Professional Documents

Culture Documents

Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter Engine

Uploaded by

nagaraju b 334Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter Engine

Uploaded by

nagaraju b 334Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/343148333

Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using

Scooter Engine

Article · July 2020

DOI: 10.46610/JoAAEn.2020.v05i02.002

CITATIONS READS

0 9,036

3 authors:

Hanumesha Pujar Prashant D Banakar

Visvesvaraya Technological University KLE Institute of Technology

9 PUBLICATIONS 2 CITATIONS 4 PUBLICATIONS 0 CITATIONS

SEE PROFILE SEE PROFILE

Sharanabasappa C Sajjan

KLE Institute of Technology

21 PUBLICATIONS 11 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Mechanical Ox Replacing Tractors View project

Influence of Moonpool shapes on vessel response View project

All content following this page was uploaded by Sharanabasappa C Sajjan on 30 July 2020.

The user has requested enhancement of the downloaded file.

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle

Using Scooter Engine

Hanumesha Pujar1, Prashant D Banakar1, S C Sajjan2

1

Assistant Professor, 2Professor

Department of Mechanical Engineering, K. L. E. Institute of Technology, Hubballi, Karnataka, India.

*Corresponding Author: hanupujar@gmail.com

ABSTRACT the most important sector in the world. For many

Work has been carried out to design and years, agriculture has been carried out in a small

fabricate a multipurpose agricultural vehicle, to range cultivating between 2 to 3 hectare, with the

perform agricultural operations like goods help of human labor and traditional tools such as

carrying, pesticide spraying, inter‐cultivating, wooden plough, yoke, leveler, harrow, mallet,

ploughing. These operations are carried out in spade, big sickle etc. These are used in land

sandy loam deep soil. Some modifications were preparation, sowing of seeds, weeding and

done which includes fabricating a compact harvesting.

vehicle which can be moved easily in the fields. As mentioned earlier agriculture plays a

Use of hand tools for cultivation is still leading in vital role in India’s economy. Over 58% of the rural

India because tractors need resources which families depend on agriculture for their survival.

many farmers cannot afford. The need for Agriculture counted for 17.4 of India’s GDP in

improvisation in agriculture is very much 2015-16. India stands second in agriculture output.

essential, it is important to fill the gap between Around 95 million hectares of land is being used for

farmers and technology implementation. The agriculture. [1]

improvement and sustainability of the crops Indian farmers cannot use modern

mainly depends on the adoption of improved agricultural techniques and equipment because these

resource conserving cropping systems. But most are too expensive and difficult to purchase. By

of the necessary components already exist, the inculcating scientific farming methods, we can get

information about the availability and maximum yield and we can increase the quality of

performance of equipment is very poor between the crops which can save a farmer’s life, but the

farmers and agricultural research and majority of farmers are still using ancient methods

development departments. From the recent years due to lack of knowledge or lack of expenditure for

the input to the farms increased such as fertilizer, utilizing modern tools.

insecticide, pesticides, HYV seeds, farm labor Design, Development and Fabrication of

cost etc. Increase in the cost makes small land Multipurpose Agro Machine. The focus of this

holding farmers at a risk. Due to this lack of article is to design and develop agricultural

information suicide rate is increasing yearly, we equipment to perform seed sowing, fertilizer

need to identify the common factor for this. spreading and pesticide spraying operations. The

Because of commercialization of agriculture the first among the above mentioned operations is

suicide rate is increasing. But the crisis remained mechanically driven which consist of an intermittent

untouched. Commercialization of the landscape metering mechanism to serve a primary purpose of

along with large reduction in investment in achieving uniformity between the seeds to be sown.

agriculture was the beginning of the decline. The other two operations are achieved by using a

motor and submersible pump powered by a battery

Keywords-- Agricultural Machine, CAD Model, which in turn is recharged by a photovoltaic array.

