Professional Documents

Culture Documents

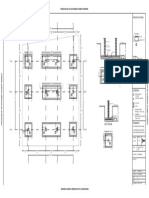

Ø Holes: Girder

Uploaded by

Erika Faye GutierrezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ø Holes: Girder

Uploaded by

Erika Faye GutierrezCopyright:

Available Formats

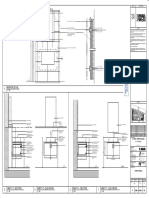

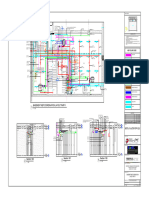

BEARING BLOCK

BEARING PLATE

CONNECTOR GUIDE

GROUT HOLE

C

L

0

210

GIRDER

CABLE DUCT 5 3300

CABLE DUCT 4 109

5

CABLE DUCT 3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 16

CABLE DUCT 2

CABLE DUCT 1

1600

FIXED STRESSED

STRESSED FIXED

FIXED STRESSED

STRESSED FIXED

FIXED STRESSED

Y1=0.100Y1=0.101Y1=0.102Y1=0.105Y1=0.109Y1=0.113Y1=0.119Y1=0.126Y1=0.134Y1=0.144Y1=0.154Y1=0.165Y1=0.177Y1=0.191Y1=0.205Y1=0.221Y1=0.238Y1=0.255

Y2=0.100Y2=0.102Y2=0.102Y2=0.111Y2=0.119Y2=0.130Y2=0.143Y2=0.159Y2=0.177Y2=0.197Y2=0.220Y2=0.245Y2=0.273Y2=0.303Y2=0.335Y2=0.370Y2=0.408Y2=0.447 3A E L E V A T I O N

Y3=0.100Y3=0.102Y3=0.107Y3=0.117Y3=0.130Y3=0.147Y3=0.167Y3=0.191Y3=0.219Y3=0.251Y3=0.286Y3=0.326Y3=0.369Y3=0.415Y3=0.466Y3=0.520Y3=0.578Y3=0.639 SP9 34 SCALE 1:50

Y4=0.100Y4=0.103Y4=0.110Y4=0.123Y4=0.140Y4=0.163Y4=0.191Y4=0.224Y4=0.262Y4=0.305Y4=0.353Y4=0.406Y4=0.464Y4=0.527Y4=0.596Y4=0.669Y4=0.748Y4=0.831

Y5=0.100Y5=0.103Y5=0.113Y5=0.129Y5=0.151Y5=0.180Y5=0.215Y5=0.256Y5=0.304Y5=0.358Y5=0.419Y5=0.486Y5=0.559Y5=0.639Y5=0.725Y5=0.818Y5=0.917Y5=1.023

