Professional Documents

Culture Documents

Foundation Engineering4

Foundation Engineering4

Uploaded by

mahmoud alawneh0 ratings0% found this document useful (0 votes)

0 views1 pageThis document discusses methods for evaluating rock quality from borehole drilling data. It defines the recovery ratio as the length of core recovered divided by the theoretical core length, which indicates the intactness of the rock. It also defines the rock quality designation (RQD) as the length of core pieces 10+ cm long divided by the core length, and provides a table relating RQD values to general rock quality classifications from very poor to excellent. The document also outlines the key information, such as subsurface conditions, water levels, sampling details, and core recovery measurements that should be recorded in a boring log during borehole drilling.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses methods for evaluating rock quality from borehole drilling data. It defines the recovery ratio as the length of core recovered divided by the theoretical core length, which indicates the intactness of the rock. It also defines the rock quality designation (RQD) as the length of core pieces 10+ cm long divided by the core length, and provides a table relating RQD values to general rock quality classifications from very poor to excellent. The document also outlines the key information, such as subsurface conditions, water levels, sampling details, and core recovery measurements that should be recorded in a boring log during borehole drilling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views1 pageFoundation Engineering4

Foundation Engineering4

Uploaded by

mahmoud alawnehThis document discusses methods for evaluating rock quality from borehole drilling data. It defines the recovery ratio as the length of core recovered divided by the theoretical core length, which indicates the intactness of the rock. It also defines the rock quality designation (RQD) as the length of core pieces 10+ cm long divided by the core length, and provides a table relating RQD values to general rock quality classifications from very poor to excellent. The document also outlines the key information, such as subsurface conditions, water levels, sampling details, and core recovery measurements that should be recorded in a boring log during borehole drilling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

2.

25 Preparation of Boring Logs 117

recovered from each run, the following quantities may be calculated for a general eval-

uation of the rock quality encountered:

length of core recovered

Recovery ratio 5 (2.70)

theoretical length of rock cored

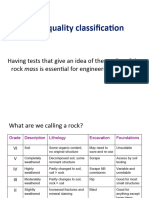

Rock quality designation (RQD)

S length of recovered pieces equal to or larger than 101.6 mm

5 (2.71)

theoretical length of rock cored

A recovery ratio of unity indicates the presence of intact rock; for highly fractured

rocks, the recovery ratio may be 0.5 or smaller. Table 2.11 presents the general relation-

ship (Deere, 1963) between the RQD and the in situ rock quality.

Table 2.11 Relation between in situ

Rock Quality and RQD

RQD Rock quality

0–0.25 Very poor

0.25–0.5 Poor

0.5–0.75 Fair

0.75–0.9 Good

0.9–1 Excellent

2.25 Preparation of Boring Logs

The detailed information gathered from each borehole is presented in a graphical form

called the boring log. As a borehole is advanced downward, the driller generally should

record the following information in a standard log:

1. Name and address of the drilling company

2. Driller’s name

3. Job description and number

4. Number, type, and location of boring

5. Date of boring

6. Subsurface stratification, which can be obtained by visual observation of the soil

brought out by auger, split-spoon sampler, and thin-walled Shelby tube sampler

7. Elevation of water table and date observed, use of casing and mud losses, and so on

8. Standard penetration resistance and the depth of SPT

9. Number, type, and depth of soil sample collected

10. In case of rock coring, type of core barrel used and, for each run, the actual length

of coring, length of core recovery, and RQD

This information should never be left to memory, because doing so often results in erro-

neous boring logs.

You might also like

- Geotechnical Logging - Quick ReferenceDocument47 pagesGeotechnical Logging - Quick ReferenceGabi LeventeNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- What Is Object Oriented Programming?: Ch-1 OOP in Python Updated & Revised by Dr. Ra'ed M. Al-Khatib (2019)Document45 pagesWhat Is Object Oriented Programming?: Ch-1 OOP in Python Updated & Revised by Dr. Ra'ed M. Al-Khatib (2019)mahmoud alawnehNo ratings yet

- Part 09 - Classification of Rock MassDocument21 pagesPart 09 - Classification of Rock MassAfendi AriffNo ratings yet

- IS-1121 Part-1 Compressive StrengthDocument8 pagesIS-1121 Part-1 Compressive StrengthSaurav KumarNo ratings yet

- ASTM D4543 - Preparing Rock Core SpecimensDocument4 pagesASTM D4543 - Preparing Rock Core SpecimensEDWINPENADILLO100% (1)

- ASTM D5361 Sampling of Compacted PavementDocument3 pagesASTM D5361 Sampling of Compacted Pavementrajeshji_000100% (5)