Inter‐Cultivator, Pesticides Sprayer, Plough And they concluded as After comparing various

models the agro machine has considerable potential

to increase productivity and decrease the labor

INTRODUCTION effort, cost and time. It is an effective replacement

for usual labour in medium and small scale farm

We all know that agriculture is the lands. The model is designed to be eco-friendly and

backbone of the Indian economy. “A man who can less maintenance, operating cost [1]. Design and

survive for three days without food for three days Fabrication of Multipurpose Agriculture Equipment.

will quarrel, for a week will fight and for a month or In this work an attempt has been made for the design

so will die”. Agriculture is the branch of science and and fabricate multipurpose agricultural vehicle for

art of farming which includes cultivating the soil, farmers at lesser cost. The different components of

production of crops and raising the economy. It is the above multipurpose machine are modeled using

7 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

one of the parametric modeling software Creo

parametric 1.0. The modeled components are PROBLEM STATEMENT

fabricated and assembled together to form a

complete machine. And they have concluded as the The present agricultural equipment is of

multipurpose field equipment is relatively cheap and high cost. The rent of the machines is also

particularly useful for medium-scale farmers. The considerably high. The machines are not easy to

cost of the machine was estimated approximately as handle. The machines require a skill labour. The

Rs.20000. The major advantage of this design is the present machines are single purpose use. In early

ability of this equipment to perform several days, to perform any task of farming we required

operations, which include automatic sowing, separate equipment for every different task. Here we

weeding, Spraying, grass cutting and land are trying to make such an equipment that will

preparation [2]. An Innovative Model for perform a number of operations like sowing,

Multipurpose Agricultural Use”. In this work they weeding, grass cutting, tillage, ploughing, grinding,

have invented a multipurpose machine for carrying water lifting and spraying etc. with engine operated

out different farming activities with less effort and Four wheeler.

in less time. It is an eco-friendly device working on

solar energy. For this purpose, we are using solar OBJECTIVES

panels as power supplying devices which convert

solar energy into electrical energy. This electrical Multipurpose agriculture equipment can

energy is further converted into mechanical energy perform a number of functions like Sowing,

by motor. This model introduces the term Weeding, Tillage, Grass Cutting, ploughing,

“Autonomous Agriculture” which means we can grinding, water lifting and Spraying. To minimize

perform agricultural operations in required time and the cost, this equipment can be run on an engine. To

in required areas which is pre-specified by the Easy handling. Also there will be a minimum weight

operator. The advantages in agricultural production and compact in size. To Spraying and Inter-

to increase productivity improve application cultivating can be done simultaneously, it will

accuracy and enhance handling safety. And they reduce the labor cost.

have concluded as the review of the papers that there

is a need for innovation of sowing, digging and COMPONENTS

others such machines for the enhancement of Engine

farmers. Due to the rapid growth in industries is

influencing the laborers who are situated in the An “Engine” is a motor which converts

villages to migrate to the cities. This will create the chemical energy into mechanical energy. Four

labor problem for agriculture. The wages for the stroke engines were first demonstrated by “Nikolaus

labor is also more. As the prices of commodities Otto in 1876”, hence it is also known as Otto cycle.

such as food grains, fuels, cloths and other essentials It consists of 4 strokes of the piston that is one cycle

of daily life is increasing rapidly the laborers is completed in every two revolutions of the

demand for more wages from the owners. These crankshaft. Each stroke consists of 180o, of

factors influence the farmers who are interested in crankshaft rotation and hence a cycle consists of

agricultural activity to leave their land uncultivated. 720o, of crankshaft rotation.

By adopting this work in the field of agriculture we In our mini farm vehicle, we have used a

can help the farmers in the earlier stage of four stroke engine. The engine is placed at the

agriculture like during the seeding and fertilizing. middle of the frame to balance the vehicle. The

[3]. Design and Development of Multi-Utility engine shaft is connected to the front axle by means

Agricultural Vehicles”. In this work they explained of chain and sprocket. The speed can be controlled

about the old method of agriculture and equipment by the accelerator provided at the right side of the

used, which do not yield more. So they developed handle [6-7].

semi-automated multipurpose agricultural wheel

hoes to use for weeding, ploughing and cultivating Shaft

in single equipment. Their aim is to reduce the

manpower required for the operation wheel hoe. The A Shaft is used to transfer the power and

only way is to automate it but they do not fully torque and also it supports reverse bending. Power

automatic it due to few constraints not available of is transmitted from an electric motor or an engine to

electricity in villages, and it will require rotating parts of the system. Shafts have circular

microprocessors and sensors which will again cross sections. Difference between a shaft and an

increase the cost and might require skill to use it. axel is that the shaft rotates to transfer power but an

And they concluded that the equipment is beneficial axel is just like a round cantilever beam, so it is not

to farmers and its performance increases when subjected to fatigue. Shafts have different modes to

operating on a smooth surface. [4] transfer power and torque such as gears, sprockets,

8 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

pulleys, etc. and also have grooves to keep elements

rigid and avoid vibration. In our work we have used

a shaft attached to the frame by means of journal

bearing, one sprocket is connected to the engine

shaft and another sprocket is connected to the front

axle [8].