1 PRESTRESSED GIRDER ELEVATION (TYPE V, L=33m) 65mmØ P.E. TUBE

SP9 34 SCALE 1:60

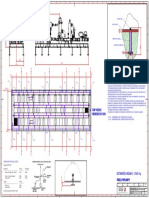

1067 1067 1067

500

76

76

76

12 - 15Ø HOLES

102

102

102

GROUT HOLE

330 102 102

102 330 330

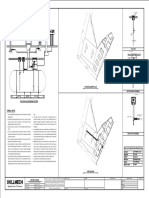

203 7-12mmØ TIES

203 203 @ 50mm O.C. PROVIDE GRIDS

1600

1600

1600

210

116

210

254 254 254 4-25mmØ

12T + 12.7 BEARING PLATE

8 - 15Ø HOLES

254

254

254

203

203

203

210 210 GROUT AFTER TENSIONING

MALE CONE

100

FEMALE CONE

1B SHOWING P/T CABLE @ SECT. 6 8T + 12.7 BEARING PLATE

1A SHOWING P/T CABLE @ MID SPAN 1C SHOWING P/T CABLE @ END POINT

SP9 34 SCALE SP9

1:20 34 SCALE 1:20 SP9 34 SCALE 1:20 GROUT HOLE / VENT SPREADED TEMPLATE

ATTACHED TO STIRRUPS

CEMENT GROUT

CONNECTOR

GUIDE

GIRDER DESIGN GUIDE

SPACE FOR POST-

TENSIONING CABLE

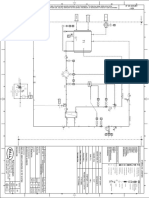

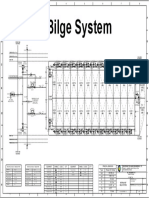

1.POST-TENSIONING STEEL:THE PROPOSEDTYPE OF TENDONSWHICH 5.THE REQUIREDSTRENGTHOF CONCRETEAT TIME OF TENSIONING

WILL BE USED IN THE POST TENSIONEDDESIGNS,ALL NECESSARY SHALLBE 28 MPA (4,000PSI). A GRIDCONSISTINGOF 12 mm ∅ BARS

ADDITIONALDETAILS INCLUDING THOSE FOR END ANCHORAGES, AT 100 CENTERSIN BOTH DIRECTIONSSHALL BE PLACED NEAR 12mm MESH BARS

METHODSTO BE EMPLOYEDAND PROCEDURESTO BE FOLLOWED, EACH ANCHORAGE OF THE POST-TENSIONINGSYSTEM. POST

SHALL BE AS APPROVEDBY THE ENGINEERS.A PORTIONOF THE TENSIONINGFORCES SHOWN BELOW COMPUTEDFOR TENDONS

TENDONS SHALL BE DRAPED LONGITUDINAL IN PARABOLIC JACKED SIMULTANEOUSLY AT BOTH ENDS, FRICTIONS #4 SPIRAL

POSITIONS,ALL TENDONSSHALLBE PLACEDSO THATTHEIRCENTER COEFFICIENTSARE K=0.0015AND u = 0.25 WITH AN ANCHORAGE 4 TURNS 5cm.

OF GRAVITYWILLBE AT THE POSITIONSHOWNON PLANS.THE TOTAL DEFORMATION OF 3 mm. PITCH

POST-TENSIONFORCEAFTERLOSSESREQUIREDAT MIDSPANSHALL

BE PROVIDED AS CALLED FOR IN THE VARIOUS DESIGNS. THE 6.HANDLING PRESTRESSED CONCRETE BEAMS:

6mmØ SPIRALS 3 LIVE ANCHORAGE DETAIL

REQUIREDFORCESAFTERLOSSESSHALLBE OBTAINEDBY APPLYING THE BEAMSSHALL BE MAINTAINEDIN AN UPRIGHTPOSITIONAND SP9 34 SCALE 1:50

INITIALTENSILEFORCESOF SUFFICIENTMAGNITUDETO ALLOWFOR SHALL BE LIFTED BY SUITABLEDEVICESPROVIDEDAT THE ENDS

ALL SUBSEQUENT LOSSES, INCLUDING THOSE FOR ELASTIC OF THE BEAMS. ATTENTIONIS DIRECTED TO THE INCREASED

SHORTENING, SHRINKAGE, CREEP, RELAXATION, FRICTION, AND DIFFICULTY OF LIFTING BEAMS WITHOUT END BLOCKS. THE

EFFICIENCY OF END ANCHORAGES.AFTER SECURING THE END CONTRACTOR'SPROPOSEDLIFTING DETAILS SHOULD BE GIVEN

2 DEAD ANCHORAGE DETAIL a

(mm)

b

(mm)

ANCHORAGESALL TENDONS SHALL BE PRESSURE GROUTED IN CAREFULLCONSIDERATIONBEFOREBEING SUBMITTEDON SHOP SP9 34 SCALE 1:50

THEIR CONDUITS IN ACCORDANCE WITH "SPECIFICATIONS". DURING CASTING 145 mm 120 mm

DRAWING FOR APPROVAL. THE USE OF HOLES FOR LIFTING AFTER STRESSING 227 mm 175 mm

PURPOSES WILL NOT BE PERMITTED. DURING SERVICE 90 mm 64 mm

2.CONCRETEFOR GIRDERS SHALL BE A MINIMUMSTRENGTHOF 35

N/mm (5,000 PSI) AT THE AGE OF 28 DAYS.

