Professional Documents

Culture Documents

Valvula 2

Uploaded by

Instrumentistas Caña brava0 ratings0% found this document useful (0 votes)

10 views2 pagesOriginal Title

valvula 2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesValvula 2

Uploaded by

Instrumentistas Caña bravaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

ND9000PA

2023-04-18 17:46:38

Performance Report

Supply Pressure 4.5 barG

Actuator Pressure Difference -31.1 bar

Valve Position 60.2 %

Target Position 0.0 %

Calculated Deviation 60.2 %

Control Out of specification

1) Steady State Deviation Trend Limit Exceeded:

There is increased friction in the valve or actuator, leakage in

the pneumatics or insufficient supply pressure. There is a

difference between the actual valve position and the setpoint

when the valve is stabile.

Run a calibration (calibrating will help to compensate for

changes in the operating conditions) and check the

performance. Inspect the stiction and steady state

deviation trends to determine if there have been any

recent significant increases. Evaluate if the warning

limits are set correctly. Check the event log fore previous

alarm conditions. Check the actuator for pneumatics

leakage. Inspect the valve during the next maintenance

activity.

2) Dynamic State Deviation Limit Exceeded:

Large dynamic state deviation is normal for example in on-off

usage and for large actuators, but can also be a result from

small air capacity from e.g. dirty supply air filter, too small

spool or small piping. Dynamic state deviation is also

influenced by supply pressure level, performance level, as well

as calibration and tuning of the device. There is a difference

between the actual valve position and the setpoint when the

valve is moving.

Inspect the valve stiction and dynamic state deviation

trends to determine if there have been any recent

significant increases. Evaluate if the warning limits are

set correctly. Check the event log for previous alarm

conditions. Check the actuator for pneumatics leakage.

Run a calibration (calibrating will help to compensate for

changes in the operating conditions) and check the

performance. Inspect the valve during the next

maintenance activity.

3) Steady State Deviation Limit Exceeded:

Friction in the valve or actuator has increased, there is a

leakage in the pneumatics, or insufficient supply pressure in

the actuator. There is a difference between the actual valve

position and the setpoint when the valve is not moving.

Run a calibration (calibrating will help compensate for

changes in operating conditions) and check the

performance. Inspect the stiction and steady state

deviation trends to determine if there have been any

recent significant increases. Evaluate if the alarm limits

are set correctly. Check the event log for previous alarm

conditions. Check the actuator for any pneumatics

leakage. Inspect the valve during the next maintenance

opportunity.

Positioner Out of specification

Spool Valve Problem Detected:

The spool valve does not move properly. The valve may not

follow the setpoint accurately.

Check the spool valve condition. If necessary, clean or

replace it according to the IMO instructions and then

re-calibrate the device.

Actuator Possible pneumatic leakage.

Check the 'Spool Valve Position' trend. Pneumatic

leakage can be seen when the trend level has increased

or decreased.

Valve Maintenance required

Stiction Trend High Limit Exceeded:

Increased friction in the valve or in the actuator is typically

caused by wear or flow media build-up. High stiction may also

be caused by an undersized actuator. The force that is needed

to move the valve has increased.

Check the control index in Performance View and the

steady state deviation trend to determine if the valve

package is controlling adequately. Check the stiction

trend for any recent significant increases. If the

performance is insufficient, perform maintenance on the

valve package during the next shutdown. Evaluate if the

warning limits are set correctly.

Environment Out of specification

Supply Pressure Too Low for Single Acting Actuator:

The positioner diagnostics have detected that the instrument

air pressure to the positioner is too low to drive the valve. The

supply pressure is too low to drive the valve fully open if

needed.

Check the condition of the air-supply system.

Performance View

You might also like

- Case Study 2Document2 pagesCase Study 2SyafiyatulMunawarahNo ratings yet

- Distillation Column HAZOPDocument6 pagesDistillation Column HAZOPAhmer SohailNo ratings yet

- General EK (Control)Document22 pagesGeneral EK (Control)Maneesh100% (1)

- Control Valve Manual - What is a Control Valve? Process Control TerminologyDocument55 pagesControl Valve Manual - What is a Control Valve? Process Control Terminologytxlucky80100% (1)

- InstrDocument31 pagesInstrSergioGaldamesPérezNo ratings yet

- SCX120 Catalog - SM PDFDocument32 pagesSCX120 Catalog - SM PDFHorea CordunianuNo ratings yet

- MCSI - UHGB - N6-3.43 Operation Manual - Eng PDFDocument7 pagesMCSI - UHGB - N6-3.43 Operation Manual - Eng PDFBatbayar NyandagjidNo ratings yet

- FC Mag - Characteristics and SizingDocument5 pagesFC Mag - Characteristics and SizingAhmed KhairiNo ratings yet

- Regulator Troubleshooting en 8109374Document4 pagesRegulator Troubleshooting en 8109374Jose Francisco GonzalezNo ratings yet

