Professional Documents

Culture Documents

WPC Proced

Uploaded by

Mahmoud SaiedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPC Proced

Uploaded by

Mahmoud SaiedCopyright:

Available Formats

See the COVID-19 Resource Center for modifications.

ENVIRONMENT, SAFETY & HEALTH DIVISION

Chapter 2: Work Planning and Control

Work Planning and Control Procedure

Product ID: 451 | Revision ID: 2333 | Date published: 10 May 2021 | Date effective: 10 May 2021

URL: https://www-group.slac.stanford.edu/esh/eshmanual/references/wpcProced.pdf

1 Purpose

The purpose of this procedure is to ensure adequate protection of workers, the public, and the environment,

through the consistent, effective, planning, authorization, and release of activity-level work. It covers the

seven core functions of SLACs’ integrated safety and environmental management system (ISEMS):

1. Define the work

2. Identify and analyze hazards

3. Develop and implement controls

4. Authorize work

5. Release work

6. Perform work within controls

7. Feedback and continuous improvement

For all activity-level work performed in or on facilities managed by SLAC, including technical and

administrative activities, experiments, operations, maintenance, and service. It does not cover project

management, scheduling, or budgeting. For construction, see Work Planning and Control: Construction

Work Planning and Control Procedure.

It applies to workers (including SLAC employees, subcontractors, and users), supervisors, field

construction and service managers and points of contact, project managers, subcontractors, area and

building managers, ESH coordinators, and associate laboratory directors.

2 Procedures

2.1 Planning, Authorization, and Release

Three key concepts of work planning and control are planning, authorization, and release. Before beginning

actual work, all work must first be planned, then authorized, and finally released. The following section

defines these concepts; Section 2.2 summarizes how they are implemented for different types of work; and

Sections 2.3 and 2.4 provide detailed procedures.

10 May 2021 SLAC-I-720-0A21C-002-R005 1 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

2.1.1 Planning

Planning consists of defining the scope of work, identifying and analyzing the hazards, and developing and

implementing controls. Identifying and analyzing hazards and controls related to both the activity and the

work area where the activity will occur are the responsibility of the person authorizing the work. A visit to

the job site may be warranted, as well as a discussion with the area or building manager and review of any

area hazard analysis (AHA). The results are documented in some form of work plan, which forms the basis

for authorization and release.

2.1.2 Authorization

Authorization means that the person who authorizes the work

1. Is sufficiently knowledgeable of the hazards to plan and authorize such work

2. Has determined the work falls within his or her area of responsibility

3. Is satisfied with the content of the work plan

4. Has determined that the persons assigned to perform work are qualified

5. Has discussed hazards and controls with those persons

The person who authorizes work is accountable for its performance. Work is typically authorized by the

supervisor of the person performing the work.

Most work at SLAC is authorized by a knowledgeable SLAC employee supervising other SLAC

employees. For construction subcontractor or high-risk service subcontractor work, the subcontractor’s

foreman/supervisor authorizes the work but the SLAC field construction manager (FCM) or the service

manager (SM), respectively, confirms the authorization. (See Work Planning and Control: Construction

Work Planning and Control Procedure for details on construction.) The SLAC point of contact (POC)

confirms all other types of subcontractor work.

Note For workers matrixed to another organization, a clear hand off of authorization responsibilities

must be initiated by the administrative supervisor to ensure that both the functional supervisor

and the worker know who is responsible for authorizing work. Workers who are unclear as to

who is authorizing their work should ask their administrative supervisor for direction.

The key, unvarying, requirement for authorizing work is that the person authorizing the work ensures that

the persons doing the work

1. Understand the scope of work and the task-specific hazards and controls

2. Are qualified

Note Supervisors are required to ensure workers are properly trained before authorizing them to

perform work and to review training assignments annually and when job activities or workplace

hazards change. The Stanford University Administrative Guide Memo 7.5.1, “Health and Safety

Performance Standards and Discipline”), which SLAC follows, requires supervisors to

communicate clearly health and safety practices to all employees and to make good health and

safety practices part of employees’ job expectations and evaluations.

10 May 2021 SLAC-I-720-0A21C-002-R005 2 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

2.1.2.1 Documentation

Requirements for documenting authorization vary with the type of work (see Section 2.2). It is important to

remember that the purpose of documenting authorization is to address and communicate to the worker

unique or specific hazards resulting from the condition of the equipment being worked on, the location of

the work, the significance of negative consequences if an intermediate step is omitted or performed out of

sequence, and so on.