7.CONTRACTORSHALL SUBMIT FOR APPROVALBY THE ENGINEER b a b

THE CALCULATEDELONGATIONOF THE PRESTRESSINGTENDONS

3.CONCRETEFOR CAST-IN-PLACESLAB HAVEA MINIMUMSTRENGTH21 SPAN AASHTO TOTAL JACKING JACKING FORCE

N/mm (4,500 PSI) AT THE AGE OF 28 DAYS.

CORRESPONDING TO THE REQUIRED JACKING FORCES.

L/4 L/4 L/4 L/4 LENGTH GIRDER FORCE PER PER GIRDER

(m) TYPE GIRDER (kN) AFTER LOSSES (kN)

4.THE CONTRACTORMAY PROPOSEDANY ALTERNATIVETENDONSIZE

AND LAYOUT AND SUBJECT SHALL MEET THE APPROVALOF THE

L 40 VI 7865 6838

ENGINEER.

4 CAMBER DIAGRAM

SP9 34

PROJECT NAME AND LOCATION: SHEET CONTENTS: SURVEYED: PREPARED: SUBMITTED: RECOMMENDED: APPROVED: SET NO. SHEET NO.

REPUBLIC OF THE PHILIPPINES

C.Y. 2023 PROJECT RONALD M. ABERIN

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS DETAILED ENGINEERING DESIGN PLAN FOR ENGINEER II

REGION - X WIDENING OF PERMANENT BRIDGES AASTHO PRESTRESSED CONCRETE GIRDER SP 35

CAGAYAN DE ORO 1st DISTRICT ENGINEERING OFFICE (TYPE V) ARDENT B. DAGALA JOSE MARCOS S. DACANAY EVELYN A. TIRADO ANA LEE M. MANZANO,DM,A.Er

IPONAN BRIDGE 2 (B01397MN) DRAFTED:

10th RES Comp. Bulua, Cagayan de Oro City CAMBER DIAGRAM ENGINEER II CHIEF, PLANNING AND DESIGN SECTION ASSISTANT DISTRICT ENGINEER DISTRICT ENGINEER

ALONG BUTUAN CITY-CAGAYAN DE ORO CITY-ILIGAN CITY RD. ERIKA FAYE S. GUTIERREZ DATE: DATE: DATE: DATE:

9 23 57

ANCHORAGE DETAILS ENGINEER II

CAGAYAN DE ORO CITY

DATE :

You might also like

- Aps 1Document1 pageAps 1Akash MohantyNo ratings yet

- Salem Heritage Trail PDFDocument1 pageSalem Heritage Trail PDFjeanscarmagnaniNo ratings yet

- SectionE 45Document1 pageSectionE 45NikNo ratings yet

- MX-8637 PidDocument1 pageMX-8637 PidSaigon Esp GlerNo ratings yet

- RENR5353Document2 pagesRENR5353Ebied Yousif AlyNo ratings yet

- Plan-Right bank-ALL MICRO PILE CABLE ANCHOR 11.08.2017 - Copy-ModelDocument1 pagePlan-Right bank-ALL MICRO PILE CABLE ANCHOR 11.08.2017 - Copy-ModelSantosh K SatiNo ratings yet

- Basic Structuraaal-20x30.3Document1 pageBasic Structuraaal-20x30.3Jom Asagra100% (1)

- A B C D A B C D: Second Floor Water Layout Ground Floor Water LayoutDocument1 pageA B C D A B C D: Second Floor Water Layout Ground Floor Water LayoutDenzelNo ratings yet