- DEZUMIDIFICATORDocument5 pagesDEZUMIDIFICATORviltermNo ratings yet

- TM 90 01Document29 pagesTM 90 01juliancardona77No ratings yet

- Tech ManualDocument44 pagesTech ManualJonathan Negrete OrtizNo ratings yet

- Diagnosing and Solving Common Control Loop ProblemDocument9 pagesDiagnosing and Solving Common Control Loop ProblemCehanNo ratings yet

- Recent Discussions on Valves, Actuators & RegulatorsDocument13 pagesRecent Discussions on Valves, Actuators & RegulatorsraulNo ratings yet

- Introduction To RegulatorsDocument7 pagesIntroduction To Regulatorsoldboy1No ratings yet

- Fundamentals of Final Control ElementsDocument57 pagesFundamentals of Final Control ElementshazemNo ratings yet

- N-100-34 Mantto InstDocument6 pagesN-100-34 Mantto InstAlejandro GomezNo ratings yet

- Balance of Plant - IntroductionDocument20 pagesBalance of Plant - IntroductionSwapanbasuNo ratings yet

- Proc Calc Alumnos CapDocument26 pagesProc Calc Alumnos Capabigail muñozNo ratings yet

- Concepts of Instrumentation Control ValvesDocument140 pagesConcepts of Instrumentation Control ValvesSnehashis BoseNo ratings yet

- CLA VAL 50-20-Install-Operation-and-Maintenance-ManualDocument28 pagesCLA VAL 50-20-Install-Operation-and-Maintenance-ManualChirasak PaksasornNo ratings yet

- Val Control de Flujo Set StopDocument46 pagesVal Control de Flujo Set StopNatalia BeltránNo ratings yet

- TroubleshootingDocument1 pageTroubleshootingSurendran RadhakrishnanNo ratings yet

- TM 136 03Document34 pagesTM 136 03ahmsa.morsyNo ratings yet

- Trouble Shooting of Screw Sludge DehydratorDocument3 pagesTrouble Shooting of Screw Sludge Dehydratorbresler_linNo ratings yet

- Healthy Control ValvesDocument2 pagesHealthy Control Valvesfawmer61No ratings yet

- Valve InspectionDocument5 pagesValve InspectionLipika Gayen100% (1)

- Troubleshooting - Construction & Mining Parts For Volvo, Allison, Funk & ZF. Centranz, Inc PDFDocument5 pagesTroubleshooting - Construction & Mining Parts For Volvo, Allison, Funk & ZF. Centranz, Inc PDFahmad fikriNo ratings yet

- Crane Troubleshooting Guide LinesDocument9 pagesCrane Troubleshooting Guide LinesgogosNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- AutomationDocument18 pagesAutomationhanshyamNo ratings yet

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- Control Valves 1678169882Document22 pagesControl Valves 1678169882Myo Myint MaungNo ratings yet

- Control Valve Selection Guide - Valve Selection - Valve HandbookDocument21 pagesControl Valve Selection Guide - Valve Selection - Valve Handbook2g2qscbv5pNo ratings yet

- Control ValveDocument35 pagesControl Valveshivani DubeyNo ratings yet

- Policies and Procedures of Equipment MaintenanceDocument9 pagesPolicies and Procedures of Equipment Maintenancerussel1435No ratings yet

- Hydraulic System Initial Start-Up and MaintenanceDocument4 pagesHydraulic System Initial Start-Up and MaintenanceLuisNo ratings yet

- 11 3-And-11 4Document3 pages11 3-And-11 4Reymond Clark AdasaNo ratings yet

- Fisher - Compressor Anti Surge ValveDocument3 pagesFisher - Compressor Anti Surge ValveAlexa MouawadNo ratings yet

- Chapter 1Document22 pagesChapter 1Guido Wilder Algarañaz MonteroNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Document24 pagesOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- Pump Operation AssessementDocument2 pagesPump Operation AssessementChanel el hifnawyNo ratings yet

- Maintaining Valves The Right Way: by Nwaoha Chikezie of CASEIDocument2 pagesMaintaining Valves The Right Way: by Nwaoha Chikezie of CASEIRajibNo ratings yet

- Content9732691 PDFDocument17 pagesContent9732691 PDFRaphael LemosNo ratings yet

- Process Control Lab ManualDocument95 pagesProcess Control Lab ManualMangaiyarakarasi VenkatachalamNo ratings yet

- S1-Gas Production SystemDocument25 pagesS1-Gas Production SystemMd Abid AfridiNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document37 pagesGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNo ratings yet

- Keeping Your Control Valves: in Good HealthDocument8 pagesKeeping Your Control Valves: in Good HealthvirtechNo ratings yet

- 7 - Andre VolschenkDocument24 pages7 - Andre VolschenkPieter Vd MerweNo ratings yet

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Liste Des Defauts 38Document5 pagesListe Des Defauts 38MMF PLUSNo ratings yet

- ABB Instrumentation: Pipeline Booster Station Control SystemsDocument6 pagesABB Instrumentation: Pipeline Booster Station Control SystemsPatricio AcuñaNo ratings yet

