Professional Documents

Culture Documents

IJRAR23B4373

Uploaded by

KARTIK KANAWADECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJRAR23B4373

Uploaded by

KARTIK KANAWADECopyright:

Available Formats

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.

org (E-ISSN 2348-1269, P- ISSN 2349-5138)

DESIGN AND FABRICATION OF SEED

SOWING MACHINE WITH FERTILIZER

DROPPING IMPLEMENTATION

1Yash Jadhav, 2Pritesh Kadam, 3Vishal Pawar, 4Akshay Hulage

1

Student 1, 2Student 2, 3Student 3, 4Student 4

1

Prof. S. V. Gosavi,

1

Mechanical Engineering,

1

P.E.S. Modern College of Engineering, Shivajinagar, Pune, India.

Abstract: Agriculture is a major sector worldwide that plays a vital role in the economic development of nations. In today's era,

there is a rapid growth across all sectors, including agriculture. Agricultural technology, known as agro technology, involves the

implementation of recent technologies to enhance crop production. When developing new products or processes, it is important to

consider the economic feasibility of the technology as well as its impact on society.

One crucial concern in the agricultural sector is the availability of labor. As labor costs increase and labor availability becomes a

significant issue for farmers, it is essential to address these challenges. Seed sowing is a fundamental and crucial operation in farming.

However, the current equipment used for seed sowing is difficult and inconvenient to handle. Therefore, there is a pressing need to

design and develop a machine that can reduce the efforts required by farmers. This machine aims to assist farmers in achieving the

best crop yield with minimal effort.

An ideal sowing machine should be suitable for all types of farms and crops, possess robust construction, and be reliable. These

are the basic requirements for a sowing machine. The primary objective of the sowing operation is to accurately place seeds and

fertilizer in rows at the desired depth and cover the seeds with soil, and provide proper compaction over the seeds. Our designed

sowing machine is manually operated and significantly reduces the efforts required by farmers, thereby increasing sowing efficiency

and mitigating the issues encountered during manual sowing. This machine allows for sowing various types of seeds and provides

flexibility in adjusting the spacing between two seeds during planting.

Keywords- Manual Seed Sowing, sowing disc, FEA, Chain and Sprockets, Agro-technology.

I. INTRODUCTION

India is known for its villages, where agriculture is the primary occupation for the majority of the population. Agriculture has

long been the backbone of the Indian economy and will continue to be so for the foreseeable future. It supports nearly 17% of the

world's population with only 2.3% of the world's geographical area and 4.2% of the world's water resources. Our entire economy is

based on agriculture, which involves the efficient production of food, feed, fiber, and other goods for humans and animals. It has

been observed that farmers in India primarily use hoes, axes, and shovels as their main farm tools for agricultural operations [4][5].

These tools are conventional and have been used for a long time without any improvements in agricultural practices. Therefore, it is

necessary to develop a system that reduces laborious tasks and is user-friendly for the agricultural community in India.

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 674

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

The major sources of agricultural growth during recent years have been the adoption of modern crop varieties, increased input

usage, and investments leading to expansion in irrigated areas. However, in areas where the "Green Revolution" technologies had a

major impact, growth has now slowed down. To push the boundaries of yield, utilize inputs more efficiently, and diversify towards

more sustainable and higher-value cropping patterns, new technologies are needed. Future agricultural growth needs to be faster,

more widespread, and better targeted.

The primary objective of sowing operations is to place seeds and fertilizer in rows at the desired depth and spacing, cover them

with soil, and provide proper compaction. In order to save farmers' time and effort, it is important to develop methods that not only

save time but also reduce their workload. Farmers often face the challenge of not having access to bullocks or tractors during the

peak sowing period, which leads them to hire them at increased costs. Traditional methods of agricultural processes result in lower

productivity compared to other regions. This is often due to imbalanced fertilizer application without knowledge of the actual nutrient

requirements for specific crops.

It is now widely recognized worldwide that in order to meet the food requirements of the growing population and rapid

industrialization, modernizing agriculture is crucial. On many farms, production suffers due to improper seedbed preparation and

delays in sowing, harvesting, and threshing. Mechanization allows for better input conservation through precise metering, ensuring

improved distribution, reducing the quantity needed for optimal response, and preventing losses or wastage of applied inputs. In

regions where human labor and draft animals are the main sources of farm power, the timeliness of field operations, including seeding,

has been identified as a major factor in increasing cropping intensity.

