Professional Documents

Culture Documents

Superheat and Sub-Cooling

Uploaded by

Cesar RodriguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Superheat and Sub-Cooling

Uploaded by

Cesar RodriguezCopyright:

Available Formats

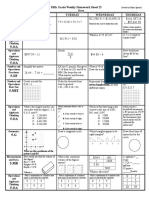

TROUBLESHOOTING A/C SUPERHEAT, SUB-COOLING & DELTA

In order for our personnel here at Gorman Industries to help you solve air conditioning problems we need some help from you.

Giving us the Superheat, Sub-Cooling and the Temperature difference across the coil of a system can help save you lots of time.

It is a well known fact in the industry that a large percentage of compressors being replaced are replaced due to improper

diagnosis, not compressor failure.

All of the steps below should be checked before any adjustments are made.

To Determine Superheat:

1. Take the low side pressure reading from your gauges and convert it to temperature using chart or gauge.

2. Then take the temperature of the Suction line as close to the condensing section as possible stay at least 6 inches from

compressor.

3. Take the difference between the above readings (Suction line temp – Saturation temp)

4. When ambient air temp (Outside air temp) is 75-85 degrees the superheat should be 12-15 degrees, if the ambient

temperature is 85 degrees or over the superheat should be 8-12 degrees.

5. If superheat is low then flooding the evaporator. Note: Do not adjust charge yet.

6. If superheat is high then starving the evaporator. Note: Do not adjust charge yet.

7. Do not adjust charge until sub-cooling is checked.

Note: When charging a system using superheat, you are basically charging the unit to the amount of air that is crossing the

evaporator.

Note: Do not adjust charge based on superheat on systems with thermal expansion valves (TXV’s). TXV’s control the superheat.

You can, however, check the superheat to see if the TXV is working properly.

To Determine Sub-Cooling:

1. Take the high side pressure and convert it to temperature using chart or gauge.

2. Then take the temperature of the liquid line as close to evaporator as possible before the metering device.

3. Take the difference between the above readings. (Saturation temp – Liquid line temp). Note liquid line temperature at

the evaporator should be within 2 degrees of liquid line temp at condensing unit. If not could be restriction or line set

too long.

4. Sub-Cooling should be around 12-15 degrees

5. Then using the information from superheat and sub-cooling we can have some idea where to look for a problem.

Example:

Suction line temp is ------- 60 degrees @ condenser

Suction Pressure is ------ 76 psi ---- 45 degrees saturation temperature

60 degrees – 45 degrees = 15 degree superheat

Liquid Pressure is ------------226 psi --------110 degrees saturation temperature

Liquid line temp is -------------95 degrees @ evaporator before metering device

110 degrees – 95 degrees = 15 degree sub-cooling

Possible Diagnosis using Superheat and Sub-Cooling:

If superheat is high and sub-cooling is low:

Charge must be adjusted. System undercharged.

If superheat is low and sub-cooling is high:

Charge must be adjusted. System overcharged

If superheat is high and sub-cooling is high:

Could have blockage in coil, orifice or line set.

If superheat is low and sub-cooling is low:

Orifice could be too big, there is no orifice in the unit of the orifice is stuck and refrigerant is by-passing it.

Superheat is telling you what is going on in the evaporator.

High Superheat = Starved Evaporator

Low Superheat = Flooded Evaporator

Sub Cooling is telling you what is going on in the condenser.

High Sub Cooling = Flooded Condenser

Low Sub Cooling = Starved Condenser

To Determine Delta T (Temperature difference across the coil):

1. While unit is running take the temperature of the air in the supply plenum near the coil (approx 12 inches.)

2. Then, while the unit is still running, take the temperature of the air in the return plenum near the unit.

3. Then take the difference between the above readings.

4. Should be around 15-18 degrees.

5. If to low then coil might not be seated in pan correctly or air bypassing coil. (Assuming superheat and Sub-Cooling are

OK.)

6. If too high then you might not be getting enough air across coil. Obviously this can cause the coil to freeze.

Checking a compressor electrically.

Check resistance (ohms) Must remove wires and check directly to compressor or it will back feed through cond fan motor.

Check for open windings.

