Professional Documents

Culture Documents

Cap. 51

Uploaded by

Marcos ValdezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cap. 51

Uploaded by

Marcos ValdezCopyright:

Available Formats

300/300LW Maintenance Manual (Rev A38)

51-00-00-001 (Rev Feb 1/09)

STRUCTURES - DESCRIPTION AND OPERATION

Being of semionocoque construction, the Super King Air Model 300 fuselage is pressurized to the skin between bulkheads at stations 84.0

and 347.75. All skin, bulkheads and structure points, plumbing and wiring connections passing through a pressure wall, access doors,

windows, control cables and torque shafts are sealed to minimize air leakage. Although the wing center section is an integral part of the

fuselage, the wing panels outboard of the nacelles are removable. To provide a convenient stairway for boarding the airplane, the cabin

entrance door on the left side of the fuselage swings down. Emergency exits are installed on both sides of the fuselage just aft of the crew

compartment partition. Individual passenger seats are provided, and the front seats may be installed facing either forward or aft.

PRIMARY STRUCTURAL COMPONENTS

The following primary structural components are essential to the proper function of the airplane. Failure occurring to any of the

components would seriously endanger the safety of the airplane and/or the passengers.

a. Control systems.

b. Engine mounts.

c. Fittings.

d. Coverings of the fuselage, wings, tail surfaces and control surfaces.

e. Wing, tail surface and control surface spars.

f. Landing gears and support structure.

g. Auxiliary members used to straighten or support other members carrying direct loads.

h. Seat and seat support structure.

SECONDARY STRUCTURAL COMPONENTS

The following secondary structural components in the event of failure would require immediate attention, but would not necessarily

endanger the safety of the airplane and/or passengers.

a. Wing tips.

b. Fairings.

c. Nose cone.

d. Non structural doors and covers.

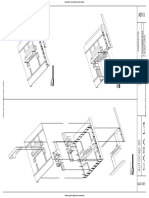

Note: See Figure 1 for locations of structural doors and fairings.

e. Furnishings and upholstery (excluding seats).

Copyright © Textron Aviation Inc. Page 1 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:25 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-001 (Rev Feb 1/09)

Figure 001 : Sheet 1 : Fig 1 - Doors, Plates, Covers and Fairings

Copyright © Textron Aviation Inc. Page 2 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:25 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-001 (Rev Feb 1/09)

Figure 001 : Sheet 1 : Fig 1 - Doors, Plates, Covers and Fairings

Copyright © Textron Aviation Inc. Page 3 of 3

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:25 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

STRUCTURES - MAINTENANCE PRACTICES

STRUCTURAL REPAIR

Warning: Drilling, modification or any type of work which creates a break in the pressure vessel is considered the responsibility

of the owner or facility performing the work. Obtaining approval of the work is, therefore, their responsibility.

Minor repair to chem-milled skins may be accomplished, provided proper edge distances (twice the rivet diameter plus 0.06 inch) are

maintained between repair rivets and all points of change in skin thickness at points of transition between the original skin thickness and

the etched portions of the skin.

In general, structural repair methods used on the Super King Air 300 may be used in accordance with AC 43.13-1A: AIRCRAFT

INSPECTION AND REPAIR MANUAL and AC 43.13-2: AIRCRAFT ALTERATIONS MANUAL. Never make a skin replacement or patch from

a materials thinner than the original skin. The following considerations are recommended in addition to AC 43.13-1A: AIRCRAFT

INSPECTION AND REPAIR MANUAL and AC 43.13-2: AIRCRAFT ALTERATIONS MANUAL for repair of the pressure vessel of the Super

King Air 300.

Caution: In the pressurized area, all skins, formers, stringers, etc. are structural members and should be treated as such.

a. All lap joints, including patches, must have at least two staggered rows of rivets.

b. All repair material must be free of any defects such as nicks, scratches, etc. which can cause stress rises.

c. Never dimple a structural member by driving the rivet head into the part.

d. Do not countersink deeper than 75% of the material thickness.

e. Scratches in the outer windows of acrylic plastic may be removed with 400 to 600 grit sandpaper, providing that not more than 0.003

inch of material is removed. Polish the repaired area smooth with buffing compound. The minimum thickness of the crew compartment

side windows is 9/32 inch and for the cabin and baggage compartment windows, 7/32 inch. No crazing or cracks are permitted in the

pressure windows.

