Professional Documents

Culture Documents

Aircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACM

Uploaded by

CHIMOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aircraft Maintenance Manual: TASK 12 13 21 610 801 Servicing of The Oil Level of The ACM

Uploaded by

CHIMOCopyright:

Available Formats

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

**ON A/C ALL

REPLENISHING, AIR CYCLE MACHINE (ACM) − SERVICING

1. General

A. The procedures that follow are for the servicing of the air cycle machine (ACM). There

are two ACMs in the air conditioning system. They are installed on each ACM support in

the aft equipment compartment.

B. The first task contains the maintenance procedure to service the oil level. The second

task contains the maintenance procedure for the draining and replenishing of the ACM.

C. Use Exxon 2380 to do the servicing of the ACM. If Exxon 2380 is not available, use an

alternative oil approved to the same specification from the list that follows:

AMBIENT TEMPERATURE ALTERNATIVE OILS

−10 to 120 °F (−23.3 to 48.8 °C) MIL−PRF−23699

−60 to 32 °F (−60 to 0 °C) MIL−PRF−7808

NOTE: Lubricating oils that you use to do the servicing of the ACM are classified as

follows:

– STD (Standard, Non−Corrosion Inhibiting)

– C/I (Corrosion Inhibiting)

– HTS (High Thermal Stability)

These oils are fully interchangeable and can be mixed together in the same

ACM. C/I oils give increased corrosion protection to the bearings and

components. HTS oils give decreased contamination and added protection at

high temperatures. If you mix these different types of oil, their qualities are

decreased to the STD type.

TASK 12−13−21−610−801

Servicing of the Oil Level of the ACM

1. Job Set−Up Information

Subtask 12−13−21−943−001

A. Tools and Equipment

REFERENCE DESIGNATION

Torque wrench 15−25 pound−inches (1.70−2.80 N·m)

Subtask 12−13−21−944−001

B. Consumable Materials

REFERENCE DESIGNATION

03−008 Oil, lubricating, synthetic base

03−010 Oil, lubricating, synthetic base, HTS (High Thermal

Stability)

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 301

May 10/2018

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

REFERENCE DESIGNATION

03−015 Oil, lubricating, synthetic base, standard,

non−corrosion inhibiting

03−016 Oil, lubricating, synthetic base, HTS (High Thermal

Stability)

03−017 Oil, lubricating, synthetic base

05−003 Lockwire

Subtask 12−13−21−945−001

C. Parts

NAME AIPC REFERENCE

Preformed packing AIPC 21−51−00−10

2. Job Set−Up

Subtask 12−13−21−010−001

A. Open the access door that follows:

REFERENCE DESIGNATION

311BB Aft equipment compartment door

3. Procedure

Subtask 12−13−21−610−001

Refer to Figure 301.

WARNING: USE APPROVED SAFETY GOGGLES AND INSULATED GLOVES WHEN

YOU FILL OR DRAIN THE ACM OIL SYSTEM. HOT OIL CAN COME OUT

OF THE OIL DRAIN PLUGS WHEN THEY ARE REMOVED. HOT OIL CAN

CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO EQUIPMENT.

WARNING: LUBRICATING OIL

DO NOT LET LUBRICATING OIL STAY ON YOUR SKIN. DO NOT

BREATHE THE FUMES RELEASED FROM LUBRICATING OIL FOR A

LONG TIME. LUBRICATING OIL IS DANGEROUS TO YOUR EYES, NOSE,

AND LUNGS.

CAUTION: ADD OIL THAT IS APPROVED TO THE SAME SPECIFICATION AS THE OIL

IN THE COMPONENT. IF YOU MIX OILS APPROVED TO DIFFERENT

SPECIFICATIONS, YOU CAN CAUSE DAMAGE TO THE COMPONENT.

CAUTION: DO NOT LET THE FLUIDS TOUCH THE ELECTRICAL COMPONENTS AND

WIRES WHILE SERVICING OR REPAIRING OIL SYSTEMS. THE FLUIDS

CAN DAMAGE THE ELECTRICAL COMPONENTS AND WIRES.