Common - Run = Medium reading

Common - Start = Lowest reading

Start – Run = Highest reading

So: C-R + S-C should equal R-S

Check for dead short.

Check all terminals to Chassis Ground. You should read nothing (OL) if you get resistance you have a short to ground.

You might also like

- AC Superheat Sub-Cooling and DeltaDocument2 pagesAC Superheat Sub-Cooling and Deltajason camacho100% (1)

- AC Troubleshooting Guide GenericDocument2 pagesAC Troubleshooting Guide GenericElaisa Kasan100% (1)

- AC & Heat Pump Troubleshooting GuideDocument2 pagesAC & Heat Pump Troubleshooting GuideBill ChambersNo ratings yet

- Why Can't You Just Measure Pressures To Check A Refrigerant ChargeDocument9 pagesWhy Can't You Just Measure Pressures To Check A Refrigerant ChargebudayaNo ratings yet

- How To Measure Superheat and SubcoolingDocument10 pagesHow To Measure Superheat and SubcoolingRay Ravel83% (6)

- Checking Charge WO GaugesDocument4 pagesChecking Charge WO GaugesNew UserNo ratings yet

- Troubleshooting AC with Volts, Amps, Superheat, SubcoolingDocument13 pagesTroubleshooting AC with Volts, Amps, Superheat, SubcoolingRupak KumarNo ratings yet

- Troubleshooting HVAC Systems in CarsDocument4 pagesTroubleshooting HVAC Systems in Carsdreamyson1983100% (1)

- Information Sheet M2-6Document20 pagesInformation Sheet M2-6Chamile BrionesNo ratings yet

- Air Conditioner ChargingDocument2 pagesAir Conditioner ChargingNorienelle Peñaranda AlasNo ratings yet

- Title:Perform Charging of Refrigerant in Air Conditioning SystemDocument3 pagesTitle:Perform Charging of Refrigerant in Air Conditioning Systemcpt.ghostNo ratings yet

- Refrigerant Compressor - Test: Thursday, July 15, 2010Document4 pagesRefrigerant Compressor - Test: Thursday, July 15, 2010phuong lamhoangNo ratings yet

- Evaluating Refrigeration SystemsDocument21 pagesEvaluating Refrigeration SystemsCesar BlNo ratings yet

- Ac IntroductionDocument28 pagesAc Introductionthermopolis3012No ratings yet

- Tech Tip: Measuring Superheat and SubcoolDocument1 pageTech Tip: Measuring Superheat and SubcoolMahmoud AliNo ratings yet

- Check AC Freon LevelDocument5 pagesCheck AC Freon Levelmister_no34No ratings yet

- Expansion Valve and Superheat Charging GuideDocument15 pagesExpansion Valve and Superheat Charging Guiderohitkb09No ratings yet

- Troubeshooting Vapour ChillersDocument8 pagesTroubeshooting Vapour Chillersazher_memonNo ratings yet

- Subcooling & SuperheatDocument3 pagesSubcooling & SuperheatMuhammadAmmarNo ratings yet

- Adp TXV PDFDocument7 pagesAdp TXV PDFhilariolussaNo ratings yet

- Compressor Troubleshooting GuideDocument40 pagesCompressor Troubleshooting GuideDejan KolarecNo ratings yet

- Charging Capillary Tube SystemsDocument2 pagesCharging Capillary Tube SystemsRay RavelNo ratings yet

- How To Recharge Air Conditioner: Purpose, Do's and Don'ts, and Some AdviceDocument11 pagesHow To Recharge Air Conditioner: Purpose, Do's and Don'ts, and Some AdviceSanjay OhriNo ratings yet

- NEWS December 3, 2018Document6 pagesNEWS December 3, 2018Insoluperez FPNo ratings yet

- Superheat charging curves for techniciansDocument6 pagesSuperheat charging curves for techniciansBill ChambersNo ratings yet

- Controlling Wrap-Around Heat Pipes for Humidity ControlDocument8 pagesControlling Wrap-Around Heat Pipes for Humidity ControlothmanNo ratings yet

- 2006FC 174R1TXVre ArticleDocument4 pages2006FC 174R1TXVre Articleremwel_No ratings yet

- Refrigerant Charging Procedure in Automotive ADocument3 pagesRefrigerant Charging Procedure in Automotive AAnnalyn MendozaNo ratings yet