Note: The window repair above is for localized repair of individual scratches only and should not be performed over the

entire window.

METAL SKIN REPAIR IN PRIMARY STRUCTURE

Isolated dents to a depth of 0.250 inch are permissible on wing upper skins, providing all requirements except for the 10% of the area

rule of SKIN DENT LIMITATIONS - BOTH SIDEDS ACCESSIBLE are met. Fill the dents with aerodynamic smoother per REPAIR WHEN

ONE SIDE IS ACCESSIBLE.

METAL SKIN DENT REPAIR IN SECONDARY STRUCTURE

The following dent repairs can be made only to secondary structural skins specified under SECONDARY STRUCTURAL COMPONENTS,

51-00-00.

SKIN DENT LIMITATIONS - BOTH SIDES ACCESSIBLE

These limitations apply only to aluminum skins.

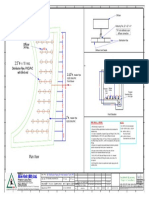

a. Dents do not exceed 0.125 inch in depth (Ref. Figure 201, Detail A).

b. Dents do not exceed 10% of total surface area in one square foot.

c. Dents are no closer than 0.50 inch to any rivet or structural area.

d. Sharp dents or penetration of skin is not permitted.

REPAIR - BOTH SIDES ACCESSIBLE

These repairs apply only to aluminum skins.

a. Remove finish from damaged area (Ref. Chapter 20-08-00).

b. Use a solid backup support and form-out dents to skin contour.

c. Inspect for cracks and uneven surfaces.

d. Dye penetrant inspect for cracks.

e. When a smoother surface is desired, apply a filler per SKIN DENT FILLER REPAIR.

SKIN DENT LIMITATIONS - ONE SIDE ACCESSIBLE

These limitations apply to aluminum skins that are accessible from one side.

a. Dents do not exceed 0.125 inch in depth (Ref. Figure 201, Detail A).

Copyright © Textron Aviation Inc. Page 1 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

b. Dents do not exceed 10% of total surface area in one square foot.

c. Sharp dents or penetration of skin is not permitted.

REPAIR - ONE SIDE ACCESSIBLE

This procedure is applicable to aluminum skins when only one side is accessible.

a. Prepare and fill dent with aerodynamic smoother per SKIN DENT FILLER REPAIR.

b. After dent has been filled, inspect for smoothness.

SKIN DENT FILLER REPAIR

a. Sand area lightly with 400 grit sandpaper.

b. Clean area with methyl propyl ketone ( Item No. 38, Chart 1, 91-00-00) and dry completely.

c. Apply primer ( Item No. 182, Chart 1, 91-00-00) and dry for a minimum of five minutes. Wipe area clean with a dry cheesecloth.

d. Fill dented area with aerodynamic smoother ( Item No. 162, Chart 1, 91-00-00) per manufacturer's instructions.

e. After four hours at room temperature, sand area smooth.

f. Apply finish as required.

REPAIR OF FIBERGLASS COMPONENTS

Field repair of fiberglass should be limited to those areas where there will not be an excessive amount of heat. In areas where fiberglass

is used, with heat reaching a temperature near 300°F (149°C) or above, a special phenolic resin impregnated fiberglass is used. It is

recommended that these parts not be repaired unless there is a shop available which is equipped for this type of fiberglass work.

a. Large holes and cracks require that the damaged area be cut out and trimmed just beyond the area of damage (Ref. Figure 202). If the

parts are painted, remove the paint and sand that portion of the part extending at least 2 inches beyond the cutout.

b. On small holes or cracks, sand lightly using 400 grit sandpaper to remove any raised or rough surface.

c. Clean with methyl propyl ketone ( Item No 38, Chart 1, 91-00-00) and wipe dry.

d. Cut fiberglass plies equal to, or greater than, the number of damaged plies. The first ply should be one inch (1.0") wider and on inch

(1.0") longer than the damaged area. Each succeeding ply should be one inch (1.0") longer then the preceding ply and should overlap

the preceding glass cloth ply by 1/2 inch step on all sides.

e. Prepare the resin (Laminac 4116, Glidpol 1001, or their equivalent) for the patch in accordance with the manufacturer's instructions.