A. Examine the oil level of the ACM through the sight plug (1).

B. If you cannot see oil in the eye of the sight plug (1), do the steps that follow:

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 302

May 10/2014

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

(1) Remove and discard the lockwire from the fill plug (2).

(2) Remove the fill plug (2) from the fill port (3). Remove and discard the preformed

packing (6).

(3) Fill the ACM with oil until the oil comes out of the fill port (3).

(4) Make sure that you can see the oil in the eye of the sight plug (1).

(5) Install the preformed packing (6) on the fill plug (2).

(6) Install the fill plug (2) in the fill port (3) and torque to 15−25 pound inches

(1.70−2.80 N·m).

(7) Safety the fill plug (2) with lockwire.

4. Close Out

Subtask 12−13−21−941−001

A. Remove all tools, equipment, and unwanted materials from the work area.

Subtask 12−13−21−410−001

B. Close the access door that follows:

ACCESS DESIGNATION

311BB Aft equipment compartment door

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 303

May 10/2018

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

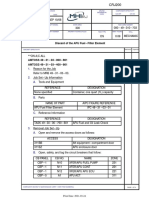

NOTE

Left side is shown.

Right side is opposite.

LEGEND.

1. Sight plug.

2. Fill plug.

3. Fill port.

4. Drain port.

5. Drain plug.

6. Preformed packing.

1

2

6 ACM

3

ram1213213_001.dc, gg/sb, 10/02/93

4

6

5

Air Cycle Machine − Servicing

Figure 301

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 304

Apr 20/2004

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

TASK 12−13−21−612−801

Oil Change of the ACM

1. Reason for the Job

Refer to MRB 21−51−13−05

2. Job Set−Up Information

Subtask 12−13−21−943−002

A. Tools and Equipment

REFERENCE DESIGNATION

Torque wrench 15−25 pound−inches (1.70−2.80 N·m)

None specified Container

Subtask 12−13−21−944−002

B. Consumable Materials

REFERENCE DESIGNATION

03−008 Oil

03−015 Oil

03−016 Oil

03−017 Oil

05−003 Lockwire

Subtask 12−13−21−945−002

C. Parts

NAME AIPC REFERENCE

Preformed packing AIPC 21−51−00−10

Subtask 12−13−21−946−003

D. Reference Information

REFERENCE DESIGNATION

TASK 12−00−07−861−801 Connect External AC Power

TASK 12−00−07−861−802 Remove External AC Power

TASK 21−00−00−910−801 Air Conditioning/Pressurization Safety Precautions

TASK 49−10−00−800−801 APU Start Sequence

TASK 49−10−00−800−802 APU Stop Sequence

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 305

May 10/2018

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

3. Job Set−Up

Subtask 12−13−21−010−002

A. Open the access door that follows:

REFERENCE DESIGNATION

311BB Aft equipment compartment door

4. Procedure

Subtask 12−13−21−612−001

Refer to Figure 302

WARNING: USE APPROVED SAFETY GOGGLES AND INSULATED GLOVES WHEN

YOU FILL OR DRAIN THE ACM OIL SYSTEM. HOT OIL CAN COME OUT

OF THE OIL DRAIN PLUGS WHEN THEY ARE REMOVED. HOT OIL CAN

CAUSE INJURIES TO PERSONS AND/OR DAMAGE TO EQUIPMENT.

WARNING: LUBRICATING OIL

DO NOT LET LUBRICATING OIL STAY ON YOUR SKIN. DO NOT

BREATHE THE FUMES RELEASED FROM LUBRICATING OIL FOR A

LONG TIME. LUBRICATING OIL IS DANGEROUS TO YOUR EYES, NOSE,

AND LUNGS.

CAUTION: ADD OIL THAT IS APPROVED TO THE SAME SPECIFICATION AS THE OIL

IN THE COMPONENT. IF YOU MIX OILS APPROVED TO DIFFERENT

SPECIFICATIONS, YOU CAN CAUSE DAMAGE TO THE COMPONENT.

A. Replace the oil from the ACM as follows:

(1) Put a container below the ACM drain port (4).

(2) Remove and discard the lockwire from the fill plug (2).