The number of seeds to be sown per unit area depends on factors such as seed size, germination percentage, expected plant cover

at maturity, and intended use of the plant for either fodder or grain. Manual planting requires farmers to spend a significant amount

of time, which is often limited for them. Consequently, more manpower is required to complete the task within the designated time,

which can be costly. Additionally, manual planting leads to more wastage. Therefore, there is a need to develop a machine that can

assist farmers in reducing their efforts during planting.

II. OBJECTIVES

1. To design and fabricate manually operated seed sowing machine.

2. To analytically validate the working model.

3. Make this machine economical and user friendly for Indian farmers to operate.

4. To implement the functionality of sowing different types of seeds.

5. To improve the efficiency of sowing operation and reduce the farmer’s fatigue.

III. METHODOLOGY

Literature review and market survey.

Identification of market requirements and farmer’s needs from the literature study.

Analytical calculations as per methods studied from research papers.

3D modelling of the machine as per the calculations.

Finite Element Analysis of the model on various iterations.

Selecting the best possible mechanism and best possible layout.

Fabrication of the machine according to the 3D design.

Farm testing for validation of objectives and evaluation of the design.

IV. CALCUALTIONS FOR AVERAGE LOADING CONDITION

Curb weight of vehicle = 10 kg and active weight of the vehicle = 15kg Total weight = 25kg. Now assuming the active wight of 15 kg

of machineis acting on horizontal members of chassis. So, 15 kg/m = 15*0.65 = 9.75kg of point load acting on the horizontal truss

members. Therefore, point load acting on member = 9.75*9.81 = 95.64 N.

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 675

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Considering the condition of simply supported beam,

Fig. UDL acting on simply supported beam

By using the Flexural formula, we can find different parameters of it, like bendingmoment, bending stress and deflection of

member. Bending formula is given by

a) Maximum bending moment is given by, Mmax = WL2/8 = (95.64) *(0.65)2/8

Hence, Mmax = 5050.9 Nmm = 5.05 Nm

b) Bending stress is given by, σb = y*(M/I) = (1.45*5050.9)/16345.3 = 0.448N/mm2

c) Deflection is given by, δ= (5WL4)/(384*EI) = (5*95.64*6504)/ (384*2.1*105*16345.3)δ=64.761mm = 65mm

(approx.) = 0.065 m (At UDL=95.64N

V. DESIGN OF MODEL

3D Model

Fig. Side View Fig. Isometric View

Fig. 2D Draft of Seed Sowing machine

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 676

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

FEA of chassis

Fig. Displacement Contour Fig. Strain Contour

Results of FEA

Based on the analysis and considering the operating conditions and material properties, it can be concluded that the design of the

seed sowing machine is suitable and meets the required safety criteria. The deformation and stress levels experienced during average

loading conditions are within acceptable limits.

The material used for the seed sowing machine is mild steel, which has a Young's modulus of 2 * 10^5 N/mm². Mild steel is known

for its strength and durability, although it may have a lower tensile strength compared to carbon steel.

In summary, the design of the seed sowing machine is considered safe due to the following factors:

1. Deformation: The deformation experienced under average loading conditions is less, indicating that the structural integrity of the

machine remains intact.

2. Stress Levels: The stress levels experienced during average loading conditions are within acceptable limits, even when using

mild steel.

3. Material Choice: Although carbon steel has a higher tensile strength than mild steel, the mild steel's tensile strength is still

adequate to handle the stress levels encountered during operation.

Therefore, based on the provided data, the design of the seed sowing machine is suitable and meets the required safety criteria, and

the use of mild steel ensures sufficient strength and durability for its intended purpose.

