Professional Documents

Culture Documents

Steel Grade Manganese Details

Uploaded by

Chaitanya MondalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Grade Manganese Details

Uploaded by

Chaitanya MondalCopyright:

Available Formats

What are the raw materials of Ferro Manganese?

The raw materials needed for the production of Fe-Mn are Mn ores, coke and fluxes such as limestone, dolomite

and quartzite. The raw materials are often stored outdoor, and the water content, including chemically bound

water in the Mn ores, may therefore be high, up to 10 %. Materials for Ferro silicon?

Main raw materials for Ferro Silicon production: are quartz, charcoal and mill scale.

Quartz contains chemical gangue besides the conglomerates of surface sticking mud coat

and earth material which contributes for slag forming tendencies.

What is difference between silico manganese and Ferro manganese?

Silico manganese is an alloy of Iron, Silicon & Manganese. It has higher Silicon content in

comparison to Ferro Manganese. Silicon reduces the solubility of carbon in manganese

alloys, so carbon contents are inversely proportional to silicon content. It is a more potent

deoxidizer of steel compared to Ferro manganese.

Description: Ferro-silico-manganese is used in the production of stainless

steel and cast iron, and is often used in the production of automobile parts.

What is Ferro silicon used for?

Steelmaking

Ferrosilicon (FeSi) is an alloy of iron and silicon that is principally used in steelmaking for

deoxidation and as an alloying component.

In the steel industry Manganese removes oxygen and sulfur when iron ore

(an iron and oxygen compound) is converted into iron. It also is an

essential alloy that helps convert iron into steel.

Manganese—It Turns Iron Into Steel (and Does So Much More)

What is steel made from? Many people would correctly respond that steel is made of iron.

Far fewer know that it is also made of manganese. Although the amount of manganese used

to make a ton of steel is small, it is just as essential as iron to produce this fundamental

building block of modern industrial societies. Put in simplest terms—you can’t make steel

without manganese. Domestic consumption of manganese is about 500,000 metric tons each

year, predominantly by the steel industry. The United States is totally reliant on imports for

this amount of manganese. Manganese is a common ferrous metal with atomic weight of 25

and the chemical symbol Mn. It constitutes roughly 0.1 percent of the Earth’s crust, making it

the 12th most abundant element. Its early uses were limited largely to pigments and oxidants

in chemical processes and experiments, but the significance of manganese to human societies

exploded with the development of modern steelmaking technology in the 1860s. Because

manganese is essential and irreplaceable in steelmaking and its global mining industry is

dominated by just a few nations, it is considered one of the most critical mineral commodities

for the United States.

How Do We Use Manganese? As much as 90 percent of manganese consumption, both in the

United States and globally, is accounted for by the steel industry. Manganese removes

oxygen and sulfur when iron ore (an iron and oxygen compound) is converted into iron. It

also is an essential alloy that helps convert iron into steel. As an alloy it decreases the

brittleness of steel and imparts strength. The amount of manganese used per ton of steel is

rather small, ranging from 6 to 9 kilograms. About 30 percent of that is used during

refinement of iron ore, and the remaining 70 percent is used as an alloy in the final steel

product. Manganese is used also as an alloy with metals such as aluminum and copper.

Important nonmetallurgical uses include battery cathodes, soft ferrites used in electronics,

micronutrients found in fertilizers and animal feed, water treatment chemicals, and other

chemicals such as those used as a colorant for automobile undercoat paints, bricks, frits,

glass, textiles, and tiles. The product “manganese violet” is used for the coloration of plastics,

powder coatings, artist glazes, and cosmetics

\Where Does Manganese Come From? Elemental manganese readily combines with oxygen,

carbon, and silicon to form a long list of manganese minerals. Manganese ores generally

contain 25 to 45 percent manganese, mostly in oxide (or hydroxide) and carbonate minerals.

Such ores are widespread, but most of the world’s supply is from a small number of

manganese mining districts. Most manganese ores are extensive layers of manganese-rich

sedimentary rocks that formed in ancient oceans under specialized conditions when changes

in the oxidation state of ocean water first caused high concentrations of dissolved manganese

and later precipitated various manganese minerals that became concentrated on the seabed.

These layers are now found within the bedrock of continents. Some are considered “primary

ore,” because they are rich enough in manganese to be of ore grade. Others are “secondary

ore”—zones where the original manganese content of the sediments has been naturally

enriched by younger geologic processes. Nearly all manganese ores are beneficiated near the

mine sites to improve the manganese grade before further processing. Most also are smelted

to form the alloys ferromanganese and silicomanganese. It is these alloys, rather than

manganese ore itself, which are used in most metallurgical applications. An additional

potential source of manganese is the vast layer of ferromanganese nodules that cover the deep

seabed of many of the world’s oceans. These potato-sized nodules are currently the target of

exploration and research by 13 organizations, aimed at economic development mostly

focused on the equatorial Pacific Ocean. Should production of these nodules prove

technically, economically, and legally viable, they could provide the world with a major new

source of manganese for a very long time.