(3) Remove and discard the lockwire from the drain plug (5).

(4) Remove the fill plug (2) from the fill port (3). Remove and discard the preformed

packing (6).

(5) Remove the drain plug (5) from the drain port (4). Remove and discard the

preformed packing (6).

(6) Let all the oil drain into the container.

(7) Install the preformed packing (6) on the drain plug (5).

(8) Install the drain plug (5) in the drain port (4).

(9) Fill the ACM with oil until the oil comes out of the fill port (3).

(10) Make sure that you can see the oil in the eye of the sight plug (1).

(11) Install the preformed packing (6) on the fill plug (2).

(12) Install the fill plug (2) in the fill port (3).

(13) Torque the fill plug (2) and the drain plug (5) to 15−25 pound inches

(1.70−2.80 N·m).

(14) Safety the fill plug (2) and the drain plug (5) with lockwire.

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 306

May 10/2018

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

5. Close Out

Subtask 12−13−21−941−002

A. Remove all tools, equipment, and unwanted materials from the work area.

Subtask 12−13−21−790−001

B. Do the oil leak check of the ACM as follows:

WARNING: OBEY ALL OF THE PRESSURIZATION SAFETY PRECAUTIONS. IF

YOU DO NOT DO THIS, YOU CAN CAUSE INJURIES TO PERSONS

AND/OR DAMAGE TO EQUIPMENT

(1) Obey all of the pressurization safety precautions (Ref. TASK 21−00−00−910−801).

(2) Make sure that the circuit breakers that follow are closed:

CB PANEL CB NO. NAME ZONE

CBP−1 F11 10TH ST B/AIR SOV L 221

CBP−1 J1 L AIR COND UNIT 221

CBP−1 J2 CKPT TEMP CONT 221

CBP−1 J3 CKPT TEMP MAN CONT 221

CBP−1 N12 XFER/APU ECU 221

CBP−2 F11 10TH ST B/AIR SOV R 222

CBP−2 J1 R AIR COND UNIT 222

CBP−2 J2 CABIN TEMP CONT 222

CBP−2 J3 CABIN TEMP MAN CONT 222

CBP−4 B1 10TH ST B/AIR ISOL 222

CBP−5 A1 APU ACT 311

(3) Connect the external ac power to the aircraft (Ref. TASK 12−00−07−861−801).

(4) Set the EICAS system as follows:

(a) On the display control panel installed in the left side panel, set the control

switch to NORM.

(b) On the display control panel installed in the right side panel, set the control

switch to NORM.

(c) On the source selector panel installed in the center pedestal, set the EICAS

switch to NORM.

(d) On the EICAS control panel, push the ECS key. Make sure that the EICAS

secondary display shows the ECS synoptic page.

(5) Make sure that the AIR−CONDITIONING panel is set as follows:

– The OFF light on the L PACK PBA is off (switch/light pushed in)

– The OFF light on the R PACK PBA is off (switch/light pushed in)

– The MAN light on the CKPT MAN PBA is off (switch/light pushed out)

– The MAN light on the CABIN MAN PBA is off (switch/light pushed out).

(6) Make sure that the CABIN PRESS panel is set as follows:

– On the PRESS CONTROL PBA, the MAN light is off (switch/light pushed out)

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 307

May 10/2011

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

– The MAN ALT selector switch is in the middle position

– On the EMER DEPR PBA, the ON light is off (switch/light pushed out).

(7) Make sure that the 10TH STAGE section of the BLEED AIR panel is set as follows:

– The CLOSED light on the L 10TH STAGE PBA is on (switch/light pushed out)

– The CLOSED light on the R 10TH STAGE PBA is on (switch/light pushed out)

– The OPEN light on the APU LCV PBA is off (switch/light pushed out)

– The OPEN light on the 10TH STAGE ISOL PBA is off (switch/light pushed out).

(8) Start the auxiliary power unit (APU) (Ref. TASK 49−10−00−800−801).

(9) Pressurize the air conditioning system as follows:

(a) On the BLEED AIR panel, push in APU LCV PBA.

(b) Make sure that the OPEN light on the switch/light comes on.