When deciding how and whether to document authorization, the following factors should be considered,

regardless of the type or location of the work:

Injury and illness rates at SLAC (see CAS Dashboards)

Potential to cause severe or disabling injuries or illness, even if there are no previous events

Possibility of one, simple human error leading to a severe event

Familiarity with the process/changes in process

Complexity of the task(s)

Frequency of encountering the hazards or controls

Existence of specific or unique personal protective equipment (PPE) requirements

2.1.3 Release

Release means permission to proceed with authorized work in a given area or on a given project. Release is

granted after the person granting the release has made sure that

1. Hazards unique to the area have been communicated

2. Affected persons have been notified

3. Work has been coordinated to avoid conflict and minimize risk

Work performed in a person’s resident area is typically released by the supervisor; non-resident area work

by the area or building manager. For work in a resident area not under the supervisor’s control, release is

also granted by area or building manager.

For construction work, the area or building manager typically transfers responsibility for daily release to

the FCM, who then releases work to the subcontractor. (See Work Planning and Control: Construction

Work Planning and Control Procedure for details.)

2.2 Authorization and Release by Type of Work

How work is planned, authorized, and released depends on the type (green, yellow, or red) and the location

(office/non-office and resident/non-resident area). The following is a summary of requirements; detailed

procedures are given in Sections 2.3 and 2.4.

1. Green work is administrative or technical in nature and does not require any permits or special ESH

training (for example, for fall protection). Green work is authorized by the completion of required new

employee/worker safety training. Green work in office areas is released with the same required new

employee/worker safety training. Green work in a non-office area (that is, an industrial area) requires

release by the area or building manager, if required on the area hazard analysis (AHA) or other

10 May 2021 SLAC-I-720-0A21C-002-R005 3 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

postings. Otherwise, if the worker is familiar with the area, has read the AHA, has no ESH concerns,

and adheres to all postings, he or she may enter the area to perform green work.

2. Yellow work in the worker’s resident area is authorized and released with an up-to-date SLAC

Training Assignment (STA) and supervisor acknowledgment of worker’s ability to carry out assigned

work. Documenting routine hazards and controls is not required. Supervisors are free to use a job

safety analysis (JSA), standard operating procedure (SOP), or activity and training authorization

(ATA), but they do not have to.

When a worker is dispatched outside his or her resident area, a JSA or SOP is typically required for

authorization, and the work is released by the area manager, if there is one, otherwise by the building

manager. (Release by an area or building manager is also required for work in resident areas, if the

area is not under the control of the worker’s supervisor.) For work involving subcontractors, a tailgate

briefing is also required as a final release before beginning any activity.

Some simple activities performed outside a worker’s resident area may be authorized without a JSA or

SOP, as determined by the supervisor. For example, climbing a ladder (which is yellow work) to

perform green work. For activities like this workers are expected to show sound judgment; requiring

written authorization in the field would not add value and might even distract the worker’s focus on the

hazards and controls for the task at hand (see Section 2.1.2.1). A work release is, however, still

required from the appropriate area or building manager.

3. Red work is authorized at the activity level like non-resident yellow work (that is, by the supervisor of

the workers involved, using a JSA or SOP). In addition, the planning efforts are documented by the

work planner with a work integration plan (WIP); a coordination meeting is held to discuss the

activities, timing, permits, and so on until the area manager is satisfied that release may be granted;

and, unless all workers are present at the coordination meeting, a tailgate briefing is required to release

work for each worker before beginning any activity. For work that is considered to have lab-wide

impact, the associate laboratory director (ALD) of the planner must indicate concurrence of adequate

planning by signing the WIP. For the authorization and release of construction work, see Work

Planning and Control: Construction Work Planning and Control Procedure.

2.3 Green Work Procedure

Green work is authorized and released by workers and their supervisors following this procedure.

Step Person / Function Action

Authorization

1. Worker Completes required new employee/worker safety training (see Site Access Control:

General Requirements)

Completes New Employee Information Sheet and Checklist (or equivalent for users

and subcontractors)

2. Authorizer Ensures all required training completed before starting work

Release

3. Worker For green work in an office area, completing training serves as the release

For green work in a non-office area (that is, an industrial area):

In areas posted with access/release/training (and additional ESH/PPE

requirements, including area hazard analyses [AHAs]), adherence to the

10 May 2021 SLAC-I-720-0A21C-002-R005 4 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Step Person / Function Action

posted requirements serves as the release (unless release by an area/building

manager is required in the postings).

