Professional Documents

Culture Documents

Powerdrive Archer Ps

Uploaded by

Masoud0 ratings0% found this document useful (0 votes)

31 views2 pagesPowerDrive Archer Spec

Original Title

powerdrive-archer-ps

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPowerDrive Archer Spec

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views2 pagesPowerdrive Archer Ps

Uploaded by

MasoudPowerDrive Archer Spec

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PowerDrive Archer

High build rate rotary steerable system

APPLICATIONS PowerDrive Archer* high build rate RSS is part of the

■■ High-curvature 3D wells

■■ Sidetrack and dogleg severity

PowerDrive* RSS family of fully rotating steerable

(DLS) assurance systems that minimize the risk of sticking. The entire

BENEFITS family has a complete direction and inclination sensor

■■ High build rates from any inclination package close to the bit for precise well placement

■■ Well trajectory previously only possible and independently generates power for 3D steering

with positive displacement motors

and control.

■■ Improved wellbore placement

in reservoir’s sweet spot In any drilling environment, the PowerDrive RSS family delivers the power

■■ Smooth wellbore to ease completion required to place wells accurately with superior borehole quality while

ensuring maximum drilling efficiency.

FEATURES

■■ Unique hybrid steering unit Unique hybrid design for greater precision and ROP

for maximum DLS The PowerDrive Archer RSS delivers complex 3D well profiles while

maintaining high ROP and wellbore quality. It minimizes well profile

■■ Near-bit continuous inclination

restriction and optimizes attack angle in troublesome formations. The

and azimuth measurement

system enables operators to maximize reservoir exposure, increasing

■■ Near-bit azimuthal gamma hydrocarbon production potential. Increased DLS capability gives control

ray measurement in challenging formations.

Flat time elimination for drilling on plan

Additional advantages of the PowerDrive Archer RSS include the ability

to drill complex curves and trajectories and perform openhole sidetracks

at any point without requiring a trip out of the hole. It can kick off deeper

and land early in the reservoir, maximizing ROP for optimal performance

in the vertical section and reducing risk of mechanical sticking while

improving wellbore quality. Fast, reliable directional openhole sidetracks

can be completed to reduce time spent drilling multilateral wells and

enable wells to be placed exactly where required.

Wellbore quality assurance for ease of completion

The PowerDrive Archer RSS produces smooth, high-quality wellbores,

reducing torque and drag as well as making it easier to run casing and

wireline logs for trouble-free well completions. Its moving components are

internal; its internal pads push against an articulated sleeve pivoted on a

universal joint to offset the steering unit from the tools’ axis. This creates

a hybrid effect that drives the bit, delivering well profiles previously only

possible with motors.

PowerDrive Archer

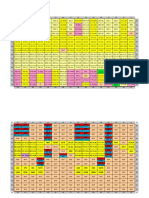

Specifications PowerDrive Archer PowerDrive Archer

475 RSS 675 RSS

Nominal OD, in [mm] 43/4 [120.7] 63/4 [171.5]

Overall length, ft [m] 14.98 [4.56] 16.15 [4.92]

Dogleg severity (DLS) capability, °/100 ft [°/30 m]† 18 [18] 15 [15]

Hole sizes, in [mm] 57/8–63/4 [149.2–171.5] 83/8–95/8 [212.7–244.5]

Bit speed, rpm 0–350 0–350

Mechanical

Maximum weight on bit, lbf [N]‡ 35,000 [155,688] 55,000 [244,652]

Maximum torque on bit, ft.lbf [N.m]§ 9,000 [12,202] 16,000 [21,693]

Maximum overpull, lbf [N] 272,000†† [1,209,916] 400,000†† [1,779,289]

Passthrough (DLS sliding), ° 30 16

Bit connection (box) 31/2 Reg 41/2 Reg

Flow range, galUS/min [L/min]‡‡ 130–355 [492–1,343] 220–650 [832–2,464]

Maximum mud density, lbm/galUS [kg/L] 18 [2.16] 18 [2.16]

Maximum sand content, % 1 1

Hydraulics§§

Lost circulation material (LCM), lbm/bbl [kg/L]††† 35 [0.13] 50 [0.19]

Acidity level, pH 9.5–12 9.5–12

Oxygen, ppm 1 1

Pressure and Maximum temperature, degF [degC] 302 [150] 302 [150]

temperature Maximum pressure, psi [MPa] 20,000 [137.9] 20,000 [137.9]