What are the main uses of manganese in industry?

Some common applications for manganese are creating structural alloys, being used as an

oxidizing agent, used in welding, and placed into glazes and varnishes. Another product that

is in high demand for manganese is battery manufacturing.

What are the main uses of manganese in industry?

It is mainly used in alloys, such as steel. Steel contains about 1%

manganese, to increase the strength and also improve workability and

resistance to wear. Manganese steel contains about 13% manganese. This

is extremely strong and is used for railway tracks, safes, rifle barrels and

prison bars.

Manganese is predominantly used to produce ferromanganese, or metallic manganese,

which is used in the production of steel to improve hardness, stiffness, and strength. It is

used in carbon steel, stainless steel, high-temperature steel, and tool steel, along with cast

iron and superalloys

Uses Of Manganese

Manganese is used to produce a variety of important alloys and to deoxidize steel and

desulfurize.

It is also used in dry cell batteries.

Manganese is used as a black-brown pigment in paint.

It is an essential trace element for living creatures

https://www.indiamart.com › ... › Manganese Ore

The Manganese Ore Lumps can be availed in different grades of 18% to 52% manganese (Mn)

content and are mainly used for the manufacturing of silicon manganese, ...

₹4,500.00

8300/T, Price of 47-48 % Mn Lumpy ore = Rs. 11,000/T.

The current market capitalization of MOIL / Manganese Ore is Rs. 3,324.95.

The prices of all ferro grades of manganese ore with manganese content of Mn-44% and above have

been reduced by 2.5% on the price prevailing

You might also like

- Minerals and Energy Resources - Shobhit NirwanDocument8 pagesMinerals and Energy Resources - Shobhit NirwanAmkk Sharma100% (1)

- Dgca Module 11 Part 02 PDFDocument21 pagesDgca Module 11 Part 02 PDFBhaskerNegiNo ratings yet

- Method Statement For Chilled Water PipesDocument5 pagesMethod Statement For Chilled Water PipesYoYoRamezNo ratings yet

- Mineral ResourcesDocument7 pagesMineral ResourcesTudor PipirigNo ratings yet

- Minerals and Energy ResourcesDocument6 pagesMinerals and Energy ResourcesVrindha Vijayan100% (1)

- Chapter 4 Mineral ResourcesDocument36 pagesChapter 4 Mineral ResourcesPrabhleen TalwarNo ratings yet

- Feasibility Study On Iron Ore Mine TailingsDocument74 pagesFeasibility Study On Iron Ore Mine TailingssrivinaymnNo ratings yet

- Chapter-3. Raw Materials Used in Steel PlantDocument8 pagesChapter-3. Raw Materials Used in Steel PlantAnkur Taneja100% (4)

- Restoration Method Statement Sliema PDFDocument13 pagesRestoration Method Statement Sliema PDFGilbertButtigiegNo ratings yet

- Especificacion Soportes - JACOBS PDFDocument252 pagesEspecificacion Soportes - JACOBS PDFHernan Vich100% (1)

- Indian Iron Ore Scenario - Low Grade Iron Ore BeneficiationDocument10 pagesIndian Iron Ore Scenario - Low Grade Iron Ore BeneficiationBhargav MadhoorNo ratings yet

- Hydrometallurgical Processing of Manganese Ores A ReviewDocument18 pagesHydrometallurgical Processing of Manganese Ores A ReviewAssyakurNo ratings yet

- Secondary Sources of Non-Ferrous MetalsDocument35 pagesSecondary Sources of Non-Ferrous MetalsNitinSrivastava100% (1)

- Manganese BeneficiationDocument43 pagesManganese BeneficiationMukesh Ranjan Behera0% (1)

- Geo Textiles: Perspective From The Construction Sector: A PresentationDocument22 pagesGeo Textiles: Perspective From The Construction Sector: A PresentationChristine ReedNo ratings yet

- 4 Metallurgical and Refractory Minerals NotesDocument9 pages4 Metallurgical and Refractory Minerals NotesNamwangala Rashid Natindu100% (1)

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- 2007, MN Review Part 1Document23 pages2007, MN Review Part 1Sumitro AgusNo ratings yet

- Element in A PeriodDocument10 pagesElement in A PeriodLavenderPonnuNo ratings yet

- Https Exploringgeography - Wikispaces.com File View Chapter+5+Mineral+and+power+resource+ (New) PDFDocument8 pagesHttps Exploringgeography - Wikispaces.com File View Chapter+5+Mineral+and+power+resource+ (New) PDFChaitanya SharmaNo ratings yet