(c) On the ECS synoptic page, make sure that the APU load control−valve is in

the open position.

(d) On the BLEED AIR panel, push in the 10TH STAGE ISOL PBA.

(e) Make sure that the OPEN light on the switch/light comes on.

(f) On the ECS synoptic page, make sure that the isolation valve is in the open

position.

(g) On the AIR−CONDITIONING panel, push in the L PACK PBA and/or the R

PACK PBA as applicable to your test.

(h) Make sure that the OFF light on the switch/light goes off.

CAUTION: DO NOT LET THE COCKPIT AND THE CABIN DUCT

TEMPERATURES (AS SHOWN ON THE EICAS SECONDARY

DISPLAY) DECREASE TO 5 °C (41 °F) OR LESS. THIS CAN

CAUSE DAMAGE TO EQUIPMENT

CAUTION: DO NOT LET THE COCKPIT AND THE CABIN DUCT

TEMPERATURES (AS SHOWN ON THE EICAS SECONDARY

DISPLAY) INCREASE TO 50 °C (122 °F) OR MORE. THIS CAN

CAUSE DAMAGE TO EQUIPMENT.

(i) On the ECS synoptic page, monitor the air conditioning pressure and

temperature indications for the air conditioning unit (ACU)1. Make sure that the

system becomes stable.

(10) Make sure that there is no oil leak at the ACM.

(11) Release the APU conditioned air from the air conditioning system as follows:

(a) On the BLEED AIR panel, push out the 10TH STAGE ISOL PBA.

(b) Make sure that the OPEN light on the switch/light goes off.

(c) On the ECS synoptic page, make sure that the isolation valve is in the closed

position.

(d) On the BLEED AIR panel, push out the APU LCV PBA.

(e) Make sure that the OPEN light on the switch/light goes off.

(f) On the ECS synoptic page, make sure that the APU load control−valve is in

the closed position.

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 308

May 10/2011

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

(12) Stop the APU (Ref. TASK 49−10−00−800−802).

(13) Remove the external ac power (Ref. TASK 12−00−07−861−802)

Subtask 12−13−21−410−002

C. Close the access door that follows:

ACCESS DESIGNATION

311BB Aft equipment compartment door

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 309

May 10/2011

Print Date: 2021-03-25

C

AIRCRAFT MAINTENANCE MANUAL

CRJ200

NOTE

Left side is shown.

Right side is opposite.

LEGEND.

1. Sight plug.

2. Fill plug.

3. Fill port.

4. Drain port.

5. Drain plug.

6. Preformed packing.

1

2

6 ACM

3

ram1213213_001.dc, gg/sb, 10/02/93

4

6

5

Air Cycle Machine − Servicing

Figure 302

Master

EFFECTIVITY: See Pageblock 12−13−21 page 301

12−13−21 Page 310

May 10/2011

Print Date: 2021-03-25

You might also like

- Aircraft Maintenance Manual: Print Date: 2021-03-25Document8 pagesAircraft Maintenance Manual: Print Date: 2021-03-25CHIMONo ratings yet

- APU PresentationDocument60 pagesAPU PresentationNejmeddine HalfaouiNo ratings yet

- G 450 ApuDocument33 pagesG 450 Apusohaib arifNo ratings yet

- List of Illustrations: Section 5 Auxiliary Power Unit (Apu)Document8 pagesList of Illustrations: Section 5 Auxiliary Power Unit (Apu)Emanøel AlvesNo ratings yet

- Guide pilots with FD systemsDocument16 pagesGuide pilots with FD systemsAlex SuarezNo ratings yet

- Auxiliary and Ground Power UnitsDocument4 pagesAuxiliary and Ground Power UnitsJacquie JimenezNo ratings yet

- Goodrich Ecu OspsDocument4 pagesGoodrich Ecu OspsturboshaftNo ratings yet

- CAO - IRI Part - MDocument102 pagesCAO - IRI Part - MDariush ShNo ratings yet

- FJ44 Service Bulletin - Fuel Flow Tube ReplacementDocument4 pagesFJ44 Service Bulletin - Fuel Flow Tube Replacementlong chenNo ratings yet

