Professional Documents

Culture Documents

PTW-02 Hot Work Permit (1601608066)

Uploaded by

jayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTW-02 Hot Work Permit (1601608066)

Uploaded by

jayCopyright:

Available Formats

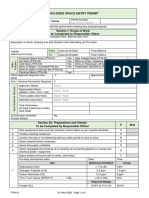

HOT WORK PERMIT

Permit Number

Vessel Avinash Kumar verma e.g.: D or E 03

/001/19

Comply with permit when carrying out any work involving temperature conditions, which are likely to be of sufficient

intensity to cause ignition of combustible gases, vapour or liquids in, or adjacent to the area involved

OUTSIDE “DESIGNATED HOT WORK AREA”.

Section 1: Scope of Work To be

Completed by Responsible Officer

Forecastle deck, bow thruster room.

Location:

Description of work and type of equipment to be used for hot work : Gas cutting of 4 bolts of pump foundation

for removal of motor and pp

Validity From Date: 20.082020 Time: 0800hrs

(Maximum 12 hours)

To Date: 20.08.20 Time: 12hrs

(See Note)

Task Enclosed Space Entry ✓ High Voltage Work. (PTW-

s In cl u d e s: (PTW-01) 07)

Hot Work (PTW-02) ✓ Work on Press. Pipelines / ✓

Vessels (PTW-08)

Cold Work (PTW-03) ✓ Work on Passenger Lift

Equipment (PTW-09)

Work at Height / ✓ Underwater Operations

Overside(PTW-04) (PTW-10)

Work on Deck In Adverse

Wx (PTW-05)

Electrical Work (PTW-06) ✓

Office Approval Required Y / No

Approval Ref:

Refer to H&S chapter ‘Hot Work’ / NA

Port / Terminal Permission Required No

Ke Approver: Master Name

y

P Responsible Officer*

er s o n n (Master // C/E // C/O // Name / Rank

el 2/E)

Pl a n n e Fire Watch (See Note) Name / Rank

d Team Leader (See Note) Name / Rank

Task Performer(s)

(See Note)

PTW-02 01-May-2019 Page 1 of 4

Is Contractor involved?

No

Provide Details

Section 2: Preparations and Checks To

be Completed by Responsible Officer Yes NA

1. Risk assessment done and risk reduction actions taken as per hazards identified. Yes

2. Toolbox meeting carried out. Yes

3. Confirm this task without interfering any other permit to work in force. Yes

Work area checked with combustible gas indicator for Hydrocarbon vapours.

HC:…………………% LEL(Carry out the test for combustible gases IMMEDIATELY

4. Yes

BEFORE COMMENCE OF HOT WORK and repeat at determined intervals as long as

the work is in progress)

5. Equipment or pipeline gas freed. Yes

6. Equipment or pipeline been blanked. Yes

7. Equipment or pipeline free of liquid. Yes

8. Equipment isolated electrically. Yes

Surrounding area safe – Consider the following dangers, but not limited to:

Heat transfer through steel structures that can cause hidden fires Yes

9. Flammable vapours rising through vent pipes

Yes

Sparks falling down ventilators or other openings

Yes

10. Fire Firefighting Equipment kept ready for immediate use. Note:

Yes

As minimum – A portable fire extinguisher and charged fire hose.

Welding and Gas equipment inspected and free from defects. Welding equipment

11. adequately earthed (See note). Yes

12. Task Performers are clothed with appropriate PPE. Yes

13. Fire watch established and Duty Officer informed. Yes

Surrounding area of hot work clean and being continuously monitored for the presence

14. Yes

of combustible gas / materials (All 6 sides).