Chain Figure 1: Cultivator Tool.

It is shown in figure 1 One way of the name

Chain and sprocket mechanism is used to

refers to frames with the teeth, soil is dragged

perform the same job as a belt and pulley, both

through it linearly. Other ways it refers to equipment

transfer motion and force from one shaft to another. which uses rotary motion of disks or teeth to achieve

A belt can slide on a pulley but the teeth on the the same result. The rotary tiller is a suitable

sprocket stop the chain from sliding. A chain and example [9].

sprocket is used wherever a positive Cultivators stir and crush the soil, either

before planting to aerate the soil, or after the crop

There are six types of power transmission chains has started growing to kill weeds.

1. General purpose roller chains, used in industry. Frame

2. High performance roller chains which are

stronger than general purpose roller chains. It as shown in figure 2 consists of an

3. Lube-free chains, used without lubrication. internal frame which supports an object in its

4. Corrosion resistant chains with special. construction. It is similar to a skeleton. Resembles

5. Specialty chains, type a, used as bicycle chains, chassis of a vehicle, consisting of the frame. If the

motorcycle chains, automotive chains wheels are included, then it is called a rolling

6. Specialty chains, Type b, including miniature chassis.

chains, leaf chains and inverted tooth chain, i.e. Chassis are considered to be one of the

Silent chain important configurations of an automobile. Frame is

used to hold both the body of the machine and the

power train. Various mechanical components like

Pump

the engine and the drivetrain, the axle assemblies

including the wheels, the suspension parts, the

It is one of the simplest equipment used in brakes, the steering components, etc., are bolted

any process plant. Purpose of this is to convert the onto the chassis. We have used a hollow square tube

energy of an electric motor or turbine. Initially into of 3×3 size.

velocity or kinetic energy and next into pressure

energy of the fluid. The energy changes occur by

means of two parts impeller and diffuser. The

impeller is the rotating part that converts driver

energy into the kinetic energy while the diffuser is

the stationary part that converts the kinetic energy

into pressure energy.

Grinding Wheel

Grinding is a metal cutting operation

performed by means of abrasive particles mounted

on a rotating wheel. Abrasive particles act as a single

point cutting tool and grinding wheel acts as a

multipoint cutting tool. Grinding is one of the

commonly used finishing operations. It removes

material in minute chips of 0.25 to 0.50 mm size. It

gives accuracy up to 0.000025 mm.

F. Cultivator tool

Figure 2: Frame.

METHODOLOGY

PLANNING

9 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

For carbon steel 𝜎𝑦 = 353𝑁/𝑚𝑚2 taking from

• Identified the problem from the formers. D.D.H.B, P.no 464, TBL No I.8

• To overcome the drawback (space

requirement, weight, cost etc.) of the present 𝜎𝑦𝑎𝑙𝑙 < 𝜎𝑦 Therefore, the design is safe.

vehicle. planned to develop a new equipment

• Design of equipment as per the plan. B. Design of key

• Estimate the cost of final equipment. Torque transmitted by a key is

• Material preparation

• Material used: Scooter engine, pump, rigid 𝑑 𝑑

𝑀𝑡𝑠 = 𝐾𝑡𝑠 = (𝜏𝑑2 𝑏𝑙)

shaft, journal bearing, metal sheets, nut and 2 2

bolt, mild steel L-angle, flat plates, wheels and

𝑑 25

tires, hollow steel tube, etc. b= = = 6.25𝑚𝑚 b = h=6.25mm

2 4

Fabrication Consider a eqn of key hence

• Cutting the raw material as per the design and Based on shear strength

shape.

• Building the frame. 2𝑀𝑡 2 × 10 × 103

• As per the dimension drill the hole on frame. 𝑏=

𝜏𝑑𝑙

⇒ 6.25 =

3.26 × 𝑙 × 25

• Fixing the journal bearing.

• Mounting of shaft in bearing. 𝑙 = 39.26 ≃ 40𝑚𝑚

• Mounting of chain and sprocket on the shaft.

• Mounting the engine and pump on frame. Based on crushing strength

• Mounting the wheel on the axle.