- Dimension Drawing XAVS 1800 WUX 9829 3587 00-01 EN - Support MountedDocument1 pageDimension Drawing XAVS 1800 WUX 9829 3587 00-01 EN - Support MountedMarkus SitanggangNo ratings yet

- Manifold pressure display panelDocument43 pagesManifold pressure display panelChriss Vzz100% (3)

- G-5011 - Vanity DetailDocument1 pageG-5011 - Vanity DetailAMF AAFNo ratings yet

- Hold Hold: 2"-0320-AP-00302-C1E2A 2"-0320-AP-00305-C1E2ADocument1 pageHold Hold: 2"-0320-AP-00302-C1E2A 2"-0320-AP-00305-C1E2ACristianJhonNo ratings yet

- m003 QGD Arc DWG Rsst010 CL 54649 Rev 1Document1 pagem003 QGD Arc DWG Rsst010 CL 54649 Rev 1vtalexNo ratings yet

- SBWR Tma-Brasilia Arc 20221229Document1 pageSBWR Tma-Brasilia Arc 20221229Daniel CiprianoNo ratings yet

- GT Turbine Cooling Air System DiagramDocument1 pageGT Turbine Cooling Air System DiagramAldo Quispe HuarachiNo ratings yet

- GK - Safira NF - 12122023Document1 pageGK - Safira NF - 12122023Safira N FatimahNo ratings yet

- PnID - PD05001258 - Rev 01 - 30082023Document1 pagePnID - PD05001258 - Rev 01 - 30082023BambangIrawan48No ratings yet

- SectionE 47Document1 pageSectionE 47NikNo ratings yet

- 308 Hyd PDFDocument1 page308 Hyd PDFchanlin100% (2)

- 20kg-P&id (Sheet 1 of 3)Document1 page20kg-P&id (Sheet 1 of 3)naurizsultanov.fxNo ratings yet

- Legend:: Nyfgby 3C X 2.5Mm, 0.6/1Kv, Iec - 60502 - 1 Nyfgby 4C X 10Mm, 0.6/1Kv, Iec - 60502 - 1Document1 pageLegend:: Nyfgby 3C X 2.5Mm, 0.6/1Kv, Iec - 60502 - 1 Nyfgby 4C X 10Mm, 0.6/1Kv, Iec - 60502 - 1Irvan ApriliandiNo ratings yet

- DJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1Document1 pageDJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1info.infinitytechnicalNo ratings yet

- 25 - Tuba en Do - MusDocument2 pages25 - Tuba en Do - MusYohan Octavio Vera DelgadoNo ratings yet

- AC Adapter Schematic DiagramDocument4 pagesAC Adapter Schematic DiagramsilictronicNo ratings yet

- Uniqlo Indonesia store designDocument1 pageUniqlo Indonesia store designPT. Rona Jaya InternusaNo ratings yet

- Notes:: Water Line Gate Valve DetailDocument1 pageNotes:: Water Line Gate Valve DetailDJNo ratings yet

- Top View/ Vedere de Sus: Estimated Weight: 17000 KGDocument1 pageTop View/ Vedere de Sus: Estimated Weight: 17000 KGLavinia DamianNo ratings yet

- Canopy&Roof TrussDocument1 pageCanopy&Roof TrussKamaleshsan GanesanNo ratings yet

- 230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Document1 page230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Mateen JawreNo ratings yet

- Water Distribution Layout Sanitary Layout: Floor Drain Detail Detail of Water MeterDocument1 pageWater Distribution Layout Sanitary Layout: Floor Drain Detail Detail of Water MeterAllen Robert WaganNo ratings yet

- Revised Plan Sheet 5Document1 pageRevised Plan Sheet 5AizaNo ratings yet

- 18.detail Standard Fire FightingDocument1 page18.detail Standard Fire FightingMuhammad ArifNo ratings yet