Make sure the your hands are free of oil, grease and dirt when handling the resin.

f. Apply an even coat of resin to the sanded area. Impregnate all three laminated glass cloth patches by laying the patches on clean

waxed paper and working the resin through the fabric with a 2 inch brush.

g. Place the large patch over the cutout area, working out all air bubbles and wrinkles. If the patch starts to sag, place a support behind

the repair area. Coat the support with automobile wax or cover with waxed paper to prevent the resin from adhering to the support.

Work out all air bubbles and wrinkles while installing the second patch over the first. Install the third patch over the second in the same

manner.

h. Brush the repaired area with an even coat of resin. After the patches have cured for the 24 hours at temperatures between 23°C

(75°F) and 66°C (150°F), blend the patch into the contour of the part with fine sandpaper. Prime and paint the repair to match the rest

of the part.

SEALING

The Super King Air 300 airplane is pressurized and sealing the skin, bulkhead seams, windows, doors, etc., is of prime importance.

Control cables and torque shafts have removable rubber seals. When making a structural repair or modification which creates a break in

the pressure vessel, the mating surfaces must be sealed with the proper sealer. All other components piercing the pressure vessel or

attached to it must be sealed with the proper sealers (Ref. Chapter 91-00-00). For effective bonding of the sealers, be sure to clean all

mating surfaces, mating parts and rubber seals thoroughly.

Copyright © Textron Aviation Inc. Page 2 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

Figure 201 : Sheet 1 : Fig 201 - Skin Dent Limitations

FA51B

085472AA.AI

Copyright © Textron Aviation Inc. Page 3 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

Figure 202 : Sheet 1 : Fig 202 - Fiberglass Repair

Copyright © Textron Aviation Inc. Page 4 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

Figure 201 : Sheet 1 : Fig 201 - Skin Dent Limitations

Copyright © Textron Aviation Inc. Page 5 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

300/300LW Maintenance Manual (Rev A38)

51-00-00-201 (Rev Feb 1/09)

Figure 202 : Sheet 1 : Fig 202 - Fiberglass Repair

Copyright © Textron Aviation Inc. Page 6 of 6

Retain printed data for historical reference only. For future maintenance, use only current data. Print Date: Wed Jun 12 11:59:42 CDT 2019

You might also like

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Cap. 23Document6 pagesCap. 23Marcos ValdezNo ratings yet

- Cap. 25Document20 pagesCap. 25Marcos ValdezNo ratings yet

- A320 - SRM - MSN - 05234 - 01-Aug-2019 - TASK 57-53-00-300-029 - Zone 1 - Skin Covered With Metal Strap RepairDocument20 pagesA320 - SRM - MSN - 05234 - 01-Aug-2019 - TASK 57-53-00-300-029 - Zone 1 - Skin Covered With Metal Strap Repairjr primeNo ratings yet

- A330-200 - 300 - SRM - 01-Oct-2020 - TASK 53-21-11-283-006 - Skin Plates - Allowable Dent LimitsDocument20 pagesA330-200 - 300 - SRM - 01-Oct-2020 - TASK 53-21-11-283-006 - Skin Plates - Allowable Dent Limitsmashobih hussururNo ratings yet

- SRM - A318/A319/A320/A321 REV DATE: Nov 01/2022 Tail Number - MSN - FSN: ALLDocument3 pagesSRM - A318/A319/A320/A321 REV DATE: Nov 01/2022 Tail Number - MSN - FSN: ALLingeniero aeroestructurasNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument3 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- 0 SRM Cesnna Citation 2Document3 pages0 SRM Cesnna Citation 2El JaminzotanNo ratings yet

- SRM 51-00-00 226 7 R20Document4 pagesSRM 51-00-00 226 7 R20leibnitz garciaNo ratings yet

- Aircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMDocument10 pagesAircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACMCHIMONo ratings yet

- Cosmetic Repair To Total Thickness (All Zones)Document7 pagesCosmetic Repair To Total Thickness (All Zones)Jorge OrtegaNo ratings yet

- Chapter 10 Parking and MooringDocument7 pagesChapter 10 Parking and MooringHrishikesh NarasimhanNo ratings yet

- Service Bulletin No. SB-300-2-97: Extra Considers Compliance MandatoryDocument8 pagesService Bulletin No. SB-300-2-97: Extra Considers Compliance MandatoryAlvaro AriasNo ratings yet