• Mounting the required attachment on a frame. 4𝑀𝑡 4×10×103

ℎ= = ⇒ h=12.26mm

• Start the work. 𝜏𝑑𝑙 3.26×40×25

The angle of twist in a shaft subjected to a torque

Working

(radians) for (axel)

𝑇𝐿

• Attach the ploughing tool to the mainframe 𝜃 = ⇒ eqn no.1.3(c)

𝐽𝐺

using nut and bolt, and complete the work.

• While leveling the soil remove the present tool 10×103 ×610

𝜃= ⇒ 𝜃 = 0.00198𝑟𝑎𝑑

38.349×103 ×80×103

and attach the leveling tool.

(0.1139°)

• While seeding attach the seed drill tool to

frame.

Gear Ratio

• While sprinkling connect pump to engine and Considering with torque

connect pump to nozzle through pipes. N1 = N3 = N5 = N7 = 4000rpm

• If grinding of tools requires attaching a From the specification of engine

grinding wheel to the engine by chain drives. N2=369rpm, d=25mm, G=84×103N/mm2, m=70kg,

• If we require cutting of grass in lawns and T=10N-m, W = 70×9.81 = 680N, P=6.25HP

garden, we can attach grass cutter to the Frame (4.6kw),

by nut and bolt L=610mm=0.61m,

𝜋 𝜋

J = 𝑑4 ⇒ × 254 = 38.394×103mm4,

DESIGN AND FABRICATION 32 32

Design of Shaft 𝑁1 4000

= 17.33⇒ N2 = ⇒ N2=230.81rpm

𝑁2 17.33

16𝑇 16×10×103 𝑁3 4000

𝜏= = 𝜏=3.26N/mm2 = 10.82⇒ N4 = ⇒ N4=369.68rpm

𝜋𝑑 3 𝜋×253 𝑁4 10.82

𝜏 3.26 𝑁5 4000

𝜏 = 0.5𝜎𝑦 ⇒ 𝜎𝑦 = = = 6.25𝑁/𝑚𝑚2 𝑁6

= 10.82⇒ N 6=

6.1

⇒ N6=655.73rpm

0.5 0.5

𝑁7 4000

= 2.75⇒ N8 = ⇒ N8=1454.54rpm

𝑁8 2.75

𝜎𝑦𝑎𝑙𝑙 = 6.25𝑁/𝑚𝑚2

10 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

D. CAD Models

Figure 3: Frame.

Figure 4: Plough Tool.

11 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

Figure 5: 200mm Sprocket.

Figure 6: Leveling Blade.

12 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

Figure 7: 3D View of Mini Farm Vehicle.

Figure 8: Assembled Mini Farm Vehicle.

13 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

RESULTS

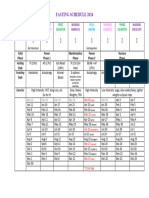

Comparison between Bullock and Mini Farm Vehicle

Table 1: Comparison Between Bullock and Mini Farm Vehicle.

Steps Involved In Primitive Method with Manual Tractor Powered

Multipurpose Mini

Agriculture and Features of Workers And Modern Method

Farm Vehicle

The Mechanization Bullock Equipment Equipment

Tilling using

cultivator once

Oxen ploughing Oxen ploughing

Field operation and gyrator

3 times 3 times

once and harrow

once

Extra workers Weeding is

Weeding cannot

required depends mechanized here

Weeding be done by using

on the area of the and no need of

tractor

land extra workers

Implementation of

scientific method and No Yes Yes

Precision farming.

Less than 3 More than 3 Less than 3

Suitable for total area of Land

Hectares Hectares Hectares

Number of workers

High Low Low

Involved

Time consumed for More Less Moderate

Working

Flexible for multipurpose

Yes No Yes

Operation

Worker condition Required skilled Required skilled

Unskilled workers can do the job.

workers Workers

Fuel consumption No 4 liter 2 liter

Performance Analysis

Table 2: Performance Analysis.

Fuel Consumption Time Required

Field Operation Land Area (acre)

(liter) (hours)

Inter-Cultivating 1 2 2

Cultivating 1 2.5 2

Ploughing 1 3-4 4

Leveling 1 2 2

Pesticide Spraying 1 1-1.5 2

CONCLUSION REFERENCES

The equipment is designed and developed 1. Prof. P.V. Bute, Shailesh Deshmukh, Govind Rai,

for the farmers having small farming land of 10-12 Chetan Patil & Vishal Deshmukh(2018,) “Design,

acre. It is useful for spraying, inter-cultivating, Development and Fabrication of Multipurpose Agro

ploughing as well as weeding at minimum cost for Machine”, International Research Journal of

the farmer so that he can afford it. The equipment Engineering and Technology (IRJET), Volume

will result more helpful when it is used in moist soil 5, Issue 1, pp, 865-968, Available at

for wedding purposes, due to moisture content https://www.irjet.net/archives/V5/i1/IRJET-

present in the soil the weed cutter can easily V5I1186.pdf

penetrate the soil and hence will easily accomplish 2. Veeresha G,Abdul Raheem, Abdul Kadeer Ansari,

the weeding process. Dinesh Yadav & Md. Mainudin Ansari (2017)