In the absence of an AHA or similar posting:

If familiar with the hazards of the area, new employee/worker safety training

serves as the release. Examples of SLAC organizations that are expected

to be aware of such hazards include Radiation Protection Field Operations

staff, Facilities electricians/mechanics, and Power Conversion technicians.

If not familiar with the area hazards or has questions, worker contacts the

area manager, if there is one, or the building manager, before entry, who

will inform the worker of unique hazards and subsequent controls, as well

as potential conditions of entry, before granting a release.

For green work in areas designated as construction sites, a release is granted by

adhering to the construction site access requirements.

For groups of visitors, tour groups, photo opportunities, lab-wide events (for

example, Kids Day and holiday parties) and other activities similar to these, a

release is required from the area manager, if there is one, otherwise the building

manager.

Perform the Work within Controls

4. Worker Regardless of how release is granted, pays attention to ongoing activities in the

area and the hazards they may present

If at any time a safety concern arises, stops the work and notifies supervisor

Feedback and Continuous Improvement

5. Worker and Authorizer Worker provides feedback, as appropriate, to improve work procedures or WPC

processes

Supervisor solicits and reviews feedback to determine if a lessons learned item or

an opportunity for continuous improvement has been identified.

2.4 Yellow and Red Work Procedure

Step Person / Function Action

Define the Work

1. Requester Identifies the need for work to be done and submits a request for the work to be

performed to service provider, with the following information:

Name and department of requester

Location of work to be performed

Description of service/work needed

Any special instructions, considerations, known area hazards, and access

requirements/training

Charge number, if required

10 May 2021 SLAC-I-720-0A21C-002-R005 5 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Step Person / Function Action

Plan - Identify and Analyze Hazards and Develop and Implement Controls

2. Planner Develops work plan by

Determining how best to perform the work, involving, where practical, workers

likely to perform the work and, as appropriate, subject matter experts (SMEs)

Defining procedures required by manufacturers of specialized equipment or

specialized installation sequences

Defining testing and acceptance criteria

Evaluating those steps that may pose unacceptable consequences if

performed out of sequence, if omitted, or if an undesired outcome occurs (for

example, a part gets jammed or equipment breaks)

Ensuring the work plan is reviewed for ESH concerns

Steps, hazards, and controls are documented as follows

For yellow resident work

Not required

For yellow non-resident work

Job safety analysis (JSA) or standard operation procedure (SOP), plus required

permits. (At the discretion of the authorizing supervisor, an ATA may be used in

place of a JSA or SOP.)

Note some simple activities performed outside a worker’s resident area, such as

climbing a ladder to perform otherwise green work, may not require documentation,

as determined by the supervisor (see Section 2.2).

For red work

JSA or SOP for the work + work integration plan (WIP). Note for work that is

considered to have lab-wide impact, the ALD of the planner must indicate

concurrence of adequate planning by signing the WIP.

Plus all required permits, plans, and other specifications (see the Hazard

Evaluation and Planning eTool for identifying SLAC ESH permits, plans, and other

requirements)

3. Authorizer Ensures the work plan is current and that the following actions occur:

Affirming the planned work has been reviewed and approved, as appropriate

Ensuring the analysis of relevant hazards is current

Obtaining the necessary permits and ensuring conditions have been met

Identifying qualified workers

Identifying necessary material and equipment

Note walking the specific area and surrounding areas where the work is to be

performed may be required to understand fully the hazards and necessary controls.

Authorization and Release

4. Authorizer Authorization

Reviews and authorizes work, if satisfied that

The work plan is complete and current

10 May 2021 SLAC-I-720-0A21C-002-R005 6 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Step Person / Function Action

The persons assigned to perform work as defined in the plan are appropriately

trained, qualified, certified, and licensed and he or she has discussed the

hazards and controls with them

The person who authorizes the work is accountable for its performance.

Authorization is documented by

For yellow resident work

Supervisor is not required to document hazards and controls provided the worker

is current with STA requirements and understands scope of work, hazards and

controls of assigned work (but see Section 2.1.2.1 for guidance on when

documentation may be appropriate)

For yellow non-resident work

JSA or SOP

Evidence of authorization: JSA or SOP cover sheet signed by the supervisor and

each worker. For subcontractor work, the foreman or superintendent authorizes the

work. The SLAC POC confirms the authorization by reviewing the JSA or SOP

cover sheet.