- Section 8 - Control Valve Flow Characteristics PDFDocument6 pagesSection 8 - Control Valve Flow Characteristics PDFMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Basic Control Valve Sizing and SelectionDocument53 pagesBasic Control Valve Sizing and SelectionAtul TripathiNo ratings yet

- Pid Algorithm and Tuning Methods: Process Control SolutionsDocument33 pagesPid Algorithm and Tuning Methods: Process Control SolutionsTrần Ngọc MẩnNo ratings yet

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringFrom EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- P&ID - Legend SheetDocument12 pagesP&ID - Legend SheetMinh Sang Phạm HuỳnhNo ratings yet

- Accumulator: Surge PressuresDocument5 pagesAccumulator: Surge PressuresMubashir KhanNo ratings yet

- Inservice Testing Program for Pumps & Valves at Watts Bar Nuclear Power PlantDocument69 pagesInservice Testing Program for Pumps & Valves at Watts Bar Nuclear Power PlantMiloud BekhitiNo ratings yet

- Horizontal Split Case LN TypeDocument38 pagesHorizontal Split Case LN TypeprojashNo ratings yet

- Api 682Document132 pagesApi 682Raul Gonzalez FernandezNo ratings yet

- Maintenance and Troubleshooting of A Bop Control SystemDocument12 pagesMaintenance and Troubleshooting of A Bop Control SystemHamid Reza BabaeiNo ratings yet

- ABE2023-Sessions - Radial Equilibrium and Free Vortex DesignDocument24 pagesABE2023-Sessions - Radial Equilibrium and Free Vortex Designaccplus194No ratings yet

- Turbocharger Vs Supercharger DownloadDocument2 pagesTurbocharger Vs Supercharger DownloadRitesh inamdarNo ratings yet

- John Deere Spraymaster - Centrifugal Pump RepairDocument36 pagesJohn Deere Spraymaster - Centrifugal Pump RepairTim LeeNo ratings yet

- 2500 Cent Pump Manual 2Document2 pages2500 Cent Pump Manual 2StefanyNo ratings yet

- Turbines, Compressors and Fans - S. M. YahyaDocument170 pagesTurbines, Compressors and Fans - S. M. YahyaHarsh Bhavsar0% (3)

- Centrifugal Compressor InductionDocument13 pagesCentrifugal Compressor Inductionthanapaet rittirutNo ratings yet

- SprinkCALC III Report - Bld7.Riser1Document30 pagesSprinkCALC III Report - Bld7.Riser1Igor CvijovicNo ratings yet

- A8P Aluminium Bent Axis PumpsDocument10 pagesA8P Aluminium Bent Axis Pumpsfredy kokNo ratings yet

- Fluid MachineryDocument38 pagesFluid MachinerySimon TudorNo ratings yet

- Samson ValvesDocument16 pagesSamson ValvesjimmiilongNo ratings yet

- Sistemes Propolsius D'aeronaus: Marc Maym o GarridoDocument19 pagesSistemes Propolsius D'aeronaus: Marc Maym o GarridomanuelNo ratings yet

- Accumulator drill test record chart analysisDocument3 pagesAccumulator drill test record chart analysisriska jayaNo ratings yet

- Fig 21150 Vag Pico PRV Druk ReduceerDocument2 pagesFig 21150 Vag Pico PRV Druk ReduceerAlberto DiazNo ratings yet

- MDD1C - FGL+G02+G03+G04 Buildings T C For QCD Upload Master Tracking S... 09-09-18Document9 pagesMDD1C - FGL+G02+G03+G04 Buildings T C For QCD Upload Master Tracking S... 09-09-18asathish.eeeNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument6 pagesPump Performance Datasheet: Operating Conditions Liquidudiptya_papai2007No ratings yet

- In-Line Balanced Pressure (ILBP) Proportioning UnitsDocument4 pagesIn-Line Balanced Pressure (ILBP) Proportioning UnitsIskandar HasibuanNo ratings yet

- FE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPDocument28 pagesFE1148 4inch FPS 4400 Sales - Tech Brochure 03 - 15 FRANKLIN ELECTRIC PUMPZaen SalimNo ratings yet

- Tugas 2 InstrumenDocument4 pagesTugas 2 Instrumendzaky fawwazNo ratings yet

- How It Works - 3565 KPHDocument1 pageHow It Works - 3565 KPHorqh007No ratings yet

- Dash8 200 300 Hydraulics PDFDocument9 pagesDash8 200 300 Hydraulics PDFShawn el'DiabloNo ratings yet

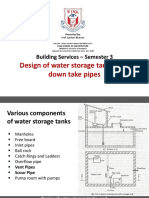

- Design of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3Document33 pagesDesign of Water Storage Tanks, and Down Take Pipes: Building Services - Semester 3sakshi meherNo ratings yet

- Process and Instrument Diagram SymbolsDocument24 pagesProcess and Instrument Diagram SymbolsBabak Hosseini100% (1)

- Annexure Fire Fighting SystemDocument4 pagesAnnexure Fire Fighting SystemShafi AshrafNo ratings yet