Inclination offset to tool bottom, ft [m] 8.41 [2.56] 9.81 [2.99]

Azimuth offset to tool bottom, ft [m] 10.51 [3.20] 12.01 [3.66]

Azimuthal gamma ray Eight bin Eight bin

Average gamma ray API calibrated API calibrated

Gamma ray offset to tool bottom, ft [m] 7.51 [2.29] 9.01 [2.75]

Measurements

Vibration range (axial), gn 0–35 0–35

Vibration range (radial), gn 0–75 0–75

Shock range, gn 625 625

Shock and vibration axis Triaxial Triaxial

Magnetic field cone of exclusion None None

Automated loop Inclination and azimuth Inclination and azimuth

Specifics

Downlinking method Flow and rpm Flow and rpm

† Value dependent on application—bit, BHA, parameters, formation type, etc.

‡ Maximum at 0-ft.lbf torque on bit; bit recommendations should be considered.

§ Maximum at 0-lbf weight on bit.

†† Universal joint will require rebuild beyond 50,000 lbf overpull at the joint.

‡‡ Dependent on mud density.

§§ Special configuration available for silicate muds.

Refer to the Schlumberger Shock and Vibration references for details regarding axial, lateral, and torsional limits of tools.

slb.com/powerdrivearcher

* Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2017 Schlumberger. All rights reserved. 17-DR-307838

You might also like

- Baker Hughes Drilling ServicesDocument176 pagesBaker Hughes Drilling Servicestxcrude100% (1)

- Can't Stop RHCP Bass TabsDocument1 pageCan't Stop RHCP Bass TabsLengKeng Tan100% (1)

- WIRING DIAGRAM Wifi VendoDocument5 pagesWIRING DIAGRAM Wifi VendoDikdik PribadiNo ratings yet

- Powerdrive Xceed PsDocument2 pagesPowerdrive Xceed PsKelly Cubillos quirozNo ratings yet

- Powerdrive Xcel PsDocument2 pagesPowerdrive Xcel PsRohith PgNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Powerdrive x6Document7 pagesPowerdrive x6ice_PLNo ratings yet

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- Tork Drive WFT081738Document10 pagesTork Drive WFT081738CARLOS SANCHEZNo ratings yet

- High Efficiency Pumps PsDocument2 pagesHigh Efficiency Pumps PsMay'Axel RomaricNo ratings yet

- High Efficiency Pumps PsDocument2 pagesHigh Efficiency Pumps PsMay'Axel RomaricNo ratings yet

- High Efficiency Pumps PsDocument2 pagesHigh Efficiency Pumps PsBehnamNo ratings yet

- Christensen 140: Surface Core Drilling RigDocument12 pagesChristensen 140: Surface Core Drilling RigAriel100% (2)

- En CTL Range Brochure B4500130 04-2018 LowResDocument8 pagesEn CTL Range Brochure B4500130 04-2018 LowResVinod GuptaNo ratings yet

- CD-500 - Centrifuge Product BulletinDocument4 pagesCD-500 - Centrifuge Product BulletinRuslan ZakirovNo ratings yet

- Martillo Epiroc 2Document8 pagesMartillo Epiroc 2Robinson ReyesNo ratings yet

- Drilling Tools CatalogDocument33 pagesDrilling Tools CatalogcharanNo ratings yet

- Binet, Rene - Contribucià N A Una Etica RacistaDocument36 pagesBinet, Rene - Contribucià N A Una Etica RacistaamericaNo ratings yet

- D25KS/D245S: Rotary Blast Hole DrillsDocument12 pagesD25KS/D245S: Rotary Blast Hole DrillsPeMar León ChangNo ratings yet

- Spec Sheet SD200Document8 pagesSpec Sheet SD200Yohanes ArgamNo ratings yet

- CM20200806 Eccff 7f5a8Document4 pagesCM20200806 Eccff 7f5a8Yoyoo SusantoNo ratings yet

- 094 XS616Document1 page094 XS616AhmedNo ratings yet

- Cop 1132 8311 1280 00-EDocument51 pagesCop 1132 8311 1280 00-EOrhanNo ratings yet

- Rotaflex Long Stroke Pumping UnitDocument12 pagesRotaflex Long Stroke Pumping UnitMaxiSanchezNo ratings yet

- Powerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementDocument6 pagesPowerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementClOudyo VirgílioNo ratings yet

- 52 D75KS Brochure 2005Document2 pages52 D75KS Brochure 2005sufea saadNo ratings yet