JSA or SOP cover sheet only needs to be signed once for each job, unless it is

changed.

Note some simple activities performed outside a worker’s resident area, such as

climbing a ladder to perform otherwise green work, may be authorized without a

JSA or SOP, as determined by the supervisor (see Section 2.2).

For red work

Evidence of authorization: JSA or SOP cover sheet signed by the supervisor and

each worker. For subcontractor work, the foreman or superintendent authorizes

work. The SLAC SM confirms the authorization by reviewing the JSA or SOP cover

sheet.

JSA or SOP cover sheet only needs to be signed once for each job, unless it is

changed.

Plus all required permits, plans, and other specifications (see the Hazard

Evaluation and Planning eTool for identifying SLAC ESH permits, plans and other

requirements)

5. Releaser Release

For yellow resident work

Supervisor releases work, if he or she controls the area, via a valid STA and

discussion of work tasks and associated hazards and controls with worker.

For yellow non-resident work

Area or building manager releases work either orally or in writing. If orally, worker

must annotate the JSA/SOP cover sheet with release information. If there is an

area manager, he or she releases the work. If there is no area manager where

work is taking place, then the building manager releases work.

For subcontractor work, the POC secures a release from the area manager, if there

is one, otherwise the building manager, and subsequently holds a documented

tailgate meeting to release the subcontractors.

For red work

10 May 2021 SLAC-I-720-0A21C-002-R005 7 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Step Person / Function Action

Area or building manager reviews the WIP, coordinates release-related details,

and concurs that work may proceed by signing the WIP.

Any boundary conditions, such as calling the Accelerator Control Center or duty

operator or attending daily coordination meetings for a release, must be noted on

the WIP.

Evidence of a signed WIP must be available to document coordination and area or

building manager concurrence.

If there is a delay in the start of work after release, and new hazards or controls are

identified, reauthorization is required before continuing. A re-release is required if

the delay is outside the boundary conditions set forth by the initial release.

6. Worker and authorizer Authorizer ensures a tailgate briefing occurs before start of work with workers and

others as appropriate, to ensure that workers understand the work underway in the

area and its hazards and controls, including when to verify controls are in place

before continuing work activity. Repeats this briefing for any worker who arrives

after the initial one.

If any worker does not agree that the hazard controls are adequate or if there are

any other scheduling or ESH concerns, work must not be started.

On completion of the tailgate briefing, further releases the work for his or her

workers to execute.

Evidence of a tailgate briefing must be available for all red work to document that

individuals who attend the meeting understand the work and its inherent hazards

and controls:

Non-construction Tailgate/Release Form is used to document final release by

SLAC of red work

Perform the Work within Controls

7. Worker and authorizer Work Execution

Worker ensures that controls are in place and hold points, if any, are clearly

understood and validated before starting work. Only work that is part of the scope

of work, for which hazards, controls, authorization, and release have been granted,

may be performed.

Authorizer ensures that work is performed as detailed in the work plan

Authorizer ensures that the complete work plan, with all pertinent documentation,

is available for reference at or near the work site

8. All workers Stop Work

Anyone observing unsafe conditions or actions should approach and notify the

worker in a way that minimizes a potential startle hazard. When requested to stop

work, worker should safely stop the activity being executed.

If at any time conditions change or work details differ from the work plan to the

point that a safety concern arises, workers must stop the work and notify their

supervisor. Examples of such changes are

Change in work scope (change in sequence or footprint, different parts,

intermediate outcomes not as expected)

Change in start or stop dates or times

Change in work location

10 May 2021 SLAC-I-720-0A21C-002-R005 8 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Step Person / Function Action

Changes that increase or introduce new hazards or environmental impacts

If the change does not create an imminent danger, work may be restarted after

work plan documents have been updated and the work re-authorized and re-

released, as deemed appropriate by the supervisor. See the Work Planning and

Control: Stop Work Procedure.

If the change creates an imminent danger, or a serious hazard that requires

immediate attention is observed or a task is assigned that poses risk of

death or serious injury, an imminent danger stop work must be initiated, as

described in Work Planning and Control: Stop Work Procedure.

9. Worker Hazard Control

At the completion of each day's work, ensures that any hazards to others

remaining in the work area where the work was performed are controlled

This can be done by the application of an administrative lock, posting and/or

barricading the area, or performing housekeeping to return the area to a secure

state.

