Professional Documents

Culture Documents

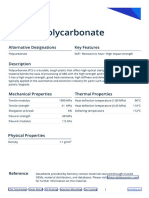

Key Features Alternative Designations

Uploaded by

Asistencia Técnica JLFOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Features Alternative Designations

Uploaded by

Asistencia Técnica JLFCopyright:

Available Formats

Data Sheet

ABS

Alternative Designations Key Features

Acrylonitrile Butadiene Styrene High rigidity and dimensional stability • Resistant to

impact and scratches

Description

This is a thermoplastic material widely known for its high resistance to impact and toughness. In

addition, it has good scratch resistance and rigidity as well as a low melting point and high weldability.

With a high strength–to–weight ratio, it is well suitable for injection moulding. It is used in the

manufacturing, automotive, and marine industries.

Mechanical Properties Thermal Properties

Tensile modulus 2270 MPa Melting temperature (20°C/min) 221 – 227°C

Tensile strength 46 MPa Heat deflection temperature (1.80 MPa) 7C

9 °

Elongation at break 48% Softening temperature 95° C

F lexural strength 69 MPa

F lexural modulus 23.5 GPa

Hardness (Shore D) 68 – 118

Physical Properties

Density 1.06 g/cm³

Reference Datasheets provided by Xometry contain materials sourced through trusted

OEMs, material distributors, and databases. Please visit Materialdatacenter.com

for further information on this material.

CNC Machining • Sheet Metal • 3D Printing • Injection Moulding • Die Casting | xometry.eu

You might also like

- PC AbsDocument1 pagePC AbsJosue OrtizNo ratings yet

- PolycarbonateDocument1 pagePolycarbonateAsistencia Técnica JLFNo ratings yet

- AcrylicDocument1 pageAcrylicAsistencia Técnica JLFNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationssribachaNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationsAsistencia Técnica JLFNo ratings yet

- Key Features Alternative DesignationsDocument1 pageKey Features Alternative DesignationsAsistencia Técnica JLFNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- Nylon-6 6Document1 pageNylon-6 6Asistencia Técnica JLFNo ratings yet

- BL4 - HM 8255Document1 pageBL4 - HM 8255ShahryarNo ratings yet

- DELRINDocument1 pageDELRINluuiissNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Acetal Copolymer (POM)Document5 pagesAcetal Copolymer (POM)DiegoTierradentroNo ratings yet

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- BL6 - HM 7255Document1 pageBL6 - HM 7255ShahryarNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

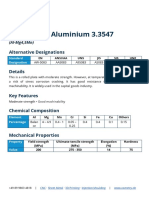

- Data Sheet: Aluminium 3.3547: Alternative DesignationsDocument2 pagesData Sheet: Aluminium 3.3547: Alternative DesignationsMemkNo ratings yet

- CFRP PropertiesDocument2 pagesCFRP Propertiesswapnil gandhiNo ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- PolyLite PETG TDS V5.3-20240309Document6 pagesPolyLite PETG TDS V5.3-20240309Freddy ArribasplataNo ratings yet

- Pom 90Document2 pagesPom 90busyNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- BL5 - HM 7746Document1 pageBL5 - HM 7746ShahryarNo ratings yet

- Copper-Alloy-C84400 (Normal)Document12 pagesCopper-Alloy-C84400 (Normal)CristianoRoecherNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Cf-Pla TDSDocument1 pageCf-Pla TDSilkerNo ratings yet

- Matrox X TDS PDFDocument1 pageMatrox X TDS PDFrajanarenderNo ratings yet

- TALLER PRESOSTATO 2 InglesDocument2 pagesTALLER PRESOSTATO 2 Inglesedisson garzonNo ratings yet

- BL7 - HM 6255Document1 pageBL7 - HM 6255ShahryarNo ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- I-Rod Adhesive: ºC 500 Hours 1,000 HoursDocument1 pageI-Rod Adhesive: ºC 500 Hours 1,000 HoursJustinNo ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- Matrox U110 TDS PDFDocument1 pageMatrox U110 TDS PDFrajanarenderNo ratings yet

- Raise3d Premium PETG TDS V3Document3 pagesRaise3d Premium PETG TDS V3Faris AlmarshadNo ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14kgrier8966No ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- TECAPEEK Natural Polyetheretherketone 14Document2 pagesTECAPEEK Natural Polyetheretherketone 14e.montgomeryNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- TDS TREVA Bioplastic TR6041 NaturalDocument2 pagesTDS TREVA Bioplastic TR6041 NaturalHenry HungNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- Rema Tip Top Remaline 70 CN PLDocument1 pageRema Tip Top Remaline 70 CN PLdedison_rNo ratings yet