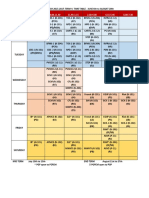

COMPONENT SPECIFICATIONS

Sr. No. Component Specification

1 Hollow Square pipe rods Size =25*25*2, material = mild steel

2 Chain and Sprocket Length = 1.5 m and teeth’s of sprocket= 18

Material = stainless steel

3 Tank Capacity of tank = 15 L and material =

Plastic

4 Hopper Capacity of hopper = 3 kg and material= MS

sheet metal

5 Bearing Type = deep groove ball bearing, ID = 10

mm

6 Axel (shaft) Material = mild steel and Diameter = 10mm

7 Seed disk Material = plastic and no. of openings = 8

Component Specifications Table

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 677

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

Actual Model after Fabrication

Fig. Actual model after fabrication

VI. RESULTS:

1. Consistent sowing rate: The machine consistently sows seeds at a steady rate, ensuring uniform distribution.

2. Varied seed spacing: The distance between consecutive seeds is approximately 10 cm, but it may vary depending on

the seed type. This indicates that the machine can be adjusted to accommodate different planting requirements.

3. Simultaneous sowing and fertilizing: The machine enable the simultaneous execution of sowing and fertilizing

operations, streamlining the planting process.

4. Seed quantity and time interval: Within a 30-minute time interval, the machine successfully sowed approximately 1.5

kg of seeds, highlighting its efficiency in terms of seed distribution capacity.

5. Comparatively lesser sowing time: It was observed that the machine's sowing time was lesser compared to manual

sowing done individually. This suggests that manual sowing may be slower for small-scale or precise planting scenarios.

6. Reduced human fatigue: The use of the machine significantly reduces human fatigue caused by lower back pain and

shoulder problems associated with manual sowing. This indicates that the machine offers ergonomic benefits and

reduces strain on the operator.

7. Cost-effective and low maintenance: The machine's cost is relatively lower compared to market competitors, and its

maintenance is minimal due to fewer components. Occasional oiling is the primary requirement for upkeep, making it

an affordable and easy-to-maintain option.

VII. CONCLUSION

This seed sowing machine has great potential for increasing the productivity of sowing operations. Until now, tractors

have been the primary source of power for farming. However, with the adoption of this seed planting machine, its purpose can be

fulfilled. Therefore, there is a need to promote this technology and make it available to small-scale farmers at affordable prices. The

design of this machine can be simplified, reducing the overall project cost and enabling easy manufacturing in existing workshops.

This manually operated seed sowing machine can fulfill the needs of poor and small-scale farmers. They can easily and effectively

sow their seeds in the field using these machines, which offer several advantages. It increases productivity, enhances sowing

efficiency, reduces human efforts, and minimizes the time and labor required for sowing.

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 678

© 2023 IJRAR June 2023, Volume 10, Issue 2 www.ijrar.org (E-ISSN 2348-1269, P- ISSN 2349-5138)

VIII. REFERENCES

[1] Adalinge N. B., Ghune G. P., Lavate G. B. and Mane R. R. (2017). Design and Manufacturing of Seed Sowing machine.

International journal of advance research ideasand innovation in technology. Vol. 3(2), 705-708.

[2] Kyada, A. R. and Patel D. B. (2014). Design and development of manually operated Seed planter machine. All India

Manufacturing Technology, Design and Research conference, IIT Guwahati, Assam, India. Vol.2(728), 1-7.

[3] Kanthiravan R. and P. Balashanmugam, (2019). Design and fabrication of manuallyoperated seed sowing machine. International

Research Journal of Engineering and Technology. Vol. 6 (6), 3767-3774.

[4] Renitha P., Vignesh P., Karthick Sories M. R. and Ramalingam D. (2018). A study about the design and fabrication of automatic

seed sowing and fertilizer Spraying machine. International journal of management, technology and engineering. Vol. 8 (4),

695-703.

[5] Marode R. V., Tayade G. P. and Agrawal S. K. (2013). Design and implementationof multi seed sowing machine. International

Journal of Mechanical engineering and robotics research. 2(4), 422-429.

