Professional Documents

Culture Documents

Mullite & Zircon

Uploaded by

dattanikmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mullite & Zircon

Uploaded by

dattanikmCopyright:

Available Formats

SPECIAL CERAMICS PVT. LTD.

www.specialceramics.in

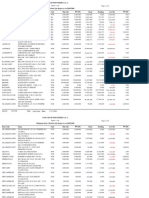

MULLITE & ALUMINA BASED PRODUCTS

Al2O3 Fe2O3 SiO2 B.D. A.P. C.C.S. R.U.L. P.C.E. R.T.E. T.C. Mortar

Brand Name Typical Application

(%) (%) (%) gm/cc (%) kg/cm2 taºC Orton (%) w/mºK Recommended

PRESSED PRODUCTS - BRICKS & SQUARE BLOCKS

SCL-72 70.0 0.6 28.0 2.70 18 500 1640 36 0.62 1.98 SCL-70M Port, Regenerator, etc.

SCL-MUL 72.0 0.2 27.0 2.60 17 800 1700 38 0.60 1.92 SCL-MULM Port, Walls, Crowns &

SCL-MULS 78.0 0.2 21.0 2.65 18 800 1700 38 0.66 1.98 SCL-MULM Regenerator etc.

SCL-90 90.0 0.2 6.0 2.95 18 800 1700 38 0.72 2.10 SCL-90M Distributor Bottom & Side Walls,

SCL-99 99.4 0.1 0.1 3.10 18 900 1700 38 0.80 2.22 SCL-99M Forehearth

VIBRO-CAST PRODUCTS - BLOCKS & SHAPES

SCL-72 CAST 70.0 0.6 28.0 2.66 20 500 1640 36 0.62 1.92 SCL-70M

SCL-MULCAST 72.0 0.2 27.0 2.55 19 800 1700 38 0.60 1.86 SCL-MULM Port, Regenerator, etc.

SCL-MULCAST S 78.0 0.2 21.0 2.60 20 680 1700 38 0.64 1.90 SCL-MULM

SCL-90 CAST 90.0 0.2 6.0 2.90 20 700 1700 38 0.70 2.02 SCL-90M

Distributor, Forehearth

SCL-99 CAST 99.4 0.1 0.1 3.00 20 750 1700 38 0.76 2.18 SCL-99M

ZIRCON AND ZIRCON-MULLITE PRODUCTS

Al2O3 Fe2O3 ZrO2 B.D. A.P. C.C.S. R.U.L. P.C.E. R.T.E. T.C. Mortar

Brand Name Typical Application

(%) (%) (%) gm/cc (%) kg/cm2 taºC Orton (%) w/mºK Recommended

PRESSED PRODUCTS - BRICKS & SQUARE BLOCKS

SCL-ZRN 0.5 63.0 3.60 20 600 1650 36 0.50 2.50 SCL-ZRM Sub-paving in tank bottom

SCL-ZRD 0.3 65.0 3.65 20 600 1680 38 0.52 2.54 SCL-ZRM Neutral layer, Sub-paving

SCL-ZRS 0.2 67.0 3.70 19 700 1700 38 0.54 2.57 SCL-ZRM For Boro-silicate glass

SCL-ZM 68.0 0.2 18.0 3.20 18 800 1680 38 0.60 1.76 SCL-ZMM Port wall & crown, Tank Superstructure

SCL-ZMD 59.0 0.2 25.0 3.30 18 800 1700 38 0.62 1.85 SCL-ZMM

For severe corrosion areas

SCL-ZMS 50.0 0.2 31.0 3.35 18 800 1700 38 0.65 1.92 SCL-ZMM

VIBRO-CAST PRODUCTS - BLOCKS & SHAPES

SCL-ZIRCAST - 0.5 62.0 3.55 22 600 1650 36 0.50 2.46 SCL-ZRM

Burner Blocks, Plugs, etc.

SCL-ZIRCAST S - 0.3 64.5 3.60 22 600 1680 38 0.52 2.50 SCL-ZRM

SCL-ZMCAST 67.0 0.2 18.0 3.15 20 800 1680 38 0.60 1.71 SCL-ZMM

Burner Blocks, Curtain arch, etc.

SCL-ZMCAST S 58.0 0.2 25.0 3.25 20 800 1700 38 0.62 1.78 SCL-ZMM

Note :

1. These values are average and may be changed from time to time without any information.

2. These values are for standard bricks of 228x114x64 mm size. For any other shape/size there may be reasonable variations.

B.D. : Bulk Density; A.P. : Apparent Porosity; C.C.S. : Cold Crushing Strength; R.U.L. : Refractoriness Under Load;

P.C.E. : Pyrometric Cone Equivalent; R.T.E. : Reversible Thermal Expansion at 1000ºC; T.C. : Thermal Conductivity at 1000ºC HF

You might also like

- Toilet Layout Details PDFDocument1 pageToilet Layout Details PDFVetrivel AjanNo ratings yet

- Tank Foundation Ringwall Design - English API 650 Input ParametersDocument9 pagesTank Foundation Ringwall Design - English API 650 Input ParametersAJ sedoNo ratings yet

- Aluminum and Its AlloyDocument18 pagesAluminum and Its AlloyJackylyn SagadalNo ratings yet

- Example Problems For Compression MembersDocument8 pagesExample Problems For Compression MembersBona HirkoNo ratings yet

- Quality Plan Outline for Bridge ProjectDocument51 pagesQuality Plan Outline for Bridge ProjectcarlorbeNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PWA-201-R0-Foundation Details For Ware House PDFDocument1 pagePWA-201-R0-Foundation Details For Ware House PDFjhon_darshanNo ratings yet

- Load ScheduleDocument20 pagesLoad ScheduleGerico CastroNo ratings yet

- Mythology of GirderDocument18 pagesMythology of GirderCivil WorkNo ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- Iv. Cooling TowersDocument13 pagesIv. Cooling TowersCharlyn FloresNo ratings yet

- Design the Perfect Earthing Cross SectionDocument5 pagesDesign the Perfect Earthing Cross Sectionfake fNo ratings yet

- Weldability 2Document56 pagesWeldability 2vivek bhangaleNo ratings yet

- N2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVDocument5 pagesN2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVmuhammad wafiNo ratings yet

- MortarsDocument1 pageMortarsAjit YadavNo ratings yet

- Special Products & InsulationsDocument1 pageSpecial Products & InsulationsAjit YadavNo ratings yet

- Feeder RefractoriesDocument1 pageFeeder RefractoriesAjit YadavNo ratings yet

- Drilling Fluid Services Report, ONGC LtdDocument7 pagesDrilling Fluid Services Report, ONGC Ltdongcchemist gd chitraNo ratings yet

- pm3600 SeriesDocument3 pagespm3600 SeriesAli AbbasNo ratings yet

- Rig: GD Chitra 12.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present OperationDocument7 pagesRig: GD Chitra 12.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 500M. Present Operationongcchemist gd chitraNo ratings yet

- O&M Manual - SCS-B1Document684 pagesO&M Manual - SCS-B1Mohamed AbdelnabyNo ratings yet

- KNDocument42 pagesKNtalibanindonesiaNo ratings yet

- Lat UtsDocument8 pagesLat Uts325Sukma Luong AyuNo ratings yet

- Bs 6622 3 Core Aluminium PVC 11Kv Mains CableDocument2 pagesBs 6622 3 Core Aluminium PVC 11Kv Mains CableFoaad AhmadNo ratings yet

- 1990 Siemens Discrete Semiconductors For Surface MountingDocument952 pages1990 Siemens Discrete Semiconductors For Surface MountingKannanDevanNo ratings yet

- Technical - Spec SkirtDocument25 pagesTechnical - Spec SkirtStructures ProductionNo ratings yet

- MonolithicsDocument1 pageMonolithicsAjit YadavNo ratings yet

- R1 - Nanak Electric StoreDocument11 pagesR1 - Nanak Electric StoreAmit SharmaNo ratings yet

- Rig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present OperationDocument7 pagesRig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present Operationongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 19.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present OperationDocument7 pagesRig: GD Chitra 19.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present Operationongcchemist gd chitraNo ratings yet

- Mitsubishi Propulsion Engine SpecsDocument42 pagesMitsubishi Propulsion Engine SpecssilviaNo ratings yet

- Rig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present OperationDocument7 pagesRig: GD Chitra 18.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1554M. Present Operationongcchemist gd chitraNo ratings yet

- TL - Genius - Bulb - CTRL - v1 1Document4 pagesTL - Genius - Bulb - CTRL - v1 1gautamkr15No ratings yet

- Data (Al Conductors)Document13 pagesData (Al Conductors)Amarnath ReddyNo ratings yet

- REUSABLE STAINLESS STEEL 100 MESH SUCTION STRAINERDocument1 pageREUSABLE STAINLESS STEEL 100 MESH SUCTION STRAINERVijayendran VijayNo ratings yet

- Scrs DatasheetDocument2 pagesScrs DatasheetenzosilviaNo ratings yet

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- Saura Keiki Magnetic Compass Sr-165Document51 pagesSaura Keiki Magnetic Compass Sr-165leticia walkerNo ratings yet

- BS 6622 XLPE PVC 12KV Cable Technical DatasheetDocument5 pagesBS 6622 XLPE PVC 12KV Cable Technical DatasheetAnonymous EaCgJPfs41No ratings yet

- Rig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present OperationDocument7 pagesRig: GD Chitra 16.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1063M. Present Operationongcchemist gd chitraNo ratings yet

- And Accessories: Hydroline FiltersDocument20 pagesAnd Accessories: Hydroline FiltersRajendra MehtaNo ratings yet

- Contactors and Contactor AssembliesDocument18 pagesContactors and Contactor AssemblieschochoroyNo ratings yet

- Servo Part ListDocument2 pagesServo Part ListahmetNo ratings yet

- Drilling Fluid Services ReportDocument7 pagesDrilling Fluid Services Reportongcchemist gd chitraNo ratings yet

- Rig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present OperationDocument7 pagesRig: GD Chitra 15.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 711M. Present Operationongcchemist gd chitraNo ratings yet

- Moq20 05 09Document6 pagesMoq20 05 09vassim123No ratings yet

- PKZM4 58Document1 pagePKZM4 58samirNo ratings yet

- Especificaciones Tecnicas Bateria Classic GROEDocument8 pagesEspecificaciones Tecnicas Bateria Classic GROEEdwin Alfaro GNo ratings yet

- Rig: GD Chitra 20.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1563M. Present OperationDocument7 pagesRig: GD Chitra 20.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1563M. Present Operationongcchemist gd chitraNo ratings yet

- TL Genius - Hub BomDocument3 pagesTL Genius - Hub Bomgautamkr15No ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- Rig: GD Chitra 17.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1208M. Present OperationDocument7 pagesRig: GD Chitra 17.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 1208M. Present Operationongcchemist gd chitraNo ratings yet

- Fuel Control System Variable Bleed Valve DiagramDocument10 pagesFuel Control System Variable Bleed Valve DiagramJivendra Kumar -No ratings yet

- Ceramic Fiber Blanket CatalogDocument7 pagesCeramic Fiber Blanket Catalogevelyn reksaNo ratings yet

- Inventory Report for PT. Merapi Bintang PersadaDocument173 pagesInventory Report for PT. Merapi Bintang PersadaWahyu WijayadiNo ratings yet

- CDA 84400 phosphor bronze alloy propertiesDocument4 pagesCDA 84400 phosphor bronze alloy propertiesShariq KhanNo ratings yet

- Complete Knife Stella For CombineDocument4 pagesComplete Knife Stella For CombineVolodymyr KuruchNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationGopi KrishnanNo ratings yet

- Koolwal MATERIALDocument2 pagesKoolwal MATERIALSunil KoolwalNo ratings yet

- Kit Spindle 7722619Document2 pagesKit Spindle 7722619Luis Eduardo Amancio HolandaNo ratings yet

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- An 10005Document4 pagesAn 10005ClenaNo ratings yet

- Autosol Ra 2% 22Swg TSC 0.25Kg Autosol Ra 2% 18Swg TSC 0.25KgDocument7 pagesAutosol Ra 2% 22Swg TSC 0.25Kg Autosol Ra 2% 18Swg TSC 0.25Kgاوس محمد رؤوف لؤيNo ratings yet

- SKF Vibracon BrochureDocument4 pagesSKF Vibracon BrochureMo ZeidNo ratings yet

- Quadrac Triacs: Internally Triggered Triacs for AC SwitchingDocument6 pagesQuadrac Triacs: Internally Triggered Triacs for AC SwitchingArmando MartinezNo ratings yet

- 20 30 40 - R MDpowertempDocument6 pages20 30 40 - R MDpowertempbogdan darcaciuNo ratings yet

- Tubular Plate Open Battery (Opzs) : CharacteristicsDocument1 pageTubular Plate Open Battery (Opzs) : CharacteristicsFlavio Cesar contreras chuquitarquiNo ratings yet

- Short DPR - GD - 08.06.2022Document7 pagesShort DPR - GD - 08.06.2022ongcchemist gd chitraNo ratings yet

- Seeflex 040EDocument1 pageSeeflex 040EArstNo ratings yet

- Lesson 4 Analysis and Design For Axial Tension (Part 2)Document3 pagesLesson 4 Analysis and Design For Axial Tension (Part 2)EJ Dela CruzNo ratings yet

- Tutorial Solution 1Document5 pagesTutorial Solution 1WizardWannabeNo ratings yet

- Section 13Document21 pagesSection 13HAFIZ IMRAN AKHTERNo ratings yet

- Analysis Flange: Design ConditionsDocument35 pagesAnalysis Flange: Design ConditionsahmadNo ratings yet

- LG Inverter SCAC CatalogDocument20 pagesLG Inverter SCAC Catalogsk luko100% (1)

- Steel BS4360 43A PDFDocument1 pageSteel BS4360 43A PDFscmNo ratings yet

- Floodlight FLDX16Document1 pageFloodlight FLDX16EliasNo ratings yet

- Piping Class B2Document5 pagesPiping Class B2Yousab JacobNo ratings yet

- Mekanika Kekuatan Material: Axial LoadingDocument20 pagesMekanika Kekuatan Material: Axial LoadingYusron Bachtiar ArdhiNo ratings yet

- Cantilever Beam Experiment B58SBDocument9 pagesCantilever Beam Experiment B58SBSunNo ratings yet

- Mixing Water Used in The Production of Hydraulic Cement ConcreteDocument5 pagesMixing Water Used in The Production of Hydraulic Cement ConcreteYasin BaturNo ratings yet

- Comparison of The Processing of Epoxy Resins in Pultrusion With Open Bath Impregnation and Closed-Injection PultrusionDocument11 pagesComparison of The Processing of Epoxy Resins in Pultrusion With Open Bath Impregnation and Closed-Injection PultrusionfahadNo ratings yet

- Experimental Analysis and Fabrication of Industrial Safety Helmet Using Hybrid CompositeDocument7 pagesExperimental Analysis and Fabrication of Industrial Safety Helmet Using Hybrid CompositeMassive MindsNo ratings yet

- ROOF SA Slab 100 - Excellent acoustic & thermal insulationDocument2 pagesROOF SA Slab 100 - Excellent acoustic & thermal insulationRaihan AhmedNo ratings yet

- Theories of Failure: Machine Design StructuralDocument3 pagesTheories of Failure: Machine Design Structuralamarkiran vinayakNo ratings yet

- Preventing and Curing Barite Sag in Highly Deviated WellsDocument3 pagesPreventing and Curing Barite Sag in Highly Deviated WellsJorge Garcia Cardoso100% (1)

- Electrical CalloutsDocument9 pagesElectrical CalloutsJason d HernandezNo ratings yet

- Butterfly Valve AMRIDocument20 pagesButterfly Valve AMRIMASOUDNo ratings yet

- Belino CE152P 2 Experiment2 Module1Document3 pagesBelino CE152P 2 Experiment2 Module1Sittie Ainna Acmed UnteNo ratings yet

- Indalco TablesDocument7 pagesIndalco TablesAdhish Gupta100% (1)

- Industrial Training: Construction of Flyover From Jagdeo Path To Sheikhpura ModeDocument15 pagesIndustrial Training: Construction of Flyover From Jagdeo Path To Sheikhpura ModeBibek BhattaraiNo ratings yet