Section 3: Energy Isolations and Special Precautions To be Y N/A

Completed by Responsible Officer and Isolating Authority

Risk from following energy sources identified: Y

◻ Electrical shocks / sudden starting of machinery

◻ Hazardous moving machinery parts

◻ Contact with extreme hot / cold temperatures

◻ Sudden release of pressurised or hazardous fluid / gas in system

List the Isolation points identified: Y

PTW-02 01-May-2019 Page 2 of 4

Lockout / Tagout devices put on isolating points. Y

Test carried out to ensure positive isolation of the above risks and release of pressure. Y

Isolating Authority

Name / Rank /Sign 2/E

(E/O // C/E // C/O // 2/E)

Special precautions, if any:

Section 4: Acceptance and Authorisation

Following persons must sign upon completion of sections 1, 2 and 3:

Person Sign Date Time

Responsible Officer

Avinash Kumar verma 20.08.20

(Master // C/E // C/O // 2/E )

Team Leader / Task Performer

Approver: Master

Section 4A: Office Approval

Office Approval obtained by other electronics means / emails also acceptable.

Department Supdt./ Vessel Manager Date / Time Approved

Name/Rank/Sign: Y/N

Name/Rank/Sign: Y/N

Office Comments, if any

Caution: This permit is rendered invalid in case there are changes in stated conditions. Stop the work

immediately and resume only after re-checking and re-instating the condition with a new permit.

“Re-checking Atmosphere Log”

At Interval of_______ (max 2 hours) and after each break.

Completed by Responsible Officer / Other Certified Officer

O2 HC

Date Time Tested by

(% Vol) (% LEL)

Section 5: Completion and Cancellation

Date Time

To be Completed By Responsible Officer and Isolating Authority

PTW-02 01-May-2019 Page 3 of 4

Job completed.

Area is safe and risk of fire no longer exists.

Person, material and equipment in use withdrawn.

System restored and LOTO device removed.

Note: ONLY ISOLATING AUTHORITY will remove the LOTO device after job completion and when safe to

do so.

Duty Officer informed.

Office informed of completion of Hot Work.

Isolating Authority

Sign

(C/E // E/O // C/O // 2/E)

Responsible Officer

Sign

(Master // C/E // C/O // 2/E )

Approver :Master Sign

Notes

1. Company procedures available in H&S Chapter ‘Hot Work’.

2. Do not exceed the STARTING / FINISHING TIME beyond Responsible Officer’s working hours. In any case,

the permit validity must not exceed 12 hours.

3. RESPONSIBLE OFFICER and TEAM LEADER or TASK PERFORMER must be separate person, unless

suitability relieved by another Responsible Officer and countersigning the permit.

4. FIRE WATCH and TASK PERFORMER must be separate person. Fire Watch must not leave the area

unattended or engage in other duties until suitably relieved.

5. Keep FIRE WATCH with FFA in readiness in area of hot work, and in adjacent spaces, where the transfer of

heat or accidental damage may create a hazard – for example, work on compartment boundaries, damage to

hydraulic lines, electrical cables, thermal oil lines, etc.

6. Post additional Fire Watch, if the MONITORING AREAS are out of Fire Watch’s sight and control.

7. Issue the Hot Work Permit immediately before performing the work. In In the event of a DELAY to the start of

the work, re-check and record all safety measures before actual commencement of work.

8. INFORM Master / Chief Engineer prior to the start of and on completion of hot work.

PTW-02 01-May-2019 Page 4 of 4

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- PTW-02 Hot Work PermitDocument4 pagesPTW-02 Hot Work PermitjayNo ratings yet

- PTW-01 Enclosed Space Entry Permit (1601608066)Document4 pagesPTW-01 Enclosed Space Entry Permit (1601608066)jayNo ratings yet

- Hot Work Permit: 1. General PrecautionsDocument3 pagesHot Work Permit: 1. General PrecautionsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Format PTW-Revised 00Document17 pagesFormat PTW-Revised 00yogesh.divekar8941No ratings yet

- Hot Work Permit New FormDocument3 pagesHot Work Permit New FormMohammed HamzaNo ratings yet