10. Authorizer Final Completion of Work

Ensures the work site is left in a clean and safe condition

Feedback and Continuous Improvement

11. Worker and authorizer Lessons Learned

Supervisor should solicit and review feedback to determine if a lessons learned

item or an opportunity for continuous improvement has been identified. If a lessons

learned item is identified, incorporates it into the SLAC lessons learned database.

Worker should provide feedback, as appropriate, to improve work procedures or

WPC processes.

12. Authorizer / project Closeout

manager / requester Once all work activities have been completed

For yellow resident work

Not required

For yellow non-resident work

Supervisor closes out work plan and retains for 90 days to enable review for

lessons learned and WPC process improvements

For red work

Project manager/requester closes out and retains for 90 days to enable review

for lessons learned and WPC process improvements

3 Forms

Documentation requirements vary by type of work, but generally there must be evidence in some form of

scope of work, authorization, and release. Such evidence includes meeting notes, a signed release, or even a

phone conversation, with the result noted on some document. Leaving a voice mail or sending an e-mail,

without obtaining a response, does not constitute evidence of a release.

10 May 2021 SLAC-I-720-0A21C-002-R005 9 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Whether documentation is required or not, no one should forget that the purpose of the documentation is to

ensure adequate planning, meet regulatory requirements, and most of all communicate critical steps,

hazards, and controls to minimize unacceptable consequences.

These documents together with any others required to direct the execution of the work constitute the work

plan. Note work plan requirements are cumulative, starting with the minimum documentation, adding JSAs

or SOPs and permits for non-resident work, and work integration plans and tailgate briefings for high-risk

yellow and all red work.

The following forms and tools support this procedure:

Work Planning and Control: Activity Training and Authorization Form (SLAC-I-730-0A21J-033).

Form for documenting authorization and release of resident yellow work. Not required

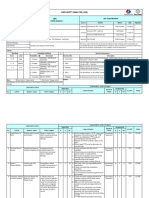

Work Planning and Control: Job Safety Analysis Form (SLAC-I-730-0A21J-034). Form for

documenting authorization and release of yellow, red, and construction work

Work Planning and Control: SOP Authorization and Release Form (SLAC-I-730-0A21J-035). Form

for documenting authorization and release of yellow, red, and construction work

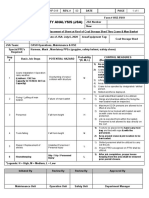

Work Planning and Control: Work Integration Plan Form (SLAC-I-730-0A21J-036). Form for

documenting planning, coordination, and release of complex/red work

Work Planning and Control: Non-construction Tailgate/Release Form (SLAC-I-730-0A21J-038). Form

for documenting final release of red work

Hazard Evaluation and Planning eTool. Tool for identifying SLAC ESH permits, plans, and other

requirements

Term Release and Notification Tool. Tool for requesting term releases and notifying area and building

managers of status

SLAC Training Assignment (STA). System for assigning and tracking training

4 Recordkeeping

The following recordkeeping requirements apply for this procedure:

Red work packages must be kept by the project manager or FCM/SM for 90 days after the job is

complete. Yellow work packages must be kept by the authorizing supervisor for 90 days after the job is

complete.

5 References

SLAC Environment, Safety, and Health Manual (SLAC-I-720-0A29Z-001)

Chapter 2, “Work Planning and Control”

– Work Planning and Control: Construction Work Planning and Control Procedure

– Work Planning and Control: Stop Work Procedure

– Work Planning and Control: Area Hazard Analysis Procedure

– Work Planning and Control (includes online tools)

10 May 2021 SLAC-I-720-0A21C-002-R005 10 of 11

SLAC National Accelerator Laboratory

Environment, Safety & Health Division

Work Planning and Control | Work Planning and Control Procedure

Chapter 55, “Site Access Control”

– Site Access Control: General Requirements (SLAC-I-720-0A04S-001)

Other SLAC Documents

New Employee Information Sheet and Checklist

Work Planning and Control: SSRL User Implementation for User Experiments (ESRD-WPC-001)

Human Resources: Policies and Guidelines

CAS Dashboards

Lessons Learned

Other Documents

Occupational Safety and Health Administration (OSHA). Job Safety Analysis (OSHA Publication

3071)

Department of Energy Handbook 1211, “Activity-Level WPC Implementation” (DOE-HDBK-1211)

Stanford University. Administrative Guide Memo 7.5.1, “Health and Safety Performance Standards

and Discipline”

10 May 2021 SLAC-I-720-0A21C-002-R005 11 of 11

You might also like

- Work Planning and Control ProcedureDocument11 pagesWork Planning and Control ProcedureHendra BudimanNo ratings yet