- Retrofitting R-22 Systems with R-421ADocument6 pagesRetrofitting R-22 Systems with R-421ABalanSelvamNo ratings yet

- Ac TroubleshootingDocument6 pagesAc TroubleshootingjaybeefineNo ratings yet

- Calibration and Leak-By Test ProceduresDocument2 pagesCalibration and Leak-By Test Proceduresromi_hamdaniNo ratings yet

- Evaluating - Ac - Performance Coleman MachDocument2 pagesEvaluating - Ac - Performance Coleman Machdavid mendible100% (1)

- Understanding SuperheatDocument9 pagesUnderstanding SuperheatElmerNo ratings yet

- Using The P-T CardDocument8 pagesUsing The P-T CardIslam RaoufNo ratings yet

- Everything You Need To Know About TX ValvesDocument6 pagesEverything You Need To Know About TX Valvescalishe1No ratings yet

- Tutorial Guide To Manifold GaugesDocument2 pagesTutorial Guide To Manifold GaugesJames MockNo ratings yet

- Troubleshooting HVACR Systems Using Superheat and SubcoolingDocument7 pagesTroubleshooting HVACR Systems Using Superheat and SubcoolingTemporiusNo ratings yet

- Lab Report: 3-Phase Compressor With Automatic Pump DownDocument5 pagesLab Report: 3-Phase Compressor With Automatic Pump DownPrecisioneticaNo ratings yet

- Dwnload Full Heat Pumps 2nd Edition Silberstein Solutions Manual PDFDocument32 pagesDwnload Full Heat Pumps 2nd Edition Silberstein Solutions Manual PDFtreen.whiles.2kz51t100% (11)

- Heat Pumps 2nd Edition Silberstein Solutions ManualDocument35 pagesHeat Pumps 2nd Edition Silberstein Solutions Manualapostolicembetterxrymjn100% (17)

- Vapor Compression Refrigeration LabDocument3 pagesVapor Compression Refrigeration LabAnand BanikNo ratings yet

- Unit 41 TroubleshootingDocument34 pagesUnit 41 TroubleshootingYuk man LawNo ratings yet

- Cascade refrigeration system explainedDocument5 pagesCascade refrigeration system explainedLeo Van Ezel Arcay100% (2)

- Air Conditioner Pump System PressuresDocument11 pagesAir Conditioner Pump System PressuresingenierosunidosNo ratings yet

- Diagnosing Nissan HVAC IssuesDocument7 pagesDiagnosing Nissan HVAC IssuesСергей ЧеNo ratings yet

- Temperature Gauge Calibration PDFDocument14 pagesTemperature Gauge Calibration PDFAlaa RamadanNo ratings yet

- 1815 12 PDFDocument21 pages1815 12 PDFUmar IftikharNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleMubarek TeshomeNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant Cycleravi prajapatNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleZakir R. AliNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleGerardo DelgadoNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleramsiNo ratings yet

- Motor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFDocument49 pagesMotor Vehicle Air Conditioning System Operation and Refrigerant Cycle of Motor Vehicles PDFmariA ANNANo ratings yet

- A C Cycle WWW - Innovationdiscoveries.spaceDocument49 pagesA C Cycle WWW - Innovationdiscoveries.spaceNaveen kumarNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleSATNA GSTNo ratings yet

- Motor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CycleDocument49 pagesMotor Vehicle Air Conditioning (MVAC) : System Operation and The Refrigerant CyclemohdNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- 1994 Harris Product Selection Guide PDFDocument330 pages1994 Harris Product Selection Guide PDFCesar Rodriguez100% (1)

- 650V 1.5Ω N-Channel MOSFETDocument5 pages650V 1.5Ω N-Channel MOSFETCesar RodriguezNo ratings yet

- 3 829Document32 pages3 829Cesar RodriguezNo ratings yet

- 2N5551 NationalSemiconductorDocument4 pages2N5551 NationalSemiconductorCesar RodriguezNo ratings yet

- 25591Document4 pages25591Cesar RodriguezNo ratings yet

- Top242 250 9213Document53 pagesTop242 250 9213zektor100% (1)