- B787 A G70!00!01 10A 663A A Electrical Harness - Standard RepairDocument4 pagesB787 A G70!00!01 10A 663A A Electrical Harness - Standard Repairdonghuizhen2004No ratings yet

- Primary StructureDocument47 pagesPrimary StructureKusum GuptNo ratings yet

- 72 00-00-200 025 A01 Over Serviceable Limit ExtensionsDocument79 pages72 00-00-200 025 A01 Over Serviceable Limit ExtensionsmailtoshiyasNo ratings yet

- Airworthiness Bulletin 61 007 Wooden Propeller Maintenance Rewrite of Aac 17 3 and Aac 187 1Document5 pagesAirworthiness Bulletin 61 007 Wooden Propeller Maintenance Rewrite of Aac 17 3 and Aac 187 1Exzy EditNo ratings yet

- TSK 542261 300 808 A01Document4 pagesTSK 542261 300 808 A01dffdgfaNo ratings yet

- 51 StructureDocument606 pages51 StructureTauqir ahmed100% (1)

- Inspection GDocument10 pagesInspection GQC145 IndamerNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument106 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) StructureDocument302 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Structurejuan100% (1)

- Slats 3, 4 and 5 - Top and Nose Skins Above The Ribs and Above The Upper Girder - Standard Flush Insert Repair DBHDocument26 pagesSlats 3, 4 and 5 - Top and Nose Skins Above The Ribs and Above The Upper Girder - Standard Flush Insert Repair DBHWattsonDiazRuizNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument55 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Panasonic: Quick Service HintsDocument3 pagesPanasonic: Quick Service HintsIon JardelNo ratings yet

- Airbus SB A320-53-1465 R00 Dated 08.apr.2021Document52 pagesAirbus SB A320-53-1465 R00 Dated 08.apr.2021Pradeep K sNo ratings yet

- Technical Notes (TN) Protections: EairbusDocument407 pagesTechnical Notes (TN) Protections: EairbusJorge OrtegaNo ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- Printed in GermanyDocument33 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Service Bulletin: SB MBB-BK117 C-2-62-006Document11 pagesService Bulletin: SB MBB-BK117 C-2-62-006Alexander OquendoNo ratings yet

- TC-2023-015 Reprotection of Eroded Missing Filler Material On Nose and Top Part of Slat Top Skin. Issue 01, Rev 00 Dated Oct 2023.Document2 pagesTC-2023-015 Reprotection of Eroded Missing Filler Material On Nose and Top Part of Slat Top Skin. Issue 01, Rev 00 Dated Oct 2023.air17046No ratings yet

- ATA 30 - Ice & Rain 09-04-18 PDFDocument143 pagesATA 30 - Ice & Rain 09-04-18 PDFDavid OwenNo ratings yet

- 51 Structure 2Document712 pages51 Structure 2Nunu ZarnujiNo ratings yet

- 51 Structure PDFDocument576 pages51 Structure PDFMIGUEL ANGEL PENA CASTILLONo ratings yet

- 72 00-00-200 025 A Over Serviceable Limit ExtensionsDocument71 pages72 00-00-200 025 A Over Serviceable Limit ExtensionsmailtoshiyasNo ratings yet

- 650 ZoningDocument4 pages650 ZoningEleazarNo ratings yet

- HTPT Rapport 2011Document120 pagesHTPT Rapport 2011Ange KonanNo ratings yet

- Electical System Fast Track Series Questions and Answers by Dale CraneDocument13 pagesElectical System Fast Track Series Questions and Answers by Dale CranesomeshNo ratings yet

- A318/A319/A320/A321 (CFM56) : StructureDocument132 pagesA318/A319/A320/A321 (CFM56) : StructureRaby Abidi100% (1)

- Section 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole RepairDocument10 pagesSection 54-10-00 Repair 029 Air Intake Cowl Acoustic Liner Facing Sheet Hole RepairDanilo SuarezNo ratings yet

- 78 36 00 410 040 BDocument5 pages78 36 00 410 040 BRohan SinghNo ratings yet

- Aircraft Structural DesignDocument6 pagesAircraft Structural DesignJohn BlackburnNo ratings yet