- Atlas-Copco 9851 2434 01 - LDocument4 pagesAtlas-Copco 9851 2434 01 - LKenneth HungNo ratings yet

- Rotrex Technical Datasheet C30 Rev6.0Document8 pagesRotrex Technical Datasheet C30 Rev6.0Николай АвраменкоNo ratings yet

- 5.000 127mm TorkBusterDocument1 page5.000 127mm TorkBustersimon_amir_luoNo ratings yet

- Guia Productos TWIN DISCDocument45 pagesGuia Productos TWIN DISCDiegoJoseAlvarezSierra100% (1)

- DX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Document46 pagesDX225LCA-7M/DX200A-7M/DX220AF-7M: DWG No 1/46Andrea T Filotto50% (2)

- Linde (HMF, VIR 02) High Pressure MotorsDocument24 pagesLinde (HMF, VIR 02) High Pressure MotorsWahyu HermantoNo ratings yet

- Forland Services LLC Long Stroke Pumping UnitDocument3 pagesForland Services LLC Long Stroke Pumping Unitals.persia.sa061No ratings yet

- D75KXDocument28 pagesD75KXDiego Duran MolinaNo ratings yet

- Twin Disc Marine Product GuideDocument45 pagesTwin Disc Marine Product GuidejubriantoNo ratings yet

- D130x150 S-Machine CatalogueDocument2 pagesD130x150 S-Machine CatalogueRa IN100% (1)

- HAT Product PortfolioDocument44 pagesHAT Product PortfolioEmrah MertyürekNo ratings yet

- H010995 WellheadDesanderDocument2 pagesH010995 WellheadDesanderslbclqrkNo ratings yet

- Ewr 40Document2 pagesEwr 40octavioNo ratings yet

- Re 530 CatalogDocument12 pagesRe 530 CatalogCarlos Antonio Gonzalez MendozaNo ratings yet

- Manual S 821 826Document4 pagesManual S 821 826Javi González100% (1)

- Design of Wind RotorDocument23 pagesDesign of Wind Rotorayash mohantyNo ratings yet

- Redbore InfoSheets Redbore40 2021Document1 pageRedbore InfoSheets Redbore40 2021RAFAEL LEZAMANo ratings yet

- Small Specalog For Cat D3 Track-Type TractorDocument4 pagesSmall Specalog For Cat D3 Track-Type Tractorlaptop.bmsNo ratings yet

- rammer_demolitiontoolsDocument36 pagesrammer_demolitiontoolsoguzhan.akselNo ratings yet

- 538 Series LIFTPrime High Efficiency E13000 Pump SpecDocument2 pages538 Series LIFTPrime High Efficiency E13000 Pump SpecJay PatelNo ratings yet

- Rotrex Technical Datasheet C38 Rev6.0Document7 pagesRotrex Technical Datasheet C38 Rev6.0pateta50No ratings yet

- Document Weiler d460 Specsheet 32020Document2 pagesDocument Weiler d460 Specsheet 32020Davies EmmanuelNo ratings yet

- Periscope PsDocument2 pagesPeriscope PsElseñorsucio CamaradaNo ratings yet

- DX140LCR Hydraulic Excavator Specs & FeaturesDocument17 pagesDX140LCR Hydraulic Excavator Specs & Featuresanzor100% (1)

- Tornardeepwaterbopcleaner 1 PDFDocument2 pagesTornardeepwaterbopcleaner 1 PDFJoan StewartNo ratings yet

- BB8100 Line Boring Machine EDocument8 pagesBB8100 Line Boring Machine EJorge Ernesto Calderon LunaNo ratings yet

- SR Catalog of WBCUDocument23 pagesSR Catalog of WBCUEdgar GomezNo ratings yet

- 5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017Document2 pages5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017felipeNo ratings yet

- Rotary Limit Switch FRM PDFDocument6 pagesRotary Limit Switch FRM PDFduque_sadeNo ratings yet

- KawasakiDocument32 pagesKawasakiToufik BenamroucheNo ratings yet

- Sheet CM RD 214 GGG HRDocument2 pagesSheet CM RD 214 GGG HRSea Man MktNo ratings yet

- MAN Engine D2862 1455202680Document4 pagesMAN Engine D2862 1455202680Abdul Fvck Meganz KhojinNo ratings yet

- CMP 2200 Product SheetDocument2 pagesCMP 2200 Product SheetOmero Austin0% (1)

- Cop Md20Document4 pagesCop Md20Isaac AliagaNo ratings yet

- 9865 0049 01a COP MD20 brochureDocument4 pages9865 0049 01a COP MD20 brochurewaldycotrina105No ratings yet

- HILTI CE - Ch.9 - Firestop PDFDocument30 pagesHILTI CE - Ch.9 - Firestop PDFValentin A.No ratings yet

- Iso 19731-2017Document6 pagesIso 19731-2017Borja Arrizabalaga UriarteNo ratings yet

- AGIP GREASE SM 2 Molybdenum GreaseDocument1 pageAGIP GREASE SM 2 Molybdenum GreaseranjanguptNo ratings yet

- 3 - MT 103 - 202 Base Procedure For Receiver Review and Comments AoDocument4 pages3 - MT 103 - 202 Base Procedure For Receiver Review and Comments Aouink wowNo ratings yet

- Computer Animation and Gaming Industry Strategies for PakistanDocument23 pagesComputer Animation and Gaming Industry Strategies for PakistanMustafa KhanNo ratings yet

- Orbital and Linear Converter With Autotuning: ACT 401-xxx - ManualDocument37 pagesOrbital and Linear Converter With Autotuning: ACT 401-xxx - ManualGeraldo Candido de Azevedo NetoNo ratings yet

- PC400 8 1Document549 pagesPC400 8 1Eka Anwar100% (1)

- Draft Nokia MSC O&M Daily and Weekly ProcessesDocument17 pagesDraft Nokia MSC O&M Daily and Weekly Processestest321yNo ratings yet

- BDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSDocument1 pageBDT 135 e-ticket booked for Adhora Ruma's journey from BBSETU_E to DHAKA on SUNDARBAN_EXPRESSMS.sumonNo ratings yet

- GE Lunar - enCORE HL7 (English)Document108 pagesGE Lunar - enCORE HL7 (English)Yinnet DionicioNo ratings yet

- Throughput Digram - Logistic Operating Curves in Theory and PracticeDocument21 pagesThroughput Digram - Logistic Operating Curves in Theory and PracticeCibelle LimaNo ratings yet

- Energy Hakan Aygun MakaleDocument18 pagesEnergy Hakan Aygun MakaleIsmail EkmekciNo ratings yet

- Mit Subs Hi ElectricDocument36 pagesMit Subs Hi ElectricnorbshvacNo ratings yet

- GNSS Processing Report for TDTV MarkerDocument9 pagesGNSS Processing Report for TDTV MarkerJoshua Paskah NugrahaNo ratings yet

- Programming Assignment Unit 5 Solution v2Document3 pagesProgramming Assignment Unit 5 Solution v2Everything PromoNo ratings yet

- Etrade 1.5M 21082020Document3 pagesEtrade 1.5M 21082020zayar ooNo ratings yet

- File (SQL Tutorial)Document81 pagesFile (SQL Tutorial)imranbaiggeekNo ratings yet

- Full Opcodes Tables of CPUs: Z80A, Z80180 (HD64180)Document9 pagesFull Opcodes Tables of CPUs: Z80A, Z80180 (HD64180)Eugene LisovyNo ratings yet

- Triaxial Accelerometer With Integral Magnet (A0643TX)Document2 pagesTriaxial Accelerometer With Integral Magnet (A0643TX)ORAMAYNo ratings yet

- Developing Web Applications Using Microsoft Visual Studio 2008Document23 pagesDeveloping Web Applications Using Microsoft Visual Studio 2008Guillermo Pardos VázquezNo ratings yet

- Log Cat 1700663779292Document144 pagesLog Cat 1700663779292Enry GomezNo ratings yet

- Solis 10K PDFDocument15 pagesSolis 10K PDFVictor Rios GarciaNo ratings yet

- BSNL Project MBADocument96 pagesBSNL Project MBAeeshwer85% (26)

- Cioks DC7Document2 pagesCioks DC7Mac MiñaNo ratings yet

- XNX Universal TransmitterDocument12 pagesXNX Universal TransmitterDiego Costella100% (1)

- Article Review 1Document24 pagesArticle Review 1limap5No ratings yet

- Linear IC Voltage RegulatorsDocument11 pagesLinear IC Voltage RegulatorsJavier Avalos GallosNo ratings yet

- MFL Floormap - How To Scan and Get DataDocument18 pagesMFL Floormap - How To Scan and Get DataNguyen PhucNo ratings yet