- New NDT Techniques For The Assessment of Fire-Damaged Concrete StructuresDocument12 pagesNew NDT Techniques For The Assessment of Fire-Damaged Concrete StructuresLarissa KirchhofNo ratings yet

- Oil & Gas Industry Cycle: Where Are The Hydrocarbons?Document38 pagesOil & Gas Industry Cycle: Where Are The Hydrocarbons?ahza hanifNo ratings yet

- Reservoir Engineering NotesDocument270 pagesReservoir Engineering Notesimogen200780% (15)

- D6032 Rock Quality Designation PDFDocument4 pagesD6032 Rock Quality Designation PDFelnaqa176No ratings yet

- D 6032 - 08-ReferensiDocument5 pagesD 6032 - 08-ReferensifzainadliNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Core Analysis ScriptDocument45 pagesCore Analysis ScriptWahid Mia100% (3)

- 5 - PENILAIAN FORMASI (Coring and Core Analysis)Document56 pages5 - PENILAIAN FORMASI (Coring and Core Analysis)Muhamad Zamzam Istimaqom100% (4)

- CH 01 - Part 1 PDFDocument21 pagesCH 01 - Part 1 PDFmahmoud alawnehNo ratings yet

- (Handouts) Geological and Geophysical Exploration in CEDocument9 pages(Handouts) Geological and Geophysical Exploration in CEJaash De GuzmanNo ratings yet

- Company Profile PT. Geoservices PDFDocument45 pagesCompany Profile PT. Geoservices PDFerwin narayudhaNo ratings yet

- Measurement and Analysis of Rock Mass Fractures and Their Applications in Civil EngineeringDocument24 pagesMeasurement and Analysis of Rock Mass Fractures and Their Applications in Civil EngineeringSlobodan Petric100% (1)

- D 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock CoreDocument4 pagesD 6032 - 96 - Determining Rock Quality Designation (RQD) of Rock Corezuheib63No ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Methods of Subsoil InvestigationDocument16 pagesMethods of Subsoil InvestigationUduebor Micheal71% (14)

- Tutorial GEOLOGYDocument43 pagesTutorial GEOLOGYFebri Deni Firdiansyah100% (2)

- RQD TestDocument5 pagesRQD Testkiko auNo ratings yet

- Clayroofingcounrrytiles, Half Roundandflattiles-SpecificationDocument8 pagesClayroofingcounrrytiles, Half Roundandflattiles-SpecificationAnonymous i6zgzUvNo ratings yet

- 5 - Study of Scale Effects of Rock Quality Designation (RQD) Measurements Using A Discrete Fracture Network Approach - 1Document2 pages5 - Study of Scale Effects of Rock Quality Designation (RQD) Measurements Using A Discrete Fracture Network Approach - 1OliverNo ratings yet

- Determination Rock Quality Designation RQD Basis On Joints: January 2011Document6 pagesDetermination Rock Quality Designation RQD Basis On Joints: January 2011rNo ratings yet

- Topic 5Document28 pagesTopic 5iffahNo ratings yet

- 6.4 - HRC-Specification-for-supply-of-Rock 块石供应说明Document21 pages6.4 - HRC-Specification-for-supply-of-Rock 块石供应说明Kevin TangNo ratings yet

- 5 - Study of Scale Effects of Rock Quality Designation (RQD) Measurements Using A Discrete Fracture Network Approach - 4Document12 pages5 - Study of Scale Effects of Rock Quality Designation (RQD) Measurements Using A Discrete Fracture Network Approach - 4OliverNo ratings yet

- Foundation and Slope Stability: Taek-Mo SHIMDocument38 pagesFoundation and Slope Stability: Taek-Mo SHIMkesharaNo ratings yet

- Design Criteria: RR FTDocument1 pageDesign Criteria: RR FTFernando FanteNo ratings yet

- Tuticorin Geotechnical ReportDocument16 pagesTuticorin Geotechnical Reportmohan890No ratings yet

- Chapter 7 Rock Mass ClassificationDocument32 pagesChapter 7 Rock Mass ClassificationsyafiqNo ratings yet

- Design of Earth SlopesDocument88 pagesDesign of Earth SlopesRajesh KhadkaNo ratings yet

- CHP 9.1 (RQD)Document17 pagesCHP 9.1 (RQD)Tuan Jalai100% (1)

- Surface & Subsurface Geotechnical InvestigationDocument5 pagesSurface & Subsurface Geotechnical InvestigationAshok Kumar SahaNo ratings yet

- Y Rtterur) : Subsurface Exploration For Earth and Rockfill Dams - Code of PracticeDocument14 pagesY Rtterur) : Subsurface Exploration For Earth and Rockfill Dams - Code of PracticeSanthan NaniNo ratings yet

- Performance of Reinforced Soil Wall Supported On Stone ColumnsDocument9 pagesPerformance of Reinforced Soil Wall Supported On Stone Columnsjinwook75No ratings yet

- Update QDocument4 pagesUpdate QAlfonsoNo ratings yet

- Core Recovery and RQD (Rock Quality Designation)Document2 pagesCore Recovery and RQD (Rock Quality Designation)Aayush Aggarwal100% (1)

- 229 - PadurDocument14 pages229 - PadurpmrameshkumarNo ratings yet

- 318 Sector C DHADocument35 pages318 Sector C DHAFAHAD JANNo ratings yet

- UNIT 1 Rock Mass ClassificationDocument28 pagesUNIT 1 Rock Mass ClassificationSanko KosanNo ratings yet

- Lndian Standard: Plastics - Methods of TestingDocument9 pagesLndian Standard: Plastics - Methods of Testinggini associatesNo ratings yet

- Deere 1988 - The Rock Quality Designation (RQD) in PracticeDocument15 pagesDeere 1988 - The Rock Quality Designation (RQD) in PracticeAndres Felipe MiraNo ratings yet

- ÇKÑFRD Fuekz.K Irfkjksa Osq Lkef Z XQ - Kksa Dks KKR Djuk Ijh (K.K I FR K¡Document8 pagesÇKÑFRD Fuekz.K Irfkjksa Osq Lkef Z XQ - Kksa Dks KKR Djuk Ijh (K.K I FR K¡Indira MukherjeeNo ratings yet

- 6 Rock Mass Classification SystemDocument48 pages6 Rock Mass Classification Systemmohamed magdyNo ratings yet

- Lim Jee Wen MFKA2015Document26 pagesLim Jee Wen MFKA2015ElaMazlanNo ratings yet

- Rev1Document6 pagesRev1Alaa AlabdullaNo ratings yet

- Rock Mass ClassificationDocument20 pagesRock Mass ClassificationmihretabNo ratings yet

- 2022 Chapter 2C Core DrillingDocument28 pages2022 Chapter 2C Core DrillingOUMAR PATHE BARRYNo ratings yet

- Geo Mec Rock Unit 3Document6 pagesGeo Mec Rock Unit 3muruganNo ratings yet

- Building Code4Document100 pagesBuilding Code4HeinMinn AungNo ratings yet

- Specimen ReportDocument18 pagesSpecimen ReportMuhammad Aamir QadriNo ratings yet

- Real-Time Specific Energy Monitoring Enhances The Understanding of When To Pull Worn PDC BitsDocument10 pagesReal-Time Specific Energy Monitoring Enhances The Understanding of When To Pull Worn PDC BitspendexxNo ratings yet

- 2013 Correlation Between RMR and SMR Based On Field Data - IJCEBS 01-01-13 ZAKARIA Et Al 2013Document4 pages2013 Correlation Between RMR and SMR Based On Field Data - IJCEBS 01-01-13 ZAKARIA Et Al 2013kenzakaria8364No ratings yet

- Determining Situ Deformation Modulus Using A Flexible Volumetric DilatometerDocument26 pagesDetermining Situ Deformation Modulus Using A Flexible Volumetric DilatometerelenaNo ratings yet

- Evaluation of Formation Damage Caused by Completion and Workover FluidsDocument4 pagesEvaluation of Formation Damage Caused by Completion and Workover FluidsarispriyatmonoNo ratings yet

- Azimian 2015Document8 pagesAzimian 2015Kevin RiosNo ratings yet

- Verification Without Test Pile FactorsDocument27 pagesVerification Without Test Pile FactorsDavid NewbyNo ratings yet

- D 6032 - 96 Determining Rock Quality Designation (RQD) of Rock Core1Document6 pagesD 6032 - 96 Determining Rock Quality Designation (RQD) of Rock Core1annaselemelaNo ratings yet

- Consistency Limits 1Document41 pagesConsistency Limits 1ipog_2k1No ratings yet

- A Review of Field Performance of Stone Columns in Soft SoilsDocument12 pagesA Review of Field Performance of Stone Columns in Soft SoilsVee VNo ratings yet

- Understanding of Soil MechanicsDocument27 pagesUnderstanding of Soil Mechanicsnimish.aquamarineNo ratings yet

- Rock Mass ClassificationDocument40 pagesRock Mass ClassificationLeoNo ratings yet

- Well LoggingDocument20 pagesWell LoggingShining PearlsNo ratings yet

- Chapter GeologyDocument5 pagesChapter GeologyAkash BhartiNo ratings yet

- Fire Fighting-Shovel For Forest Fires-Specification: Indian StandardDocument6 pagesFire Fighting-Shovel For Forest Fires-Specification: Indian StandardTushal DiyoraNo ratings yet

- Is 2210 PDFDocument18 pagesIs 2210 PDFShailendra ArunNo ratings yet

- 3 Rock QualityDocument33 pages3 Rock QualityManoj KitchappanNo ratings yet

- Foundation Engineering2Document8 pagesFoundation Engineering2mahmoud alawnehNo ratings yet

- Foundation Engineering3Document5 pagesFoundation Engineering3mahmoud alawnehNo ratings yet

- Yarmouk University Al-Hijjawi Faculty For Engineering Technology Civil Engineering DepartmentDocument4 pagesYarmouk University Al-Hijjawi Faculty For Engineering Technology Civil Engineering Departmentmahmoud alawnehNo ratings yet

- Chapter 6 - Sediment and Sedimentary Rocks PDFDocument45 pagesChapter 6 - Sediment and Sedimentary Rocks PDFmahmoud alawnehNo ratings yet

- Chapter 3 - Igneous Rocks PDFDocument31 pagesChapter 3 - Igneous Rocks PDFmahmoud alawnehNo ratings yet

- Method Statement Rev 00 - Geotechnical InvestigationDocument35 pagesMethod Statement Rev 00 - Geotechnical Investigationenjazco.rsgNo ratings yet

- Geotechnical Investigations and Studies: APRIL 1991Document35 pagesGeotechnical Investigations and Studies: APRIL 1991roshan_geo078896No ratings yet

- Tripp DKK 2002-Karaha Gravity ModellingDocument9 pagesTripp DKK 2002-Karaha Gravity ModellingAlyssa JutaNo ratings yet

- REPORT Bridge No. 2 P6 and P10 PDFDocument49 pagesREPORT Bridge No. 2 P6 and P10 PDFumerNo ratings yet

- 4a.1 Jairam PDFDocument47 pages4a.1 Jairam PDFJaganathan ChokkalingamNo ratings yet

- CoringDocument6 pagesCoringAgam SharmaNo ratings yet

- FoundationEngineeringNotes PDFDocument253 pagesFoundationEngineeringNotes PDFNabin YadavNo ratings yet

- Concrete Coring (Eng) PDFDocument2 pagesConcrete Coring (Eng) PDFSanchai_SaNo ratings yet

- Exploration for china clay in Kadayattu, Puthiyaveedu Padinjattumbhagom, and Kanjirakode area of Mulavana village, Kollam district, Kerala Sughada Pradeep and K N Raman Nampoothiri Directorate of Mining and Geology KeralaDocument25 pagesExploration for china clay in Kadayattu, Puthiyaveedu Padinjattumbhagom, and Kanjirakode area of Mulavana village, Kollam district, Kerala Sughada Pradeep and K N Raman Nampoothiri Directorate of Mining and Geology KeralaS.Alec KnowleNo ratings yet

- Formation Damage and Remedial: StimulationDocument17 pagesFormation Damage and Remedial: StimulationaliNo ratings yet

- Dry Matter Kit InstructionsDocument2 pagesDry Matter Kit Instructionsthomas4321No ratings yet

- Link Rupa ReportDocument56 pagesLink Rupa Reportupasana9No ratings yet

- Sidewall Coring (SWC)Document19 pagesSidewall Coring (SWC)afiqahNo ratings yet

- Facies-Independent Reservoir Characterization of The Micropore-Dominated Word Field (Edwards Formation), Lavaca County, TexasDocument22 pagesFacies-Independent Reservoir Characterization of The Micropore-Dominated Word Field (Edwards Formation), Lavaca County, TexasMak RamNo ratings yet

- Understanding The Waxman-Smits Equations: (For Version 2010.1 Subject To Change by Techsia)Document11 pagesUnderstanding The Waxman-Smits Equations: (For Version 2010.1 Subject To Change by Techsia)ابوبكر عبد الباقي100% (1)

- TOR For Detail Study, EIA and Mining Plan Preparation For Limestone QuarryDocument9 pagesTOR For Detail Study, EIA and Mining Plan Preparation For Limestone QuarryDilnesa EjiguNo ratings yet

- Normas GTX Rock TestingDocument2 pagesNormas GTX Rock TestingOWEMNo ratings yet

- What Is RQD (Rock Quality Designation) ?Document4 pagesWhat Is RQD (Rock Quality Designation) ?Rajat BaghelNo ratings yet

- Shale QuantDocument11 pagesShale QuantjavacobNo ratings yet

- Mine Planning and SchedulingDocument69 pagesMine Planning and SchedulingQuinton Dean ChingokaNo ratings yet

- XPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFDocument7 pagesXPS Mineralogy - QEMSCAN, XRD, Electron Probe, Geomet Unit Flot., Drill Core Min., Filter Analysis, Au Mineralogy PDFChristian Aguilar DiazNo ratings yet