- L3 Communications CVR (FA2100) 23-70-04 - Rev 07Document268 pagesL3 Communications CVR (FA2100) 23-70-04 - Rev 07Indiomarcio Ghelardi100% (1)

- ASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public ReleaseDocument7 pagesASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public Releasesebastian eduardoNo ratings yet

- Auxiliary Power Unit (Apu) Systems ReviewDocument5 pagesAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- Vdocuments - MX - Pilatus Maintenance Organisation Capability List 2019 09 18 31 c13 AstrDocument29 pagesVdocuments - MX - Pilatus Maintenance Organisation Capability List 2019 09 18 31 c13 Astrbatteryshop100% (1)

- FAA document details Boeing 757 aircraft type certificationDocument13 pagesFAA document details Boeing 757 aircraft type certificationBRAIYAM ALEXANDER MORENO VARGAS100% (2)

- Ceb 73 6048Document5 pagesCeb 73 6048turboshaftNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- General: Bombardier Challenger 605 - Auxiliary Power UnitDocument25 pagesGeneral: Bombardier Challenger 605 - Auxiliary Power UnitMax MellmingerNo ratings yet

- 35-10-85 Rev 007 (Fullface Mask Stowage Box AssyDocument100 pages35-10-85 Rev 007 (Fullface Mask Stowage Box AssynoureldinkamalNo ratings yet

- 700 29 027 BasicDocument13 pages700 29 027 BasicHimanshu Pant100% (1)

- C47B OmmDocument12 pagesC47B OmmturboshaftNo ratings yet

- Kdi 572 Kdi 573 Kdi 574Document170 pagesKdi 572 Kdi 573 Kdi 574Felipe R ChaparroNo ratings yet

- Week 5Document116 pagesWeek 5Arief SambestNo ratings yet

- Bendix Magneto PartsDocument13 pagesBendix Magneto PartsDavidNo ratings yet

- AircraftDocument21 pagesAircraftKiran KumarNo ratings yet

- CMM Index-8 PDFDocument16 pagesCMM Index-8 PDFChandanNo ratings yet

- Chapter 3 - APU, Ext Power & RATDocument53 pagesChapter 3 - APU, Ext Power & RATHafeez Yusuf100% (1)

- Chapter 8 - Environmental Control System: REV 3, May 03/05Document40 pagesChapter 8 - Environmental Control System: REV 3, May 03/05julian marinNo ratings yet

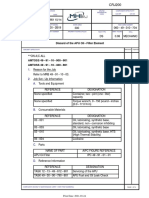

- On A/C All: Effectivity: Illustrated Parts CatalogDocument8 pagesOn A/C All: Effectivity: Illustrated Parts CatalogCHIMONo ratings yet

- DGAC-INDONESIA List of Airworthiness Directives 2010Document63 pagesDGAC-INDONESIA List of Airworthiness Directives 2010Estevam Gomes de AzevedoNo ratings yet

- Chapter 2 Ata100Document8 pagesChapter 2 Ata100Gustavo Silva AeEngNo ratings yet

- Cessna T337H Pilot's Handbook Supplement for Avionics UpgradeDocument45 pagesCessna T337H Pilot's Handbook Supplement for Avionics UpgradeChatchai PrasertsukNo ratings yet

- Procedure For DFDR DataDocument1 pageProcedure For DFDR DataAbhishek Roy100% (1)

- IFR AEROFLEX ATC 601 2 Mode S A C Transponder Ramp Test Set Manual AvionTEq PDFDocument164 pagesIFR AEROFLEX ATC 601 2 Mode S A C Transponder Ramp Test Set Manual AvionTEq PDFjorge furtado de freitas0% (1)

- Honeywell 36-100 APUDocument3 pagesHoneywell 36-100 APUAlmas QasimNo ratings yet

- 51-60!02!500 Control Surface Balancing - Rudder - Adjustment - TestDocument8 pages51-60!02!500 Control Surface Balancing - Rudder - Adjustment - TestArmandoNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNo ratings yet