- Propipe Polyurethane Tech Data Rev 03Document2 pagesPropipe Polyurethane Tech Data Rev 03fadialkasrawiNo ratings yet

- ViperSkin PS July2019-WEB 2Document2 pagesViperSkin PS July2019-WEB 2pareshkmNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Desmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Document2 pagesDesmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Johnny SyluanciaNo ratings yet

- PolyTerra-PLA TDS V5.3-20231113Document6 pagesPolyTerra-PLA TDS V5.3-20231113nerze0777No ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- Reflective Wave Phenomena Defined Design Considerations For VFD Applications-2Document4 pagesReflective Wave Phenomena Defined Design Considerations For VFD Applications-2Asistencia Técnica JLFNo ratings yet

- Safety Data Sheet For ACDC Compact Fans and Drive Systems - enDocument2 pagesSafety Data Sheet For ACDC Compact Fans and Drive Systems - enAsistencia Técnica JLFNo ratings yet

- For Solid Fuel Heating Systems: Fans and BlowersDocument100 pagesFor Solid Fuel Heating Systems: Fans and BlowersAsistencia Técnica JLFNo ratings yet

- Propag EFT2 1990Document10 pagesPropag EFT2 1990Asistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 5: Structural Materials: Metallic and CompositeDocument398 pagesSpace Engineering: Thermal Design Handbook - Part 5: Structural Materials: Metallic and CompositeAsistencia Técnica JLFNo ratings yet

- 48 Pulses Rectifier DesignDocument7 pages48 Pulses Rectifier DesignAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 8: Heat PipesDocument151 pagesSpace Engineering: Thermal Design Handbook - Part 8: Heat PipesAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 4: Conductive Heat TransferDocument156 pagesSpace Engineering: Thermal Design Handbook - Part 4: Conductive Heat TransferAsistencia Técnica JLFNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 11: Electrical HeatingDocument48 pagesSpace Engineering: Thermal Design Handbook - Part 11: Electrical HeatingAsistencia Técnica JLFNo ratings yet

- Snoa 748 CDocument20 pagesSnoa 748 CAsistencia Técnica JLFNo ratings yet

- A Novel Design of The Roots BlowerDocument13 pagesA Novel Design of The Roots BlowerAsistencia Técnica JLFNo ratings yet

- App Note 53Document7 pagesApp Note 53Asistencia Técnica JLFNo ratings yet

- Condition Monitoring of Rotating Ma PDFDocument11 pagesCondition Monitoring of Rotating Ma PDFAsistencia Técnica JLFNo ratings yet

- Antique Radio Forums - View Topic - Tektronix 2235 Scope Power Supply ProblemDocument4 pagesAntique Radio Forums - View Topic - Tektronix 2235 Scope Power Supply ProblemAsistencia Técnica JLFNo ratings yet

- Altech E StopsDocument2 pagesAltech E StopsAsistencia Técnica JLFNo ratings yet

- Resistors 101 VishayDocument8 pagesResistors 101 VishayAsistencia Técnica JLFNo ratings yet

- Power-integrity-eGuide Misc en 3608-6531-92 v0200Document44 pagesPower-integrity-eGuide Misc en 3608-6531-92 v0200Asistencia Técnica JLFNo ratings yet

- Review of Owon B41TDocument17 pagesReview of Owon B41TAsistencia Técnica JLFNo ratings yet

- Stepping Motor EncoderDocument32 pagesStepping Motor EncoderAsistencia Técnica JLFNo ratings yet

- MS-L3P-L4P Servo-Stepper DriverDocument9 pagesMS-L3P-L4P Servo-Stepper DriverAsistencia Técnica JLFNo ratings yet

- Review of Owon B35TDocument15 pagesReview of Owon B35TAsistencia Técnica JLFNo ratings yet

- MS-L3 Servo-Stepper Drive User ManualDocument12 pagesMS-L3 Servo-Stepper Drive User ManualAsistencia Técnica JLFNo ratings yet

- ES86 Stepper Drive+motor Encoder (Rev.2)Document7 pagesES86 Stepper Drive+motor Encoder (Rev.2)Asistencia Técnica JLFNo ratings yet

- TIP Demos Final ColorDocument39 pagesTIP Demos Final ColorAsistencia Técnica JLFNo ratings yet

- UTI85ADocument1 pageUTI85AAsistencia Técnica JLFNo ratings yet

- Multimeter DesignDocument17 pagesMultimeter DesignAsistencia Técnica JLFNo ratings yet

- MQTTDocument9 pagesMQTTAsistencia Técnica JLFNo ratings yet