The performance of the equipment will “Design and Fabrication of Multipurpose

increase when it is operating on the smooth surface Agriculture Equipment”, International Research

or less uneven surface and also it will be more Journal of Engineering and Technology (IRJET),

effective when it is used on the crops with the same Volume 5 Issue 7, PP. 912-914, Available at

height and have less gap between two crops. https://www.irjet.net/archives/V5/i7/IRJET

V5I7157.pdf

3. Jayesh, A., Aakash, B., Mayur, P., Ensiya, T., &

Sham, K. (2017), “An Innovative Model for

14 Page 7-15 © MAT Journals 2020. All Rights Reserved

Journal of Automation and Automobile e-ISSN: 2582-3159

Engineering Volume-2, Issue-2 (May-August, 2020)

www.matjournals.com https://doi.org/10.46610/JoAAEn.2020.v05i02.002

Multipurpose Agricultural Use”, International Multipurpose Farm Equipment”, International

Journal of Advance Engineering and Research Journal of Innovative Research in Advanced

Development, Volume 4, Issue 3, Available at Engineering (IJIRAE), Issue 2, Volume 3, PP 30-36,

http://www.ijaerd.com/papers/finished_papers/An Available at

%20Innovative%20Model%20For%20Multipurpos https://www.ijirae.com/volumes/Vol3/iss2/05.FBA

e%20Agricultural%20Use- E10093.pdf

IJAERDV04I0378655.pdf 8. Nitin Kumar Mishra, Shashwat Khare, Sumit Singh

4. Karthikeyam, K., Sundar, S. S., Subramaniam, C. S., & Mithun Dabur (2017), “Multi-Purpose

& Sivakumar, P. S. (2017), “Design and Agriculture Machine”, International Journal of

development of a multi-utility agricultural vehicle”, Advances in Science Engineering and Technology,

IEEE Technological Innovations in ICT for Volume 5, Issue 1, Spl. Issue-2, PP 40-43, Available

Agriculture and Rural Development (TIAR) pp. 109- at

111, Available at 10.1109/TIAR.2017.8273695 http://www.iraj.in/journal/journal_file/journal_pdf/

5. Shree Harsha B T, Saketh Chellur, Aparna Latha A 6-342-149432479240-43.pdf

& Sandeep Kumar Y H M (2017) “Multi-Purpose 9. Raut, L. P., Jaiswal, S. B., & Mohite, N. Y. (2013),

Agricultural Vehicle”, Imperial Journal of “Design, development and fabrication of

Interdisciplinary Research (IJIR), Volume 3, Issue- agricultural pesticides sprayer with weeder”,

6, PP 125-129, Available at International Journal of Applied Research and

http://www.onlinejournal.in/IJIRV3I6/024.pdf Studies (Ijars), Volume 2, Issue 11, PP 1-8,

6. Dr. C.N. Sakhale et.al. (2016) “A Review Paper on Available at

Multipurpose Farm Machine”, International https://scholar.google.com/scholar?hl=en&as_sdt=

Research Journal of Engineering and Technology 0%2C5&q=Design%2C+development+and+fabrica

(IRJET), Volume 3, Issue 9, PP 900-995, Available tion+of+agricultural+pesticides+sprayer+with+wee

at https://www.irjet.net/archives/V3/i9/IRJET- de&btnG=

V3I9177.pdf

7. M.V.Achutha, Sharath Chandra. N & Nataraj.G.K

(2016), “Concept Design and Analysis of

15 Page 7-15 © MAT Journals 2020. All Rights Reserved

View publication stats

You might also like

- Design and Fabrication of Ginger Harvesting MachineDocument19 pagesDesign and Fabrication of Ginger Harvesting MachineNarender YadavNo ratings yet

- Fabrication of Automatic Pneumatic Clamping IgnovDocument7 pagesFabrication of Automatic Pneumatic Clamping IgnovChockalingam AthilingamNo ratings yet