- Protecting Workers: The Purpose and Procedures of PTW SystemsDocument41 pagesProtecting Workers: The Purpose and Procedures of PTW SystemsRiyadh SalehNo ratings yet

- Permit To Hot WorkDocument2 pagesPermit To Hot WorkSaleh AlomariNo ratings yet

- PTW-06 Electrical Work PermitDocument3 pagesPTW-06 Electrical Work PermitjayNo ratings yet

- PTW-Revised New R3Document11 pagesPTW-Revised New R3anasgour883No ratings yet

- Rustomjee Work Permit Format - R1Document8 pagesRustomjee Work Permit Format - R1Nikhil ManjrekarNo ratings yet

- JSA Hot TappingDocument7 pagesJSA Hot TappingsagarauceNo ratings yet

- PermitDocument7 pagesPermitdeepak bhagatNo ratings yet

- JSA FormDocument4 pagesJSA Formandrew rachmanNo ratings yet

- Checklist For Working in Substations or Vicinity of Energized Panels-1Document1 pageChecklist For Working in Substations or Vicinity of Energized Panels-1Madhu Electricals & EngineeringNo ratings yet

- JR Shipping Lines Inc.2.0Document3 pagesJR Shipping Lines Inc.2.0mcknotbradlyNo ratings yet

- Hot Work Permit - PTW HOTDocument2 pagesHot Work Permit - PTW HOTMamar Zrary0% (1)

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoNo ratings yet

- Others - Argon : One Calender DayDocument1 pageOthers - Argon : One Calender Dayantopaul2No ratings yet

- HPCL Hot Work Permit-1Document3 pagesHPCL Hot Work Permit-1Mahmoud MoussaNo ratings yet

- 001 - Safe Work Permit Form - R2Document2 pages001 - Safe Work Permit Form - R2John Renz Caling RetiroNo ratings yet

- IRM Energy Work Permit SEODocument1 pageIRM Energy Work Permit SEOवात्सल्य कृतार्थNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitrajamohamdedhanaNo ratings yet

- QUDS 21.08 - Hot - Work - Permit Bunker RepairDocument2 pagesQUDS 21.08 - Hot - Work - Permit Bunker RepairJan KubišNo ratings yet

- SMS 013 Permit To WorkDocument1 pageSMS 013 Permit To WorkLincoln AkintolaNo ratings yet

- Work Permit: PT Thermax International IndonesiaDocument3 pagesWork Permit: PT Thermax International Indonesiaadam rizkiNo ratings yet

- Daily Work Permit ChecklistDocument1 pageDaily Work Permit ChecklistIndraNo ratings yet

- Permit To Work: C-HSSE Dept. C-HSSE Dept. Upon PTW IssuanceDocument1 pagePermit To Work: C-HSSE Dept. C-HSSE Dept. Upon PTW IssuanceKalithasan RamanNo ratings yet

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- VIL HSW: Working at Height: Vodafone Idea LTDDocument5 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- Job Safety Analysis Form: CSCCB Hole WatchDocument4 pagesJob Safety Analysis Form: CSCCB Hole WatchFrank ElizardoNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- General Electric Work PermitDocument2 pagesGeneral Electric Work PermitFaiqah AzmirNo ratings yet

- Work Approval (PTW) : Initiator'S ChecklistDocument2 pagesWork Approval (PTW) : Initiator'S ChecklistC&I REGLNo ratings yet

- Confined Space Work PermitDocument2 pagesConfined Space Work PermitDimas Dwi SwarnaNo ratings yet

- PTW For Hot Work: Pakistan EPCL PVC Expansion ProjectDocument1 pagePTW For Hot Work: Pakistan EPCL PVC Expansion ProjectMuhammad RafiqueNo ratings yet

- Hot & Cold Work PermitDocument10 pagesHot & Cold Work PermitSubratNo ratings yet