IJRAR23B4373 International Journal of Research and Analytical Reviews (IJRAR) 679

You might also like

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- Multicrop Harvesting MachineDocument9 pagesMulticrop Harvesting MachineIJRASETPublicationsNo ratings yet

- Design and Fabrication of Multipurpose Agricultural MachineDocument7 pagesDesign and Fabrication of Multipurpose Agricultural MachineIJRASETPublicationsNo ratings yet

- Experimental Optimization of Corn Shelling Machine - A ReviewDocument7 pagesExperimental Optimization of Corn Shelling Machine - A ReviewIJRASETPublicationsNo ratings yet

- Design and Fabrication of Spraying MachineDocument9 pagesDesign and Fabrication of Spraying MachineIJRASETPublicationsNo ratings yet

- Design and Fabrication of IoT Operated Cono WeederDocument7 pagesDesign and Fabrication of IoT Operated Cono WeederIJRASETPublicationsNo ratings yet

- Universal Multipurpose Cultivator: International Research Journal of Engineering and Technology (IRJET)Document6 pagesUniversal Multipurpose Cultivator: International Research Journal of Engineering and Technology (IRJET)Shivam ShahNo ratings yet

- 207Document7 pages207varshitNo ratings yet

- Fabrication of Paddy Transplanter Machine PDFDocument7 pagesFabrication of Paddy Transplanter Machine PDFRushab KadamNo ratings yet

- Automatic Seed Sowing Robot for Agricultural FieldsDocument18 pagesAutomatic Seed Sowing Robot for Agricultural FieldsSandeep ArduNo ratings yet

- Rice Transplanter Research PaperDocument8 pagesRice Transplanter Research Paperfzgz6hyt100% (1)

- Maize Shller ThreshingDocument13 pagesMaize Shller ThreshingFrancisco ToroNo ratings yet

- Design of Cutting Blade of Agricultural Harvester Using Bionic PrincipleDocument11 pagesDesign of Cutting Blade of Agricultural Harvester Using Bionic PrincipleIJRASETPublicationsNo ratings yet

- Optimization and Development of Existing Corn Sheller MachineDocument5 pagesOptimization and Development of Existing Corn Sheller MachineIJRASETPublicationsNo ratings yet

- Modifying crop cultivating machinesDocument11 pagesModifying crop cultivating machinessingamNo ratings yet

- Palm FruitDocument13 pagesPalm FruitTofunmi MatthewNo ratings yet

- Design Development of Automatic Seed Sowing Machine by Utilizing Solar EnergyDocument17 pagesDesign Development of Automatic Seed Sowing Machine by Utilizing Solar EnergyFlip ItNo ratings yet

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- Vinayak PDFDocument5 pagesVinayak PDFrajput sunilNo ratings yet

- Design and Fabrication of Agricultural SprayerDocument7 pagesDesign and Fabrication of Agricultural SprayerIJRASETPublicationsNo ratings yet

- Design of Crop Cutter MachineDocument6 pagesDesign of Crop Cutter MachineVijay PulavarthiNo ratings yet

- K U S E D: Project Proposal OnDocument15 pagesK U S E D: Project Proposal OnANGUS PRASAINo ratings yet

- Research Paper On Maize ShellerDocument4 pagesResearch Paper On Maize Shellerfznn7hzd100% (1)

- Design, Fabrication and Experimentation of Equidistant Seed Sowing Cum Fertilizer MachineDocument3 pagesDesign, Fabrication and Experimentation of Equidistant Seed Sowing Cum Fertilizer MachineIJIRSTNo ratings yet

- Capstone Project Report PDFDocument26 pagesCapstone Project Report PDFVishwas AroraNo ratings yet

- Seed Sowing MachineDocument6 pagesSeed Sowing MachineVasuNo ratings yet

- Design and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurDocument2 pagesDesign and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurSaiNo ratings yet

- An Innovative Model For Multipurpose Agricultural Use-IJAERDV04I0378655Document3 pagesAn Innovative Model For Multipurpose Agricultural Use-IJAERDV04I0378655Praveen KumarNo ratings yet

- Agriculture: Study On The Method of Matched Splice Grafting For Melon Seedlings Based On Visual ImageDocument16 pagesAgriculture: Study On The Method of Matched Splice Grafting For Melon Seedlings Based On Visual ImageJose LuisNo ratings yet

- Design and Fabrication of A Motorized Rice HullingDocument11 pagesDesign and Fabrication of A Motorized Rice HullingridwanmuhammadtajudeenNo ratings yet

- Thesis Final Proposal PresentationDocument25 pagesThesis Final Proposal Presentationkibromkb100% (1)

- Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineDocument10 pagesDesign and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter Enginenagaraju b 334No ratings yet