- Ceb 1393Document5 pagesCeb 1393turboshaftNo ratings yet

- Champion Aerospace 2010 Technical Publications IndexDocument4 pagesChampion Aerospace 2010 Technical Publications Indexstarsalingsoul8000No ratings yet

- M250-C30R3M Inspection Check SheetsDocument15 pagesM250-C30R3M Inspection Check SheetsturboshaftNo ratings yet

- Embraer 145 - Electrical - 1Document62 pagesEmbraer 145 - Electrical - 1DVSNo ratings yet

- Legacy 600 sn145678 SpecDocument10 pagesLegacy 600 sn145678 SpecDoor URNo ratings yet

- TTM Single Aisle Line & Base Ata 49 GTCPDocument162 pagesTTM Single Aisle Line & Base Ata 49 GTCP林至伟No ratings yet

- 8140B-30 Altimeter EncoderDocument48 pages8140B-30 Altimeter Encoderwilliam abraaoNo ratings yet

- Saft General PDFDocument84 pagesSaft General PDFESAVENo ratings yet

- St01829at, 12-22-05Document2 pagesSt01829at, 12-22-05Nkemakolam Celestine Chukwu100% (1)

- General Practices Manual Maintenance Procedures Aircraft Wheel BearingsDocument26 pagesGeneral Practices Manual Maintenance Procedures Aircraft Wheel Bearingskien Duy PhanNo ratings yet

- Revision: MODEL 650 Illustrated Parts CatalogDocument4,036 pagesRevision: MODEL 650 Illustrated Parts CatalogAsep HidayatNo ratings yet

- AirspeedDocument9 pagesAirspeednabawi24No ratings yet

- LED anti-collision strobe lightsDocument8 pagesLED anti-collision strobe lightsoglasifwdNo ratings yet

- Vol. 1 Auxiliary Power UnitDocument22 pagesVol. 1 Auxiliary Power UnitRicardo GarciaNo ratings yet

- Airborne Fuel Pump 2Document1 pageAirborne Fuel Pump 2Luis Martinez GerdingNo ratings yet

- PC 12Document8 pagesPC 12Gopinath Srinivasan100% (1)

- ATR Part Numbers Reference GuideDocument23 pagesATR Part Numbers Reference Guideasif27No ratings yet

- 429 Asb 15 19Document4 pages429 Asb 15 19Samir PeraltaNo ratings yet

- Rockwell Collin SILDocument16 pagesRockwell Collin SILAlphard DarmawanNo ratings yet

- TB 430-04-37Document63 pagesTB 430-04-37Amparo AlvarezNo ratings yet

- Dassualt Falcon 7X-Water and Waste System Study GuideDocument36 pagesDassualt Falcon 7X-Water and Waste System Study GuideGourav DasNo ratings yet

- EASA TCDS - DHC-8 - Iss 12Document34 pagesEASA TCDS - DHC-8 - Iss 12bittekeinspam123100% (1)

- CRJ200.MTCM Lump 2 (54) .MTCM060 49 310 704Document4 pagesCRJ200.MTCM Lump 2 (54) .MTCM060 49 310 704CHIMONo ratings yet

- CRJ200.MTCM (54) .MTCM000 49 310 704Document4 pagesCRJ200.MTCM (54) .MTCM000 49 310 704CHIMONo ratings yet

- CRJ200.MTCM (54) .MTCM000 49 310 703Document4 pagesCRJ200.MTCM (54) .MTCM000 49 310 703CHIMONo ratings yet

- CRJ200.MTCM Lump 2 (54) .MTCM060 49 310 703Document4 pagesCRJ200.MTCM Lump 2 (54) .MTCM060 49 310 703CHIMONo ratings yet

- CRJ200 FM-PFZ (75) FCOM1 - ch22-3Document8 pagesCRJ200 FM-PFZ (75) FCOM1 - ch22-3CHIMONo ratings yet

- Confidentiality and Privilege in Mediation Australian Perspective - FinalDocument4 pagesConfidentiality and Privilege in Mediation Australian Perspective - FinalCHIMO100% (1)

- Lawyers and Confidentiality PDFDocument34 pagesLawyers and Confidentiality PDFAbegail Olario AdajarNo ratings yet