- LooooooooooooooouiDocument1 pageLooooooooooooooouirim deNo ratings yet

- Spill Fill Manhole w/ Cap & AdapterDocument1 pageSpill Fill Manhole w/ Cap & Adapterashier dave calulotNo ratings yet

- DWG - No.02 - 42 20 SP003 - BGDocument1 pageDWG - No.02 - 42 20 SP003 - BGSean Chen GyarinoNo ratings yet

- GAS STATION v1Document1 pageGAS STATION v1ashier dave calulotNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 210002 - CDocument1 page07 522213 4800000612 WSP SLT DRG 210002 - CMOHD NAZEEF KHANNo ratings yet

- 7stanes Innerleithen Trail Map Info PDFDocument2 pages7stanes Innerleithen Trail Map Info PDFdareenNo ratings yet

- SPCL 1st Resubmission Drawing ApprovalDocument1 pageSPCL 1st Resubmission Drawing Approvalrohitbhagat005No ratings yet

- Details of Water MeterDocument1 pageDetails of Water MeterKlausmene AveriaNo ratings yet

- Specifications:: Produced by An Autodesk Student VersionDocument1 pageSpecifications:: Produced by An Autodesk Student VersionBharani MadamanchiNo ratings yet

- Traffic Signages LayoutDocument1 pageTraffic Signages LayoutabigailNo ratings yet

- Home floor plan designDocument1 pageHome floor plan designYessica TerronesNo ratings yet

- Plant AC SLD - TN Sunrise - R2Document1 pagePlant AC SLD - TN Sunrise - R2newattelectricNo ratings yet

- Detail 3 - Stair DetailsDocument1 pageDetail 3 - Stair DetailsManoj JaiswalNo ratings yet

- Esquema - MCF Global PartsDocument1 pageEsquema - MCF Global PartswillianNo ratings yet

- Electrical Wiring: DN 32 DN 32Document1 pageElectrical Wiring: DN 32 DN 32juring bitolaNo ratings yet

- Lincoln MKZ Bi-Wire Schematic DiagramDocument1 pageLincoln MKZ Bi-Wire Schematic DiagramQuang Linh LêNo ratings yet

- K MalakondaiahDocument1 pageK Malakondaiahshaik moizNo ratings yet

- FX 400-2000 460V UL Electrical Diagram Montecchio 2205044709 Ed02Document1 pageFX 400-2000 460V UL Electrical Diagram Montecchio 2205044709 Ed02francisco jose arruda de sousaNo ratings yet

- Ezgo_2008_RXV_wiring_diagramDocument1 pageEzgo_2008_RXV_wiring_diagramЭль ГаджиNo ratings yet

- Section E-E: Slab On Grade CORBEL 20x16ht DemolitionDocument1 pageSection E-E: Slab On Grade CORBEL 20x16ht DemolitionjafarNo ratings yet

- 20 Gie 001 - M 1 2Document1 page20 Gie 001 - M 1 2fouad belalNo ratings yet

- 3 Detalle 2 Detalle: IE IE IEDocument1 page3 Detalle 2 Detalle: IE IE IEHans ContrerasNo ratings yet

- Ground Floor Plan First Floor Plan: Elevation Section Aa' Section BB'Document1 pageGround Floor Plan First Floor Plan: Elevation Section Aa' Section BB'saqib ullahNo ratings yet

- TU - Trumpet in BB 2Document1 pageTU - Trumpet in BB 2Manuel Moncada GarzonNo ratings yet

- 2Nd Storey Plan - Lightning Protection: Construction DrawingDocument1 page2Nd Storey Plan - Lightning Protection: Construction DrawingrajavelNo ratings yet

- Abetong Tank c14 TryckDocument2 pagesAbetong Tank c14 TryckingemekanicalNo ratings yet

- 4 ODS-OCS Phase-IV PDFDocument551 pages4 ODS-OCS Phase-IV PDFravi raghav100% (1)

- Irc Classification of Roads:: National Highways (NH)Document20 pagesIrc Classification of Roads:: National Highways (NH)Vijju VijayNo ratings yet

- Liceo de Cagayan University College of Engineering Prestressed Concrete Design Take Home ExamDocument1 pageLiceo de Cagayan University College of Engineering Prestressed Concrete Design Take Home ExamdbircsNo ratings yet

- 2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankDocument40 pages2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankAdam JonesNo ratings yet

- SP 1102BDocument106 pagesSP 1102BJesu Doss75% (4)

- Curriculum M Tech Structural Construction Engineering 2019Document27 pagesCurriculum M Tech Structural Construction Engineering 2019SumanNo ratings yet

- FEMA全国美国&R应急反应系统结构垮塌技师培训手册Document50 pagesFEMA全国美国&R应急反应系统结构垮塌技师培训手册van wiNo ratings yet

- CCL - Civils - Poster - XM SystemDocument2 pagesCCL - Civils - Poster - XM SystemfatNo ratings yet

- As 5100.5-2004 Bridge Design ConcreteDocument10 pagesAs 5100.5-2004 Bridge Design ConcreteSAI Global - APAC0% (1)

- 4234r 98 PDFDocument20 pages4234r 98 PDFFred PrzNo ratings yet

- PTI 2009 PrestressedTanksDocument38 pagesPTI 2009 PrestressedTanksRodrigo LameirasNo ratings yet

- Prestressed DWallDocument4 pagesPrestressed DWallTimotei VasileNo ratings yet

- Prestressed ConcreteDocument21 pagesPrestressed ConcreteAmar WadoodNo ratings yet

- BS4486 1980 Alloy Steel BarDocument13 pagesBS4486 1980 Alloy Steel BarRed FolderNo ratings yet

- Elplanation of Excessive Long Time Deflections of Collapsed Record Span Box Girder BridgesDocument32 pagesElplanation of Excessive Long Time Deflections of Collapsed Record Span Box Girder BridgesEr.Praveen RajNo ratings yet

- Raina Manual-4 PDFDocument271 pagesRaina Manual-4 PDFsivNo ratings yet

- mIDAS Civil 2020 v11 UPDATES PDFDocument27 pagesmIDAS Civil 2020 v11 UPDATES PDFani4576No ratings yet

- 2010-Tindall Specification FinalDocument12 pages2010-Tindall Specification Finalshahhassa9No ratings yet

- Pres Tress I-Girder Design SheetDocument70 pagesPres Tress I-Girder Design Sheetarif_rubinNo ratings yet

- Grouting in PostDocument7 pagesGrouting in PostDeven PatleNo ratings yet

- Assignment #5: Manuel S. Enverga University Foundation College of EngineeringDocument6 pagesAssignment #5: Manuel S. Enverga University Foundation College of EngineeringRozhelle PedernalNo ratings yet

- Cable Anchors: A Prestressed Cable Anchor Is A High Strength Steel Tendon, Fitted With ADocument13 pagesCable Anchors: A Prestressed Cable Anchor Is A High Strength Steel Tendon, Fitted With AAnonymous RBDKAkBPoFNo ratings yet

- NSCP Definition of TermsDocument25 pagesNSCP Definition of TermsMary AnneNo ratings yet

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDocument18 pagesJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321No ratings yet

- Cable BoltingDocument12 pagesCable BoltingMohnit Ghosh100% (1)

- Final Paper ASCE - UHPC Segmental Bridge ConstructionDocument12 pagesFinal Paper ASCE - UHPC Segmental Bridge ConstructionyyingmunNo ratings yet

- NSCP 2010Document758 pagesNSCP 2010Cherish Taguinod Aliguyon100% (2)

- As 3735 2001 Concrete Structures Retaining Liquids MK1Document27 pagesAs 3735 2001 Concrete Structures Retaining Liquids MK1Viswanathan NaraNo ratings yet

- Ada405009 PDFDocument253 pagesAda405009 PDFKristi Gonzales100% (1)