- S 9.28L - Pump Room and BT Space Entry Record BookDocument4 pagesS 9.28L - Pump Room and BT Space Entry Record BookWILLIAMNo ratings yet

- Hot Work Permit ChecklistDocument1 pageHot Work Permit ChecklistSrini VasanNo ratings yet

- Permit To Work Form - JNH BINADocument1 pagePermit To Work Form - JNH BINARajkumar AnnaNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitManesh MNo ratings yet

- Permit for Hot WorksDocument1 pagePermit for Hot WorksNethiyaaRajendranNo ratings yet

- Hot Work ChecklistDocument1 pageHot Work ChecklistloganathanNo ratings yet

- Hotwork Permit Rev 3Document1 pageHotwork Permit Rev 3Mohd AzwadiNo ratings yet

- Hot Works PermitDocument1 pageHot Works Permitabhilash sureshNo ratings yet

- PTW - Lifting PermitDocument2 pagesPTW - Lifting PermitJahanzaib KhanNo ratings yet

- HH:MM Dd/Mm/Yyy HH:MM Dd/Mm/Yyy: Yes No N/A Sr. Yes No N/ADocument3 pagesHH:MM Dd/Mm/Yyy HH:MM Dd/Mm/Yyy: Yes No N/A Sr. Yes No N/AechaNo ratings yet

- SC-03 Hot Work Jan 2006 - Rev 2 Nov 07Document2 pagesSC-03 Hot Work Jan 2006 - Rev 2 Nov 07Sumit NarayanNo ratings yet

- General Work Permit Sample FormatDocument2 pagesGeneral Work Permit Sample FormatCharleston VillamorNo ratings yet

- HSE Hot Work Permit ProcedureDocument2 pagesHSE Hot Work Permit ProcedureHSE S4No ratings yet

- PTW RenyDocument8 pagesPTW RenyDarwin OlivaNo ratings yet

- Cme Iraq CF Oi 5 1 Cold Work PermitDocument1 pageCme Iraq CF Oi 5 1 Cold Work Permitmurtadanajem1999No ratings yet

- General PermitDocument1 pageGeneral Permitanasgour883No ratings yet

- Iman - Safe Work Procedure-Format Ver C-Sample MCO Rev2Document13 pagesIman - Safe Work Procedure-Format Ver C-Sample MCO Rev2nursharunNo ratings yet

- Work Permit Syst.Document9 pagesWork Permit Syst.MEEDNo ratings yet

- NPT Notification DRL PR 001 FM 01 011Document4 pagesNPT Notification DRL PR 001 FM 01 011cmrig74No ratings yet

- HSE 10 Excavation PermitDocument1 pageHSE 10 Excavation PermitBa N Nhim100% (1)

- VIL HSW: Working at Height: Vodafone Idea LTDDocument4 pagesVIL HSW: Working at Height: Vodafone Idea LTDMuthiah ManiNo ratings yet

- Ot Work Permit: Safe Working PracticesDocument3 pagesOt Work Permit: Safe Working Practicesedward snowden100% (1)

- Ship Operation and ManagementDocument29 pagesShip Operation and ManagementjayNo ratings yet

- PTW-06 Electrical Work PermitDocument3 pagesPTW-06 Electrical Work PermitjayNo ratings yet

- Report Lse 0Document190 pagesReport Lse 0DiegoNo ratings yet

- Harnessing Public Research For Innovation in The 21st CenturyDocument544 pagesHarnessing Public Research For Innovation in The 21st CenturyjayNo ratings yet

- Unit 10 Conic Sections ProjectDocument8 pagesUnit 10 Conic Sections Projectapi-290873974No ratings yet

- 3 Demand ForecastingDocument23 pages3 Demand Forecastingnareshshendge100% (1)

- Lenses and Optical Instruments: Major PointsDocument20 pagesLenses and Optical Instruments: Major Points陳慶銘No ratings yet