- CRJ Pre - After Flight ChecklistDocument4 pagesCRJ Pre - After Flight ChecklistCHIMONo ratings yet

- LAZ PAPER Ethics Ethical Conduct Challenges and Opportunities in Modern PracticeDocument15 pagesLAZ PAPER Ethics Ethical Conduct Challenges and Opportunities in Modern PracticenkwetoNo ratings yet

- On A/C All: Effectivity: Illustrated Parts CatalogDocument8 pagesOn A/C All: Effectivity: Illustrated Parts CatalogCHIMONo ratings yet

- Aircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGDocument12 pagesAircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGCHIMONo ratings yet

- CRJ200.MTCM Lump 2 - 54 - .MTCM060 79 310 001Document5 pagesCRJ200.MTCM Lump 2 - 54 - .MTCM060 79 310 001CHIMONo ratings yet

- LegalDocument137 pagesLegalstephanieNo ratings yet

- Scholarship at GEORGETOWN LAW Scholarship at GEORGETOWN LAWDocument49 pagesScholarship at GEORGETOWN LAW Scholarship at GEORGETOWN LAWCHIMONo ratings yet

- On A/C All: Effectivity: Illustrated Parts CatalogDocument8 pagesOn A/C All: Effectivity: Illustrated Parts CatalogCHIMONo ratings yet

- Ethics Opinion RO 2009 01 Ethical Obligations of A Lawyer When His Client Has Committed or Intends To Commit PerjuryDocument9 pagesEthics Opinion RO 2009 01 Ethical Obligations of A Lawyer When His Client Has Committed or Intends To Commit PerjuryCHIMONo ratings yet

- CRJ200.MTCM Lump 2 - 54 - .MTCM060 79 310 001Document5 pagesCRJ200.MTCM Lump 2 - 54 - .MTCM060 79 310 001CHIMONo ratings yet

- Lawyers and Confidentiality PDFDocument34 pagesLawyers and Confidentiality PDFAbegail Olario AdajarNo ratings yet

- CRJ200.MTCM (54) .MTCM000 27 900 007Document6 pagesCRJ200.MTCM (54) .MTCM000 27 900 007CHIMONo ratings yet

- On A/C All: Effectivity: Illustrated Parts CatalogDocument8 pagesOn A/C All: Effectivity: Illustrated Parts CatalogCHIMONo ratings yet

- File - Engineering Training MatrixDocument2 pagesFile - Engineering Training MatrixCHIMONo ratings yet

- LAZ PAPER Ethics Ethical Conduct Challenges and Opportunities in Modern PracticeDocument15 pagesLAZ PAPER Ethics Ethical Conduct Challenges and Opportunities in Modern PracticenkwetoNo ratings yet

- An Analytical Overview of The Effectiveness and Adequacy of Corporate Insolvency Laws in ZambiaDocument86 pagesAn Analytical Overview of The Effectiveness and Adequacy of Corporate Insolvency Laws in ZambiaCHIMONo ratings yet

- FAA 2012 0721 0009 - Attachment - 5Document119 pagesFAA 2012 0721 0009 - Attachment - 5CHIMONo ratings yet

- File Employee LeavingDocument2 pagesFile Employee LeavingCHIMONo ratings yet

- Zambian Open University School of Law: Senior Lecturer, ZAOUDocument129 pagesZambian Open University School of Law: Senior Lecturer, ZAOUCHIMONo ratings yet

- Aircraft Maintenance Manual: Task 21 51 13 140 801 Restoration (Cleaning) of The Water Separator CoalescersDocument8 pagesAircraft Maintenance Manual: Task 21 51 13 140 801 Restoration (Cleaning) of The Water Separator CoalescersCHIMONo ratings yet

- Mipunga N A0001Document60 pagesMipunga N A0001CHIMONo ratings yet

- Afman 11-2C-130H V3 Operations ProceduresDocument209 pagesAfman 11-2C-130H V3 Operations ProceduresAndrés SarmientoNo ratings yet

- Boeing C17 Globemaster ManualDocument28 pagesBoeing C17 Globemaster ManualGourav Das100% (1)