- Automatic Tapping Drilling MachineDocument76 pagesAutomatic Tapping Drilling MachineChandramanikandanNo ratings yet

- Fabrication of Portable Noodle Making Ma Fd82a2eeDocument4 pagesFabrication of Portable Noodle Making Ma Fd82a2eeankush belkarNo ratings yet

- (##) Low Cost Harvesting MachineDocument98 pages(##) Low Cost Harvesting MachinemohanNo ratings yet

- Development of Plastic Bottle Shredding Machine 2252 5211 1000336Document4 pagesDevelopment of Plastic Bottle Shredding Machine 2252 5211 1000336salfm08100% (1)

- Design of Seed Sowing MachineDocument7 pagesDesign of Seed Sowing MachinePranshu GuptaNo ratings yet

- Automatic Plaster MachineDocument4 pagesAutomatic Plaster MachineIJMTST-Online JournalNo ratings yet

- Lemon Grass HarvesterDocument61 pagesLemon Grass HarvesterKok HuanNo ratings yet

- Vegetable Cutting MachineDocument48 pagesVegetable Cutting MachineOo PoutNo ratings yet

- Design and Fabrication of River Cleaning Machine PDFDocument8 pagesDesign and Fabrication of River Cleaning Machine PDFABHIJITH ANo ratings yet

- Design of A Hoisting System For A Small Scale MineDocument8 pagesDesign of A Hoisting System For A Small Scale MineAlfredtungu PiusNo ratings yet

- Fabricate Sugarcane Bud Chipper MachineDocument37 pagesFabricate Sugarcane Bud Chipper MachineAakash DindigulNo ratings yet

- Design and Fabrication of Ginger Juice Extracting MachineDocument33 pagesDesign and Fabrication of Ginger Juice Extracting MachineSanman SawantNo ratings yet

- Fabrication of Multipurpose 4 in 1 Agriculture Robotic VehicleDocument33 pagesFabrication of Multipurpose 4 in 1 Agriculture Robotic Vehicleanne valiaNo ratings yet

- 3.fabrication of CoconutDocument30 pages3.fabrication of CoconutMahesh Jadhav0% (1)

- Design Plastic Bottle CrusherDocument4 pagesDesign Plastic Bottle CrusheragungNo ratings yet

- Conceptual Design of Coconut Dehusking MachineDocument10 pagesConceptual Design of Coconut Dehusking Machineசிங்கக்குட்டி சின்னக் கவுண்டர்No ratings yet

- Sugarcane Cutting Machine GPDocument24 pagesSugarcane Cutting Machine GPDIPAK VINAYAK SHIRBHATE100% (7)

- Organic Potting Mix BasicsDocument11 pagesOrganic Potting Mix BasicsEl-Elohei Yeshua JesheuaNo ratings yet

- Design and Fabrication of Multipurpose Eco-Friendly Cleaning MachineDocument5 pagesDesign and Fabrication of Multipurpose Eco-Friendly Cleaning MachineIJRASETPublications0% (1)

- Motorized Vegtable Cutting MahineDocument21 pagesMotorized Vegtable Cutting MahineP24 Innovation CenterNo ratings yet

- Design and Fabrication of Groundnut ShellerDocument7 pagesDesign and Fabrication of Groundnut ShellerIJRASETPublications100% (1)

- Introduction To Modern Industrial EngineeringDocument221 pagesIntroduction To Modern Industrial EngineeringYober Arteaga IreneNo ratings yet

- Motorized Ramming MachineDocument53 pagesMotorized Ramming Machineilayaraja6100% (1)

- Design of An Innovative Coconut Grating Machine Using TinkercadDocument5 pagesDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Design and Fabrication of Groundnut Thresher MachineDocument5 pagesDesign and Fabrication of Groundnut Thresher MachineBhanu Hi100% (1)

- Bullock Cart Prototyping Using Catia and 3D PrintingDocument13 pagesBullock Cart Prototyping Using Catia and 3D PrintingAzure MidoriyaNo ratings yet

- Engineering Mechanics Solutions ManualDocument269 pagesEngineering Mechanics Solutions ManualAjay Kaushik100% (2)

- Design of A Portable Hydraulic Water Borehole Drilling RigDocument10 pagesDesign of A Portable Hydraulic Water Borehole Drilling RigAlexander DeckerNo ratings yet

- Design & Fabrication of Water Tank Cleaning MachineDocument5 pagesDesign & Fabrication of Water Tank Cleaning MachineIJRASETPublications100% (1)