- Dive Scubapro - Mk10 HI Intermediate-Pressio - Eng Bulletin 248Document1 pageDive Scubapro - Mk10 HI Intermediate-Pressio - Eng Bulletin 248manonpomNo ratings yet

- AMA Sample ExamDocument13 pagesAMA Sample Examwaterholic broNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument3 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- AMA Sample ExamDocument12 pagesAMA Sample ExamJulian BillonesNo ratings yet

- 01 Aircraft General PracticesDocument56 pages01 Aircraft General PracticesSaif AbuRummanNo ratings yet

- 51 Structure PDFDocument614 pages51 Structure PDFAnonymous 298xlo3uU100% (1)

- 51 StructureDocument712 pages51 StructureLuiz Fernando Carvalho100% (1)

- Tof Aw 074 Repair Proposal ExampleDocument10 pagesTof Aw 074 Repair Proposal ExampletasteslikekeysNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Aircraft General PracticesDocument78 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Aircraft General PracticesjuanNo ratings yet

- A320 SRM 01-May-2020 133 TASK 53-41-13-283-002 - Stringer Outer Flange Between STGR33LH and STGR33RH (Lower Part) - Allowable Damage and Blend Out (Rework)Document8 pagesA320 SRM 01-May-2020 133 TASK 53-41-13-283-002 - Stringer Outer Flange Between STGR33LH and STGR33RH (Lower Part) - Allowable Damage and Blend Out (Rework)ArteezyNo ratings yet

- DFPRM-51-12-00-350-828-A01-Replacement of Polyimide Foam Insulation On Glasscloth DuctsDocument5 pagesDFPRM-51-12-00-350-828-A01-Replacement of Polyimide Foam Insulation On Glasscloth DuctsFredy BonillaNo ratings yet

- Replace Front and Mid Aero Shield Panels: Tesla, IncDocument2 pagesReplace Front and Mid Aero Shield Panels: Tesla, IncJimmyNo ratings yet

- 51-21-00-001-Protective Treatment-A320Document4 pages51-21-00-001-Protective Treatment-A320FredNo ratings yet

- Application Specification: Ctx150™ Matte Seal Receptacle TerminalDocument15 pagesApplication Specification: Ctx150™ Matte Seal Receptacle TerminalJitendra yadavNo ratings yet

- Design and Analysis of Fuselage Skin Repair Joint: Dr. S. Solomon Raj, Dr. G. Laxmaiah & V. Ravi KumarDocument8 pagesDesign and Analysis of Fuselage Skin Repair Joint: Dr. S. Solomon Raj, Dr. G. Laxmaiah & V. Ravi KumarTJPRC PublicationsNo ratings yet

- Design and Analysis of Fuselage Skin Repair Joint: Dr. S. Solomon Raj, Dr. G. Laxmaiah & V. Ravi KumarDocument8 pagesDesign and Analysis of Fuselage Skin Repair Joint: Dr. S. Solomon Raj, Dr. G. Laxmaiah & V. Ravi KumarTJPRC PublicationsNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Cap. 28Document55 pagesCap. 28Marcos ValdezNo ratings yet

- Form 8130-FAADocument1 pageForm 8130-FAAJoel Cordova100% (2)

- G1000 KingAir200 B200 CockpitReferenceGuideDocument104 pagesG1000 KingAir200 B200 CockpitReferenceGuideAde SudengNo ratings yet

- C210SM69Document422 pagesC210SM69Marcos ValdezNo ratings yet

- Beachcraft C90 Normal ChecklistDocument1 pageBeachcraft C90 Normal ChecklistGourav DasNo ratings yet

- BB200 RDocument8 pagesBB200 RIgnacio NicolásNo ratings yet

- InFlight C310G Checklist Series 6 20 14 PDFDocument8 pagesInFlight C310G Checklist Series 6 20 14 PDFMarcos ValdezNo ratings yet

- c310 Checklist 1 PDFDocument15 pagesc310 Checklist 1 PDFMarcos ValdezNo ratings yet

- c310 Checklist 1 PDFDocument15 pagesc310 Checklist 1 PDFMarcos ValdezNo ratings yet

- Java Q & ADocument57 pagesJava Q & ARAJESH PNo ratings yet

- Thermaline 4900 PDSDocument4 pagesThermaline 4900 PDSDuongthithuydungNo ratings yet

- PO 50 Questions QCM 3 Réponses À ValiderDocument16 pagesPO 50 Questions QCM 3 Réponses À Validermouhoubi.naima2No ratings yet

- Communication and Stakeholder Management - AngDocument36 pagesCommunication and Stakeholder Management - AngWendelynn Giannina AngNo ratings yet

- Where Have All The Textbooks Gone?: Toward Sustainable Provision of Teaching and Learning Materials in Sub-Saharan AfricaDocument295 pagesWhere Have All The Textbooks Gone?: Toward Sustainable Provision of Teaching and Learning Materials in Sub-Saharan AfricaAgus ZuhriNo ratings yet

- Specifications of Checkpoint VPNDocument1 pageSpecifications of Checkpoint VPNvijay6996No ratings yet

- Kalol 17 01 2020Document1 pageKalol 17 01 2020Chirag SiddhpuraNo ratings yet

- EPIC32BDocument1 pageEPIC32BAnyie EliasNo ratings yet

- Machine Learning Applications in EpilepsyDocument2 pagesMachine Learning Applications in EpilepsyAbdullah ShihabNo ratings yet

- Social Media Analytics AssignmentDocument9 pagesSocial Media Analytics AssignmentVarun SinhaNo ratings yet

- Belkin TuneCast II FM Transmitter PDFDocument2 pagesBelkin TuneCast II FM Transmitter PDFИгор Македонски СтаматовскиNo ratings yet

- Guitar SeminarDocument4 pagesGuitar SeminarAvinash N KunchamNo ratings yet

- Vessel, Jacketed Vessel, Reactor Atmospheric Tank, Storage: 7.8 Documentation ExamplesDocument7 pagesVessel, Jacketed Vessel, Reactor Atmospheric Tank, Storage: 7.8 Documentation ExamplesnmulyonoNo ratings yet

- Optical Fiber Connector Handbook - Ver2Document62 pagesOptical Fiber Connector Handbook - Ver2GcNo ratings yet

- Chapter 4Document35 pagesChapter 4hailomNo ratings yet

- VE IT2 Tests PR Test 03Document3 pagesVE IT2 Tests PR Test 03وليد طه67% (3)

- Casa L4 - A1-03Document1 pageCasa L4 - A1-03Benjamin CarrionNo ratings yet

- Manual Operacion Ifc-640Document84 pagesManual Operacion Ifc-640Robel MTNo ratings yet

- Qnavigator: User GuideDocument38 pagesQnavigator: User Guideoclin marcel coulibalyNo ratings yet

- Introduction To Java (UNIT I)Document38 pagesIntroduction To Java (UNIT I)Sana MhatreNo ratings yet

- DaVinci Resolve 17 Fusion Visual EffectsDocument379 pagesDaVinci Resolve 17 Fusion Visual Effectsmaan ti100% (1)

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Mathematics: Quarter 2 - Module 4: Algebraic ExpressionsDocument23 pagesMathematics: Quarter 2 - Module 4: Algebraic ExpressionsMa.Cristine Joy Inocentes50% (2)

- Paper-Jam Error (GXXX Errors) : Chapter 17. Panel MessagesDocument2 pagesPaper-Jam Error (GXXX Errors) : Chapter 17. Panel MessagesKaramfil 'Trun' HristovNo ratings yet

- 5 Complaint Brgy. Ibabang Taykin, Liliw LagunaDocument5 pages5 Complaint Brgy. Ibabang Taykin, Liliw LagunaDante Arcigal JrNo ratings yet

- Example 4 (Minimization Problem) Unique and Optimum Solution Refer - OR by J K Sharma Page 123 Ex 4.9Document7 pagesExample 4 (Minimization Problem) Unique and Optimum Solution Refer - OR by J K Sharma Page 123 Ex 4.9Aman PaniyaNo ratings yet

- SDM Download and Install InstructionsDocument16 pagesSDM Download and Install InstructionsAbdus SalamNo ratings yet

- TurretDocument22 pagesTurretВладимир НNo ratings yet

- PT6A Small Customer Training OptimizadoDocument221 pagesPT6A Small Customer Training Optimizadonestor ivan jerez francoNo ratings yet

- 1.daftar Harga Suku CadangDocument2 pages1.daftar Harga Suku CadangCahyadi AndhikaNo ratings yet