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Work Authorization ProtocolDocument10 pagesWork Authorization Protocolyasir543No ratings yet

- Prince2 for Beginners - Introduction to Prince2 Project Management ConceptsFrom EverandPrince2 for Beginners - Introduction to Prince2 Project Management ConceptsRating: 5 out of 5 stars5/5 (1)

- Work Planning and Control ProcedureDocument8 pagesWork Planning and Control ProcedureThe BRT ConsultNo ratings yet

- Practical Project Management: Learning to Manage the Professional, Second EditionFrom EverandPractical Project Management: Learning to Manage the Professional, Second EditionRating: 2.5 out of 5 stars2.5/5 (2)

- Construction Work Planning and Control ProcedureDocument7 pagesConstruction Work Planning and Control ProcedureHendra BudimanNo ratings yet

- General Work Permit: 1. PurposeDocument5 pagesGeneral Work Permit: 1. PurposeGanesh YadavNo ratings yet

- Safe Work Permit SOPDocument3 pagesSafe Work Permit SOPLuis Adrián ElguézabalNo ratings yet

- SMG 06-003 Job Safety Analysis (JSA)Document12 pagesSMG 06-003 Job Safety Analysis (JSA)md shadab anwarNo ratings yet

- Procedure For Job Safety Analysis (Final CO-HSE)Document17 pagesProcedure For Job Safety Analysis (Final CO-HSE)sanrexiNo ratings yet

- SPEAR3 Industrial HazardsDocument6 pagesSPEAR3 Industrial HazardsFazle Riaz KhanNo ratings yet

- Permit To Work Procedure (10.11.2018)Document20 pagesPermit To Work Procedure (10.11.2018)Bebe BucătaruNo ratings yet

- Permit To Work ProcedureDocument10 pagesPermit To Work ProceduremasahinNo ratings yet

- PROCEDURE FOR PERMIT TO WORKDocument16 pagesPROCEDURE FOR PERMIT TO WORKVictor Thembinkosi Makhubele100% (1)

- CP - 105 - Safety Task Analysis-Job Hazard AnalysisDocument10 pagesCP - 105 - Safety Task Analysis-Job Hazard AnalysisYusufNo ratings yet

- OHS Code Guide Part 2 - Hazard Assessment, Elimination & ControlDocument34 pagesOHS Code Guide Part 2 - Hazard Assessment, Elimination & ControlLeonardo RioNo ratings yet

- PNR-000068 - 08 - PNR 000068 - Guideline For JSADocument7 pagesPNR-000068 - 08 - PNR 000068 - Guideline For JSAWesley BrunNo ratings yet

- Hazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsDocument29 pagesHazards Control: 1. Scope 2. Purpose 3. Definitions 4. Responsibilities 5. Instructions 6. References 7. AttachmentsP Eng Suraj Singh100% (1)

- HSSE management requirementsDocument8 pagesHSSE management requirementsCris Jan BanaagNo ratings yet

- Control of WorkDocument2 pagesControl of WorkDanar Syahrial PradhiptaNo ratings yet

- 2023 - 12 - 22 - Work Permit SystemDocument13 pages2023 - 12 - 22 - Work Permit SystemDejen HaileslassieNo ratings yet

- 4.3 Hoechy Permit To Work ProcedureDocument15 pages4.3 Hoechy Permit To Work Proceduredozzi chuckzNo ratings yet

- Basics for ComplianceDocument42 pagesBasics for ComplianceEmenike Donald EjiejiNo ratings yet

- 14 - Management of Change WebDocument9 pages14 - Management of Change WebsahlaNo ratings yet

- WorkPermitReceiver PDFDocument2 pagesWorkPermitReceiver PDFAbu sufyanNo ratings yet

- Work Method Statement Date of Revision 07 Sep 2015 Rev.01Document5 pagesWork Method Statement Date of Revision 07 Sep 2015 Rev.01Lanceal TanNo ratings yet

- Permit Work ProcedureDocument8 pagesPermit Work Proceduretnsv22No ratings yet

- Standard Volume 8 Subcontract EHS RequirementsDocument8 pagesStandard Volume 8 Subcontract EHS RequirementsAbhishek KumarNo ratings yet

- WPC Form JsaDocument2 pagesWPC Form JsaNoLo ParamartoNo ratings yet

- EHS Contruction RegulationsDocument37 pagesEHS Contruction RegulationsRf HssnNo ratings yet