- Top242 250 9213Document53 pagesTop242 250 9213zektor100% (1)

- Pump Motor UniversityDocument52 pagesPump Motor UniversityCesar RodriguezNo ratings yet

- Operate Screen OverviewDocument2 pagesOperate Screen OverviewCesar RodriguezNo ratings yet

- Plcd15v OiDocument20 pagesPlcd15v OiCesar RodriguezNo ratings yet

- Tda7266 PDFDocument9 pagesTda7266 PDFRenato HernandezNo ratings yet

- Bee Unit-IiDocument98 pagesBee Unit-IiHemant Ingale100% (1)

- CPC-COM-SU-4743-G External CoatingsDocument24 pagesCPC-COM-SU-4743-G External Coatingsaslam.amb100% (1)

- The Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsDocument52 pagesThe Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsHoda El HALABINo ratings yet

- Intro To Factor AnalysisDocument52 pagesIntro To Factor AnalysisRawnak JahanNo ratings yet

- Homework1 SKKK1113 1112-2Document1 pageHomework1 SKKK1113 1112-2Khairul Anwar Abd HamidNo ratings yet

- 3 6 17weekly Homework Sheet Week 23 - 5th Grade - CcssDocument3 pages3 6 17weekly Homework Sheet Week 23 - 5th Grade - Ccssapi-328344919No ratings yet

- 5 - Architect Fee AgreementDocument4 pages5 - Architect Fee AgreementJoevince Neil Gacus100% (2)

- 9607 Syllabus Media StudiesDocument28 pages9607 Syllabus Media StudiesmisterNo ratings yet

- Mercury MasterDocument18 pagesMercury MastersatishmuggulaNo ratings yet

- Chapter 5Document31 pagesChapter 5Marvin VinasNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- Yuken Series PVL Vane Pumps Catalogue en PDFDocument69 pagesYuken Series PVL Vane Pumps Catalogue en PDFAgilRinaldiNo ratings yet

- Coaching PhilosophyDocument2 pagesCoaching Philosophyapi-457181424No ratings yet

- MDP Module 2Document84 pagesMDP Module 2ADITYA RAJ CHOUDHARYNo ratings yet

- Achmad Nurdianto, S.PD: About MeDocument2 pagesAchmad Nurdianto, S.PD: About Medidon knowrezNo ratings yet

- Jhamuna Tower Design DataDocument15 pagesJhamuna Tower Design DataArindam RoyNo ratings yet

- COE10205, Other Corrosion Monitoring TechniquesDocument62 pagesCOE10205, Other Corrosion Monitoring Techniquesامين100% (1)

- Electrical Tools, Eq, Sup and MatDocument14 pagesElectrical Tools, Eq, Sup and MatXylene Lariosa-Labayan100% (2)

- API Documentation Alpha VantageDocument55 pagesAPI Documentation Alpha VantageFun WorldNo ratings yet

- Internship Reflection PaperDocument8 pagesInternship Reflection Paperapi-622170417No ratings yet

- P0880 TCM Power Circuit InspectionDocument5 pagesP0880 TCM Power Circuit InspectionLojan Coronel José HumbertoNo ratings yet

- Block Ice Machine Bk50tDocument6 pagesBlock Ice Machine Bk50tWisermenNo ratings yet

- Very Basic GSADocument46 pagesVery Basic GSATim ChongNo ratings yet

- HoraceDocument8 pagesHoraceapolonius31No ratings yet

- Paul Ramesh Forensic Neuro Psychological InterviewDocument43 pagesPaul Ramesh Forensic Neuro Psychological Interviewnonam2100% (2)

- Nanowires - Fundamental ResearchDocument564 pagesNanowires - Fundamental ResearchJosé Ramírez100% (1)

- Cooler Catalogue PDFDocument12 pagesCooler Catalogue PDFCărunta-Crista CristinaNo ratings yet

- Akhtamov A.A. - Destination C1-C2, Test CollectionDocument37 pagesAkhtamov A.A. - Destination C1-C2, Test CollectionNguyen NhiNo ratings yet

- Adaboost With Totally Corrective Updates For Fast Face DetectionDocument6 pagesAdaboost With Totally Corrective Updates For Fast Face DetectionNguyen Quoc TrieuNo ratings yet