- VIII SEM ROBOTICS AND AUTOMATION PREVIOUS YEAR QUESTION PAPERSDocument117 pagesVIII SEM ROBOTICS AND AUTOMATION PREVIOUS YEAR QUESTION PAPERSKALAIVANINo ratings yet

- Theoretical Design of A Plantain Peeling Machine: December 2018Document12 pagesTheoretical Design of A Plantain Peeling Machine: December 2018Óscar Alfonso Gómez SepúlvedaNo ratings yet

- AGRIDocument15 pagesAGRISantosh DineshNo ratings yet

- Rice Transplanter DesignDocument74 pagesRice Transplanter Designhoney mae100% (1)

- Minale 2021Document52 pagesMinale 2021Mustofa AdemNo ratings yet

- Agricultural Projects CollectionDocument3 pagesAgricultural Projects CollectionChandra Sekar100% (2)

- PS Chapter 3Document2 pagesPS Chapter 3Barlo Yñigo AlcantaraNo ratings yet

- Rural Mechanics Course 2 PDFDocument139 pagesRural Mechanics Course 2 PDFplutocowNo ratings yet

- Design and Fabrication of Low-Cost Groundnut Sheller MachineDocument31 pagesDesign and Fabrication of Low-Cost Groundnut Sheller MachineSaurabh Vaidya100% (1)

- Arecanut Harvesting MachineDocument14 pagesArecanut Harvesting MachineAnchith JoshiNo ratings yet

- Design of Power Weeder For Low Land Paddy Cultivation PDFDocument8 pagesDesign of Power Weeder For Low Land Paddy Cultivation PDFBOSS BOSS100% (1)

- Design and Fabrication of Agricultural CultivatorDocument6 pagesDesign and Fabrication of Agricultural Cultivatornagaraju b 334No ratings yet

- Advanced Pepper Separator Machine: A Project ReportDocument42 pagesAdvanced Pepper Separator Machine: A Project ReportSports GalleryNo ratings yet

- Project Submitted in Partial Fulfillment of The Requirement For The Award of Degree ofDocument42 pagesProject Submitted in Partial Fulfillment of The Requirement For The Award of Degree ofDinesh WasalwarNo ratings yet

- Design and fabrication of multi-purpose sieving machineDocument6 pagesDesign and fabrication of multi-purpose sieving machineMICHEL RAJ MechNo ratings yet

- Mais Thresher PDFDocument6 pagesMais Thresher PDFHenry DatangelNo ratings yet

- Pedal Operated Flour MillDocument49 pagesPedal Operated Flour MillYidenek Ngussie100% (1)

- IRC SP 100 - 2014 Cold Mix Technology in Construction PDFDocument95 pagesIRC SP 100 - 2014 Cold Mix Technology in Construction PDFrjg_vijay50% (2)

- Pedal-Powered Groundnut Sheller Design for Rural VillagesDocument37 pagesPedal-Powered Groundnut Sheller Design for Rural VillagesPankajDhobleNo ratings yet

- Fabrication of Tube Rolling MachineDocument6 pagesFabrication of Tube Rolling MachineSaravanan ViswakarmaNo ratings yet

- A Seminar Report OnDocument7 pagesA Seminar Report OnSagar Pandit0% (1)

- Design and Testing of Mechanical Juice Extraction Especially For Sugar Cane - 24 PagesDocument24 pagesDesign and Testing of Mechanical Juice Extraction Especially For Sugar Cane - 24 PagesMoHaMMeD HaLaBy50% (6)

- Automated Pneumatic Sheet Metal Cutting MachineDocument9 pagesAutomated Pneumatic Sheet Metal Cutting MachineRushikesh Patil100% (1)

- Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineDocument10 pagesDesign and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineTony StarkNo ratings yet

- VTU Synopsis on Solar Operated Automatic Multi Utility Agro VehicleDocument8 pagesVTU Synopsis on Solar Operated Automatic Multi Utility Agro VehicleSharath SuriNo ratings yet

- Dual Purpose Agri Robot Muthu Vinoth of 9-j1Document13 pagesDual Purpose Agri Robot Muthu Vinoth of 9-j1bbggamers1418No ratings yet

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- Remote Farming : Harnessing Automation and Robotics in AgricultureFrom EverandRemote Farming : Harnessing Automation and Robotics in AgricultureNo ratings yet

- Mini Power Tiller Machine Fabrication GuideDocument21 pagesMini Power Tiller Machine Fabrication Guidenagaraju b 334No ratings yet

- Design and Fabrication of Agricultural CultivatorDocument6 pagesDesign and Fabrication of Agricultural Cultivatornagaraju b 334No ratings yet

- Portable Electric Tiller Machine: IjarsctDocument4 pagesPortable Electric Tiller Machine: Ijarsctnagaraju b 334No ratings yet

- MEC215Document4 pagesMEC215spark mechanicsNo ratings yet

- Fabrication of Electric Agriculture Cultivator: IntroductionDocument5 pagesFabrication of Electric Agriculture Cultivator: Introductionnagaraju b 334No ratings yet

- Design and Fabrication of Agricultural CultivatorDocument6 pagesDesign and Fabrication of Agricultural Cultivatornagaraju b 334No ratings yet

- City MSJDocument50 pagesCity MSJHilary LedwellNo ratings yet

- 266 009-336Document327 pages266 009-336AlinaE.BarbuNo ratings yet

- Barcelona Smart City TourDocument44 pagesBarcelona Smart City TourPepe JeansNo ratings yet

- Act 1&2 and SAQ No - LawDocument4 pagesAct 1&2 and SAQ No - LawBududut BurnikNo ratings yet

- DNA Affirmative - MSDI 2015Document146 pagesDNA Affirmative - MSDI 2015Michael TangNo ratings yet

- Week 4 Gen EconDocument10 pagesWeek 4 Gen EconGenner RazNo ratings yet

- Analysis and Design of Multi Storey Building by Using STAAD ProDocument5 pagesAnalysis and Design of Multi Storey Building by Using STAAD Prolikith rockNo ratings yet

- Banu Maaruf of The LevantDocument6 pagesBanu Maaruf of The LevantMotiwala AbbasNo ratings yet

- Grace Lipsini1 2 3Document4 pagesGrace Lipsini1 2 3api-548923370No ratings yet

- Membandingkan Recall 24 Jam Nutri Survey Dengan TkpiDocument7 pagesMembandingkan Recall 24 Jam Nutri Survey Dengan TkpiFransisca SihotangNo ratings yet

- 2 Druid StreetDocument4 pages2 Druid StreetthamestunnelNo ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- Corporate Governance in SMEsDocument18 pagesCorporate Governance in SMEsSana DjaanineNo ratings yet

- Request For Proposal Construction & Phase 1 OperationDocument116 pagesRequest For Proposal Construction & Phase 1 Operationsobhi100% (2)

- Oracle Apps Quality ModuleDocument17 pagesOracle Apps Quality ModuleSantOsh100% (2)

- Soal Kelas 4 IIDocument5 pagesSoal Kelas 4 IIes tougeNo ratings yet

- Moon Fast Schedule 2024Document1 pageMoon Fast Schedule 2024mimiemendoza18No ratings yet

- History and Development of the Foodservice IndustryDocument23 pagesHistory and Development of the Foodservice IndustryMaria Athenna MallariNo ratings yet

- Timber, PVCu and aluminium window and door hardware systemsDocument24 pagesTimber, PVCu and aluminium window and door hardware systemsOmul Fara NumeNo ratings yet

- Plastic Welding: We Know HowDocument125 pagesPlastic Welding: We Know Howprabal rayNo ratings yet

- Airs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayDocument19 pagesAirs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayRamil J. Merculio100% (1)

- Durand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyDocument6 pagesDurand Et Al JHRC 1997 Experimental Design Optimization of The Analysis of Gasoline by Capillary Gas ChromatographyCatalinaSalamancaNo ratings yet

- Internal Peripherals of Avr McusDocument2 pagesInternal Peripherals of Avr McusKuldeep JashanNo ratings yet

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- Early Diabetic Risk Prediction Using Machine Learning Classification TechniquesDocument6 pagesEarly Diabetic Risk Prediction Using Machine Learning Classification TechniquesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- GD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreDocument1 pageGD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreVinay ManjuNo ratings yet

- X RayDocument16 pagesX RayMedical Physics2124No ratings yet

- Mad LabDocument66 pagesMad LabBalamurugan MNo ratings yet

- One - Pager - SOGEVAC SV 320 BDocument2 pagesOne - Pager - SOGEVAC SV 320 BEOLOS COMPRESSORS LTDNo ratings yet

- Power Team PE55 ManualDocument13 pagesPower Team PE55 ManualTitanplyNo ratings yet