 65 (20-45) - PAPEDocument1 pageFicha Técnica Film KORO-ForM 65 (20-45) - PAPEJonathan Elvira VeraNo ratings yet

- Tecapeek SD Black Datasheet Ver A0Document1 pageTecapeek SD Black Datasheet Ver A0kgrier8966No ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- Product Design With PlasticsDocument256 pagesProduct Design With Plasticsvicksgeorge0% (1)

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- Somos DMX SL 100 Leaflet v2 PDFDocument2 pagesSomos DMX SL 100 Leaflet v2 PDFBenjamin NGNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- PVDF Material V1R2Document2 pagesPVDF Material V1R2Niemand InversionesNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- TECAPEEK PVX Black 7 PDFDocument1 pageTECAPEEK PVX Black 7 PDFHARSHANo ratings yet

- Kemflex 1 TdsDocument1 pageKemflex 1 TdsmohamedNo ratings yet

- Berutox FE 18 EP: Technical Product InformationDocument1 pageBerutox FE 18 EP: Technical Product InformationMauricio SánchezNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Thermal Transfer Polyester Label Material: Technical Data May 2017Document5 pagesThermal Transfer Polyester Label Material: Technical Data May 2017Sebastian BaenaNo ratings yet

- Diamant Technical Data Sheet Plasticmetal Model Ceram SetDocument4 pagesDiamant Technical Data Sheet Plasticmetal Model Ceram SetRogério FreitasNo ratings yet

- CFRP PropertiesDocument2 pagesCFRP Propertiesswapnil gandhiNo ratings yet

- Kaysun Tight Tolerance WhitepaperDocument6 pagesKaysun Tight Tolerance WhitepaperShree Nayak0% (1)

- eSUN PETG-Filament TDS V4.0Document2 pageseSUN PETG-Filament TDS V4.0AlbertNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

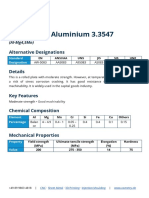

- Data Sheet: Aluminium 3.3547: Alternative DesignationsDocument2 pagesData Sheet: Aluminium 3.3547: Alternative DesignationsMemkNo ratings yet

- DH2211 - High Tear Strength Silicone Membrane PDFDocument1 pageDH2211 - High Tear Strength Silicone Membrane PDFJiyang WangNo ratings yet

- Datasheet Cast Acrylic Sheet enDocument1 pageDatasheet Cast Acrylic Sheet entrippNo ratings yet

- Engineering Thermoplastics: Products and GradesDocument20 pagesEngineering Thermoplastics: Products and GradesmadkatteNo ratings yet

- Product DescriptionDocument9 pagesProduct DescriptionMichael Stevens AgudeloNo ratings yet

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- High Density PolyethyleneDocument1 pageHigh Density PolyethyleneSyed MoinNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- 370HR DatasheetDocument3 pages370HR DatasheetasdNo ratings yet

- Chopped Strand Mat EmulsionDocument2 pagesChopped Strand Mat EmulsionWaseem AkramNo ratings yet

- Tilara Polyplast EcatalogueDocument16 pagesTilara Polyplast EcatalogueRohit ChudasamaNo ratings yet

- Reflective Wave Phenomena Defined Design Considerations For VFD Applications-2Document4 pagesReflective Wave Phenomena Defined Design Considerations For VFD Applications-2Asistencia Técnica JLFNo ratings yet

- Safety Data Sheet For ACDC Compact Fans and Drive Systems - enDocument2 pagesSafety Data Sheet For ACDC Compact Fans and Drive Systems - enAsistencia Técnica JLFNo ratings yet

- For Solid Fuel Heating Systems: Fans and BlowersDocument100 pagesFor Solid Fuel Heating Systems: Fans and BlowersAsistencia Técnica JLFNo ratings yet

- PolycarbonateDocument1 pagePolycarbonateAsistencia Técnica JLFNo ratings yet

- Propag EFT2 1990Document10 pagesPropag EFT2 1990Asistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 5: Structural Materials: Metallic and CompositeDocument398 pagesSpace Engineering: Thermal Design Handbook - Part 5: Structural Materials: Metallic and CompositeAsistencia Técnica JLFNo ratings yet

- 48 Pulses Rectifier DesignDocument7 pages48 Pulses Rectifier DesignAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 8: Heat PipesDocument151 pagesSpace Engineering: Thermal Design Handbook - Part 8: Heat PipesAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 4: Conductive Heat TransferDocument156 pagesSpace Engineering: Thermal Design Handbook - Part 4: Conductive Heat TransferAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 11: Electrical HeatingDocument48 pagesSpace Engineering: Thermal Design Handbook - Part 11: Electrical HeatingAsistencia Técnica JLFNo ratings yet

- Snoa 748 CDocument20 pagesSnoa 748 CAsistencia Técnica JLFNo ratings yet

- A Novel Design of The Roots BlowerDocument13 pagesA Novel Design of The Roots BlowerAsistencia Técnica JLFNo ratings yet

- App Note 53Document7 pagesApp Note 53Asistencia Técnica JLFNo ratings yet

- Condition Monitoring of Rotating Ma PDFDocument11 pagesCondition Monitoring of Rotating Ma PDFAsistencia Técnica JLFNo ratings yet

- Antique Radio Forums - View Topic - Tektronix 2235 Scope Power Supply ProblemDocument4 pagesAntique Radio Forums - View Topic - Tektronix 2235 Scope Power Supply ProblemAsistencia Técnica JLFNo ratings yet

- Altech E StopsDocument2 pagesAltech E StopsAsistencia Técnica JLFNo ratings yet

- Resistors 101 VishayDocument8 pagesResistors 101 VishayAsistencia Técnica JLFNo ratings yet

- Power-integrity-eGuide Misc en 3608-6531-92 v0200Document44 pagesPower-integrity-eGuide Misc en 3608-6531-92 v0200Asistencia Técnica JLFNo ratings yet

- Review of Owon B41TDocument17 pagesReview of Owon B41TAsistencia Técnica JLFNo ratings yet

- Stepping Motor EncoderDocument32 pagesStepping Motor EncoderAsistencia Técnica JLFNo ratings yet

- MS-L3P-L4P Servo-Stepper DriverDocument9 pagesMS-L3P-L4P Servo-Stepper DriverAsistencia Técnica JLFNo ratings yet

- Review of Owon B35TDocument15 pagesReview of Owon B35TAsistencia Técnica JLFNo ratings yet

- MS-L3 Servo-Stepper Drive User ManualDocument12 pagesMS-L3 Servo-Stepper Drive User ManualAsistencia Técnica JLFNo ratings yet

- ES86 Stepper Drive+motor Encoder (Rev.2)Document7 pagesES86 Stepper Drive+motor Encoder (Rev.2)Asistencia Técnica JLFNo ratings yet

- TIP Demos Final ColorDocument39 pagesTIP Demos Final ColorAsistencia Técnica JLFNo ratings yet

- UTI85ADocument1 pageUTI85AAsistencia Técnica JLFNo ratings yet

- Multimeter DesignDocument17 pagesMultimeter DesignAsistencia Técnica JLFNo ratings yet

- MQTTDocument9 pagesMQTTAsistencia Técnica JLFNo ratings yet