- Hazard Analysis ProcedureDocument26 pagesHazard Analysis ProcedureRaghu Venkata100% (5)

- Project Site Safety Management PlanDocument17 pagesProject Site Safety Management PlanRom Reyes Dela CruzNo ratings yet

- Permit Work 2Document12 pagesPermit Work 2Jimmy KudiNo ratings yet

- Permit To Work ProcedureDocument5 pagesPermit To Work ProceduresinghajitbNo ratings yet

- NIOSH WPA - GlomaxDocument28 pagesNIOSH WPA - Glomaxyewminyun6098100% (4)

- Dosecc Health ManualDocument62 pagesDosecc Health ManualRachmad HazanNo ratings yet

- 3.11.3 Hot Work GuidanceDocument31 pages3.11.3 Hot Work GuidanceAbdus SamadNo ratings yet

- GN-Permit To Work SystemDocument13 pagesGN-Permit To Work SystemchachaNo ratings yet

- Stop Work Procedure 1 Purpose: Work Planning and ControlDocument6 pagesStop Work Procedure 1 Purpose: Work Planning and ControlMahmoud SaiedNo ratings yet

- 13 Job Safety Analysis ProgramDocument3 pages13 Job Safety Analysis ProgramSajid HusainNo ratings yet

- Learning Guide-14: Plan and PrepareDocument13 pagesLearning Guide-14: Plan and PrepareTsegaye KenenisaNo ratings yet

- CFA Process Improvement for Enhanced Facility SafetyDocument19 pagesCFA Process Improvement for Enhanced Facility SafetyparapencarituhanNo ratings yet

- JHA Development ProcessDocument9 pagesJHA Development Processahmadmakky121No ratings yet

- WM GL Hal HMS 503BDocument6 pagesWM GL Hal HMS 503BWellington Evans Pereira GomesNo ratings yet

- Job Safety Analysis (JSA) - GuidelineDocument10 pagesJob Safety Analysis (JSA) - Guidelineabdulla amraNo ratings yet

- Job Safety Analysis: Construction Safety Consensus GuidelinesDocument10 pagesJob Safety Analysis: Construction Safety Consensus GuidelinesZurain AliNo ratings yet

- ABG-HSE-MS.0012 (Behavior Based Safety)Document4 pagesABG-HSE-MS.0012 (Behavior Based Safety)muavizmahmoodNo ratings yet

- Section 2: Procedural Control of Temporary Works: 6 ProceduresDocument38 pagesSection 2: Procedural Control of Temporary Works: 6 Proceduresezzularab100% (3)

- Stop Work AuthortyDocument8 pagesStop Work AuthortyRonald Sarillana100% (1)

- AL UDEID AIR BASE RACEWAY MODIFICATION PROJECTDocument12 pagesAL UDEID AIR BASE RACEWAY MODIFICATION PROJECTgangadharan000No ratings yet

- Title: Contractor Management Procedure: Central Office Use OnlyDocument6 pagesTitle: Contractor Management Procedure: Central Office Use OnlyTholang PhumoNo ratings yet

- HSP AuditDocument10 pagesHSP AuditslusafNo ratings yet

- Updated PDG Ind Ohsmsm 1304 Permit To WorkDocument24 pagesUpdated PDG Ind Ohsmsm 1304 Permit To Worksufiyan sskNo ratings yet

- Management of ChangeDocument6 pagesManagement of Changedozzi chuckz100% (1)

- PMOC Safety Checklist for New Equipment InstallationsDocument4 pagesPMOC Safety Checklist for New Equipment Installationswiss gaderNo ratings yet

- EOHSP 01 Identification Evaluation of AspectsDocument5 pagesEOHSP 01 Identification Evaluation of Aspectsjulio_salas_59No ratings yet

- OHS PlanDocument35 pagesOHS Plansefto0% (1)

- Roles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunDocument11 pagesRoles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunArsalan QadirNo ratings yet

- 3M Half Facepiece Respirator 7500 Series Technical SpecificationsDocument2 pages3M Half Facepiece Respirator 7500 Series Technical SpecificationsBarasNo ratings yet

- 8 Ringers r075 Pds UsDocument2 pages8 Ringers r075 Pds UsMahmoud SaiedNo ratings yet

- Accommodation Inspection Checklist: Safe@WorkDocument4 pagesAccommodation Inspection Checklist: Safe@WorkMontadhar HaithamNo ratings yet