- Seed sowing machine design and fabricationDocument5 pagesSeed sowing machine design and fabricationMaahiNo ratings yet

- Shredder Design ArticleDocument9 pagesShredder Design ArticleEphraim MekonnenNo ratings yet

- Design and Fabrication of Crop ReaperDocument9 pagesDesign and Fabrication of Crop ReaperIJRASETPublicationsNo ratings yet

- Mechanization of Sugarcane Cultivation PDFDocument9 pagesMechanization of Sugarcane Cultivation PDFJennifer Jacinto WeberNo ratings yet

- Adefidipeand Adetola 2022Document14 pagesAdefidipeand Adetola 2022Marj EspinosaNo ratings yet

- Design and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesDocument12 pagesDesign and Fabrication of Multi-Purpose Cutting Machine For Agricultural UsesIJRASETPublicationsNo ratings yet

- Review On Pulverization MachineDocument7 pagesReview On Pulverization MachineIJRASETPublicationsNo ratings yet

- Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineDocument10 pagesDesign and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineTony StarkNo ratings yet

- Design and Analysis of Modified Agricultural Sprayer MachineDocument11 pagesDesign and Analysis of Modified Agricultural Sprayer MachineIJRASETPublicationsNo ratings yet

- Design and Fabrication of Solar Seed Sprayer Machine: July 2016Document5 pagesDesign and Fabrication of Solar Seed Sprayer Machine: July 2016लविश जाटNo ratings yet

- Engineering Properties of Paddy For Designing of Threshing MechanismDocument10 pagesEngineering Properties of Paddy For Designing of Threshing MechanismTJPRC PublicationsNo ratings yet

- PROPOSALDocument9 pagesPROPOSALmaeklltechNo ratings yet

- Cultivator FinalDocument3 pagesCultivator FinalArufuredo GurenNo ratings yet

- Design and Fabrication of A Hand Operated Small Scale Maize ShellerDocument8 pagesDesign and Fabrication of A Hand Operated Small Scale Maize ShellerleeNo ratings yet

- Design and Fabrication of Universal Seed Sowing Machine: P. Baladarshini S. Monika N. Dhanalakshmi, Dr. A. AshaDocument14 pagesDesign and Fabrication of Universal Seed Sowing Machine: P. Baladarshini S. Monika N. Dhanalakshmi, Dr. A. Ashazain abideenNo ratings yet

- 109am - 5.EPRA JOURNALS-5089Document7 pages109am - 5.EPRA JOURNALS-5089ashraf.imraishNo ratings yet

- 1994-Article Text-3743-1-10-20210301Document5 pages1994-Article Text-3743-1-10-20210301B S chethanNo ratings yet

- Groundnut Thrasher DesignDocument27 pagesGroundnut Thrasher DesignBoopathi KalaiNo ratings yet

- Solar Powered Seed Sprayer: A Report on the Design of a Solar Powered Seed Spraying MachineDocument15 pagesSolar Powered Seed Sprayer: A Report on the Design of a Solar Powered Seed Spraying MachineSiddharth KumarNo ratings yet

- Design, Construction and Performance Evaluation of Multi-Crop Grater MachineDocument16 pagesDesign, Construction and Performance Evaluation of Multi-Crop Grater MachineAbas S. AcmadNo ratings yet

- JETIRBQ06023Document5 pagesJETIRBQ06023eyNo ratings yet

- Irjet V5i6410Document4 pagesIrjet V5i6410Flip ItNo ratings yet

- 4 5882069874942938061Document8 pages4 5882069874942938061Tesfay AbebeNo ratings yet

- FinalPaperDESIGN AND FABRICATION OF SOLAR PADDY THRESHING MACHINE FOR AGRICULTURE PURPOSE191502 PDFDocument5 pagesFinalPaperDESIGN AND FABRICATION OF SOLAR PADDY THRESHING MACHINE FOR AGRICULTURE PURPOSE191502 PDFFachryan NaufalNo ratings yet

- Design and Development of "Crop Cutter": September 2018Document7 pagesDesign and Development of "Crop Cutter": September 2018faiza_No ratings yet

- Thesis Outline Abas2.1Document24 pagesThesis Outline Abas2.1Abas S. AcmadNo ratings yet

- Correction MergedDocument20 pagesCorrection MergedPrajwal NayakNo ratings yet

- Test Bank For The Human Body in Health and Disease 7th Edition by PattonDocument11 pagesTest Bank For The Human Body in Health and Disease 7th Edition by PattonLaurence Pence100% (23)

- The Origins Development and Possible Decline of The Modern StateDocument65 pagesThe Origins Development and Possible Decline of The Modern StateJasper Jade MartinNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- Test Paper Trigonometric Functions and Equations PDFDocument9 pagesTest Paper Trigonometric Functions and Equations PDFkaushalshah28598No ratings yet

- Pre-Admission Interview Slip TemplateDocument1 pagePre-Admission Interview Slip TemplateLeaniel SilvaNo ratings yet

- Rubrics For Interd TaskDocument3 pagesRubrics For Interd Taskapi-265986384No ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- Operation Manual for XMT-808 Digital Temperature ControllerDocument23 pagesOperation Manual for XMT-808 Digital Temperature Controllerjonathan_calixto_4100% (1)

- Surveyquestionnaire 1Document6 pagesSurveyquestionnaire 1Almira IbarraNo ratings yet

- NSTP Law and ROTC RequirementsDocument47 pagesNSTP Law and ROTC RequirementsJayson Lucena82% (17)

- Z22 Double-Suction Axially-Split Single-Stage Centrifugal PumpDocument2 pagesZ22 Double-Suction Axially-Split Single-Stage Centrifugal Pumpmartín_suárez_110% (1)

- Nozomi Networks Smart Polling Data SheetDocument4 pagesNozomi Networks Smart Polling Data SheetFlávio Camilo CruzNo ratings yet

- Domestic Water-Supply - TheoryDocument19 pagesDomestic Water-Supply - Theoryyarzar17No ratings yet

- Business Communication - Module 3 - Org. 2015Document41 pagesBusiness Communication - Module 3 - Org. 2015Smriti MehtaNo ratings yet

- Term 4 Time Table & Exam Schedule.Document4 pagesTerm 4 Time Table & Exam Schedule.Anonymous FD3MCd89ZNo ratings yet

- Centrifugal PumpDocument44 pagesCentrifugal PumpAmishaan KharbandaNo ratings yet

- Smart CityDocument4 pagesSmart CityRendi NafiahNo ratings yet

- 3G FactsDocument17 pages3G Factsainemoses5798No ratings yet

- BJT AmplifiersDocument21 pagesBJT AmplifiersAligato John RayNo ratings yet

- Vray Physical Camera GuideDocument4 pagesVray Physical Camera GuideeoghanobrienNo ratings yet

- Manual Completo Sinovo SD600Document221 pagesManual Completo Sinovo SD600Felipe de PaulaNo ratings yet

- Kollmorgen S300 Servo Drive ManualDocument134 pagesKollmorgen S300 Servo Drive ManualCarlos SalazarNo ratings yet

- Hydrology Notes 4 PDFDocument12 pagesHydrology Notes 4 PDFSudin PradhanNo ratings yet

- MSC - Nastran 2014 Linear Static Analysis User's Guide PDFDocument762 pagesMSC - Nastran 2014 Linear Static Analysis User's Guide PDFFeiNo ratings yet

- Microsoft MB-210 Exam Dumps With Latest MB-210 PDFDocument10 pagesMicrosoft MB-210 Exam Dumps With Latest MB-210 PDFJamesMartinNo ratings yet

- Human Rights Law IntroductionDocument8 pagesHuman Rights Law IntroductionXander ZingapanNo ratings yet

- Branding and Marking GuideDocument15 pagesBranding and Marking GuideJhonNagaNo ratings yet

- El 5036 V2 PDFDocument86 pagesEl 5036 V2 PDFCriss TNo ratings yet

- International Emergency Nursing: Karen Hammad, Lingli Peng, Olga Anikeeva, Paul Arbon, Huiyun Du, Yinglan LiDocument5 pagesInternational Emergency Nursing: Karen Hammad, Lingli Peng, Olga Anikeeva, Paul Arbon, Huiyun Du, Yinglan LiRuly AryaNo ratings yet

- IdkDocument2 pagesIdkKyle FikaniNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingFrom EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNo ratings yet

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)