- Enhancing The Efficiency of Manganese Recovery From Pyrolusite Ore Through Hydrometallurgical Techniques Utilizing Nitric Acid and Distilled WaterDocument13 pagesEnhancing The Efficiency of Manganese Recovery From Pyrolusite Ore Through Hydrometallurgical Techniques Utilizing Nitric Acid and Distilled WaterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MineralDocument11 pagesMineral12345krish0guptaNo ratings yet

- Minerals 2Document39 pagesMinerals 2amulyajadhav119No ratings yet

- Chapter 1Document28 pagesChapter 1Mohammad ShoebNo ratings yet

- Manganese Metallurgy Part IDocument23 pagesManganese Metallurgy Part IRichard Jesus VillagarayNo ratings yet

- Mineral ResourcesDocument3 pagesMineral ResourcesDhruvi SinghNo ratings yet

- Manganese-It Turns Iron Into Steel (And Does So Much More) : How Do We Use Manganese?Document2 pagesManganese-It Turns Iron Into Steel (And Does So Much More) : How Do We Use Manganese?Nia AzZuhra AngelicaNo ratings yet

- Minerals &energy Resources Solved QDocument7 pagesMinerals &energy Resources Solved QIDK SUPERNo ratings yet

- Geography Mineral and Energy Resources NotesDocument7 pagesGeography Mineral and Energy Resources NotesBhavesh KalkhandaNo ratings yet

- Role of Metallurgy in Engineering 2Document6 pagesRole of Metallurgy in Engineering 2MUHAMAD HAMMAD AHMEDNo ratings yet

- ICSE Geography ProjectDocument28 pagesICSE Geography ProjectAditya KasaudhanNo ratings yet

- Me Faculty of Engineering and GeosciencesDocument9 pagesMe Faculty of Engineering and Geosciencestinashe tagariraNo ratings yet

- Mineral and Energy Resources NotesDocument6 pagesMineral and Energy Resources Notesnairaditya0104No ratings yet

- Assignment 1Document35 pagesAssignment 1NitinSrivastavaNo ratings yet

- Earth Science PPT 5Document32 pagesEarth Science PPT 5Ghieonn VillamorNo ratings yet

- Minerals and Energy Resources Study MaterialDocument7 pagesMinerals and Energy Resources Study MaterialdhrumanranaNo ratings yet

- Group 4Document10 pagesGroup 4tinashe tagariraNo ratings yet

- Iron OreDocument12 pagesIron OreAnonymous P1xUTHstHTNo ratings yet

- (Prelim) Mineral ResourcesDocument19 pages(Prelim) Mineral ResourcesMarkNo ratings yet

- Mineral Resources: MineralsDocument4 pagesMineral Resources: MineralsMohitNo ratings yet

- Manganese Removal in Base Metal Hydrometallurgical ProcessesDocument17 pagesManganese Removal in Base Metal Hydrometallurgical ProcessesJeromeNo ratings yet

- LME Zinc FactsheetDocument6 pagesLME Zinc FactsheetOscar Zuñiga SolariNo ratings yet

- Minerals Position PaperDocument3 pagesMinerals Position Paperapi-285354240No ratings yet

- Chapter One Composite Materials and AlmmcsDocument8 pagesChapter One Composite Materials and AlmmcsMohamed KadhimNo ratings yet

- Mineral Resources Handout (B)Document2 pagesMineral Resources Handout (B)PunchyDoodlesNo ratings yet

- The Metallic and Non-Metallic Minerals Found in The Various Parts of The PhilippinesDocument2 pagesThe Metallic and Non-Metallic Minerals Found in The Various Parts of The PhilippinesCalilap ShanleyNo ratings yet

- Industrial Uses of Some Copper AlloysDocument7 pagesIndustrial Uses of Some Copper AlloysBart FrienderNo ratings yet

- Minerals and Energy Resources Class 10 Notes Geography Chapter 5Document7 pagesMinerals and Energy Resources Class 10 Notes Geography Chapter 5sonamkheriaNo ratings yet

- Iron Ore - Ground Breaking PerspectiveDocument15 pagesIron Ore - Ground Breaking PerspectivecoderNo ratings yet

- WAWADocument11 pagesWAWAkolo boloNo ratings yet

- Iron Ore, Steel and Coal: by Group 4Document26 pagesIron Ore, Steel and Coal: by Group 4Harshavardhan GuntupalliNo ratings yet

- Tin and Its AlloysDocument2 pagesTin and Its AlloysSri GowthamNo ratings yet

- Alloys of Zinc and Their ApplicationsDocument4 pagesAlloys of Zinc and Their ApplicationsBookMaggotNo ratings yet

- تقريرDocument5 pagesتقريرjmalahmed853No ratings yet

- Rakchem Industries LLC - Steel Product ProfileDocument8 pagesRakchem Industries LLC - Steel Product ProfileRohith KommuNo ratings yet

- Environmental IssuesDocument8 pagesEnvironmental IssueskaumaaramNo ratings yet

- Minerals and Energy Resources: Page No: 48 (Topic: Introduction)Document11 pagesMinerals and Energy Resources: Page No: 48 (Topic: Introduction)Monika JasujaNo ratings yet

- Minerals and Energy Sources Class 10Document12 pagesMinerals and Energy Sources Class 10snowrat76No ratings yet

- Araling Panlipunan ReportDocument4 pagesAraling Panlipunan ReporthaniNo ratings yet

- Magnesium Resources, Reserves and Production-MetalpediaDocument6 pagesMagnesium Resources, Reserves and Production-MetalpediaP B ChaudharyNo ratings yet

- Alloys MGDocument16 pagesAlloys MGJuan Diego Ospina FlorezNo ratings yet

- Rigon PentecostesDocument9 pagesRigon PentecostesMarlNo ratings yet

- Afghanistan MineralsDocument101 pagesAfghanistan MineralsKhan MohammadNo ratings yet

- Graphene Based BrickDocument20 pagesGraphene Based Brickakash pandeyNo ratings yet

- Conceptual Design of Blanking Tool For Washer Special IJERTV4IS050270 PDFDocument4 pagesConceptual Design of Blanking Tool For Washer Special IJERTV4IS050270 PDFahmad nasarNo ratings yet

- Gabion Catalog: Samafe International, S.ADocument4 pagesGabion Catalog: Samafe International, S.Arsiqueirasantos5711No ratings yet

- MeldharDocument91 pagesMeldharborntowin08No ratings yet

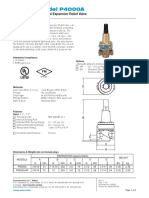

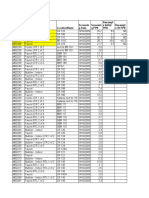

- P4000A - Thermal Expansion Relief ValveDocument2 pagesP4000A - Thermal Expansion Relief ValveAndy QuynhNo ratings yet

- CM & CD EstimateDocument130 pagesCM & CD EstimateSaiteja PanyamNo ratings yet

- RDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Document12 pagesRDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Bintang DwiPutraNo ratings yet

- SAMASH Construction PLCDocument4 pagesSAMASH Construction PLCAsheNo ratings yet

- Asme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureDocument1 pageAsme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureRicardo LanderNo ratings yet

- Meter Quotation-2Document2 pagesMeter Quotation-2umanathmech_75899977No ratings yet

- ASTM A108-03e1Document7 pagesASTM A108-03e1NadhiraNo ratings yet

- Swaging Process Swaging Process: Homework #2 Authored By: MASA FUADDocument11 pagesSwaging Process Swaging Process: Homework #2 Authored By: MASA FUADMasa FuadNo ratings yet

- Vinnapas 8034 H TDSDocument2 pagesVinnapas 8034 H TDSSiddhesh Kamat MhamaiNo ratings yet

- Jed-050m 008 eDocument5 pagesJed-050m 008 egsuoagNo ratings yet

- 21.01.11 Cowan Windows To GralcoDocument39 pages21.01.11 Cowan Windows To GralcomeghadurganNo ratings yet

- Worldwide: Disc Bottom Outlet ValvesDocument6 pagesWorldwide: Disc Bottom Outlet ValvesmaygomezNo ratings yet

- Test Paper 1 (Concrete Technology)Document7 pagesTest Paper 1 (Concrete Technology)atulqweNo ratings yet

- 2.1. Design ParametersDocument2 pages2.1. Design ParametersFarly VergelNo ratings yet

- Responsive DocumentsDocument178 pagesResponsive DocumentsWJLA-TVNo ratings yet

- Grey Iron A Unique MaterialDocument13 pagesGrey Iron A Unique MaterialmetkarthikNo ratings yet

- AFNOR NF Cu-B2 NF A51-050Document2 pagesAFNOR NF Cu-B2 NF A51-050dneprmt1No ratings yet

- Paint Systems For MRTS88Document72 pagesPaint Systems For MRTS88asankaNo ratings yet

- 1635 PDFDocument7 pages1635 PDFKaushal KishoreNo ratings yet

- Hooks For SlatingDocument4 pagesHooks For SlatingDevi PraseedaNo ratings yet

- Prestolok/Prestolok II Fittings: Advantages Assembly InstructionsDocument11 pagesPrestolok/Prestolok II Fittings: Advantages Assembly InstructionsJosé A. RamírezNo ratings yet