- Progress Test 1B (Units 1-3)Document6 pagesProgress Test 1B (Units 1-3)SvetlanaNo ratings yet

- En Subject C08Document13 pagesEn Subject C08jmolfigueiraNo ratings yet

- (1902) The Centennial of The United States Military Academy at West Point New YorkDocument454 pages(1902) The Centennial of The United States Military Academy at West Point New YorkHerbert Hillary Booker 2nd100% (1)

- Data Center Cooling Solutions That Lower Costs With High Energy SavingsDocument5 pagesData Center Cooling Solutions That Lower Costs With High Energy Savingskhamsone pengmanivongNo ratings yet

- Quiz Bowl QuestionsDocument8 pagesQuiz Bowl QuestionsKeenan Dave RivoNo ratings yet

- MMA2019 SDocument2 pagesMMA2019 SToni IbrahimNo ratings yet

- Hangnails and HomoeopathyDocument7 pagesHangnails and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNo ratings yet

- Aluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Document1 pageAluminum Extrusions (HFS6 Series) Aluminum Extrusions (HFS6 Series)Jesus ValenciaNo ratings yet

- Introduction 130407092142 Phpapp01Document69 pagesIntroduction 130407092142 Phpapp01Pari Savla100% (1)

- Partnership Dissolution QuizDocument8 pagesPartnership Dissolution QuizLee SuarezNo ratings yet

- Kyle Capodice Ecet Candidate ResumeDocument1 pageKyle Capodice Ecet Candidate Resumeapi-394690479No ratings yet

- 9 Measures of Variability DisperseDocument14 pages9 Measures of Variability DisperseSourabh ChavanNo ratings yet

- Seniors Playing Record Nov 20 To Dec 2021 New SystemDocument6 pagesSeniors Playing Record Nov 20 To Dec 2021 New Systemapi-313355217No ratings yet

- Plattischemic Stroke Lesson PlanDocument18 pagesPlattischemic Stroke Lesson Planapi-216258123100% (3)

- Current Openings: The Sirpur Paper Mills LTDDocument3 pagesCurrent Openings: The Sirpur Paper Mills LTDMano VardhanNo ratings yet

- Catalogue of Turkic Language BooksDocument26 pagesCatalogue of Turkic Language BooksBerhiv Şilan BiliciNo ratings yet

- AUMUND Bucket Elevators 180801Document16 pagesAUMUND Bucket Elevators 180801Tino TorehNo ratings yet

- Indigenous Peoples SyllabusDocument9 pagesIndigenous Peoples Syllabusapi-263787560No ratings yet

- English Club ConstitutionDocument27 pagesEnglish Club ConstitutionJude Martin AlvarezNo ratings yet

- Stone Fox BookletDocument19 pagesStone Fox Bookletapi-220567377100% (3)

- Hidden Divergence Reveals Profitable Trading PatternsDocument12 pagesHidden Divergence Reveals Profitable Trading PatternsSubrata PaulNo ratings yet

- Lighting Design: Azhar Ayyub - Akshay Chaudhary - Shahbaz AfzalDocument27 pagesLighting Design: Azhar Ayyub - Akshay Chaudhary - Shahbaz Afzalshahbaz AfzalNo ratings yet

- Device Test ModeDocument14 pagesDevice Test ModeNay SoeNo ratings yet

- Year 11 GCSE Revision Guidance and Exam Booklet Solihull PDFDocument27 pagesYear 11 GCSE Revision Guidance and Exam Booklet Solihull PDFNoor Ulain Nabeela83% (6)

- Biology and Aquaculture of Tilapia-Routledge (2022)Document324 pagesBiology and Aquaculture of Tilapia-Routledge (2022)Pablo Antonio Pintos TeránNo ratings yet

- Impact of MusicDocument15 pagesImpact of MusicSterling GrayNo ratings yet

- CECB School Profile 23122020 1Document6 pagesCECB School Profile 23122020 1Anas SaadaNo ratings yet