- DA7 Flight Manual 2003Document730 pagesDA7 Flight Manual 2003OS BL100% (2)

- A300 Checklist PT1Document2 pagesA300 Checklist PT1Sam AlcaláNo ratings yet

- A320 Opc 2021-1-Instruktori FinalDocument18 pagesA320 Opc 2021-1-Instruktori FinalzokiNo ratings yet

- Airbus A310 ChecklistDocument4 pagesAirbus A310 ChecklistJonathan NoriegaNo ratings yet

- Zibo Mod Checklist - Training ChecklistDocument37 pagesZibo Mod Checklist - Training ChecklistlucksimNo ratings yet

- B1-11 (1) .4.1 Air Supply B-1 (2008)Document10 pagesB1-11 (1) .4.1 Air Supply B-1 (2008)Kisna BhurtelNo ratings yet

- ToLiss AirbusA321 V1.3.2 AircraftManualDocument57 pagesToLiss AirbusA321 V1.3.2 AircraftManualQuandale DingleNo ratings yet

- A-320 Study Notes PDFDocument158 pagesA-320 Study Notes PDFM DarwishNo ratings yet

- Aircraft Life Cycle Costing AnalysisDocument61 pagesAircraft Life Cycle Costing AnalysisMd Jalal Uddin Rumi100% (1)

- A320 Maintenance Cost AnalysisDocument8 pagesA320 Maintenance Cost AnalysisIbrahim KhalilNo ratings yet

- A320 Displays & PanelsDocument1,752 pagesA320 Displays & PanelsOleg TysiachnyiNo ratings yet

- 737 Bleed Air System NotesDocument2 pages737 Bleed Air System NotesPhil100% (1)

- Opencockpits Overhead MapeadoIO IOmappingDocument4 pagesOpencockpits Overhead MapeadoIO IOmappingImanolLopezNo ratings yet

- APU Start by External PowerDocument6 pagesAPU Start by External PowerKeilaeFrancisco ArceNo ratings yet

- Appendix A Trema and AbbreviationsDocument30 pagesAppendix A Trema and AbbreviationsGeorge ManoliosNo ratings yet

- SPM 49-00-01-Rev05Document7 pagesSPM 49-00-01-Rev05franjov22No ratings yet

- 24-27 - Ac Generation Monitoring and Indicating PDFDocument19 pages24-27 - Ac Generation Monitoring and Indicating PDFMohammad NorouzzadehNo ratings yet

- Airbus 00 A300 A310 Airframe System IntroductionDocument10 pagesAirbus 00 A300 A310 Airframe System IntroductionElijah Paul Merto100% (1)

- Hawker 800 800XP FlashCardsDocument485 pagesHawker 800 800XP FlashCardsPolo Soto100% (3)

- A330 Fuel System Technical TrainingDocument134 pagesA330 Fuel System Technical TrainingSohaib Aslam ChaudharyNo ratings yet

- NAVY T-44 Training WorkbookDocument168 pagesNAVY T-44 Training WorkbookjjfugedyNo ratings yet

- Embraer DiferencialDocument792 pagesEmbraer DiferencialBoris83% (6)

- AFM Embraer 170 Emergency and Abnormal Procedures 1385 003 FAA SECTION04Document140 pagesAFM Embraer 170 Emergency and Abnormal Procedures 1385 003 FAA SECTION04Vitor Palomanes100% (1)

- Vintage Airplane - Oct 1997Document36 pagesVintage Airplane - Oct 1997Aviation/Space History LibraryNo ratings yet

- 737 Check ListDocument7 pages737 Check ListGuillermo Pinzón AmayaNo ratings yet

- Getting To Grips With Fuel EconomyDocument82 pagesGetting To Grips With Fuel EconomyShafiNo ratings yet

- Learning Module No. 3 - Aircraft Pneumatics SystemDocument15 pagesLearning Module No. 3 - Aircraft Pneumatics SystemDavidSamsonNo ratings yet

- APU controls and indicatorsDocument9 pagesAPU controls and indicatorsEhsan Ul HaqueNo ratings yet