- 2 32 2 1 06 01-Work-PermitDocument31 pages2 32 2 1 06 01-Work-PermitMahmoud Saied100% (1)

- 2 32 2 1 16 01-TMCDocument52 pages2 32 2 1 16 01-TMCMahmoud SaiedNo ratings yet

- WPC Form JSADocument2 pagesWPC Form JSAMahmoud SaiedNo ratings yet

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyNo ratings yet

- Risk Management Peer-Reviewed: JSA's Role TodayDocument10 pagesRisk Management Peer-Reviewed: JSA's Role TodayyayuliNo ratings yet

- JACK IN Piling WorkDocument9 pagesJACK IN Piling WorkShaheed AzharNo ratings yet

- Jsa Energizing Final Tapping Back FeedingDocument7 pagesJsa Energizing Final Tapping Back FeedingekapadwiNo ratings yet

- JSA Form 2Document7 pagesJSA Form 2ekapadwiNo ratings yet

- JSA - Repair or Replacement of Coal Shed SheetsDocument1 pageJSA - Repair or Replacement of Coal Shed SheetsUmar YaqoobNo ratings yet

- Marine Department - MCVS&RDocument5 pagesMarine Department - MCVS&REliza's Soothing Sounds100% (1)

- Job Safety Analysis: Bureau of Workers' Comp PA Training For Health & Safety (Paths)Document20 pagesJob Safety Analysis: Bureau of Workers' Comp PA Training For Health & Safety (Paths)kananiNo ratings yet

- Is18347 2023Document16 pagesIs18347 2023RAVIKANT SINDHENo ratings yet

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- JSA For MPIDocument3 pagesJSA For MPIMohammed MinhajNo ratings yet

- 9 Hazard Identification Risk AssessmentDocument10 pages9 Hazard Identification Risk Assessmentvasanth pugazhendhiNo ratings yet

- HSE Plan Medco Energi shale shaker project 2023Document27 pagesHSE Plan Medco Energi shale shaker project 2023Syaifulloh AmroNo ratings yet

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

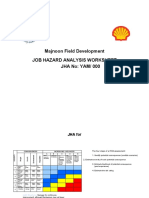

- Majnoon Field Development JHA: Identifying Job Hazards for Safe OperationsDocument8 pagesMajnoon Field Development JHA: Identifying Job Hazards for Safe OperationsMohammed AdnanNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Job Safety Analysis: Client: ContractorDocument7 pagesJob Safety Analysis: Client: Contractorloveson709No ratings yet

- Communicating Workplace SafetyDocument13 pagesCommunicating Workplace SafetyMaria Ana DanganNo ratings yet

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Electrical Safety ProcedureDocument33 pagesElectrical Safety ProcedurePraful E. Pawar100% (1)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisvenkateshbitraNo ratings yet

- 03B FORM-KI-TMS-P-03-014b. Subcont HSE Pre Qualification Quest. - Medium - High RiskDocument10 pages03B FORM-KI-TMS-P-03-014b. Subcont HSE Pre Qualification Quest. - Medium - High RiskRizki StiawanNo ratings yet

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- Workplace Health and Safety Program EssentialsDocument24 pagesWorkplace Health and Safety Program EssentialsOce Brownies100% (1)

- Jsa Refresher Training: YOHO Development Project EPC2 Offshore Nigeria YQ PlatformDocument10 pagesJsa Refresher Training: YOHO Development Project EPC2 Offshore Nigeria YQ Platformalam dooNo ratings yet

- JSA External Window Cleaning To 2 Story Building Simplified ReportDocument10 pagesJSA External Window Cleaning To 2 Story Building Simplified ReportMaja DakicNo ratings yet

- CWP Checklist (Foundation Work)Document7 pagesCWP Checklist (Foundation Work)aizatNo ratings yet

- Rig Safety Officer Sample CVDocument2 pagesRig Safety Officer Sample CVAlekhya100% (3)

- 2F 5 Radiation Risk AssessmentDocument1 page2F 5 Radiation Risk AssessmentNurul SyaheerahNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- FreeCAD | Design Projects: Design advanced CAD models step by stepFrom EverandFreeCAD | Design Projects: Design advanced CAD models step by stepRating: 5 out of 5 stars5/5 (1)

- Contactless Vital Signs MonitoringFrom EverandContactless Vital Signs MonitoringWenjin WangNo ratings yet

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Autodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersFrom EverandAutodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersNo ratings yet

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet